Setra Systems SRIMV Operating instructions

Table of contents

Other Setra Systems Measuring Instrument manuals

Setra Systems

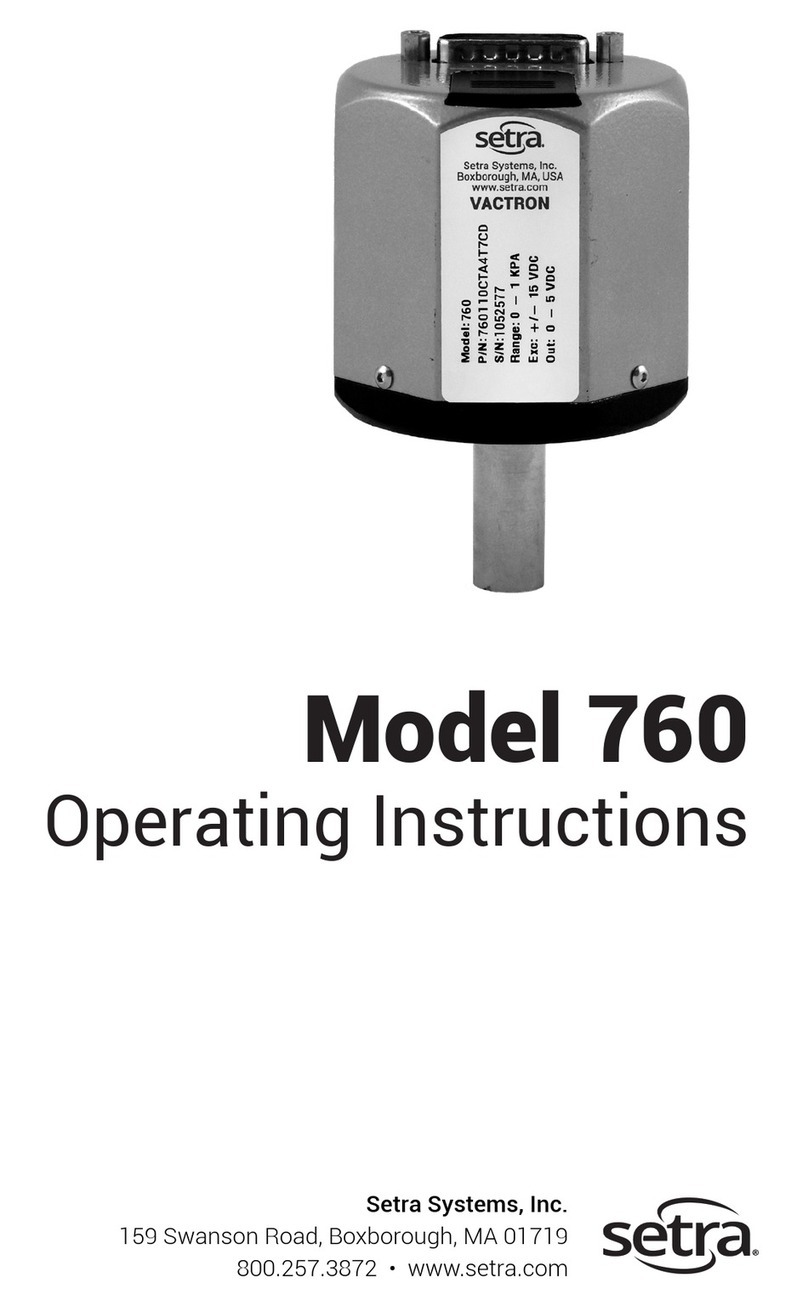

Setra Systems 760 User manual

Setra Systems

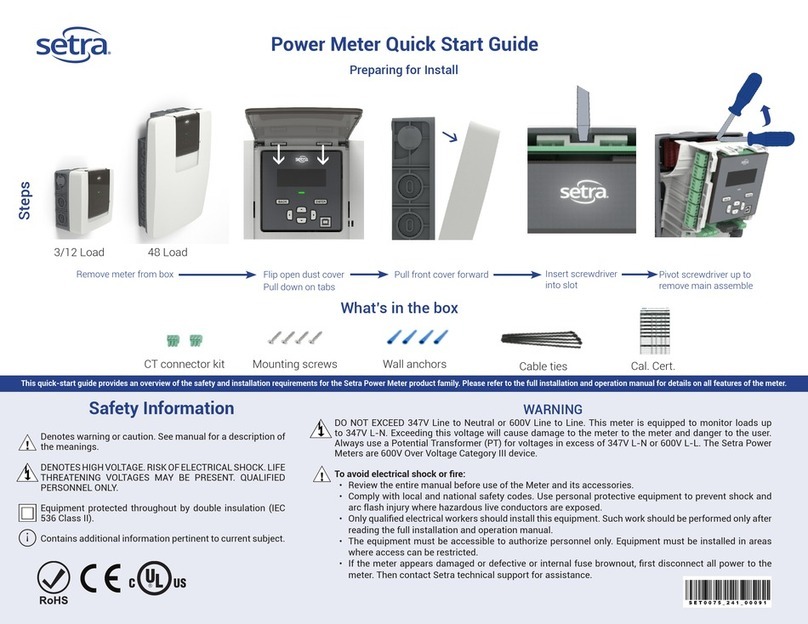

Setra Systems Power Patrol Manual

Setra Systems

Setra Systems Model 730 User manual

Setra Systems

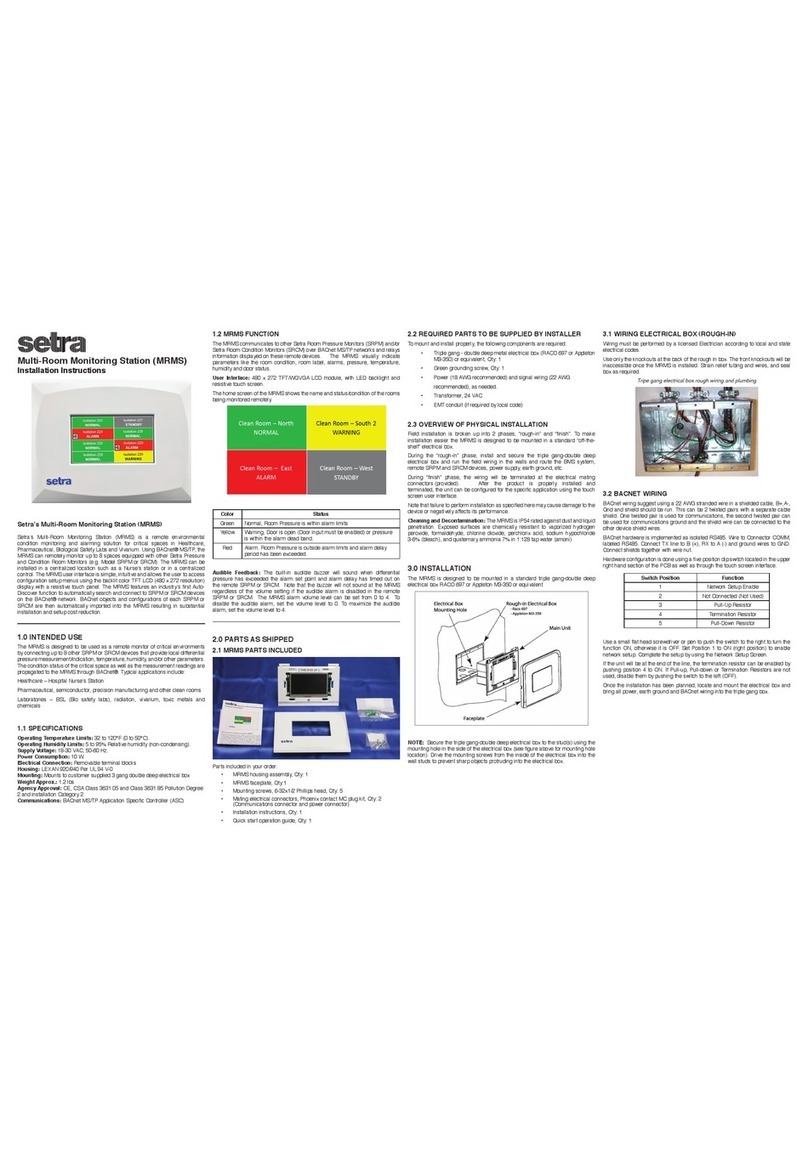

Setra Systems MRMS User manual

Setra Systems

Setra Systems SS-SPM User manual

Setra Systems

Setra Systems 370 User manual

Setra Systems

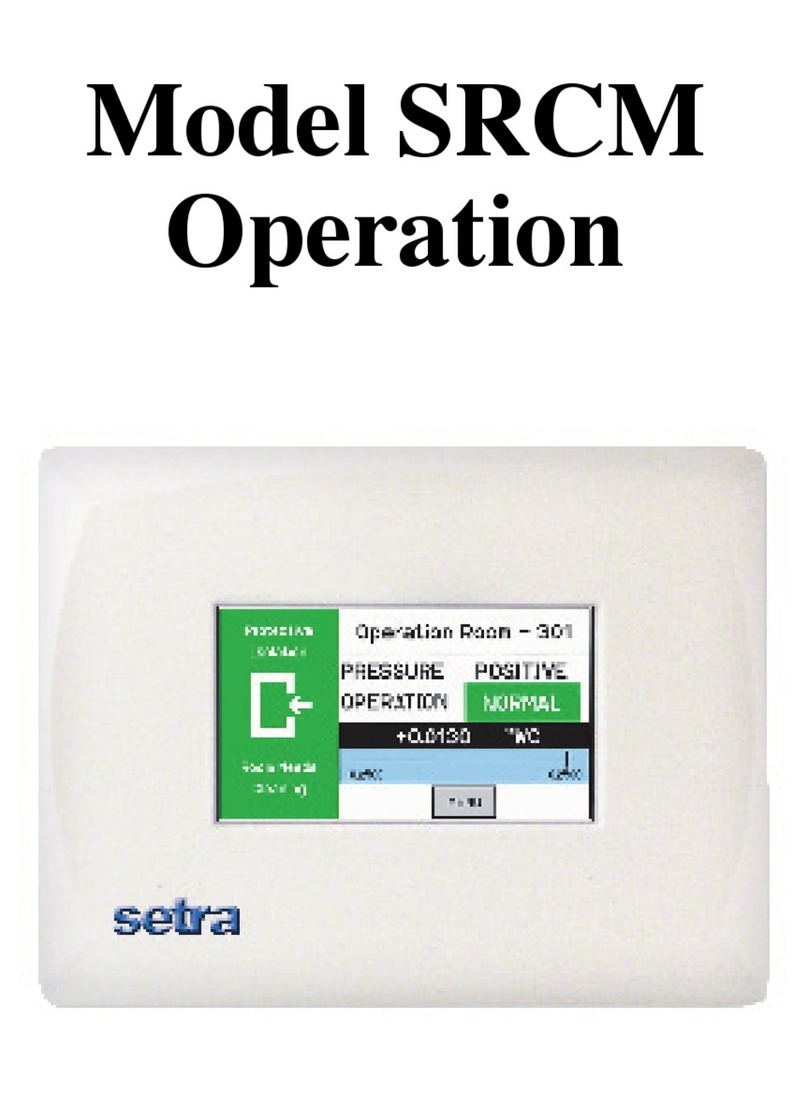

Setra Systems SRCM Installation manual

Setra Systems

Setra Systems DATUM 2000 User manual

Setra Systems

Setra Systems SRIM1 User manual

Setra Systems

Setra Systems 761 User manual

Popular Measuring Instrument manuals by other brands

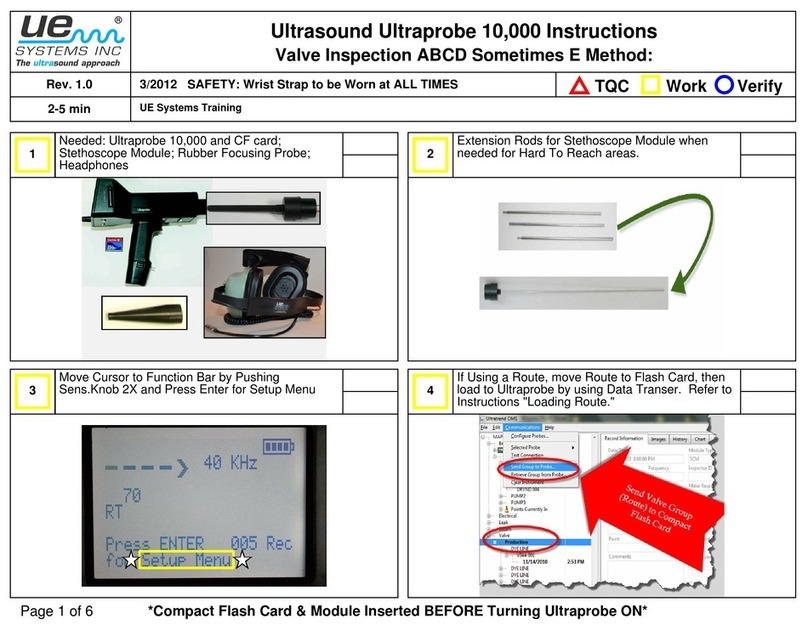

UE Systems

UE Systems ULTRAPROBE 10000 instructions

Delmhorst

Delmhorst J-Lite owner's manual

Keysight Technologies

Keysight Technologies N9000B Configuration guide

Sierra

Sierra 780S Series Flat-Trak Quick install guide

NARDA

NARDA ESM-10 RadMan Mobile operating manual

Valeport

Valeport DataLog x2 Installation and user guide

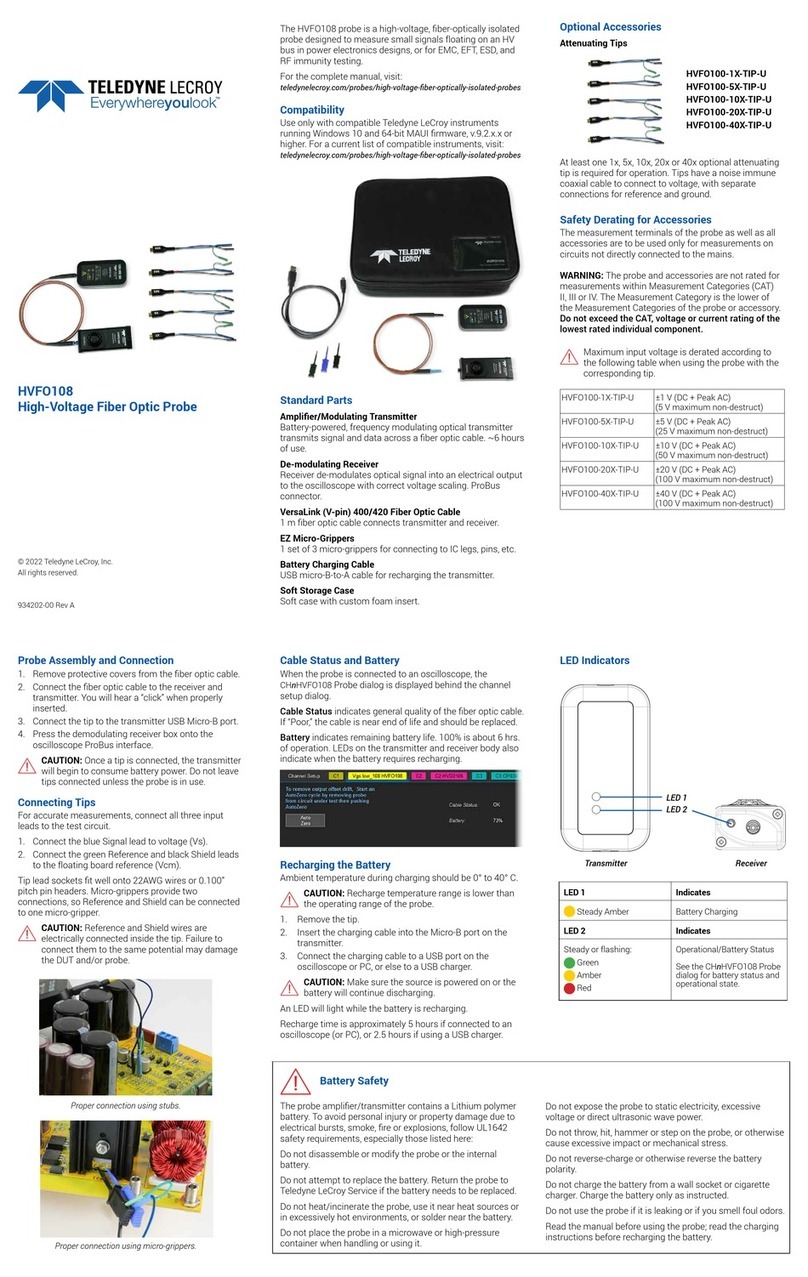

Teledyne Lecroy

Teledyne Lecroy HVFO108 manual

Oxford Technical Solutions

Oxford Technical Solutions xNAV user manual

Keysight

Keysight P-Series Technical Overview and Self-Guided Demonstration

Riken Keiki

Riken Keiki RM-592 Operating instructions manual

Kestrel

Kestrel 2000 manual

Wetekom

Wetekom 364489 instruction manual