星火全自动缝纫控制系统使用说明书

Operation Instruction for Xing Huo Automatic Sewing Control System

4.13 Insert Functional Code............................................................................................................. 36

4.14 Save File................................................................................................................................... 37

Chapter V Modify File.................................................................................................. 39

5.1 Main Interface of Modify File................................................................................................... 39

5.2 Add Needle Point....................................................................................................................... 41

5.3 Delete Needle Point....................................................................................................................42

5.4 Forward and Backward Reinforcing..........................................................................................43

5.5 Closed Reinforcing.....................................................................................................................44

5.6 Delete Multi-Needle...................................................................................................................45

5.7 Append Needle Point..................................................................................................................47

5.7.1 Append Single Needle........................................................................................................ 47

5.7.2 Append Multi-Needle......................................................................................................... 48

5.8 Modify Functional Code............................................................................................................ 49

5.9 Modify Needle Position............................................................................................................. 50

5.9.1 Modify Current Point Needle Position...............................................................................51

5.9.2 Modify All Needle Positions after Current Point...............................................................52

5.10 Section Offset........................................................................................................................... 52

5.11 Section Speed Modification..................................................................................................... 54

5.12 Overall Offset........................................................................................................................... 55

5.13 Secondary Origin Modification............................................................................................... 56

5.14 Section Modification................................................................................................................57

Chapter VI User Settings.............................................................................................. 59

6.1 User Settings Interface............................................................................................................... 59

6.2 User Settings Parameters Introduction.......................................................................................61

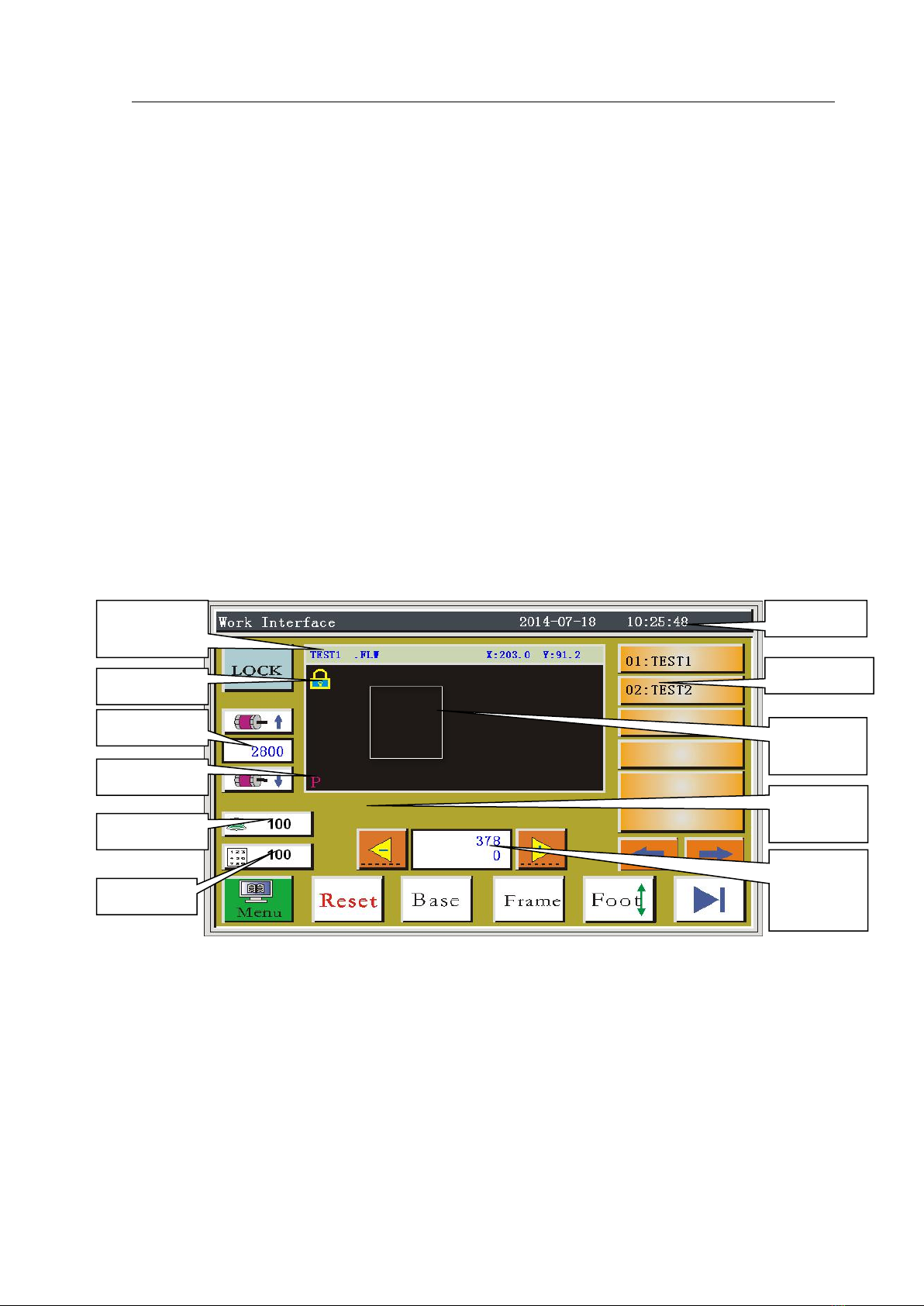

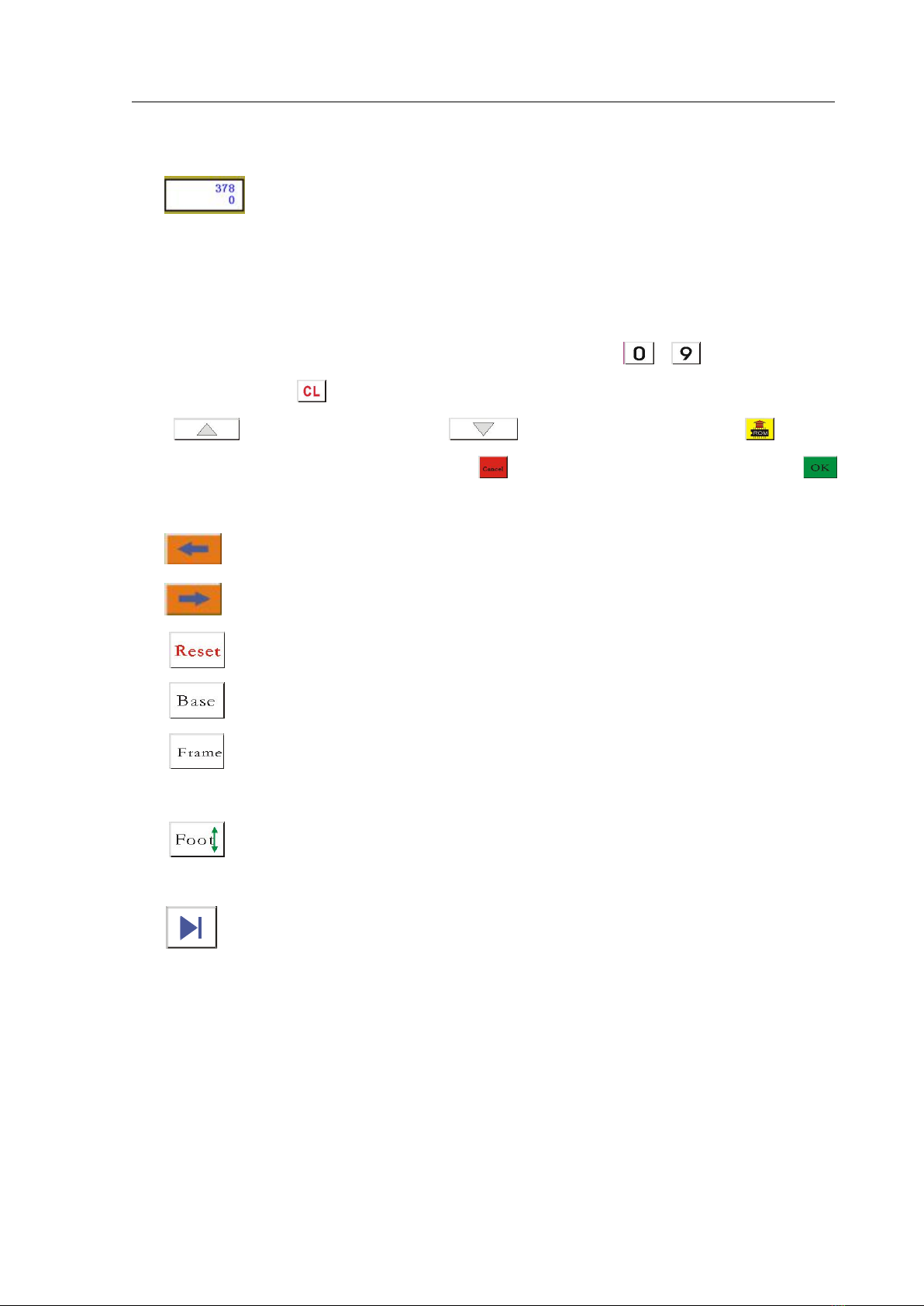

Chapter VII Auxiliary Operation................................................................................ 66

7.1 Auxiliary Operation Interface.................................................................................................... 66

7.2 Combine File.............................................................................................................................. 67

7.3 Export Parameters...................................................................................................................... 68

7.4 Output Detection........................................................................................................................ 68

7.5 Input Detection...........................................................................................................................69

7.6 Lock Machine Settings...............................................................................................................70

7.7 Date Settings...............................................................................................................................71

7.8 Version Information....................................................................................................................71

7.9 System Update............................................................................................................................71

Chapter VIII Ex-Factory Parameters......................................................................... 73

Appendix I: Description and Solution of Information Tips...................................... 75

Appendix II: Introduction to Quick Start...................................................................78