Type SB

Washdown Nozzle, Flush Deck

United States Navy

Page 1 of 4 AUGUST 2018 TFP825

IMPORTANT

Refer to Technical Data Sheet

TFP2300 for warnings pertaining to

regulatory and health information.

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and instal-

lation of sprinkler systems and com-

ponents. Improper handling and

installation can permanently damage

a sprinkler system or its compo-

nents and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

Worldwide

Contacts

www.tyco-fire.com

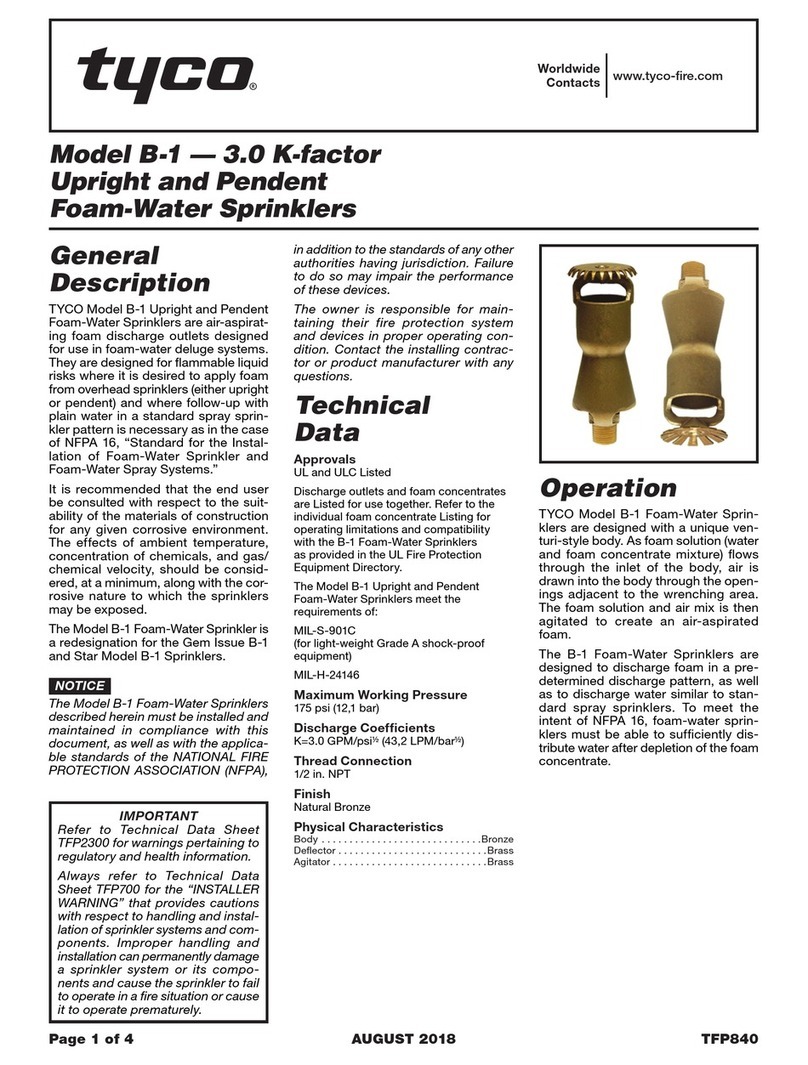

General

Description

The TYCO Type SB Flush Deck Nozzles

are washdown nozzles for use on

United States Navy ships. They are

welded into position flush with the

deck surface. The inlet to the nozzle is

sized for welding or brazing to 1/2 inch

(DN15) pipe.

The Flush Deck Nozzles have a Ball

that normally rests in the exit orifice to

prevent debris from falling into it. When

water is flowing, the Ball is lifted up and

remains centered by the combination

of the threaded insert and the inside

edges of the three webs. The sepa-

rable Truss Head Machine Screw and

Fender Washer supplied with the Type

SB Flush Deck Nozzles are used to

temporarily cover the nozzle when the

deck is being restored.

The Type SB Replacement Parts Kit

that includes a Web with Modified

Threaded Insert, Ball, Modified Insert,

Truss Head Machine Screw, and

Fender Washer is illustrated in Figure

2. A Threaded Insert Installation Tool is

also available.

Technical

Data

Approvals

The Type SB Flush Deck Nozzles and

related items are manufactured in com-

pliance with NAVSEA Drawing No. 803-

1385828. They have been qualified to

the High Impact Shock requirements

of MIL-S-901C (Navy), Grade A, Hull

Mounted, Class I, Light Weight Test.

Discharge Coefficient

5.1 GPM /psi½(73,4 LPM/bar½)

Water Discharge Pattern

The approximate water discharge

pattern at zero wind velocity is shown

in Figure 3, for reference purposes only.

Nozzle spacing is to be in accordance

with the applicable standards of the

Naval Sea Systems Command.

The recommended range of flowing

pressure at the Nozzle inlet is 30 to 50

psi (2,1 to 3,4 bar).

Thread Connection

1/2 in. (DN15) welding or brazing

Markings

Stainless Steel Nozzle:

S S -SB -110 -. 43 8

Replacement Stainless Steel Web:

SS SB

Weight

Stainless Steel: 1.0 lb (0,45 kg)

Physical Characteristics

The Body of the stainless steel Nozzle

and the stainless steel Replacement

Web are cast from austenitic stainless

steel per ASTM A 351 (UNS J92800).

Maximum carbon content is 0.03

percent for weldability. The castings

are solution annealed for maximum

corrosion resistance.

• The Ball is Type 302 stainless steel.

• The Modified Threaded Insert is

stainless steel per AMS7245.

• The Truss Head Machine Screw is a

Type 18-8 stainless steel.

• The Fender Washer is plated (zinc

or cadmium) SAE 1008-1020 carbon

steel.