Neptune L900 Product manual

5015 B.U. Bowman Drive Buford, GA 30518 USA

Certification Exhibit

FCC ID: P2SL900M

IC: 4171B-L900M

FCC Rule Part: 15.247

ISED Canada Radio Standards Specification: RSS-247

Project Number: 72126503

Manufacturer: Neptune Technology Group Inc.

Model: L900M

Manual

L900™ MIU Pit Installation and Maintenance Guide

L900™ MIU Pit Installation and Maintenance Guide

L900™ MIU Pit Installation and Maintenance Guide

Copyright

This manual is an unpublished work and contains the trade secrets and

confidential information of Neptune Technology Group Inc., which are not to be

divulged to third parties and may not be reproduced or transmitted in whole or

part, in any form or by any means, electronic or mechanical for any purpose,

without the express written permission of Neptune Technology Group Inc. All

rights to design or inventions disclosed herein, including the right to manufacture,

are reserved to Neptune Technology Group Inc.

The information contained in this document is subject to change without notice.

Neptune reserves the right to change the product specifications at any time

without incurring any obligations.

Trademarks used in this manual

L900 and ProRead are trademarks of Neptune Technology Group Inc.

ARB, E-CODER, MACH 10, and R900 are registered trademarks of

Neptune Technology Group Inc. Other brands or product names are

trademarks or registered trademarks of their respective holders.

FCCNotice

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that

may cause undesired operation.

Note: This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCCRules. These limits are

designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses, and can radiate radio

frequency energy and if not installed and used in accordance with the instruction,

may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does not cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following

measures.

lReorient or relocate the receiving antenna.

lIncrease the separation between the equipment and receiver.

lConnect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

lConsult the dealer or an experienced radio/TV technician for help.

RF Exposure Information

This equipment complies with the FCC RF radiation requirements for

uncontrolled environments. To maintain compliance with these requirements, the

antenna and any radiating elements should be installed to ensure that a

minimum separation distance of 20cm is maintained from the general population.

Changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to

operate the equipment.

Professional Installation

In accordance with section 15.203 of the FCC rules and regulations, the L900

MIU must be professionally installed by trained utility meter installers.

Industry Canada (IC) Statements:

Section 8.4 of RSS-GEN

This Device complies with Industry Canada License-exempt RSS standard(s).

Operation is subject to the fol¬lowing two conditions: 1) this device may not

cause interference, and 2) this device must accept any interfer¬ence, including

interference that may cause undesired operation of the device.

Cet appareil est conforme aux normes RSS exonérées de licence d'Industrie

Canada. L'opération est soumise aux deux conditions suivantes: 1) cet appareil

ne doit pas provoquer d'interférence, et 2) cet appareil doit accepter toute

interférence, y compris les interférences pouvant entraîner un fonctionnement

indésirable de l'appareil.

Section 8.3 of RSS-GEN

Under Industry Canada regulations, this radio transmitter may only operate using

an antenna of a type and max¬imum (or lesser) gain approved for the transmitter

by Industry Canada. To reduce potential radio interference to other users, the

antenna type and its gain should be so chosen that the equivalent isotropically

radiated power (e.i.r.p.) is not more than that necessary for successful

communication.

This radio transmitter IC: 4171B-L900M has been approved by Industry Canada to

operate with the antenna types listed below with the maximum permissible gain

and required antenna impedance for each antenna type indicated. Antenna types

not included in this list, having a gain greater than the maximum gain indicated for

that type, are strictly prohibited for use with this device.

lMaximum permissible gain of +1 dBi and required impedance of 75 ohm.

lApproved Antenna type(s)

oR900 Pit Antenna, part number 12527-XXX

En vertu de la réglementation d'Industrie Canada, cet émetteur radio ne peut

fonctionner qu'avec une antenne d'un type et un gain maximal (ou inférieur)

approuvé pour l'émetteur par Industrie Canada. Pour réduire les interférences

radio potentielles avec d'autres utilisateurs, le type d'antenne et son gain

devraient être choisis de manière à ce que la puissance rayonnée

isotropiquement équivalente (e.i.r.p.) ne soit pas supérieure à celle nécessaire à

une communication.

Cet émetteur radio IC: 4171B-L900M a été approuvé par Industrie Canada pour

fonctionner avec les types d'antennes énumérés ci-dessous avec le gain

maximal admissible et l'impédance d'antenne requise pour chaque type

d'antenne indiqué. Les types d'antenne non inclus dans cette liste, ayant un gain

supérieur au gain maximal indiqué pour ce type, sont strictement interdits pour

être utilisés avec ce périphérique.

lGain maximal admissible de +1 dBi et impédance requise de 75 ohms.

lType (s) d'antenne approuvé

oR900 Pit antennaaximum

L900™ MIU Pit Installation

andMaintenance Guide

Literature No. IM L900 Pit MIU 09.17

Part No. 13381-001

Neptune Technology Group Inc.

1600 Alabama Highway 229

Tallassee, AL 36078

Tel: (800) 633-8754

Fax: (334) 283-7293

Copyright © 2017

Neptune Technology Group Inc.

All Rights Reserved

Contents

Chapter 1: Product Description 1

Product Description 2

L900 MIU Programming 2

RF Protocol Error Detection 2

RF Frequency Control Algorithm 2

RF Transmission Period and Randomness 2

Low Battery RF Emissions 2

Chapter 2: L900 Specifications 3

Electrical Specifications 3

Transmitter Specifications 3

Encoder Register Interface 3

Specifications - L900 MIU Pit 4

Environmental Conditions 4

Functional Conditions 4

Dimensions and Weight 4

Chapter 3: General Installation Guidelines 7

Tools and Materials 7

Safety and Preliminary Checks 8

Verifying/Preparing the Encoder Register 8

Installation of a Register (Non Pre-Wired or Potted Only) 9

Chapter 4: Pit Installation 13

Prior to Installation 13

Storage 13

Unpacking 13

Tools and Materials 14

Site Selection 14

L900 MIU Pit Installation 15

Installing the Antenna 16

L900 MIU Pit Installation and Maintenance Guide v

Begin the Installation 17

Threading the F-Connector 18

Installing the Scotchloks 19

Connecting the Splice Tube 21

Tying the Cable and Magnet Swiping the L900 MIU 22

Testing the Installation 23

Chapter 5: Data Logging Extraction 25

About Data Logging 25

Accessing Data Logging 25

Initializing the Data Logger 27

Initiating RF-Activated Data Logging 30

Sample Data Logging Graphs 31

Off-Cycle Data Extraction 33

R900 Belt Clip Transceiver 34

Chapter 6: Maintenance and Troubleshooting 35

Six- and Four-Wheel Encoders 35

Six-Wheel Encoders Normal Operation 35

Four-Wheel Encoders Normal Operation 35

Troubleshooting 36

Replacement Parts 36

Chapter 7: Contact Information 37

By Phone 37

By Fax 37

By Email 37

Glossary 39

Index

vi L900 MIU Pit Installation and Maintenance Guide

Contents

Figures

Figure 1 – L900 MIU - Pit 1

Figure 2 – L900 MIU - Pit Dimensions - Front 5

Figure 3 – L900 MIU Pit Dimensions - Side 5

Figure 4 – L900 MIU Pit Antenna 6

Figure 5 – Wiring a Neptune Encoder Register 10

Figure 6 – L900 MIU Color Code for Wires 10

Figure 7 – Cable Threaded Around Strain Relief Posts 11

Figure 8 – Application of the Sealant 11

Figure 9 – Covering the Terminal Screws 12

Figure 10 – L900 MIU Kit 13

Figure 11 – Antenna Placement for Low Traffic Areas 14

Figure 12 – Antenna Placement for High Traffic Areas 15

Figure 13 – Inserting the Antenna into the Pit Lid 16

Figure 14 – Locking Nut on Antenna 16

Figure 15 – Securing the Locking Nut 16

Figure 16 – Installation Completed 17

Figure 17 – Black Thread Guard from Male F-Connector 17

Figure 18 – Seating Washer 17

Figure 19 – Apply Novaguard 18

Figure 20 – Tightening Connector 18

Figure 21 – Gasket and Connector 18

Figure 22 – Scotchloks Connector 19

Figure 23 – Color Code for Wires 19

Figure 24 – Seating Connector Wires 19

Figure 25 – URCrimping Tool 20

Figure 26 – Improper Connections 20

Figure 27 – Three Color Wires Connected 20

Figure 28 – Splice Tube 21

Figure 29 – Gray Wire in Slots 21

Figure 30 – Cover in Place 21

L900 MIU Pit Installation and Maintenance Guide vii

Figure 31 – L900 MIU Attached to Antenna 22

Figure 32 – Magnet Swipe the L900 MIU 22

Figure 33 – HHU Home Screen 25

Figure 34 – N_SIGHTMain Screen 26

Figure 35 – Data Logger Options 26

Figure 36 – Reader ID Input 27

Figure 37 – HHU Time Confirmation 27

Figure 38 – Initialize RF Device 28

Figure 39 – L900 MIU ID Entry 28

Figure 40 – Capture Button 29

Figure 41 – Meter Size Selection 29

Figure 42 – Start Button 30

Figure 43 – Listening for Data 30

Figure 44 – Receiving Data 31

Figure 45 – Graph Button 31

Figure 46 – Examples of Data Logging Graphs 32

Figure 47 – HHU Home Screen 33

Figure 48 – HHU Menu Screen 33

Figure 49 – Off-Cycle Option 34

viii L900 MIU Pit Installation and Maintenance Guide

Figures

Tables

Table 1 – Supported Encoder Maximum Cable Length 4

Table 2 – L900 MIU Pit Environmental Conditions 4

Table 3 – L900 MIU Pit Functional Specification 4

Table 4 – L900 MIU Pit Functional Specification 4

Table 5 – Recommended Tools 7

Table 6 – Recommended Materials 8

Table 7 – Cable Length and Manufacturer 15

Table 8 – Data Logging Graph Legend 32

Table 9 – Examples of Reading Values 36

Table 10 – Available Replacement Parts 36

L900 MIU Pit Installation and Maintenance Guide ix

This page intentionally left blank.

xL900 MIU Pit Installation and Maintenance Guide

Tables

L900 MIU Pit Installation and Maintenance Guide 1

Chapter 1: Product Description

This chapter provides a general description of the L900™ Pit meter interface unit

(subsequently referred to as L900 MIU).

The L900 MIU by Neptune is a compact electronic device that collects meter

reading data from an encoder register. It then transmits the data for collection by

the meter reader. A walk-by handheld unit (HHU), mobile unit, R900®Gateway

collector, or LoRa®(Long Range) collector receives the data and stores it to be

downloaded into the utility billing system for processing.

The L900 MIU is easily installed and operates within a radio frequency (RF)

bandwidth which does not require an operating license. Because the L900 MIU can

be mounted as far as 500 feet from the encoder register, optimum broadcast signal

strength is obtainable, ensuring a high percentage of accurate, one-pass readings.

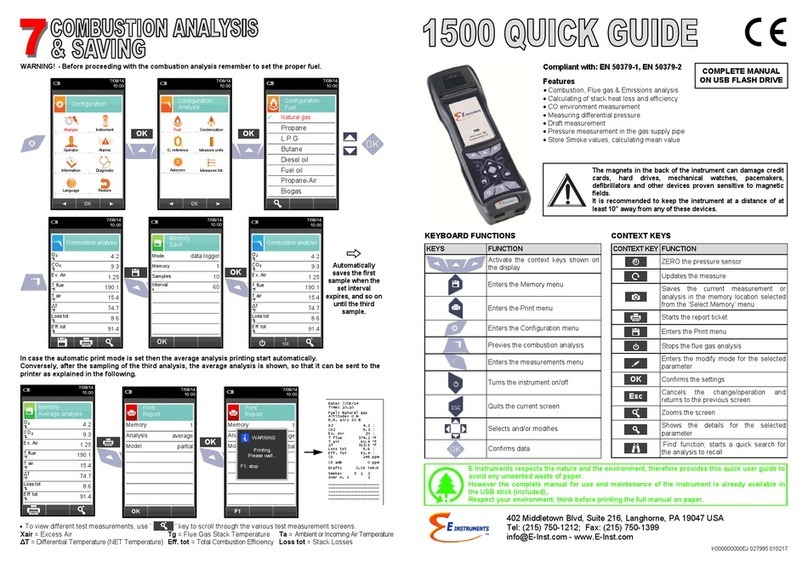

Figure 1 – L900 MIU - Pit

The L900 MIU meets FCC regulations Part 15.247, allowing higher output power

and greater range. The L900 MIU uses frequency-hopping, spread-spectrum

technology to avoid RF interference and enhanced security. The L900 MIU reads

the encoder registers at 15-minute intervals and transmits a mobile message that

includes the meter reading data and the unique nine-digit L900 MIU ID every 20

seconds. This allows the meter to be read by an HHU or mobile data collection

unit. The L900 MIU also transmits a high power fixed network message every

seven and one-half minutes on an interleaved basis to an R900 Gateway.

In addition to the mobile message that is transmitted every 20 seconds and the

fixed network message that is transmitted every seven and one-half minutes, the

L900 MIU is capable of supporting fixed network using a LoRa network.

The fixed network message that transmits for use on a LoRa network is sent every

three hours.

The L900 MIU is designed to offer advantages to utility organizations of all sizes:

lIncreases meter reading accuracy.

lEliminates infrastructure concerns and the burden of managing collection

devices.

lEliminates “hard-to-read” meters.

lProtects utility liability by increasing meter reader safety.

lRequires no programming.

Product Description

This section gives an overview of the L900 MIU.

L900 MIU Programming

The L900 MIU does NOT require field programming.

RF Protocol Error Detection

The RF protocol is comprised of a header, data packet, and an error detection

mechanism that reduces the erroneous data.

RF Frequency Control Algorithm

The L900 MIU’s frequency-hopping, spread-spectrum has a sequence of at least 50

different channels for transmitting data. Associated with the 50 channels are 50

frequencies that can be pre-selected in a pseudo random manner. These 50

frequencies are coded into the software.

The L900 MIU avoids 914 MHz to prevent collision with the Advantage probe.

RF Transmission Period and Randomness

The random period generation uses the same random seed created for the channel

definition to generate the transmission randomness. The randomness algorithm is

defined so that no two consecutive transmissions from two L900 MIUs interfere

with one another.

Low Battery RF Emissions

The L900 MIU stops RF transmissions when the battery discharges below the

normal operating voltage.

2 L900 MIU Pit Installation and Maintenance Guide

Chapter 1: Product Description

L900 MIU Pit Installation and Maintenance Guide 3

Chapter 2: L900 Specifications

This chapter provides you with the specifications for the L900 MIU.

Electrical Specifications

The power is supplied by a Lithium battery.

Transmitter Specifications

This section provides information on transmitter specifications.

Transmit Period lEvery 20 seconds - R900®standard mobile

message

lEvery seven and one-half minutes - R900 standard,

high power, fixed network message

lEvery three hours - LoRa fixed network message

Encoder Reading Encoder registers every 15 minutes

Transmitter

Channels

50

Channel Frequency 902 - 928 MHz

Output Power Meets FCC Part 15.247

FCC Verification Part 15.109

Encoder Register Interface

This section provides information on the maximum cable lengths required for

different registers. See the table on the following page.

Neptune ARB®V1300 feet (91 meters)

Neptune ProRead™ and E-CODER®500 feet (152 meters)

Sensus Protocol registers 200 feet (61 meters)

1Meets manufacturer's published specifications for wire length between encoder

and remote receptacle. The length is based on solid three conductor wire, 22

AWG.

Table 1 – Supported Encoder Maximum Cable Length

Specifications - L900 MIU Pit

Environmental Conditions

This section provides the environmental specifications for the

L900 MIU.

Operating Temperature -22° to 149°F (-30° to 65°C)

Storage Temperature -40° to 158°F (-40° to 70°C)

Operating Humidity 0 to 100% Condensing

Table 2 – L900 MIU Pit Environmental Conditions

Functional Conditions

This section provides the functional specification of the L900

MIU.

Register Reading Eight digits

L900 MIU ID Nine digits

Table 3 – L900 MIU Pit Functional Specification

Dimensions and Weight

This section provides the dimensions and weight of the L900

MIU.

Dimensions Refer to Figure 3 and Figure 4

Weight 1.0 lbs. (454 grams)

Table 4 – L900 MIU Pit Functional Specification

4 L900 MIU Pit Installation and Maintenance Guide

Chapter 2: L900 Specifications

Figure 2 – L900 MIU - Pit Dimensions - Front

Figure 3 – L900 MIU Pit Dimensions - Side

L900 MIU Pit Installation and Maintenance Guide 5

Chapter 2: L900 Specifications

Figure 4 – L900 MIU Pit Antenna

6 L900 MIU Pit Installation and Maintenance Guide

Chapter 2: L900 Specifications

L900 MIU Pit Installation and Maintenance Guide 7

Chapter 3: General Installation Guidelines

This chapter describes tools, materials, and general installation guidelines for the

L900 MIU.

Tools and Materials

Table 5 below and Table 6 on the next page show the recommended tools and

materials you need to successfully install the L900 MIU.

It is possible that some items do not apply to your specific installation, or the

list does not contain all required tools or materials.

Item Description/Recommendations Use

Took Kit Contains standard tools including:

lAssorted screwdrivers

lNeedle-nose pliers

lWire stripper

lDiagonal cutters

lElectrician's knife

lHammer

lCrimping tool (Part # 5500-158)

Performs various installation procedures.

Magnet 6 lb. force (Part # 12287-001) Magnet swipe the L900 MIU.

Table 5 – Recommended Tools

Table of contents

Other Neptune Measuring Instrument manuals

Neptune

Neptune E-CODER User manual

Neptune

Neptune HP PROTECTUS III Product manual

Neptune

Neptune E-CODER User manual

Neptune

Neptune R450 User manual

Neptune

Neptune E4000 Manual

Neptune

Neptune Leak Spy User manual

Neptune

Neptune MACH 10 Product manual

Neptune

Neptune E4000 User manual

Neptune

Neptune R900 Product manual

Neptune

Neptune R450 User manual

Neptune

Neptune R450 Reference guide

Neptune

Neptune MACH 10 Product manual

Neptune

Neptune HP PROTECTUS III Product manual

Neptune

Neptune Advantage II User manual

Neptune

Neptune E-CODER) R450i Product manual

Neptune

Neptune E4000 User manual

Neptune

Neptune TRU/FLO Product manual

Neptune

Neptune E4000 Manual

Neptune

Neptune HP Turbine Product manual