Firestone 2239 User manual

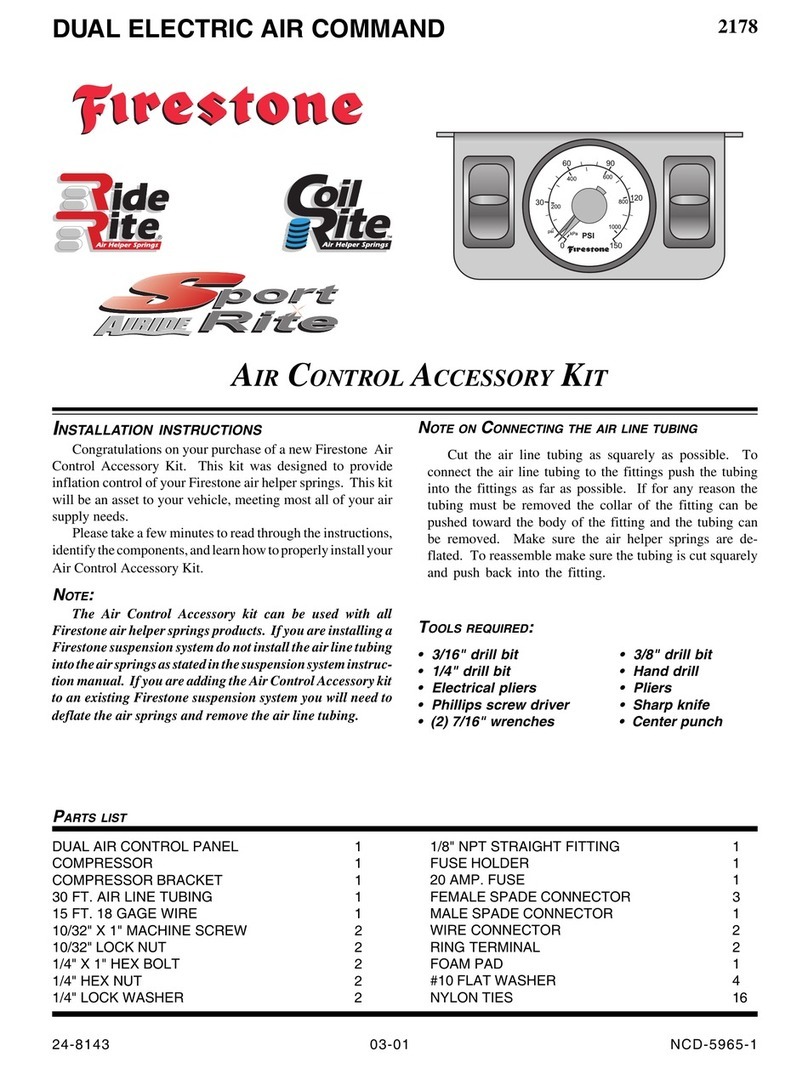

Air

Pressure

0

2

4

68

10

12

14

15

0

20

40

60

psi

lb/in3220

80

100 120

140

160

180

200

kg/cm2

Bar

0

200

400

600 800

1000

1200

1400

1500

kpa

AIR COMPRESSOR

ACCESSORY KIT

COMPRESSOR 9335 1

AIR TANK 9127 1

PRESSURE SWITCH 9016 1

COMPRESSOR T-FITTING 3066 1

1/4" NPT PTC MALE FITTING 3

BULK HEAD FITTING 1

DRY COUPLER FITTING 1

INFLATION GAUGE UNIT 1

25 FT. EXTENSION HOSE 1

3/8" -16 x 1" HEX BOLT 4

3/8" -16 FLANGED HEX NUT 4

3/8"FLATWASHER 4

10 -32 x 1" MACHINE SCREW 3

10 -32 NYLON-INSERT HEX NUT 3

3/16"FLATWASHER 4

18 FT. AIR LINE TUBING 1

NYLON TIE 6

15 FT. 14 GAGE WIRE 1

WIRE CONNECTOR 1

FEMALESPADETERMINAL 1

25AMPBLADEFUSE 1

FUSE HOLDER 1

AIR COMMAND

24-8216 08-06 NAD-30734-3

PARTS LIST

INSTALLATION INSTRUCTIONS

Congratulations on your purchase of a new Air

CompressorAccessoryKit. Thiskitwillbeanassettoyour

vehicle, meeting nearly any of your air supply needs.

Please take a few minutes to read through the

instructions, identify the components, and learn how to

properlyinstallyourAirCompressorAccessoryKit.

NOTE ON CONNECTING AIR LINE TUBING:

Cuttheairlinetubingassquareaspossible. Toconnect

theairlinetubingtothefitting,pushthetubingintothefitting

asfaraspossible. Ifthetubingmustberemovedfromthe

fitting,firstreleasetheairpressurefromthesystem. Push

thecollar onthe fittingtoward thebody ofthe fittingand

pulloutthetubing.

TOOLS REQUIRED:

• UTILITY KNIFE • 3/8" DRILL BIT

• PHILLIPS SCREW DRIVER • 11/16" DRILL BIT

• WIRE CRIMPER/STRIPPER • ELECTRIC DRILL

• (2) 9/16"OPEN-END WRENCH • 1/2"WRENCH

• CENTERPUNCH • 3/8"WRENCH

2239

NOTE:

THISKITIS NOTDESIGNED TORUN AIRPOWEREDTOOLS.

THE COMPRESSOR IS DESIGNED TO RUN AT A20%DUTY

CYCLEWITH AMAXIMUM RUN TIME OF 6MINUTES.PLEASE

ALLOW ADEQUATE TIME FOR THE COMPRESSOR TO COOL

BETWEENRUNNINGS.

25 AMP FUSE

5

STEP 1 - PREPARE THE VEHICLE

Remove the negative terminal on the battery.

STEP 2 - PREPARE THE COMPRESSOR

Install the rubber isolator feet onto the compressor mounting

brackets. Insert the brass sleeves into the top of the isolator feet, see

Figure "B". Install the compressor T-fitting into the threaded

exhaust port on the compressor head, see Figure "A". Tighten the

fitting sufficiently to engage the pre-applied orange thread sealant.

(Torque to 40 in. lbs.) DO NOT OVERTIGHTEN THE FITTING.

InstallthepressureswitchintothecompressorT-fitting. Installtheair

filter into the threaded inlet port on the compressor head (finger

tight). Installthe positive(red) wirefrom thecompressor ontoeither

spade on the pressure switch, see Figure "A".

STEP 3 - MOUNT THE COMPRESSOR

Selectaconvenientlocationtomountthecompressor. Thislocation

shouldprovideampleairflowandbeprotectedfromairbornedebrisand

moisture. The mounting surface should be rigid to support the compressor, such as under the hood on a fender well

or in a vented storage compartment. The compressor is oil-less and can be mounted in any orientation necessary for

installation.

Usingthe compressor as a template, center punch, and drill three 3/16" holes. Before drilling, ensure that thereare

no electrical , fuel, or brake lines on the opposite side of the mounting surface that can be damaged by the drill. Any

burrsintheholesshouldberemovedtopreventdamagetotherubberisolators. Mountthecompressorusingthesupplied

10 -32 x 1" machine screws, 10 -32 lock nuts, and 3/16" washers. SeeFigure "B". Maximum vibration isolation can

be achieved by properly mounting the compressor. The machine screw and nut should be tightened only enough to

bottom-out the brass insert, see Figure "B". DO NOT OVERTIGHTEN. Overtightening will crush the brass insert

andtherubberisolator,thereby reducing vibrationisolation.

Attach the black wire from the compressor to a grounded component of the vehicle's chassis.

STEP 4 - MOUNT THE AIR TANK

Installthemalepush-to-connectfittingsintobothportsontheairtank. Tightenthefittingsufficientlytoengagethe

pre-appliedorangethreadsealant.Selectalocationtomounttheairtank. Thisshouldbeaprotectedlocationtoprevent

damagefromflyingrocksordebris. Usingtheholesinthetankbracketsasatemplate,markthelocationsofthemounting

holesonthemountingsurface.Useacenterpunchtomarkthecenteroftheholesonthemountingsurface.Beforedrilling,

ensurethattherearenoelectrical,fuel,orbrakelinesontheoppositesideofthemountingsurfacethatcanbedamaged

by the drill. Drill four 7/16" holes on the center marks. Using the supplied 3/8" hex bolts and flanged hex nuts, attach

theairtankintothemountingsurface.SeeFigure"A". Ensureclearaccesstothefittingsontheairtankismaintained.

Do not exceed 120 psi in the tank.

STEP 5 - MOUNT BULK HEAD FITTING

Installthebulkheadfittinginaconvienentprotectedlocation.Thelocationcouldbeanyrigidflatsurfacethatwould

beaccessibleforeasydischargeofairfortheenduser.Beforedrilling,ensurethattherearenoelectrical,fuel,orbrake

lines on the opposite side of the mounting surface that can be damaged by the drill. Mark and drill a 11/16" hole in the

desiredlocation.Installthebulkheadfittingandtighten,seeFigure"E". Installthe1/4NPTfittingonthecompressor

side of the bulk head fitting and tighten the fitting sufficiently to engage the pre-applied thread sealant. Install the dry

couplerfittingontheothersideofthebulkheadfittingandtightenthefittingsufficientlytoengagethepre-appliedsealant.

Figure "B"

BRASS SLEEVE

COMPRESSOR

FOOT

RUBBER

ISOLATOR

BRASS SLEEVE

COMPRESSOR

FOOT

RUBBER

ISOLATOR

#10 FLAT WASHER

#10 FLAT WASHER

VEHICLE

MOUNTING

SURFACE

#10 -32 LOCK

NUT

#10-32 x 1 PAN HEAD

SCREW

STEP 6 - ROUTE THE AIR LINE TUBING

Routealengthofairlinetubingfromthepush-to-connectfittingon

the air tank to the T-fitting on the compressor. See Figure "A".

Route a length of the airline tubing from the tank to the bulk head

fitting,seeFigure"A".Routetheairlinetoavoidsharpedgesorheat

fromtheengineor exhaust system. Using arazorknife,makethe cut

as square as possible and push the air line into the fittings as far as

possible. Do not fold or kink the air line tubing.

STEP 7 - WIRE THE SYSTEM

Strip1/4"offtheendof the red 14 gage wire supplied withthekit.

Crimp a female spade connector onto the end of the red wire. Install

thefemalespadeconnector onto theremainingspadeonthe pressure

switch. Usingawireconnector,attachtheoppositeendofthewireto

an ignition activated, positive 12 Volt, 25 Amp minimum power

source. Consult the manufacturer's wiring diagram for your

vehicle. Slip the wire connector over the existing ignition activated

wireandinserttheun-stripped14gagewireintotheconnector. Close

the wire connector over the wires with pliers, see Figure "C".

Install an in-line fuse in the 14 gage power wire, as close to the

power source as conveniently possible. Cut the 14 gage wire and

inserttheun-stripped ends intothefuseholder. Closethefuseholder

with pliers and insert a 25 Amp blade fuse. See Figure "D".

NOTE: Shouldadditionalwirebenecessary,14gagemultistrand

wire may be used.

STEP 8 - TEST THE SYSTEM

Re-attachthenegativeterminalonthebattery.Turnonthevehicle'signition. Theaircompressorwillrunforashort

time to build pressure in the tank. Once the pressure reaches 120 psi in the air tank, the pressure switch will turn the

compressor off. It will not restart until the pressure in the tank drops below 90 psi.

USING THE AIR COMPRESSOR ACCESSORY KIT

Yoursystemisnowreadytouse. Withthecoiledtubingprovided,attachtheendwiththecoupler fittingtothebulk-

headfitting.Installthecouplerfittingonthegaugeunitthenattachthegaugeunittothecoiledtubing Youcannowuse

theairchuck gauge unitforinflation.

FILTER MAINTENANCE

It is recommended that the air compressor filter be inspected periodically. If the filter is sufficiently clogged with

road debris or moisture, it will require replacement.

EXISTING

POWER

WIRE

CONNECTINGWIRE

PLASTIC

CONNECTOR

Figure "C"

Figure "D"

FUSE HOLDER

Figure "E"

Other Firestone Air Compressor manuals

Popular Air Compressor manuals by other brands

Stanley

Stanley AirPro 120 HRC120DS instruction manual

Jefferson Professional Tools & Equipment

Jefferson Professional Tools & Equipment JEFC200L10B-230 user manual

HSS Hire

HSS Hire 42CFM Operating & safety guide

Sparmax

Sparmax TC-610H user manual

BENDIX

BENDIX BX-2150 installation instructions

Dynaset

Dynaset HKR 500 user manual

Chicago Pneumatic

Chicago Pneumatic CPC 40 G Instruction book

Curtis

Curtis OL 512 Operation and instruction manual

Sullair

Sullair ES-6 series Operators manual and parts lists

Will Burt

Will Burt 185 instructions

Schneider Airsystems

Schneider Airsystems UNM STL 1250-10-270 Original operating manual

Central Pneumatic

Central Pneumatic 95275 Set up and operating instructions