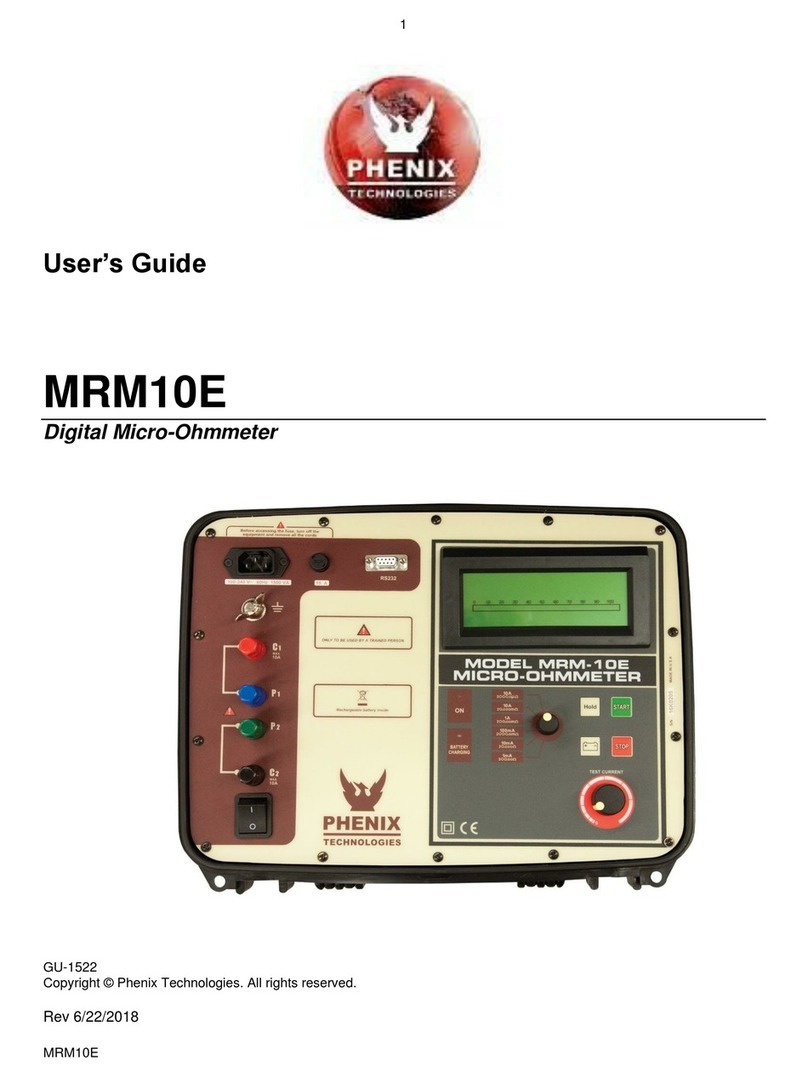

2-1

SEÇÃO 2: CONTROLES EINDICADORES

PAINEL DE CONTROLE

(Ref.aFigura2-1).

1. ENTRADA DE ALIMENTAÇÃO AC . Conecte em uma tomada adequadamente aterrada. Consulte a

etiqueta de especificações na unidade para obter os requisitos de tensão e corrente.

2. BLOQUEIO EXTERNO. Se desejar, remova o jumper do conector e substitua por contato (s) que devem

ser mantidos fechados durante o teste. Alguns exemplos incluem pedal, interruptor de segurança, , botão

de pânico, etc.

3. SOBRECARGA TÉRMICA. O disjuntor protege o primário do transformador de alta tensão. Se o disjuntor

desarmar, desligue a alta tensão e retorne o botão de controle de tensão a zero antes de reinicializar.

4. F1. Fusível

5. DISJUNTOR DE ENERGIA PRINCIPAL. Pressione I para conectar a alimentação, pressione O para

desconectar.

6. INDICADOR DE ALIMENTAÇÃO PRINCIPAL. Luzes para indicar que a energia está disponível para

teste.

7. Ajuste da corrente de trip: O dial ajusta de 1 a 11 correspondendo a aproximadamente 10% a 110% da

faixa de corrente de saída selecionada. A lâmpada de Corrente de Trip/Reset acende e a alta tensão é

desligada quando a corrente de saída excede a configuração, fazendo com que o circuito desarme. O

circuito também atua como proteção contra curto-circuito e sobrecarga na saída de alta tensão. Para

reativar a alta tensão, o controle de tensão deve ser retornado a zero e a chave Reset deve ser

pressionada para limpar o circuito de disparo de corrente.

8. Reset. A lâmpada de reset acende para mostrar que o circuito de desarme atual desarmou. Os circuitos

de alta tensão são desativados. O interruptor de reset momentânea deve ser pressionado para apagar a

lâmpada de reset para permitir que a alta tensão seja reaplicada após retornar o controle de tensão

para zero.

9. High Voltage On. Pressione para ligar a alta tensão. As condições necessárias para que a alta

tensão seja ativada são:

•Controle de tensão em Zero Start

•Malha de intertravamento externo fechada.

•Current Trip circuit Reset.

10. Alta tensão desligada. Pressione para desligar a saída de alta tensão. Em circunstâncias normais, o

controle de tensão deve retornar a zero, e a alta tensão deve cair perto de zero antes de desligar a alta

tensão. CUIDADO: Cargas capacitivas podem reter a tensão por um curto período após a alta tensão ser

desligada, enquanto o circuito interno libera sua carga para o aterramento. A lâmpada de alta tensão

desligada deve estar acesa antes que a alta tensão LIGADA possa ser ativada. As condições exigidas

para a iluminação são:

•External Interlock loop must be closed.

•Overcurrent Trip/Reset circuit must not be tripped. (Push Reset if circuit is tripped)