FISCHBEIN PBC-6000 User manual

FISCHBEIN®Co. MODEL PBC-6000™

OPERATOR’S MANUAL

REV. D 2005-03 1

TABLE OF CONTENTS

Page

1. INTRODUCTION………………………………………………………………………………….. 3

1.1 General Safety Precautions……………………………………………………………. 4

1.2 Safety Statement……………………………………………………………………………4

1.3 Revision Changes……………………………………………………………………………4

2. WARRANTY STATEMENT………………………………………………………………………4

3. WARNINGS…………………………………………………………………………………………. 4

4. COMMON APPLICATIONS OF THE PBC 6000……………………………………… 5

4.1 System Illustration………………………………………………………………………… 6

4.2 System Characteristics…………………………………………………………………… 7

4.3 Accessories and Options………………………………………………………………… 9

5. INSTALLATION……………………………………………………………………………………. 10

5.1 Recommended Work Area Layout…………………………………………………… 10

5.2 Site and System Preparation………………………………………………………….. 10

5.3 Unpacking Procedure…………………………………………………………………….. 11

6. ON LINE PREPARATION……………………………………………………………………… 13

6.1 Safety Guidelines……………………………………………………………………………13

6.2 Electrical System…………………………………………………………………………… 13

6.3 Pneumatic System…………………………………………………………………………. 14

6.4 Leveling and Centering……………………………………………………………………14

6.5 Speed Checks and Synchronization…………………………………………………. 16

6.6 Folder …………………………………………………………………………………………..17

6.7 Compression Belts and Rollers………………………………………………………… 17

6.8 Setting the Temperature………………………………………………………………… 18

6.8.1 Determining the Correct Temperature………………………………….18

6.8.2 Using the Temperature Controller………………………………………..19

7. OPERATING THE PBC 6000………………………………………………………………… 20

7.1 Process Description………………………………………………………………………. 20

7.2 Operating the PBC 6000

(START UP PROCEDURE)

………………………. 22

7.3 Shutdown Procedure……………………………………………………………………… 23

FISCHBEIN®Co. MODEL PBC-6000™

OPERATOR’S MANUAL

REV. D 2005-03

2

8. MAINTENANCE AND ADJUSTMENTS…………………………………………………… 24

8.1 Scheduled Maintenance………………………………………………………………… 24

8.1.1 DailyMaintenance……………………………………………………………… 24

8.1.2 Monthly Maintenance………………………………………………………… 24

8.2 System Frame………………………………………………………………………………. 26

8.3 Pneumatics…………………………………………………………………………………… 26

8.4 Sensors………………………………………………………………………………………… 27

8.4.1 Thermocouple…………………………………………………………………… 27

8.4.2 Proximity Sensors……………………………………………………………… 27

8.4.3 Airflow Sensor……………………………………………………………………27

8.5 Belts, Rollers and Wheels………………………………………………………………. 28

8.5.1 Carry Through Belts……………………………………………………………28

8.5.2 Compression Belts……………………………………………………………. 30

8.5.3 Compression Rollers………………………………………………………….. 37

8.5.4 Takeup Rollers…………………………………………………………………..38

8.5.5 Pulleys, Drive, Sprocket and Tension…………………………………… 39

8.5.6 Creaser Wheel……………………………………………………………………42

8.6 Bag Guide (Manual Infeed)……………………………………………………………. 47

8.7 Folder and Guides…………………………………………………………………………. 49

8.8 Hot Air (Heater) Manifold………………………………………………………………..51

8.9 Temperature Controller…………………………………………………………………..54

8.10 Drive Motor and Gears…………………………………………………………………… 55

9. QUALITY CONTROL GUIDE…………………………………………………………………. 56

9.1 General Conditions for a Good Seal………………………………………………… 56

9.2 Typical Bag Closures……………………………………………………………………… 57

10. TROUBLESHOOTING…………………………………………………………………………… 60

11. SPARE PARTS LISTS…………………………………………………………………………… 61

12. SAFELY DISPOSING OF A PBC 6000…………………………………………………… 62

13. GLOSSARY…………………………………………………………………………………………… 62

14. ASSEMBLY DRAWINGS AND PARTS LISTS………………………………………… 63

FISCHBEIN®Co. MODEL PBC-6000™

OPERATOR’S MANUAL

REV. D 2005-03 3

READ

INSTALLERS AND OPERATORS OF THIS EQUIPMENT

SHOULD READ THIS ENTIRE DOCUMENT BEFORE

ATTEMPTING TO HANDLE OR OPERATE THE PINCH BAG

CLOSER (PBC 6000) SYSTEM.

BE SURE TO LOCATE AND READ THE ADDITIONAL

COMPONENT MANUALS STORED IN THE ELECTRICAL

ENCLOSURE.

1. INTRODUCTION

The Fischbein Company is a premier packaging company that specializes in bag closing systems.

The original one-man business, founded and established by Dave Fischbein in Minneapolis,

Minnesota in 1910, has now grown to an international firm recognized as the global leader in bag

closing technology which manufactures a variety of state-of-the-art bag closing and handling

machines for diverse packaging applications. Fischbein’s first portable sewing machine for bag

closing was developed over 50 years ago and is still widely used throughout the world for a variety

of bag closing applications. Through our bag sewing, closing and sealing technologies, Fischbein

offers automated solutions for nearly every powder and bulk material packaging requirement.

The product line has greatly expanded from those early days, and the company continues to lead

the industry in helping customers increase productivity through improved product production with

efficient, up-to-date automated packaging solutions.

This Operator’s Manual is intended to help our customers set up, operate and maintain their new

Fischbein Pinch Bag Closer System (PBC). For information not covered in this manual, you can

contact Fischbein through the worldwide web at www.fischbein.com or by writing or calling our

North American or European offices:

North American Office Main European Office

Fischbein Company Fischbein SA

151 Walker Road Paepsem Business Park

Statesville, NC 28625 Boulevard Paepsem 18B

Phone: (704) 871-1159 1070 Brussels, Belgium

FAX: (704) 872-3303 Phone: 32-2-521-01-94

FAX: 32-2-520-33-90

FISCHBEIN®Co. MODEL PBC-6000™

OPERATOR’S MANUAL

REV. D 2005-03

4

1.1 GENERAL SAFETY PRECAUTIONS

The PBC 6000 system is driven by strong motors, contains moving parts with pinch points and sharp

edges and hot machine surfaces. Therefore, technical training and familiarity with this type of

equipment are required to operate and maintain the system. Installers and operators of PBC 6000

should wear proper eye, foot, and hand protection. Turn off and lock out air and power sources when

cleaning or performing maintenance. Once the air source has been locked out, existing air pressure in

the system will be released.

1.2 SAFETY STATEMENT

F

ISCHBEIN IS NOT RESPONSIBLE FOR DAMAGE OR INJURIES CAUSED BY MISUSE OF THE

EQUIPMENT

,

FOR CARELESS OPERATION OR IF IT IS USED TO SEAL MATERIALS FOR WHICH IT

WAS NEVER DESIGNED

. Installers of this machine should wear eye and foot protection at all times

and gloves when working around the hot machine surfaces. Operators must always wear proper

eye protection when operating this machine and not wear loose clothing or jewelry. Long hair

must be pulled back and tied to avoid getting caught in the belts and rollers.

1.3 REVISION CHANGES

The revision of this manual has been upgraded to D to reflect the improvements to the assemblies

on drawings 17708 and 17701A in the back of this manual.

2. WARRANTY STATEMENT

Nothing contained in this document is intended to extend any promise, warranty or representation,

expressed or implied, regarding the FISCHBEIN products described herein. Any such warranties

or other terms and conditions of products shall be in accordance with the standard terms and

conditions of sale for such products, which are available upon request. FISCHBEIN reserves the

right to make changes and improvements to products without notice and without incurring any

obligation to make such changes or add such improvements to products sold previously.

3. WARNINGS

• Always use genuine Fischbein parts. Our parts are specifically designed for Fischbein equipment

to provide optimum performance and safety. Use of non-Fischbein parts can also void the product

warranty.

• Employees shall receive training by the employer on proper equipment operation and shutdown

of this machine.

• Let the machine do the work. Do not pull the bag or materials through it.

• This PBC 6000 system is not suitable to operate in an area where explosive materials are present

(explosive gas, powders, vapors or liquids).

• Read and follow the manuals for the devices used in the PBC 6000 System. The accompanying

manuals are in the electrical enclosure. These manuals will provide the appropriate instructions

for operating and maintaining individual components.

FISCHBEIN®Co. MODEL PBC-6000™

OPERATOR’S MANUAL

REV. D 2005-03 5

• When used in a dusty environment, NEMA12 (IP54) electrical equipment must be used.

• Frequently clean the machine to prevent accumulation of dust, bag and glue materials. Doing this

prevents the accumulation of material that may cause malfunctions or poor bag seals.

• Frequently, clean the compression rollers by using a dull edge to remove excess glue. Be careful

not to cut or gouge the belt surface.

• The PBC 6000 utilizes two HI-temperature heater cartridges. The surfaces surrounding the hot

air manifold will become hot and can cause burns if touched. Never operate the machine

without the guards. Be careful while operating the machine to avoid being injured.

• Electrical service and troubleshooting of this unit must be performed by trained and qualified

personnel. Any OSHA regulations such as electrical and pneumatic lockouts must be followed.

• Turn off the Pinch Bag Closer at the main switch and remove all power going to the electrical

box before making adjustments to the machine.

• Do not operate this machine with guards removed!

• Replacement of the quick release air coupling (P/N P4945) may violate OSHA safety

regulation #1910 for controlling hazardous energy, which may cause serious personal injury.

See equipment shutdown procedures.

4. COMMON APPLICATIONS OF THE PBC 6000

The PBC 6000 is a heavy-duty, production line system that folds and closes pre-glued, multi-wall

paper bags with a fold of up to 1 7/8 inches (48 mm). Note: the PBC is also available with the

option to fold 2 3/8” folds. The system is designed for easy opening as a primary safety factor in

case of an emergency. This feature also prevents the motor from overload if a bag becomes

jammed.

The patented break-away feature provides immediate access to the machine’s heating assembly, drive

belts, and other moving parts requiring maintenance. The unit is compact and adjustable to allow

various bag sizes, conveyor speeds, and heights.

This equipment services the bagging needs of a broad range of products. Common uses include

flour, pet food, agricultural seed, animal feeds, feed additives, lawn fertilizers, absorptive

materials, industrial and agricultural chemicals, powdered dairy products, and bakery mixes.

FISCHBEIN®Co. MODEL PBC-6000™

OPERATOR’S MANUAL

REV. D 2005-03

6

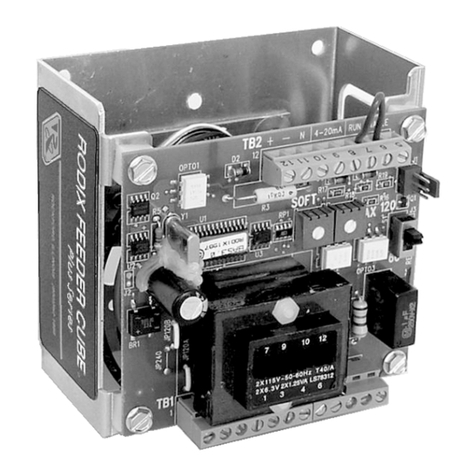

4.1 SYSTEM ILLUSTRATION

1. Casters (2) standard 11. Pin, Swing Arm-Holding (for shipping only)

2. Frame (pedestal and overarm) 12. Infeed (Automated Style Shown)

3. Swing Arm Assembly 13. Locking Casters (2)

4. Motor, Drive – Gear 14 Electrical Connection

5. Cylinder, Pneumatic – Swing Channel 15. Electrical Enclosure

6. Electrical Control Panel 16. Height Adjustment Lock

7. Chain Tension Assembly 17. Compression Belts

8. Height Adjustment Handle 18. Carry Through Belts

9. Flowmeter 19. Belt Guards

10. Air Flow Regulator

FISCHBEIN®Co. MODEL PBC-6000™

OPERATOR’S MANUAL

REV. D 2005-03 7

4.2 SYSTEM CHARACTERISTICS

PHYSICAL CHARACTERISTICS

Total palletized system weight: 770 lbs. (350 kg)

Total system weight: 710 lbs. (323 kg) (standard machine)

System Dimensions:

FISCHBEIN®Co. MODEL PBC-6000™

OPERATOR’S MANUAL

REV. D 2005-03

8

Air Consumption Minimum Requirement: 420 SCFH (11,9 SCMH)

Air Pressure Requirement: 90 PSI (6,2 bar) (with ½ inch air line)

Swing Channel Design: The PBC 6000 is designed with a front breakaway channel,

which swings outward. This allows quick access into the

machine for safety, to clear bag jams, cleaning and maintenance.

Air Scrubber: Blows debris from the bag top that could otherwise prevent a good seal.

Caster Wheels: Two locking in the back and two standard wheels in the front.

Electrical Requirements: The following electrical information is in

accordance with provision 4.7.1 from NFPA 79 (National Fire

Protection Association) Electrical Standard for Industrial

Machinery, 1997 Edition:

TABLE 1

MODEL VOLTAGE PHASE HERTZ F.L.A. MAX. COMP. LOAD

PBC 6000 230 1 60 22 14

PBC 6000 230 3 60 19 14

PBC 6000 380 3 50 12 8

PBC 6000 460 3 60 10 7

PBC 6000 575 3 60 9 5.5

PERFORMANCE CHARACTERISTICS

System Speed Ranges:

(Range 1): Standard: 30-85 feet per min (9,1 – 25,9 meters per min)

(Range 2): Greater than 85 feet per minute (25,9 meters per minute)

(Range 3): Less than 30 feet per minute (9,1 meters per minute)

NOTE: Speeds above 85 FPM (25,9 MPM) are obtainable upon request, but are

dependent upon bag types; please consult the Fischbein representative to determine

the machine capabilities, given the closing requirements.

Fold Size Maximum: 1 7/8 inches (48mm)

Bag Jam Detector: A proximity switch that shuts the heaters off and swings open the

front channel in the event of a detected bag jam.

Bag Size Range (empty):

Width: Variable

Length: 56 inches (1422mm) maximum

Minimum Free Top: 6 inches (153mm) (standard fold minimum)

Overheat Sensor: Shuts down the heaters if the temperature rises above a set

maximum. Still allows air to flow through the hot air

manifold to cool the heaters and prevent any damage.

FISCHBEIN®Co. MODEL PBC-6000™

OPERATOR’S MANUAL

REV. D 2005-03 9

4.3 ACCESSORIES AND OPTIONS

The PBC 6000 is available by request with some special options:

Larger Folder: Kits are available to convert Left-to-Right and Right-to-Left PBC

machines with 1 ¾” folders to 2 3/8” folders and to convert 2 3/8”

folder to 1 ¾”.

Extended Infeed: An automated 17inch (432mm) infeed is available for specific

applications.

Infeed Options: The PBC is available with an automated infeed or a manual infeed.

The manual infeed is extended and has a bag guide to assist the

operator in properly feeding a bag top into the machine. Some kits are

available to convert between automate and manual infeeds.

Bag Counter: The PBC 6000 is capable of having a digital bag counter mounted on

the face of the electrical control panel.

Coder: An ink coder is available for printing on the front or back side of the

bag.

Air Dryer: For compressed air systems that do not dry their air, an air dryer is

available for the PBC pneumatic system.

Height Extension: The PBC frame is available with an extension for the vertical range of

motion. The extension adds about 12 inches (304,8mm) to the height

range of the machine.

Motorized Height

Adjustment: The standard PBC 6000 comes with a manual system to raise and

lower the machine. A motorized system is available, with a control

switch on the front control panel. The system also has electrical limit

switches to prevent the machine from going too far on the ACME

screws within the frame.

Left to Right: The standard PBC 6000 transports and seals bags through its system in

a right to left direction. The machine can be ordered to seal the bags in

a left to right orientation.

Reverse Fold: The standard PBC 6000 folds the bag top towards the front of the

machine. It can be ordered to seal the bag by folding the top towards

the rear of the machine. This option is also available in the left to right

oriented machines.

NEMA 4: The PBC 6000 is available in a NEMA 4 configuration.

Bearings Kit: Optional drive shaft upgrade bearing kit (#17896). Includes heavy

duty flange bearings and drive shafts.

FISCHBEIN®Co. MODEL PBC-6000™

OPERATOR’S MANUAL

REV. D 2005-03

10

5 INSTALLATION

5.1 RECOMMENDED WORK AREA LAYOUT

5.2 SITE AND SYSTEM PREPARATION

ELECTRICAL POWER HOOKUP

The system is wired at the factory for the voltage specified when ordered. Customers are required

to supply incoming electrical connections. SO 12/4 (12 AWG/4 wire) (4 mm2) is recommended.

CAUTION: Be sure machine is connected to building electrical ground. Follow National

Electrical Code (NEC) and all local electrical codes during installation. Note: Electrical

schematics for each unit’s particular voltage option are shipped inside the electrical connection

box on the back of the unit. For load specifications refer to TABLE 1 on page 8.

PNEUMATICS HOOKUP

Connect the air source with a female quick release air coupling (Foster Series 3, #3003 or

equivalent) to the safety shut-off valve, located on the pneumatic control panel (Illustration 6,

page 14). Air hose connections must have a minimum 1/2 in. (13 mm) ID. The PBC 6000

requires compressed, clean, dry, non-lubricated air. The supply must be capable of sustaining 90

PSI (6,2 bar) of pressure and a volume flow rate of at least 400 SCFH (11,3 SCMH).

Illustration 5.1

(

To

p

View

)

FISCHBEIN®Co. MODEL PBC-6000™

OPERATOR’S MANUAL

REV. D 2005-03 11

Illustration 5.2 (Pneumatics Diagram and Schematic)

5.3 UNPACKING PROCEDURE

Every Fischbein system is packaged to protect the unit during normal shipping, storage and

handling. Before the unit is unpacked, inspect the box and skid for any signs of shipping damage.

If possible, record any suspected shipping damage with a digital or Polaroid®camera. Report

anything missing or any damages in writing to the shipper and your Fischbein representative.

CAUTION:

A packaged, palletized PBC 6000 system with all options weighs

approximately 820 lbs. or 373kg and is dimensionally (74”x 56”x

71”) (1880mm x 1422mm x 1803mm) in size.

1. Cut the two plastic straps and remove the lid. At least 7 feet (2,13 m) overhead clearance

will be needed to remove the box itself.

2. Using a pry bar and claw hammer, pry out the nails that fasten the box to the pallet. With the

aid of a forklift, carefully lift the box up and off the PBC system.

Polaroid is the registered trademark of the Polaroid Corporation 1995-2002

FISCHBEIN®Co. MODEL PBC-6000™

OPERATOR’S MANUAL

REV. D 2005-03

12

3. Any system that is exported will have a ferrous shroud film or bag covering the unit inside

the box. Simply cut this away and remove. Also, a yellow Zerust®vapor capsule (approx.

2.25” x 1.5” x 1.0”) or (57mm x 38mm x 25,4mm) will be attached to a hidden surface of the

frame at its approximate center or a sample of moisture-absorbing powder will be placed in

the bottom of the ferrous film. Find and remove this before continuing to unpack and install

the system.

4. Remove the lag bolts securing the frame to the crate’s pallet. Locate the box of casters in the

crate and prepare to mount them on the machine.

5. Use 1000 lb-rated hoist straps and loop them around the overarms of the machine’s frame.

(Illustration 5.3) Make sure they are do not pinch and wires or pneumatic hoses. Loop the

straps securely over the forks of a forklift or an overhead hoist.

6. Use the forklift from the front or back of the machine to raise the machine above the pallet,

just enough to slide the pallet from under the machine. (Illustration 5.3) Each side of the

machine must be monitored as the machine is slowly lifted. Monitors must allow the

machine to gently tilt forward, but prevent the machine from swinging.

7. Remove the pallet, mount the casters (locking casters in the rear) and lower the machine to

the floor.

8. Roll the machine to the desired work area. Be sure to provide the needed space around the

system as shown in Illustration 5.1.

9. Lock the rear caster wheels once the machine is in place.

10. The swing channel is held in the down position by a holding pin, installed for shipment only.

Remove the pin. The machine should never be operated with the pin installed!

(Illustration 6.1)

NOTE:

The front swing channel will rotate open once the pin is

removed.

Once the machine is completely unpacked, inspect it for physical damage or missing components.

Report anything missing or any damages in writing to the shipper and your Fischbein representative.

Zerust is the registered trademark of Northern Technologies International Corporation

Illustration 5.3

FISCHBEIN®Co. MODEL PBC-6000™

OPERATOR’S MANUAL

REV. D 2005-03 13

6 ON LINE PREPARATION

6.1 SAFETY GUIDELINES

Operators of the PBC 6000 system must be fully trained on the performance, operation,

adjustments and safety standards of this machine before attempting to operate it. Long hair must

be pulled back and tied to avoid getting caught in any moving parts of the system. Operators of this

machine must wear eye and foot protection at all times and gloves when working around the hot or

sharp machine surfaces. Operators must always wear proper eye protection when operating this

machine and not wear loose clothing or jewelry.

The surrounding area around the machine must be kept clear of objects and potential hazards so the

operator can have quick easy access to any part of the PBC. The PBC 6000 must never be

operated without all of its components. The covers, guides, guards and shrouds must be installed

on the machine when being operated. Only use the PBC 6000 for its intended use.

The PBC 6000 is equipped with a three position Motor Enabled Switch, located on the side of the

electrical enclosure. (Illustration 8.5, page 28) The “AUTO” position is used during normal

operation of the machine. The drive motor will only activate when the swing channel begins to

close. The “STOP” and “RUN” positions are provided only for technicians, to perform

maintenance on the machine. The “STOP”

position disables the drive motor, but will still

allow the pneumatic controls to work. The “RUN”

position is used to enable the drive motor only

when the machine is powered. This mode does

permit the drive motor to rotate, when the swing

channel is open.

6.2 ELECTRICAL SYSTEM

The system is wired at the factory for the voltage

specified when ordered. Customers are required to

supply incoming electrical connections. SO 12/4

(12 AWG/4 wire) (4 mm2) is recommended.

CAUTION: Be sure machine is connected

to building electrical ground.Follow

National Electrical Code (NEC) and all local

electrical codes during installation. Note: Electrical

schematics for each unit’s particular voltage option

are shipped inside the electrical connection box on

the back of the unit. For load specifications refer to

TABLE 1 on page 8.

While performing maintenance to the machine,

always turn “OFF” and lock out the electrical

supply. (Illustration 6.1) Operate the PBC 6000

with the designed electrical needs. The electrical system of the machine should never be altered.

Illustration 6.1

FISCHBEIN®Co. MODEL PBC-6000™

OPERATOR’S MANUAL

REV. D 2005-03

14

6.3 PNEUMATIC SYSTEM

Connect the air source with a female quick release air coupling (Foster Series 3, #3003 or

equivalent) to the safety shut-off valve located on the pneumatic control panel (Illustration 6.2).

Air hose connections must have a minimum 1/2 in. (13 mm) ID. The PBC 6000 requires

compressed, clean, non-lubricated air. The supply must be capable of sustaining 90 PSI (6,2 bar)

of pressure and a volume flow rate of at least 400 SCFH (11,3 SCMH).

The pneumatics control panel is

equipped with a safety control valve.

While performing maintenance on the

PBC 6000, the pneumatic supply must

be turned “OFF” and locked out.

(Illustration 6.2) When shutting down

the machine, always be sure that the

heaters have COMPLETELY cooled

before turning off the pneumatic

supply. Not allowing the heaters to cool

will damage the heater cartridges and

the pneumatic tubing. The machine

usually takes approximately 10-20

minutes to cool down enough to turn off

the air supply under normal conditions.

6.4 LEVELING AND CENTERING

The quality of the bag seal depends on a number of factors. The most basic of these factors is

whether the bag is being fed into the machine correctly. When first preparing the machine for

operation, it must be properly placed vertically and horizontally in relation to the conveyor system.

LEVELING

To maintain an even fold on the bag top, the sealing operation of the PBC must run parallel to the

conveyor. To check this, measure the distance between the bottom of the carry through belts and

the surface of the conveyor belts. This distance should be the same at both the input and output

ends of the PBC. (Illustration 6.3) If there is a significant difference, the bag seal will be uneven

from leading to trailing edge of the bag. Make the necessary adjustments to achieve a parallel and

straight seal line.

Illustration 6.2

FISCHBEIN®Co. MODEL PBC-6000™

OPERATOR’S MANUAL

REV. D 2005-03 15

CENTERING

There are two conditions to satisfy the centering required for a good seal. Where the two carry

through belts come together to grasp the bag top, must be centered above the middle of the

conveyor (i.e. the centerline of travel for the bags’ path). (Illustration 6.4) If a bag enters the

system too far towards the back or front of the machine, the bag may not enter the system straight

(affecting the seal quality) or the bag may be tilted too far and tip over. If the bags are being fed

into the system manually, the operators should be careful to center the bags between the carry

through belts. For automated systems, the PBC 6000 can easily be moved after unlocking the two

rear casters.

The second condition involves centering the bag top vertically

with the carry through belts. The height adjustment on the

PBC 6000 is used to bring the machine’s creaser wheel (the

device used to create the crease-line for the fold) to the correct

elevation with the entering bags. To determine the correct

height, allow a filled bag sample to come up to the infeed on

the PBC and then stop the conveyor system. Note the location

of the glue line on the bag top. The bottom edge of the glue

line should be just above the creaser wheel. It can be a little

higher, but the crimp must be made below the bottom of the

glue edge. (Illustration 6.5)

For the manual infeed, once the creaser wheel has been

adjusted to the correct height, the bag top guide can be

adjusted (vertically) to match the height of the bag top.

(Illustration 6.6) The guide is provided to help operators feed

the bag into the machine at the correct height. Illustration 6.4

Illustration 6.3

FISCHBEIN®Co. MODEL PBC-6000™

OPERATOR’S MANUAL

REV. D 2005-03

16

Free top is the term used to describe the distance between the

top edge of the unfolded bag and the top surface of the product

in the bag. (Illustration 6.5) For best results, the PBC 6000

requires a free top of 6 inches (153 mm) for standard size folds

and greater than 6 inches for wider folds. Using a shorter free

top may cause the bag to bulge and be torn by the shrouds.

6.5 SPEED CHECKS AND SYNCHRONIZATION

Synchronizing the PBC 6000 involves adjusting external and internal rates to provide a good

strong seal. The external synchronization is between the machine and the conveyor system. The

carry through belts of the PBC provide the machine speed for folding and sealing the bag top.

Illustration 6.6

Illustration 6.7

Illustration 6.5

FISCHBEIN®Co. MODEL PBC-6000™

OPERATOR’S MANUAL

REV. D 2005-03 17

These belts must be set to run at the same linear rate as the conveyor system. If the timing between

the two systems does not match, the bag will be tilted forward or backward and will not completely

seal the bag. Use a hand-held tachometer set for measuring feet per minute or meters per minute

and check the linear speeds of the two systems. The PBC 6000 can easily be adjusted by turning

the “Speed” dial on the electrical control panel. (Illustration 6.7) Always remember to adjust the

speed of the PBC, when the line speed changes.

The internal synchronizing of the PBC is between the rear (fixed channel) and front (swing

channel) belts. The drive system within the two channels is synchronized by two large spur gears,

beneath the drive gear motor. (Illustration 6.8) A pulley drives the carry through belts at the end

of the drive shafts on the underside of the machine. If the belts are loose, they may slip while

passing over the drive

pulleys and skew the bag

top as a result. Make sure

the belts are tight before

operating or synchronizing

the machine. To tighten the

carry through belts, refer to

Section 8.5.1, page 28.

Although the compression

belts must also be

synchronized, it is not

likely that they will be

different since they are

toothed timing belts, turned

by timing sprockets.

However, if they become

loose, refer to Section

8.5.2, page 30, to adjust

and tighten them.

6.6 FOLDER

Check the folder assembly to ensure that it is not loose and remove any glue build up on the edges.

The bag must be able to flow through the folder without catching on edges or glue remnants. If the

bag thickness is being changed, run test bags through the machine first to ensure that the folder is

set properly to make a complete, even seal. The folder should not have to be adjusted for most

common bag types and thicknesses. If minor adjustments are required, refer to Section 8.7, page

49.

6.7 COMPRESSION BELTS AND ROLLERS

Check the compression belts for gouges and glue buildup. Carefully remove the glue with a dull

edged tool. The belt should be tight on the rollers and wheels. Where the two compression belts

come together, they should just be touching. If they are coming together with too much or too

little force, the seal on the bag could be wrinkled or not completely sealed. To adjust the

compression section of the machine, refer to Sections 8.5.2 - 8.5.4, pages 30-39.

Illustration 6.8

FISCHBEIN®Co. MODEL PBC-6000™

OPERATOR’S MANUAL

REV. D 2005-03

18

6.8 SETTING THE TEMPERATURE

The temperature of the heaters is controlled and regulated by the temperature controller located on

the control panel. (Illustration 6.9) The temperature should be set based on the following criteria:

1. Type of adhesive used on the bag. (i.e. glue melting point)

2. Speed of the conveyor system.

3. Room temperature.

4. Ambient bag temperature.

5. Relative humidity of the bag material.

Since the bag and glue take time to heat up, the faster the system is required to seal bags, the

higher the temperature setting must be. Keep in mind that every time the conveyor and machine

speed is changed the temperature should be changed. Leaving the temperature set higher than

needed for a new setting, my cause the bag or glue to char. THIS IS A FIRE HAZARD AND

MUST ALWAYS BE AVOIDED!

6.8.1 DETERMINING THE CORRECT TEMPERATURE

The PBC 6000 is designed to accommodate a variety of heat-activated glues. Each type of bag

could require a different temperature setting for a variety of production line speeds. Check with the

bag supplier, to determine the temperature needed to melt the glue. Due to the rate at which the

bags pass through the system and the thermal properties of the bag, the temperature will have to be

set higher than the glue’s melting point. For safety, always start at a lower temperature

and slowly increase the setting as needed. For many common bag types and a line running

at 40 –45 FPM (12,2 –13,7 MPM), the temperature can be set at 450oF (232oC).

The room temperature and humidity can affect the seal quality. It is important to always keep in mind

all conditions while operating the PBC 6000. The temperature of the bag material when it passes into

the machine will also determine the setting for the temperature. It is best to allow the bags to reach

room temperature before filling and sealing them. Always allow the machine to heat up completely

before adjusting the temperature. (Approximately: 20-30 minutes)

The temperature should be adjusted accordingly while the machine is being operated. Take time

during the operation of the machine to inspect the seal quality and then adjust the temperature as

needed. Keep a record of the ambient room temperature, bag type and the production line speed in

order to reduce the set up time for determining the temperature settings, when changes occur.

Illustration 6.9

FISCHBEIN®Co. MODEL PBC-6000™

OPERATOR’S MANUAL

REV. D 2005-03 19

After reaching the desired temperature setting, test a couple of bags and inspect them. The glue

must be making a strong bond to the bag. You can test this by gently pulling open the bag, after it

has cooled. If the glue is bonding correctly, fibers of bag material will be sticking in the entire

adhesive area. If the bag opens easily and you can tell that parts of the glue are not bonding to the

bag, the temperature setting will likely have to be increased, if the compression rollers are set

correctly. Be sure to only increase the temperature in small increments of 10 – 20 degrees at a

time, until the desired bond is achieved. After changing the temperature, allow the machine time

to fully adjust.

If the setting is too high, parts of the glue may be charred or burnt. If the glue appears to have

darkened, then the glue has begun to char. When the temperature is set too high, the glue may

begin to drip off the bag and land on the manifold. Glue build up on the manifold will clog the air

holes. Lower the temperature significantly and begin testing again. Always start at a lower

temperature and slowly increase the setting until the desired bond is achieved.

If the glue does not appear to be making a strong bond with the bag, although the temperature is

high enough to melt the adhesive, and the compression rollers are set correctly, then check the

surface of the bag. If the bag surface is too dusty or has a liquid contamination on it, the glue may

not properly bond with the bag fibers. The PBC is equipped with an air scrubber at the infeed end

of the machine. Make sure it is directed at the seal area and that it is effectively removing the

debris. The airflow can be adjusted through the scrubber by rotating the flow control valve in the

air line to the scrubber. (Illustration 8.3, page 26)

At the factory the machine is set to the specifications defined at the time the order was taken. If

sample bags were sent to Fischbein prior to shipment, the machine will be adjusted to the materials

sent.

6.8.2 USING THE TEMPERATURE CONTROLLER

The temperature controller is very easy to understand and use. The manual that comes with the

controller (located in the electrical enclosure) contains more detailed information and instructions

that are available. This PBC 6000 manual will only cover how to read, change and autotune the

controller.

STARTUP

When the system’s main power is ON, the heater switch turned ON and the green START button is

pushed, the controller’s display will light up. After a few seconds the display will alternate

between displaying the current temperature in the heater manifold and –AL-. The temperature will

begin to increase indicating that the heaters are heating to bring the manifold to the set point. Once

the temperature reaches the set point, the display will stop alternating displays and only show the

current temperature in the manifold.

SET POINT DISPLAY AND CHANGES

To display the set point, push and hold in the “*” button. The display (Illustration 6.10) will

alternate between the set point temperature and the temperature scale (oC for Celsius and oF for

Fahrenheit). To change the set point, push and hold in the “*” button and then press the “▲” or

“▼” keys to increase or decrease the setting. Release the buttons when done. Only make small

FISCHBEIN®Co. MODEL PBC-6000™

OPERATOR’S MANUAL

REV. D 2005-03

20

increment changes to the set point until the desired closure is achieved. Be sure to allow five to ten

minutes for the heaters to reach their optimum level before sealing bags in the PBC 6000.

7.0 OPERATING THE PBC 6000

The PBC 6000 system is designed to fold, heat and then seal the top edge of a PBC bag. The

system forms a crease line and then proceeds to fold the adhesive side of the bag top. When

properly heated the adhesive flap will adhere to the opposite bag surface and seal the bag from

product leaking out through the top of the bag. Following is the precise details on how the PBC

6000 processes a bag to seal it.

7.1 PROCESS DESCRIPTION

Once the system has been properly prepared (Section 6, pages 13), the pneumatic and electrical

systems are turned “ON”. The airflow gage for the manifold should be no less than 400 SCFH

(11,3 SCMH). The heaters are activated and the machine is allowed to warm up for a minimum of

15-20 minutes.

A filled bag travels towards the PBC infeed after it has been prepared by the operator. The

operator reforms the gussets on the bag, “breaks” the bag top and straightens the top of the bag in

preparation for the PBC. (Illustration 7.1) In an automated system the operator does not have to

manually feed the bag top into the PBC infeed. The PBC 6000 firmly grasps the bag top and

transports it through the system. Just as the bag enters between the channels, the air scrubber

blows dust and debris from the seal area to ensure a clean region for the glue to attach to the bag

surface. After entering the machine the bag travels between the creaser wheels, where the bag is

scored below the glue line to form a line for the fold.

Illustration 6.10

Table of contents

Other FISCHBEIN Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Vestil

Vestil BOL Series quick start guide

Ingersoll-Rand

Ingersoll-Rand ARO SHOCK BLOCKER SB10 Series Operator's manual

Minebea Intec

Minebea Intec S-Type Load Cell LC Tigo PR 76 installation manual

Siemens

Siemens 3SU1400-1LL10-.BA1 Original operating instructions

Jorc

Jorc NUFORS-CR Maintenance instructions

CHERNE

CHERNE Test-Ball Safety & instruction manual