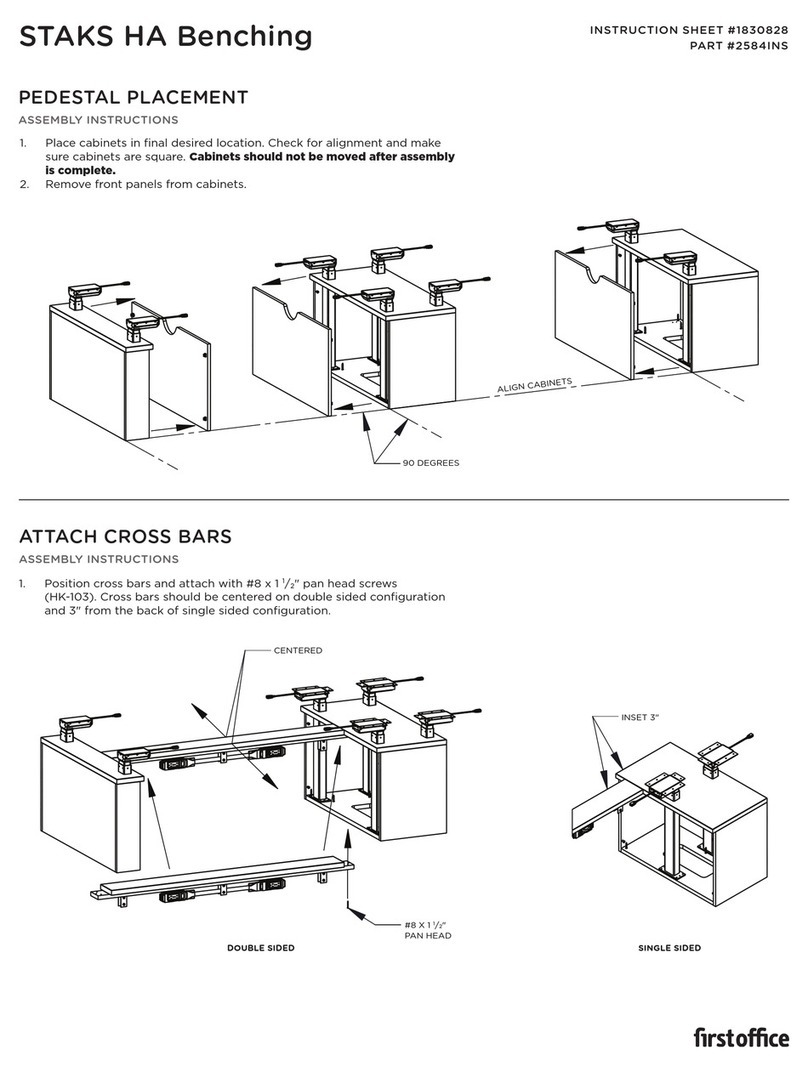

1. Panel

2. Initialization Procedure

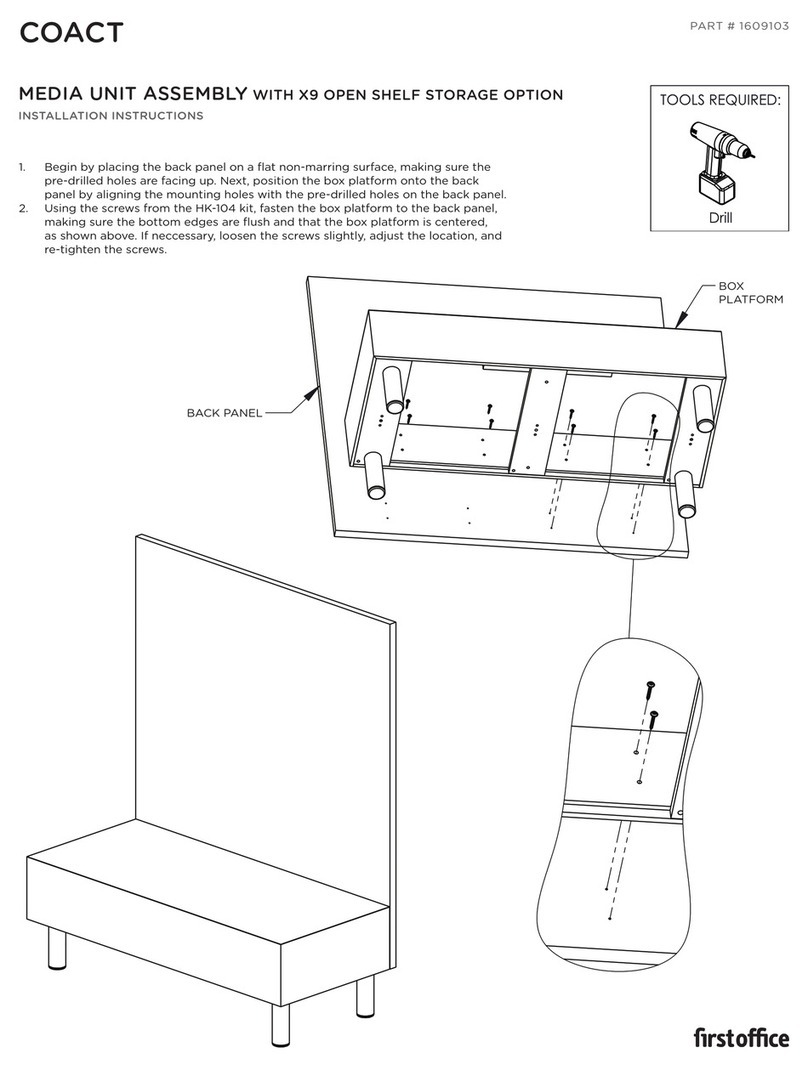

The initalization procedure must be completed before the first running table after the

table is installed or parts replaced.

• Press and Hold & simultaneously for more than 3 seconds, the legs begin to move

down at half speed of normal operation.

• Keep pressing the & , notice the legs move down to the lowest position and rebound

2-5 mm, then stop.

• Then release & together, the initialization process is complete.

3. Move Up & Down

• Press and Hold and the legs move up.

• Release and the legs stop.

• Press and Hold and the legs move down.

• Release and the legs stop.

4. Set Memory Positions

• Press and Hold & , then release and run the legs to the position you want the table surface to be.

• Click button S, and then click button 1 , 2 , or 3 within next 3 seconds, this is how you save the positions.

5. Move to the Memorized Positions

• Press and hold the button 1 , 2 , or 3, and the legs will return to corresponding positions saved.

6. Verify the Display Switch Data to Table Height

Check the switch display format in inches or centimeters and toggle to the unit you like and match

to the actual measurement. In inches format, the minimum adjustable height is 0.5 inches, while in

centimeters format is 1 centimeter.

• Set the table at any height (reccommended at the bottom position), measure the table actual height

and write down the number in inches or in centimeters.

• Press and Hold the button S, then press and hold , keep for about 3 seconds. The first number should

start flashing on the screen.

• Release the buttons and click on either or to change the first number. The first number is being

increased or decreased to the first number you measured.

• Click button S and the second number should start flashing on the screen.

• Click or to change the number, the second number is being increased or decreased to the second

number you measured.

• Click button S, the third number should start flashing on the screen.

• Click or to change the number, The third number is being increased or decreased to the third

number you measured.

• Click button S, completed.

DIGITAL HANDSET OPERATION

OPERATION INSTRUCTIONS

RANGE INSTRUCTION SHEET #2577INS

PART #1730534

• 1 Button: Preset 1

• 2 Button: Preset 2

• Display: Reads in 1/2" Increments

• 3 Button: Preset 3

• S Button: Select