Firesafe Flowmeter User manual

702-0049.22

September 2020

Firesafe™ Flowmeter

Instructions for Use

Contents

1. Symbols ................................................................................................................................................... 2

2. Warnings and Cautions ........................................................................................................................... 2

2.1. Warnings! ......................................................................................................................................... 2

2.2. Cautions! .......................................................................................................................................... 3

3. Functional Description ............................................................................................................................. 4

3.1. Intended Use .................................................................................................................................... 4

3.2. Technical Description ....................................................................................................................... 4

4. Operating Instructions ............................................................................................................................. 6

4.1. Connecting to Gas Supply ................................................................................................................ 6

4.2. Adjusting the Flow ............................................................................................................................ 6

4.3. Reading the Flowmeter .................................................................................................................... 6

4.4. Connecting to Patient ....................................................................................................................... 6

4.5. During Use ....................................................................................................................................... 7

4.6. After Use .......................................................................................................................................... 7

5. Cleaning and Disinfection ........................................................................................................................ 7

5.1. Cleaning ........................................................................................................................................... 7

5.2. Suspected Contamination ................................................................................................................ 7

6. Maintenance ............................................................................................................................................ 7

6.1. Interim Inspection ............................................................................................................................. 7

6.2. Service and Repair ........................................................................................................................... 7

7. Specification ............................................................................................................................................ 8

8. Troubleshooting ....................................................................................................................................... 9

9. Parts and Spares ................................................................................................................................... 10

10. Distributor Details .................................................................................................................................. 11

2

1. Symbols

Warning! Indicates a potentially hazardous situation which, if not avoided, could result in

personal injury to the user or others

Caution! Indicates a potentially hazardous situation which, if not avoided, could result in

damage to the equipment or property

Note Highlights points that might allow more convenient or efficient operation of the

equipment

Use no oil

Flow should be read level with the top of the float

2. Warnings and Cautions

2.1. Warnings!

Read through this entire instruction manual before using or showing others how to use this

flowmeter. As with all medical equipment, attempting to use this device without a thorough

understanding of its operation may result in patient or user injury.

Medical gases are, or should be considered a drug and should only be used for medical purposes

as prescribed by a physician or authorised clinician and in accordance with their instructions.

Oxygen therapy may be a critical treatment. Additional risk control measures such as SpO2

monitoring with an alarm and a backup oxygen supply with delivery device should be provided for

patients who might suffer distress or injury if their oxygen supply is not available or is stopped

unexpectedly.

The flowmeter is not MRI compatible.

Ensure that the medical gas supply is sufficient for the proposed therapy and is supplied within

the pressure range given in the Device Specification. If the supply is a gas cylinder, check the

cylinder contents gauge regularly.

This flowmeter is only for use with the medical gas indicated on the device label. Check the

cylinder or supply is the correct medical grade gas before use. Always check that the flowmeter

is connected to the correct gas specific terminal unit.

Gas specific connectors are fitted to the flowmeter. Do not attempt to modify the fittings to suit

other gases or fitting systems.

Oxygen is not flammable; however the presence of it will drastically increase the rate and severity

of combustion. Oil and/or grease in the presence of an oxygen enriched atmosphere will become

highly combustible. Oxygen must never be allowed to come into contact with oil, grease or other

petroleum-based substances. Do not use oil or grease on this flowmeter.

Many hand creams and moisturisers contain paraffin and petroleum bases which are highly

flammable and must never be allowed to contact the Firesafe Flowmeter. Ensure hands are clean

and dry before operating the equipment.

Do not smoke around oxygen equipment.

3

Only appropriately trained personnel working in controlled conditions may disassemble or

assemble this flowmeter.

Do not disassemble the flowmeter whilst under pressure.

Secure cylinders to a wall, stand or cart in accordance with local safety regulations.

Do not stand in front of a flowmeter or regulator outlet when opening a cylinder valve.

Do not allow any fluid to enter this device.

The accuracy of the flowmeter can be affected significantly if the input pressure is other than

stated in the technical specification and the device label.

Do not directly connect the flowmeter output to another pressurised gas source as this may lead

to corruption of one or other of the gas supplies (e.g. connecting an oxygen flowmeter to an air

flowmeter via a Y-piece in an attempt to blend their outputs).

Only use this flowmeter with the flow tube in a vertical position. Failure to do so may result in

incorrect flow rates being displayed.

Arrange the oxygen tubing and gas hose carefully to avoid damage to the hose and the potential

for causing a trip hazard. Never pull or apply excessive force to the gas hose. A leaking hose

may result in high local oxygen and nitrous oxide concentrations and an increased risk of fire.

Gas flow may be prevented if the supply tubing is kinked or occluded.

Care should be taken to ensure that the flow control valve is free from obstruction and unintended

pressure. These scenarios may result in temporary changes in flow.

2.2. Cautions!

The performance of the flowmeter may be affected if it is stored or transported in temperatures

outside of the range -20 °C to 60 °C (-4 °F to 140 °F).

The flowmeter is not suitable for autoclaving.

Where a threaded fastener is used, do not use the device to tighten or lock connection.

The performance of the flowmeter may be affected if the flow control valve is over-tightened when

switching off flow. Apply the minimum force required to switch off gas flow.

4

3. Functional Description

3.1. Intended Use

The Firesafe™ Flowmeter is used to precisely control the flow of medical oxygen or medical air

(model dependant) from a low pressure supply. Inlet pressure ranges can be found in the

Technical Specification.

Medical gases are, or should be considered, drugs and should only be used for medical purposes

on the authority of a physician or authorised clinician and then strictly in accordance with their

instructions.

This product is designed for use in homecare applications, in hospitals, other managed clinical

environments and by the emergency services.

3.2. Technical Description

The Firesafe™ enables accurate control of the flow of either medical oxygen or medical air (model

dependent) in the range of 1 to 15 l/min.

A precision rotating float rises inside a transparent graduated flow tube. The flow tube has a scale

printed upon it that indicates the rate of gas flow in litres per minute (l/min). The reading should

be taken at the top of the float. The flow of gas through the tube is controlled by a valve

downstream of the flow tube.

BPR Medical Ltd products enhance patient and user safety and as such the Firesafe™ Flowmeter

includes many unique features to maximise safety and minimise exposure to risk. These features

include:

Scale

Flow Tube

Gas Specific Inlet

Connector

Firesafe™ Nozzle

Precision Rotating Float

Flow Control Valve

5

3.2.1. Firesafe™ Nozzle

Every Firesafe™ Flowmeter is fitted with a Firesafe™ Nozzle, minimising the known risks of fire

associated with oxygen therapy. The Firesafe™ Nozzle is discernible from a standard tubing

connector as it features a bright orange band. The Firesafe™ Nozzle can limit the impact of an

oxygen fire by automatically arresting the oxygen flow. Acting like a fuse, it automatically isolates

the oxygen supply as a fire tracks back along the tubing towards the oxygen source. Activation of

the Firesafe™ Nozzle during a fire requires is highly reliable at oxygen flows above 1 l/min. The

Firesafe™ Nozzle is not suitable for use as a fire risk control measure outside this range.

3.2.2. Flowsafe™ Valve

The Flowsafe™ Valve is another feature unique to the Firesafe™ Flowmeter that further lowers

the risk of fire associated with oxygen use. In the event of the flow tube being inadvertently

sheared from the flowmeter body, it automatically isolates the oxygen flow, preventing a free flow

of oxygen into the hospital ward. The pipeline pressure is therefore maintained, negating the

need to isolate the ward oxygen supply, upon which other patients may be dependent.

3.2.3. Precision Rotating Float

Unlike conventional ball and glass style flowmeters, the Firesafe™ Flowmeter incorporates a

precision float with a fluted rim, which continuously rotates in the gas stream to provide visual

confirmation that gas is flowing and the device is providing an accurate reading. Historically,

incidents have occurred with conventional designs whereby static charge within the flow tube has

caused the ball to stick to the surface and provide a false reading.

Unlike conventional ball style flowmeters, where there is often doubt as to where a reading should

be taken, the Precision Rotating Float has a red band indicating the position at which the flow

reading should be taken.

3.2.4. Static Control (Triboelectric Charge Dissipation)

The Firesafe™ Flowmeter incorporates two separate static control measures in order to rapidly

dissipate any charge generated during use. These unique measures control the recognised

phenomena of static charge, which is known to cause the ball in conventional flowmeters to stick

to the flow tube inner surface, leading to either an inaccurate reading or indicating a flow exists

when the valve is closed.

3.2.5. Flush Flow Mode

The flowmeter has a Flush Flow Mode. This mode may be used to deliver approximately

25-30 l/min to supply a resuscitation bag.

3.2.6. Inlet Filter

The flowmeter is fitted with a 25 μm filter to ensure that large particles of debris that might be

resident in the gas supply do not contaminate the flowmeter or pass through to the patient.

3.2.7. Gas Specific Connector

The gas specific quick connection probe has characteristics to prevent connections between

different gas services.

6

4. Operating Instructions

4.1. Connecting to Gas Supply

Before use, visually check both the flowmeter and hose (if fitted) for any damage or

contamination. Do not connect or use the device if there are any doubts about its condition.

The flowmeter is supplied with a gas specific connector that is designed to connect to a mating

gas specific outlet. Gas specific outlets might be a terminal unit in a medical gas pipeline system

or part of a pressure regulator outlet on a gas cylinder.

If you are using a cylinder supply, ensure that the cylinder contents are adequate for planned

therapy and turn on the supply at the cylinder.

Connect the gas specific quick connect to the appropriate gas specific outlet.

For indirect connection flowmeters the Medirail bracket should be fastened to a suitable medical

rail system (compliant with BS EN ISO 19054 Rail systems for supporting medical equipment)

using the thumb screw in the Medirail bracket.

Warning! Where the gas specific connector is dependent on a threaded fastener (e.g. DISS CGA

– V5 1240, AS 2896/SIS handwheel) offer device to outlet and connect a few turns. Align device

to the final vertical position and fully hand tighten the connection before turning on the supply

pressure. Do not use the device to tighten or lock the connection.

For quick connector probes (e.g. BS 5682, DIN, AFNOR), ensure that the connection is correctly

made by gently pulling the flowmeter body or hose (as applicable) before turning on the supply

pressure.

Connect a sufficient length of patient tubing (not supplied) to the outlet barb.

Note: Removal of the Firesafe™ Nozzle when fitting a humidifier will temporarily disable the

oxygen arresting capability of the flowmeter in the event of a cannula fire. Always remember to

refit the Firesafe™ Nozzle (indicated by a distinctive orange band) when the humidifier is no

longer needed.

4.2. Adjusting the Flow

Turn the flow control valve anti-clockwise to turn on and increase the flow of gas.

If the flowmeter does not operate correctly, remove it from use and refer to the trouble shooting

guide in Section 8 of this booklet.

4.3. Reading the Flowmeter

The diagram opposite shows the correct reading

level in relation to the float position for both float

type and ball type variable area flowmeters.

The right hand illustration indicates the correct

reading level for this Firesafe™ Flowmeter i.e. at

the top of the float.

4.4. Connecting to Patient

Connect the other end of the oxygen tubing to the patient or patient enclosure using the

appropriate connector (not supplied).

ReadingLevel

Float Ball

7

4.5. During Use

Continue to monitor the level of gas flow during the procedure or therapy and the contents level of

the cylinder (if applicable) and be aware that the supply tubing and hose (if applicable) may be a

trip hazard.

4.6. After Use

If the supply is from a gas cylinder, close the cylinder valve and disconnect the flowmeter when

therapy is no longer required.

5. Cleaning and Disinfection

Ensure the flowmeter is disconnected from the gas supply before attempting to clean it.

Caution! The flowmeter is not suitable for autoclaving.

5.1. Cleaning

Wipe over the outside of the flowmeter and the gas supply hose with an alcohol or disinfecting

wipe.

5.2. Suspected Contamination

If you suspect that the flowmeter is contaminated, remove it from use and refer the device to the

appropriate department.

Never immerse the flowmeter in any fluid or attempt to clean internal parts.

6. Maintenance

6.1. Interim Inspection

The flowmeter should be regularly cleaned, inspected for damage and checked for performance.

The frequency of inspection and performance checks depends upon usage. As a guideline, if the

flowmeter is used daily this may need to be performed every six months; if used infrequently an

annual check may suffice.

6.1.1. Leak Test

Attach the flowmeter to a low pressure medical gas supply with a nominal supply pressure as

specified on the rating label of the device and close the flow control valve. Connect supply tubing

to the outlet barb and immerse the other end of the tube in water, the presence of gas bubbles in

the water indicates a leak. Remove the tube and apply an oxygen compatible leak test solution to

all outlets and fittings and check for leaks. A flowmeter that fails these tests should be removed

from use.

6.1.2. Flow Test

Verify flow rates at all flow settings against those given in the Device Specification in section 6.

Mass flow meters with appropriate full-scale ranges for the flow rates are particularly suitable for

this.

Alternatively, where flow measuring equipment is not available, a qualitative check can be

performed by confirming that gas flow can be sensed to be increasing with each step increase in

flow across the full flow range. For higher flow rates, this can be sensed audibly or by holding a

hand close to the flow outlet; moistening the skin can increase the cooling sensation and therefore

sensitivity to the flow.

For very flow rates, this may better be achieved by placing the end of a connected tube in a glass

of water to observe the bubbles.

8

6.2. Service and Repair

Direct connection flowmeters do not require routine servicing but can be repaired. The device can

be returned to a recognised BPR Medical Service Centre, details of which can be found at

www.bprmedical.com.

Indirect connection flowmeters should have the hose assembly replaced after four years use or

five years from the date of manufacture. The manufacture date can be found on the device label.

Device life can be calculated by adding 7 years to the date of manufacture.

Disassembly, repair or reassembly must be carried out by a suitably qualified person working in a

controlled environment.

7. Specification

Specification Value

Flow Scale 0 – 15 l/min

Inlet Pressure Range

Model specific between 370 – 550 kPa

Note: The flowmeter is able to operate safely within the pressure range 370 kPa

to 550 kPa, but the flowmeter will only deliver accurately when connected to an

input pressure as shown on the device. Any input pressure other than shown on

the device will result in flow rates different from the flow settings

Supply Pressure Range Minimum 370 kPa

Maximum 550 kPa

Accuracy

Nominal Pressure: ±10 % of indicated reading between 1 – 15 l/min

Valve Settling: < 2 % from initial setting within 3 hours

Temperature: 3 % flow increase/decrease per 5 °C temperature increase/decrease

Inlet Pressure: 4 % increase/decrease per 10 kPa increase/decrease from nominal

pressure

Outlet Flow Resistance: Negligible up to 230 kPa gauge back pressure

Gas Compatibility Medical Oxygen or Medical Air (model dependant)

Maximum Flow (Flush Flow

Mode) 25 – 30 l/min

Firesafe™ Nozzle Flow Range 1 – 25 l/min

Inlet Filtration 25 µm

Environmental

Transport and Storage Temperature: -20 °C to 60 °C (-4 °F to 140 °F)

Operating Temperature: 0 °C to 40 °C (32 °F to 104 °F)

Humidity: 0-100% RH non-condensing

Regulatory CE: Medical Device Directive 93/42/EEC – Active Medical Device – Class IIa

Applied Standards

BS EN ISO 5359 Low pressure hose assemblies for use with medical gases

BS EN ISO 15001 Anaesthetic and respiratory equipment. Compatibility with oxygen

BS EN ISO 15002 Flow-metering devices for connection to terminal units of medical gas pipeline

systems

BS EN ISO 19054 Rail systems for supporting medical equipment

9

BS 5682 Probes (quick connectors) for use with medical gas pipeline systems

AS 2902 Medical gas systems. Low pressure flexible hose assemblies

8. Troubleshooting

Fault Possible Cause Solution

No gas flow Flowmeter is not connected

properly.

Check gas supply. Check that the gas specific probe

is correctly connected.

Gas cylinder empty. Replace gas cylinder.

Medical gas terminal unit on a

pipeline system is isolated.

Seek advice from someone authorised to operate the

medical gas pipeline system isolation valves.

Inlet filter blocked. Repair required.

Flowsafe™ Valve has activated. Flowsafe™ Valve is designed to activate when an

exceptionally high flow of gas passes through the

device. Disconnect from the gas supply and check the

flow meter for damage or rupture.

Firesafe™ Nozzle has activated

due to fire or mechanical damage.

Replace Firesafe™ Nozzle.

Audible gas leak Seal is worn or damaged. Repair required.

Flow tube cracked or damaged. Repair required.

Probe nose worn or damaged. Repair required.

Medical gas hose damaged. Replacement required.

Constant gas flow Valve or valve seat damaged. Repair required.

10

9. Parts and Spares

Part Number* Description Calibration

Pressure

829-0301 Firesafe™ Flowmeter - O2 Single Direct 0 – 15 l/min - BS 5682 connector 400 kPa

829-0302 Firesafe™ Flowmeter - O2 Dual Direct 0 – 15 l/min - BS 5682 connector 400 kPa

829-0303 Firesafe™ Flowmeter - O2 Single Indirect (1.5m) 0 – 15 l/min - BS 5682 connector 400 kPa

829-0304 Firesafe™ Flowmeter - O2 Dual Indirect (1.5m) 0 – 15 l/min - BS 5682 connector 400 kPa

829-0351 Firesafe™ Flowmeter - Air Single Direct 0 – 15 l/min - BS 5682 connector 400 kPa

829-0352 Firesafe™ Flowmeter - Air Dual Direct 0 – 15 l/min - BS 5682 connector 400 kPa

829-0353 Firesafe™ Flowmeter - O2 Dual Indirect (3m) 0 – 15 l/min - BS 5682 connector 400 kPa

829-0901 Firesafe™ Flowmeter - O2 Single Direct 0 – 15 l/min - SIS connector (AS 2896) 400 kPa

829-0902 Firesafe™ Flowmeter - O2 Dual Direct 0 – 15 l/min - SIS connector (AS 2896) 400 kPa

829-0951 Firesafe™ Flowmeter - Air Single Direct 0 – 15 l/min - SIS connector (AS 2896) 400 kPa

829-0952 Firesafe™ Flowmeter - Air Dual Direct 0 – 15 l/min - SIS connector (AS 2896) 400 kPa

829-1001 Firesafe™ Flowmeter - O2 Single Direct 0 – 15 l/min - BS 5682 connector (New Zealand) 400 kPa

829-1002 Firesafe™ Flowmeter - O2 Dual Direct 0 – 15 l/min - BS 5682 connector (New Zealand) 400 kPa

829-1051 Firesafe™ Flowmeter - Air Single Direct 0 – 15 l/min - BS 5682 connector (New Zealand) 400 kPa

829-1052 Firesafe™ Flowmeter - Air Dual Direct 0 – 15 l/min - BS 5682 connector (New Zealand) 400 kPa

*All listed part numbers are standard configurations; please contact your BPR Medical distributor for others

Spare Parts

827-0031 Firesafe™ Nozzle (10 pack) 9/16” UNF (DISS) Female

11

10. Distributor Details

Australia

BOC Healthcare

Customer Service Centre

10 Julius Avenue

North Ryde

Sydney

NSW, 2113

T: +61 (0)2 8874 4400

F: +61 (0)2 9886 9000

www.boc.com.au

New Zealand

BOC Healthcare

Customer Service Centre

970-992 Great South Road

Penrose 1061

Auckland

New Zealand

T: +64 (0)9 525 5600

www.boc.co.nz

12

13

BPR Medical Limited +44 (0)1623 628 281 Qarad EC-REP BV

22 Hamilton Way, Mansfield, Notts. [email protected] Pas 257, 2440 Geel

NG18 5BU, United Kingdom www.bprmedical.com Belgium

This manual suits for next models

15

Table of contents

Popular Measuring Instrument manuals by other brands

Keysight

Keysight 34450A Service guide

Teledyne Lecroy

Teledyne Lecroy RP4030 Operator's manual

Shimpo Instruments

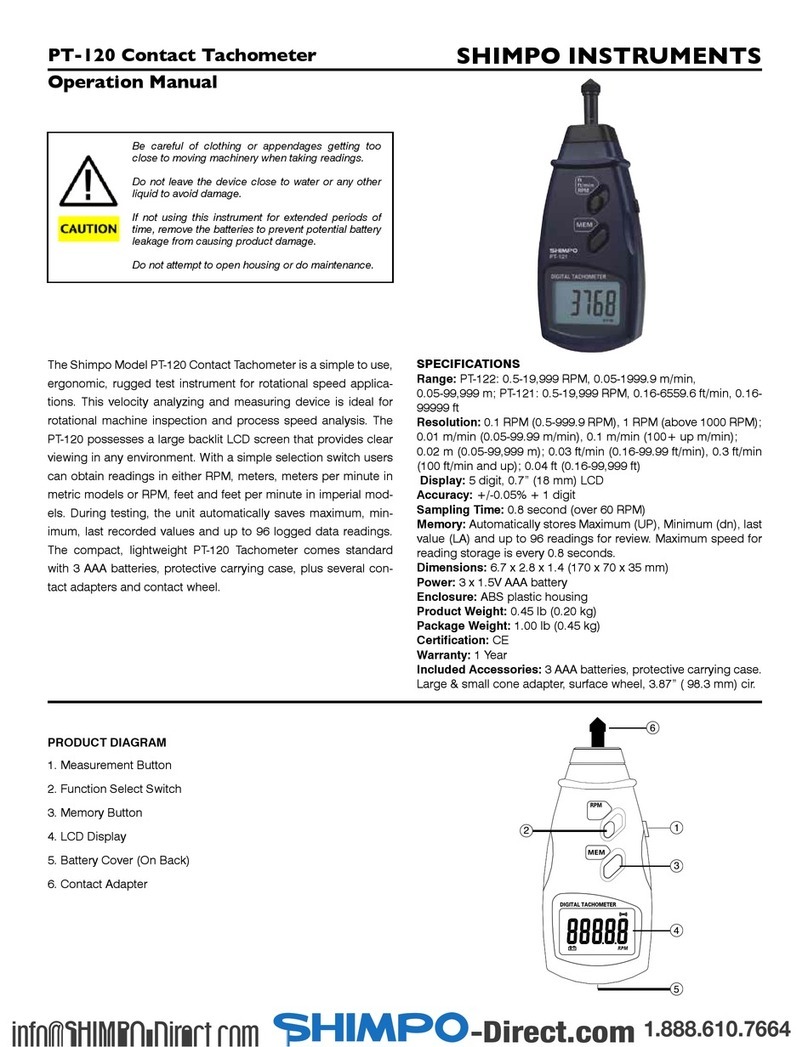

Shimpo Instruments PT-120 Operation manuals

Chauvin Arnoux

Chauvin Arnoux MEMO MD32 quick start

VOLTCRAFT

VOLTCRAFT VC-1310 operating instructions

Interacoustics

Interacoustics PA5 Operation manual