FISCHBEIN D Series User manual

Form No.

116-1067

FISCHBEIN

SEWING

HEAD

SERIES

D

PARTS

ILLUSTRATIONS

MAINTENANCE

INSTRUCTIONS

ADJUSTMENTS

Copyright 1961

By

DAVE

FISCHBEIN

COMPANY

2700

30TH

AVENUE

SO.

MINNEAPOLIS.

MINN.

55406,

U.S.A.

U.S.A.

and

Foreign

Pats. Other Pats.

Pending

Printed

in U.S.A.

From the library of: Superior Sewing Machine & Supply LLC

S)ro—

®»—-

?

cn

^

CO

A

If

>

N

IH

From the library of: Superior Sewing Machine & Supply LLC

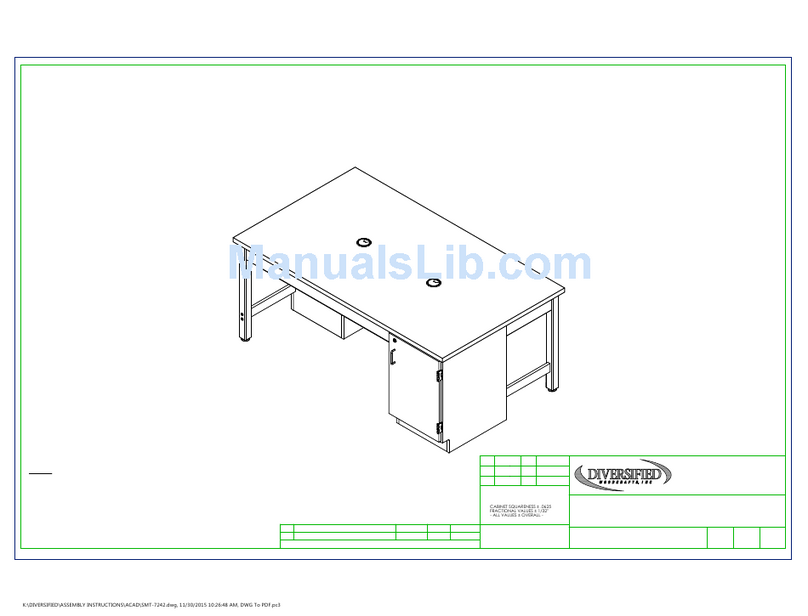

PLATE

B

80

1

74 73 72

71

63 64 65 66

From the library of: Superior Sewing Machine & Supply LLC

MAINTENANCE

Clean and oil machine daily. For best results, use genuine Fischbein Cleaning Solvent and Lubricating

Oil obtainable from the

Dave

Fischbein

Company

or any Authorized Representative.

Wash

out dirt as

follows:

Unthread

needle.

With

machine

running,

dip portion

shown,

Fig.

No.

1, in three or four inches

of solvent for about 10 seconds.

Then

in

addition

to the oil cups

on

the

machine,

oil all shafts, feed

dog carrier mechanism, and cutting knife parts. (Important: Do not use gasoline or similar as a cleaning

solvent.)

If

machine

skips stitches or fails to chain

off,

the cause

could

be any of the

following:

Excessive

wear,

requiring

rebuilding

or servicing;

improper

threading or tension (see special instructions on threading and

tension enclosed with this form); bent or incorrectly installed needle; damaged or misadjusted looper;

incorrect needle bar setting.

To

check these adjustments or replace these parts, carefully

follow

instructions

listed

below:

Do not disturb main bearing, part No. D605, or looper cam, part No. D310. They are timed and

set

at factory.

NEEDLE

INSTALLATION

Insert new needle into needle bar as far as it will go, with the long groove facing exactly outside of

machine.

The long

groove

will

enter into bar.

Lock

needle securelywith

wrench

provided

with

machine.

See Fig. No. 2.

LOOPER

INSTALLATION

Remove

needle,

throat plate,feed

dog,

and presser

foot.

(To

remove

presser

foot,

loosen

the

two

presser

foot

set

screws,

remove

needle

bar

guard,

part

No.

DlOl.

Using

a

screwdriver

as a

lever,

lift

up

the presser bar

clamp,

part

No.

D405,

which

will

allow

the presser foot

sufficient

clearance to

slide

off

the

bottom

of

presser

bar.

DO

NOT

loosen

or altersettingof the

presser

bar

clamp,

part

No.D405.

i

Loosen

looper

set

screw,

No.

SS832316

and

remove

old

looper.

Insert

new

looper,

making

sure that

it is

down

in

the

looper

holder,

part

No.D301-l,as

far as It

will

go.

Securely

tighten

looper

set

screw

against

flat

on

looper

shank.

Install

new

straight

needle.

NOTE;

The

point

of the

looper

must

pass

through

the center of the

needle

scarf

with

about

1/64"

clearance

between

looper

point

and

needle.

See

"A,"

Fig.

No.

3.

(The

scarf is the

hollowed

out

section

just

above

the

eye

of the

needle.

See

Fig.

No.

3.)

Unless

the

looper

holder

and/or

needle

bar

have

moved

or

have

slipped,

the

looper

will

time

up

automatically.

If

necessary,

adjust

clearance

between

looper

point

and

needle

by

loosening

the

looper

holder

clamp

screw

and

sliding

the

looper

holder

in

or

out

on

looper

shaft

as

required.

See next

paragraph

for

needle

bar setting.

LOOPER

TIMING

ADJUSTMENT

This adjustment does not have to be made when replacing the looper. but only after looper shaft, looper

cam, or cam follower has been replaced.

The looper stroke Is correct when there is approximately

1/32"

between looper point and edge of needle

when looper is at maximum back stroke. See "D," Figure No. 4. To adjust, first rotate machine in

sewing

direction

so that

looper

is at

maximum

back stroke

position,

then

loosen

clamp

screw

No.

SC54058in part

No.

D307

and

move

looper as necessary.

NEEDLE

BAR

ADJUSTMENT

Remove

needle

bar

guard,

part

No.

DlOl.

Torn

machine

pulley

in

normal

sewing

direction

until

looper

Is in

approximate

position

shown

in

Fig.

No.

5 as

needle

Is

on the

upstroke.

Slightly

loosen

clamping

screw on

needle

bar

clamp,

part

No.

D502.

Raise

or

lower

needle

bar and/or turn

machine

pulley

to

bring

looper

point

flush

with

or not

more

than 1/64"

back

from

edge of

needle,

see "B,"

Fig.

No.

5,

and

to

align

bottom

edge

of

looper

flush

with

top of

needle

eye,

see "C,"

Fig.

No.

5.

Do

not

change

looper

setting.

Securely

lock

needje

bar

clamp

and

replace

needle

bar

guard.

Recheck

for

proper

needle/looper clearance.

Fig.

No.

3.

STITCH

LENGTH

The length of stitch is

SVz

to the inch, when, at their highest point, the teeth of the feed dog protrude

3/32"

above the throat plate. If the stitches shorten up, check the following:

1. Teeth on feed dog may be worn down. Feed dog must then be replaced.

2. Feed dog

may

have slipped so that the teeth protrude less than 3/32".

Merely

raise the feed dog

by raising the adjusting screws No. HD64038 located on the feed carrier block. Note that there is a

set

of locking screws No. HD64038 on the under side of the feed carrier block.

D

Figure

No. 1

Figure No. 2

Figure

No.

3

Figure

No.

4

Figure

No.

5

From the library of: Superior Sewing Machine & Supply LLC

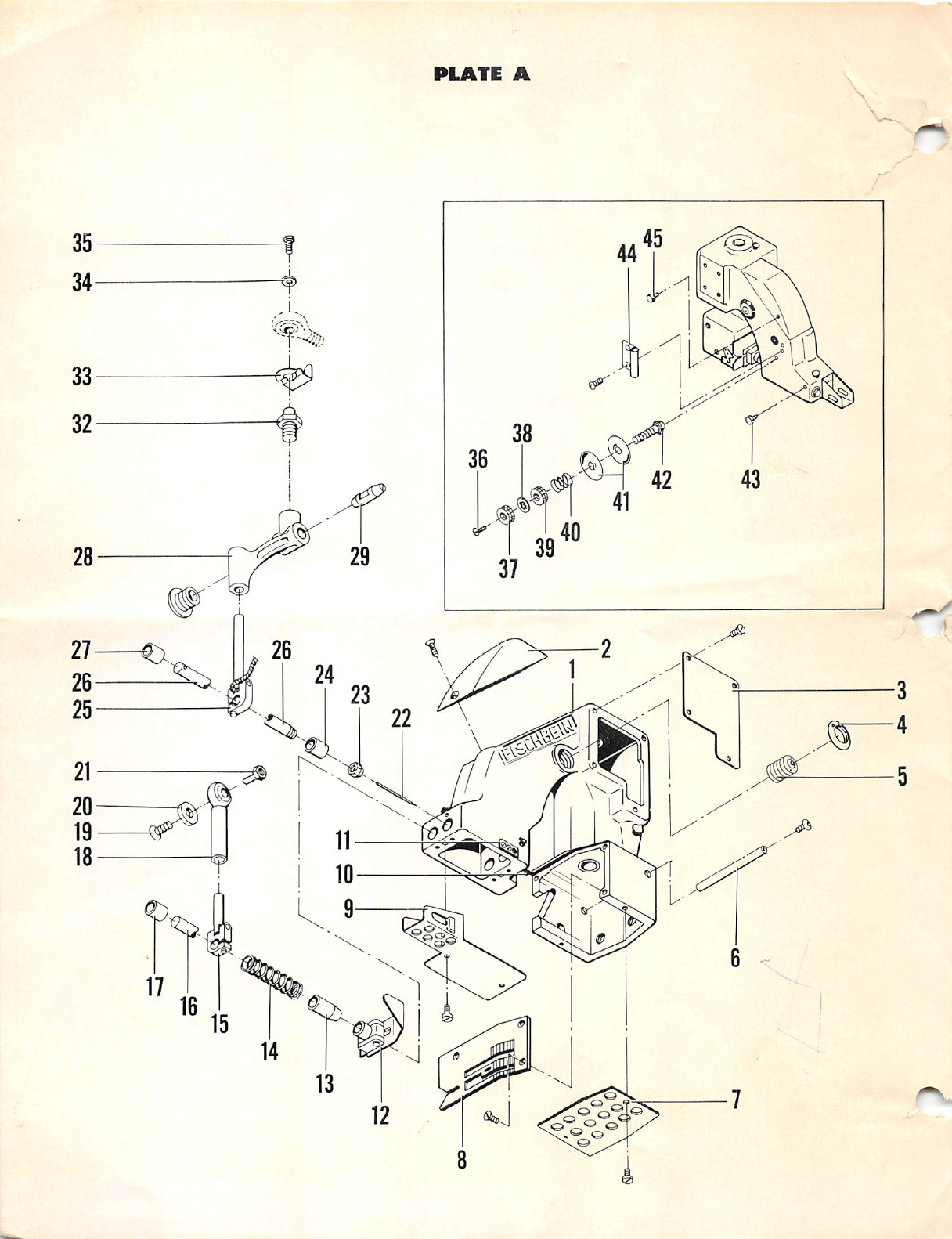

REFERENCE

PLATE

A

ORDER

BY

PART

NUMBER

INDEX NO. PART NO. DESCRIPTION QUANTITY

1DlOO

Housing,

Complete

with

Bushings

1

DHIOO

Housing,

Complete

with

Bushings,

Model

OH

1

DBIOO

Housing,

Complete

with

Bushings,

Model

OB

1

SS832316

Screw, for all Bushings 8

D121 Oiler 5

2

0119

Cover, Top 1

0632516

Screw,Attaching, for 0119 2

3D103

Cover,

Side

Nameplate

1

DB103

Cover,

Side

Nameplate,

for

Model

OB

1

B83214S Screw,Attaching, for 0103 and

DB103

4

4D513

Lock

Ring

2

5D512

Bearing,

Cone 2

6

0214

Stud, Feed

Oog

Carrier Slide 1

SB103214

Screw,

Attaching,

for 0214 2

0102

Cover,

Looper

1

rp

0108

Screw, Attaching, for 0102 1

8

0210

Throat

Plate

1

D210T Throat Plate, Tape

Binding

1

F64038

Screw,

Attaching,

for 0210 and

D210T

9

0101

Guard,

Needle Bar 1

B832316

Screw, Attaching, for 0101

10

0110

Tube,

Thread

Guide,

Front 1

SS54018 Screw, Set, for 0110 1

11

0111

Plate, Thread Guide 1

F348316

Screw, Attaching for 0111

12

0400

Presser Foot, Complete 1

D400T Presser

Foot,

Complete,

Tape

Binding

1

SS832318FP Screw, set, for 0400 and

D400T

0402

Bolt,

Hinging,

for 0400 and

D400T

1

0403

Nut, for 0402 1

13

0413

Bushing, Presser Bar,

Lower

1

14

0414

Spring, Presser Bar 1

15

0405

Clamp,

Presser

Bar,

Complete

1

16 SC54012 Screw,

Clamping,

for 0405 1

0404

Presser

Bar

1

17

0412

Bushing,

Presser

Bar,

Upper

1

18

0407

Lifter

Lever,

Complete

1

19

T83212

Screw,Attaching, for 0407 1

20

0410

Washer, Felt 1

21

0417

Locknut

1

22

05

Needle

1

23

0501

Locknut, Needle 1

24

0504

Bushing, Needle Bar,

Lower

1

25

0502

Clamp,

Needle

Bar,

Complete

1

26 SC54012 Screw,

Clamping,

for 0502 1

0500

Needle

Bar 1

27

0503

Bushing,

Needle

Bar,

Upper

1

28

0505

Lever, Needle Bar 1

SS83238

Screw, for 0505

29

0511

Stud.

Needle

Bar Lever 1

32

0507

Stud, Connecting

Rod

End

1

33

0510

Spring 1

34

0208

Washer, for H103212 1

35

H103212

Bolt,

Retaining, for 0607 1

36

F64038

Screw,

Tension

Nut

Retaining

1

37

0116

Nut,

Tension,

Upper

1

38

0120

Lockwasher

1

39

0117

Nut, Tension, Lower 1

40

0115

Soring,

Tension

1

41

0114

Disc,

Tension

42

0113

Stud, Tension 1

43

0109

Eyelet 1

44

0118

Tube,

Thread

Guide,

Rear 1

B632316 Screw, Attaching, for 0118

45

0109

Eyelet 1

46

0607

Bearing,

Rod

End

1

47"

D608 Locknut, for 0607 1

From the library of: Superior Sewing Machine & Supply LLC

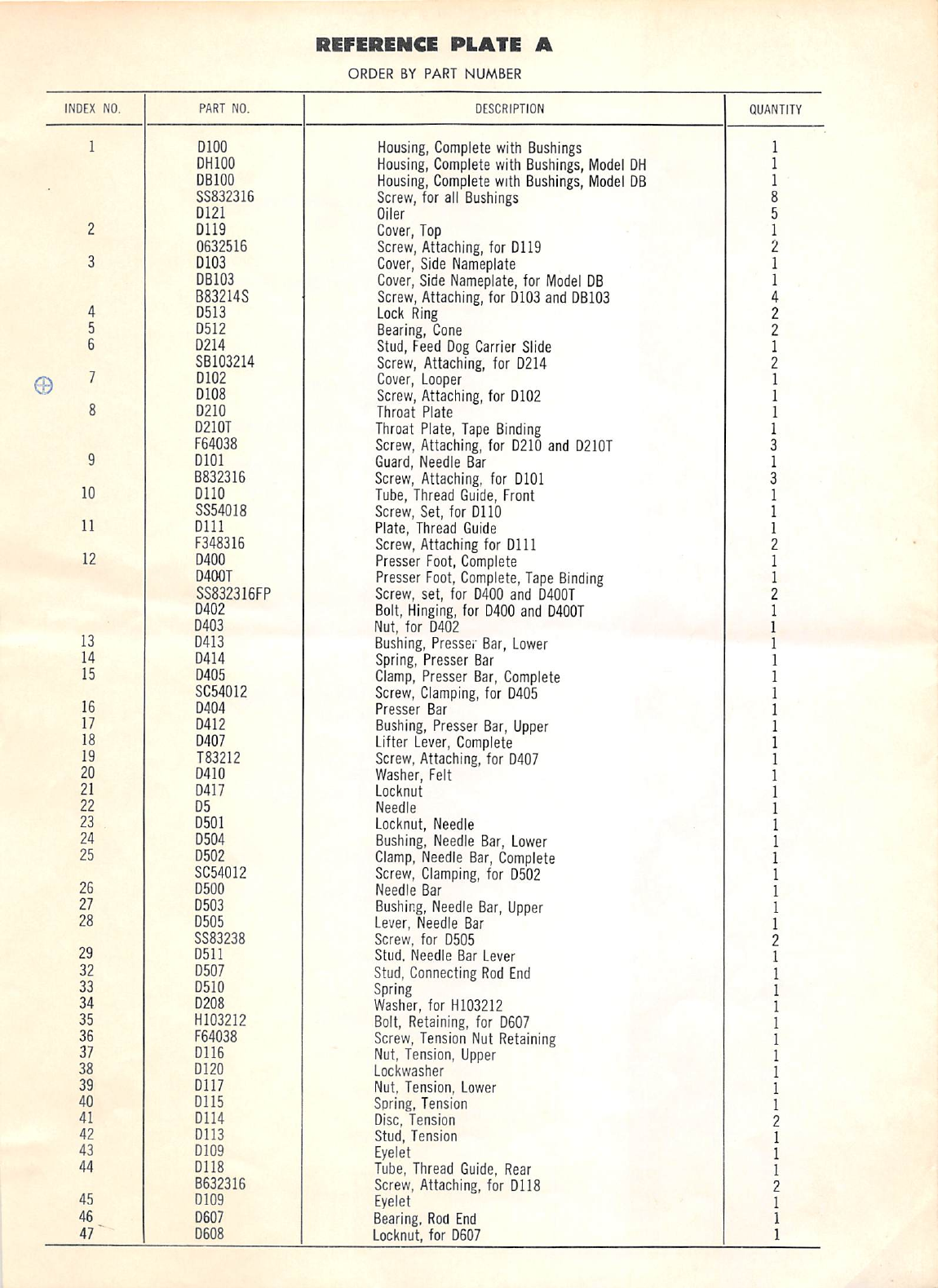

RiFERENCE

PLATE

B

ORDER

BY

PART

NUMBER

INDEX NO. PART NO. DESCRIPTION

QUANTITY

48 D609

Lockwasher

1

49

D603

Collar,

Retaining,

for 0600 1

SC54038

Screw,

Clamping,

for 0603 1

50

D605

Connecting

Rod

and Eccentric,

Complete

1

D6D6 Screw,

Cone

Point,

for 0605 1

SS1032316 Screw, Set, for 0605 1

51 D6D2

Bushing.

Main

Shaft, Front 1

DB602

Bushing,

Main

Shaft, Front,

Model

DB

Only

1

52 D600 Main

Shaft

1

53

0601

Bushing,

Main

Shaft,

Rear

1

DB601

Bushing,

Main

Shaft,

Rear,

Model

DB

Only

1

54 D310

Cam,

Looper,

Complete 1

D311 Screw, Cone Point, for 0310 1

SS103212

Screw, Set, for 0310 1

55

0308

Stud,

Cam

Follower

(order

complete

with

0307)

1

0309

Lockout, for 0308 1

56

0307

Arm,

Cam

Follower

(order

complete

with

0308)

1

SC54058 Screw, for 0307 1

0313

Washer

1

57

0304

Collar,

Looper

Shaft

SC34812

Screw,

Clamping,

for

0304

1

58

0303-1

Shaft,

Looper

1

59 D306

Bushing,

for 0303-1 1

60

0301-1

Holder, Looper 1

SS832316FP

Screw,

Looper

Set 1

SC54038

Screw,

Clamping,

for 0301-1 1

61

0300

Looper

1

62

0200

Feed

Oog

Carrier

Block

and

Slide,

Complete

1

H064038

Screw, Feed

Oog

Adjusting

4

63

H103212

Lock

Bolt

2

0208

Washer, for

H103212

2

64

0205

Slide

Block,

Adjusting 1

65 D206 Stud, Slide

Block

Adjusting Support 2

66

0209

Lockout,

for 0206 2

^.'-67

0203

Feed

Oog

1

68

0204

Screw, Attaching, for 0203 1

69

H1032516

Bolt,

Knife

Bracket 1

0714

Lockwasher,

for

H1032516

1 ©70

0711

Locknut

71

0700

Bracket,

Knife

1

72

0704

Spring,

Knife

Tension

1

73

0707

Shaft

1

74

0708

Bushing, for 0707 1

D708-1

Bushing,

for 0707,

Model

OB

Only

1

75

0702

Knife,

Moving

1

F348316

Screw, Attaching, for 0702

76

0703

Knife,

Stationary 1

F348316

Screw,

Attaching, for 0703

77

0715

Washer

1

78

SC54038

Screw, for 0709, Upper 1

79

0709

Bearing,

Double

Rod

End

1

80

0710

Bolt, for 0709,

Lower

1

81

0712

Extension,

Knife

Bracket Support 1

82

H832516

Bolt,

Attaching,

for

D712

1

0716

Lockwasher, for

H832516

1

From the library of: Superior Sewing Machine & Supply LLC

FISCHBEIN

PORTABLE

BAO

CLOSER-MODEL

D

HANDLE

AND

ELECTRIC

DRIVE

From the library of: Superior Sewing Machine & Supply LLC

PARTS

LrST

ORDER

BY

PART

NUMBER

INDEX

QUAN

NO.

PART

NO.

DESCRIPTION

TITY

1

D105-1

GUARD, BELT 1

D105-12

GUARD, BELT -

12

VOLT MODEL ONLY 1

R83258

SCREW,

ATTACHING

- FOR

DIOS

9

2

D909

BELT

1

D909-12

BELT

-

12

VOLT

MODEL

ONLY

1

3

D938

COUNTERWEIGHT

1

WS8

WASHER, LOCK 2

S883238

SCREW, SOCKET BUTTON 2

•909

PULLEY,

M9CHINE

1

SS1032516

SCREW, FOR

0909

2

5

•802

COVER,

SWITCH

1

063212

SCREW,

ATTACHING - FOR

0802

2

5

•807

INSULATION

1

D807DC

INSULATION

FOR

D806DC

1

7•

806

SWITCH

1

•806DC

SWITCH

-

DIRECT

CURRENT

ONLY

1

•819

SCREW, SWITCH TERMINAL

GROUND

3

8

•800

HANDLE

-

COMPLETE

WITH

COVER

1

D800DC

HANDLE -

COMPLETE

W/COVER

FOR

USE

W/D806DC

1

SC192039

SCREW,

ATTACHING

- FOR

D800

AND D800DC 2

9

•808

CORD

SET

1

•808-12

CORD

SET

-

12

VOLT

MODEL

ONLY

1

10

•809

CLAMP

FOR

D808

2

SS832316

SCREW

FOR

D809

1

11

•939

MOTOR

LEAD

- 3

WIRE

SJO

1

12

P3981

GRIP,

CORD 2

13

•815

THREAD

STAND

1

SF105238

SCREW, ATTACHING - FOR

D815

2

Ik

•805

WING

NUT

1

15

•809

BOLT,

THREAD

CLAMPING 1

16

•950

MOTOR -

115

VOLT

1

•951

MOTOR -

230

VOLT

1

•952

MOTOR

-

12

VOLT

DC 1

SF103238

SCREW, ATTACHING - FOR ALL

MOTORS

9

17

•902

PULLEY,

MOTOR 1

•902-12

PULLEY,

MOTOR -

12

VOLT MODEL ONLY 1

SS832316

SCREW - FOR

D902

2

SS836316

SCREW

- FOR

D902-12

2

•907-12

SPACER

-

FOR

12

VOLT

MODEL

ONLY

9

SF1G3258

SCREW, FOR

0907-12

9

ORDER

BY

PART

NUMBER

INDEX

QUAN-

NO.

PART

NO.

DESCRIPTION

TITY

18

•906

HINGED,

MOTOR MOUNT 1

•908

SCREW, SEMS LOCKING - FOR

D906

2

SF10323

8SCREW, ATTACHING FOR

0906

9

19

•927

PLATE, BALL BEARING CCLOSED) 1

•918

SCREW, BALL BEARING PLATE ATTACHING 9

20

•953

WASHER,

FELT RETAINING (CLOSED END) 1

21

•959

WASHER, SPACING AS REQ'D

22

•955

BALL

BEARING

2

•956

BALL

BEARING

-

FOR

12

VOLT

MODEL

ONLY

2

23

919-1

PLUG,

INSPECTION

HOLE 1

29

•917

SCREW, BRUSH - HOLDER CAP 2

25

•929-1

BRUSH

-

HOLDER

2

•929-12-1

BRUSH

-

HOLDER

-

FOR

12

VOLT

MODEL

ONLY

2

•930

SCREW, BRUSH - HOLDER SET 2

26

•957

END

BELL,

BRUSH END 1

•958

END BELL, BRUSH END - FOR 12 VOLT

MODEL

ONLY

1

•919

SCREW, ATTACHING - END BELL 9

27

•916

SPRING,

BRUSH 2

28

•915

BRUSH

2

•915-12

BRUSH

WITH

SPRING

-

FOR

12

VOLT

MODEL

ONLY

2

29

•959

9R.^'ATURE, COMPLETE -

115

VOLT 1

•960

ARMATURE, COMPLETE -

230

VOLT 1

•961

ARMATURE, COMPLETE - 12 VOLT 1

30

•925

RING

AND

FIELD

ASSEMBLY

COMPLETE

-

115

VOLT

1

•926

RING

AND

FIELD

ASSEMBLY

COMPLETE

-

230

VOLT

1

•925-12

RING

AND

FIELD

ASSEMBLY

COMPLETE

-

12

VOLT

1

31

D922

FIELD

-

115

VOLT

2

0923

FIELD

-

230

VOLT

2

D922-12

FIELD

-

12

VOLT

2

32

D962

WASHER,

BALL BEARING SPRING I

33

D963

END

BELL,

SHAFT

END 1

D919

SCREW, ATTACHING - END BELL 9

39

D969

WASHER,

FELT RETAINUJG (OPEN END) 1

35

•965

WASHER,

FELT

1

36

•966

•'LATE,

BALL

BEARING

(OPEN) 1

•918

SCREW, ATTACHING - FOR

D966

9

MOTOR

INSTRUCTIONS

This

motor

is intermittent

duty,

which

means that it

should

not run for

long

periods

of time

continuously.

It is

made

for start and stop operations

only,

such as required

by bag closing.

Brushes

should

be Inspected at

regular

intervals so that wear can be detected, and replaced before they are about

Vb"

in length.

To

remove

brushes, take out twoscrews

from

each side of

motor;

when

replacing brush, be sure It is replaced at the same

axial

position

as

removed.

If it Isn't, excessive sparking and loss of

power

will

result.

New

brushes are furnished with machine and can be purchased from us at any time.

No

motor

will

operate

properly

unless

the

bearings

are

kept

well

lubricated.

Ball

bearings

are

packed

with

grease

sufficient

for

a

period

of

from

one

to

two

years,

depend

ing

on

the

service

given

the

motor

and

temperature

of

the

room

in

which

It

operates.

To

refill,

remove

the

end

caos

covering

the

bearings

and

clean

out

the

old

grease

before

putting

in

the

new.

If

the

ball

bearings

are

removed

for

washing

in

gasoline,

the

built-in

grease

seal

should

be

facing

toward

the

motor

interior

when

replaced.

Use

only

well

known

make

of

SODIUM

BASE

BALL

BEARING

GREASE.

DAVE

FISCHBEIN

CO.. 2700 30th Ave. So., Minneapolis, Minnesota 55406,

U.S.A.

FORM

NO.

120-277

PRINTED

IN U.S.A.

From the library of: Superior Sewing Machine & Supply LLC