Contents

1 General Information.......................................................................................................................1

1.1 Supporting Model ...............................................................................................................1

1.2 Method for Input.................................................................................................................1

1.3 Method for Display.............................................................................................................1

1.4 Layout of Panel...................................................................................................................1

1.5 Standardization....................................................................................................................1

1.6 Method for Operation..........................................................................................................1

2 Operational Instruction ..................................................................................................................2

2.1 Name & Description of Buttons on Control Panel..............................................................2

2.2 Basic Operation...................................................................................................................3

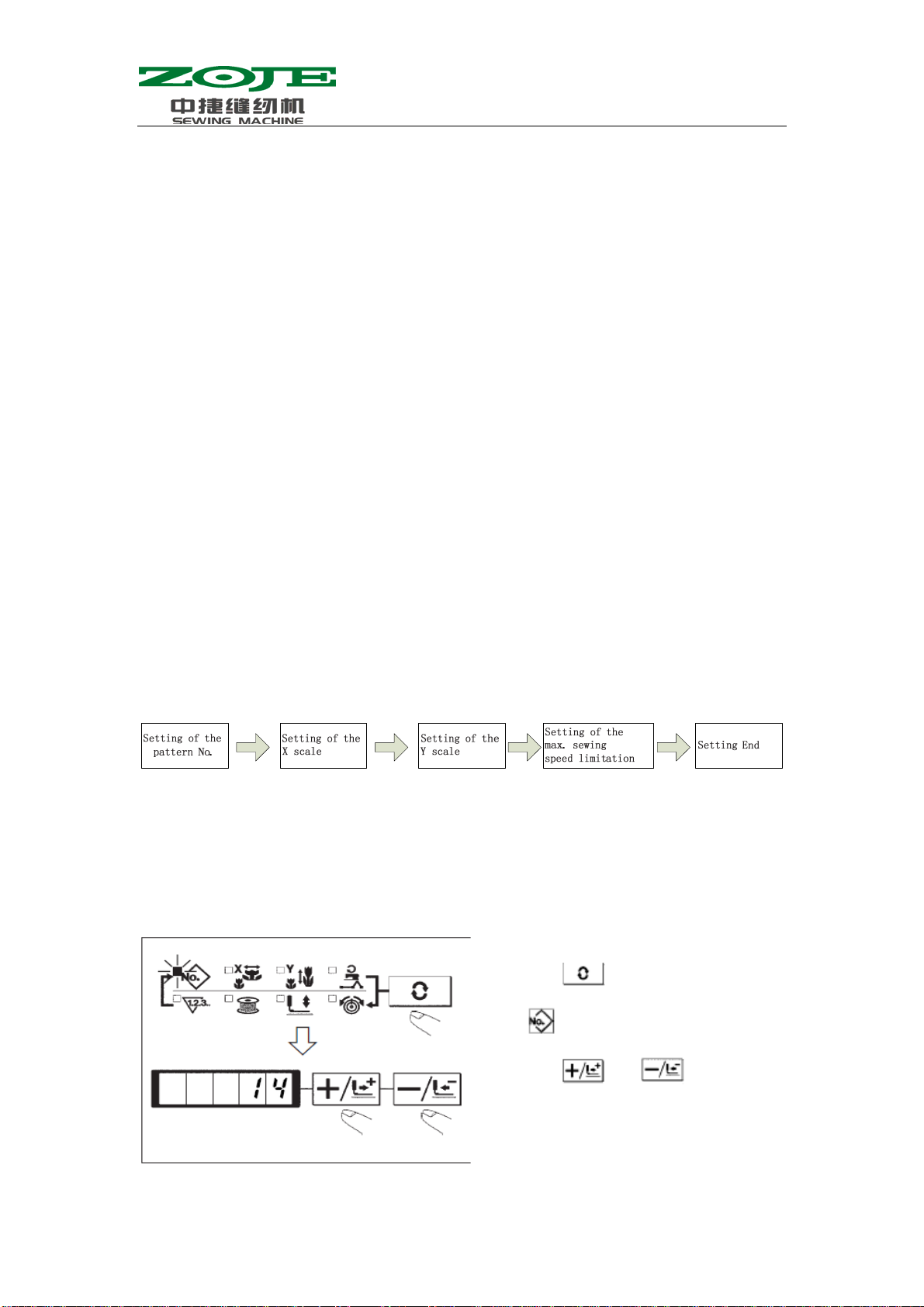

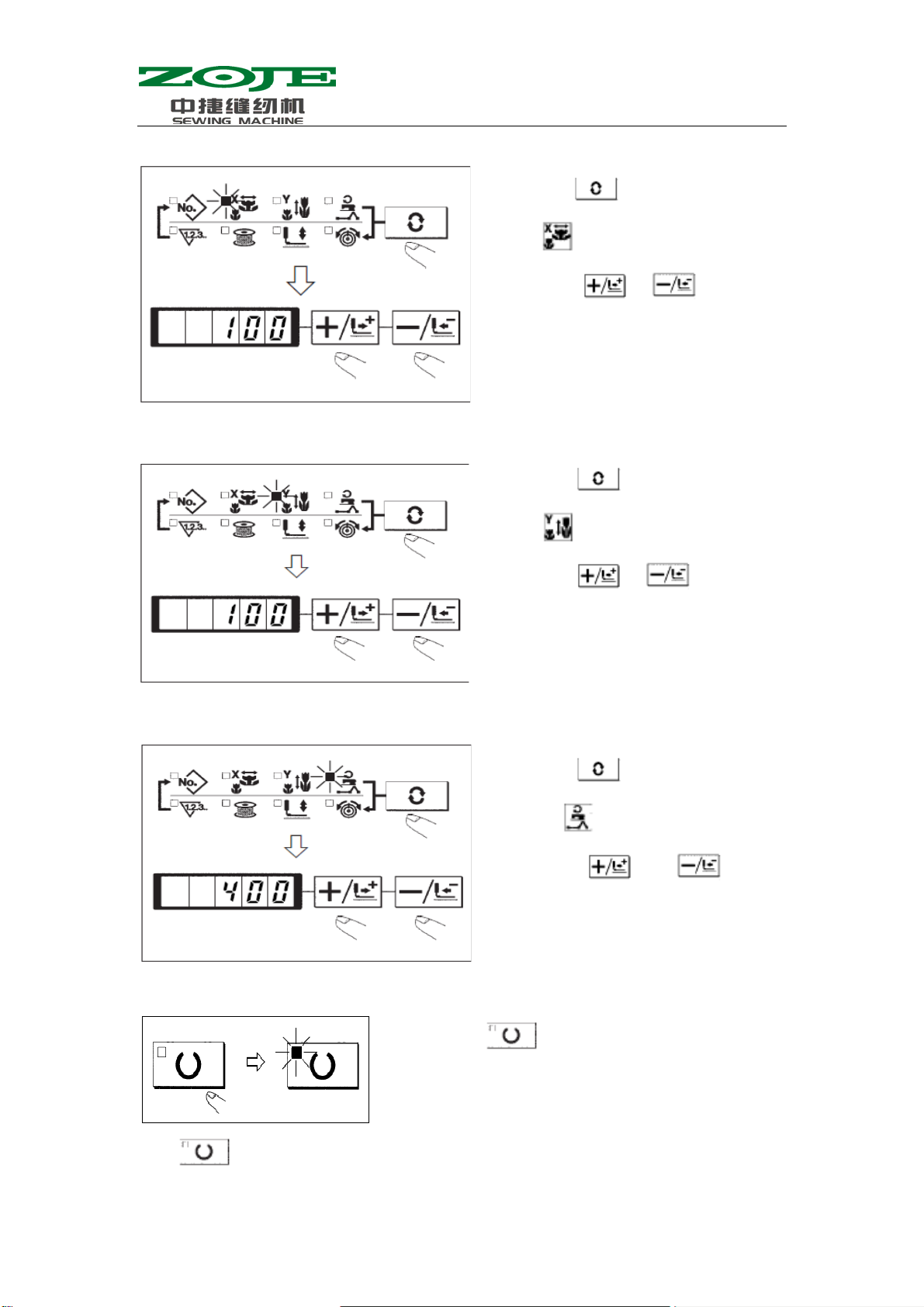

2.2.1 Settings of Item Data...............................................................................................3

2.2.2 Confirmation of Pattern Shape................................................................................5

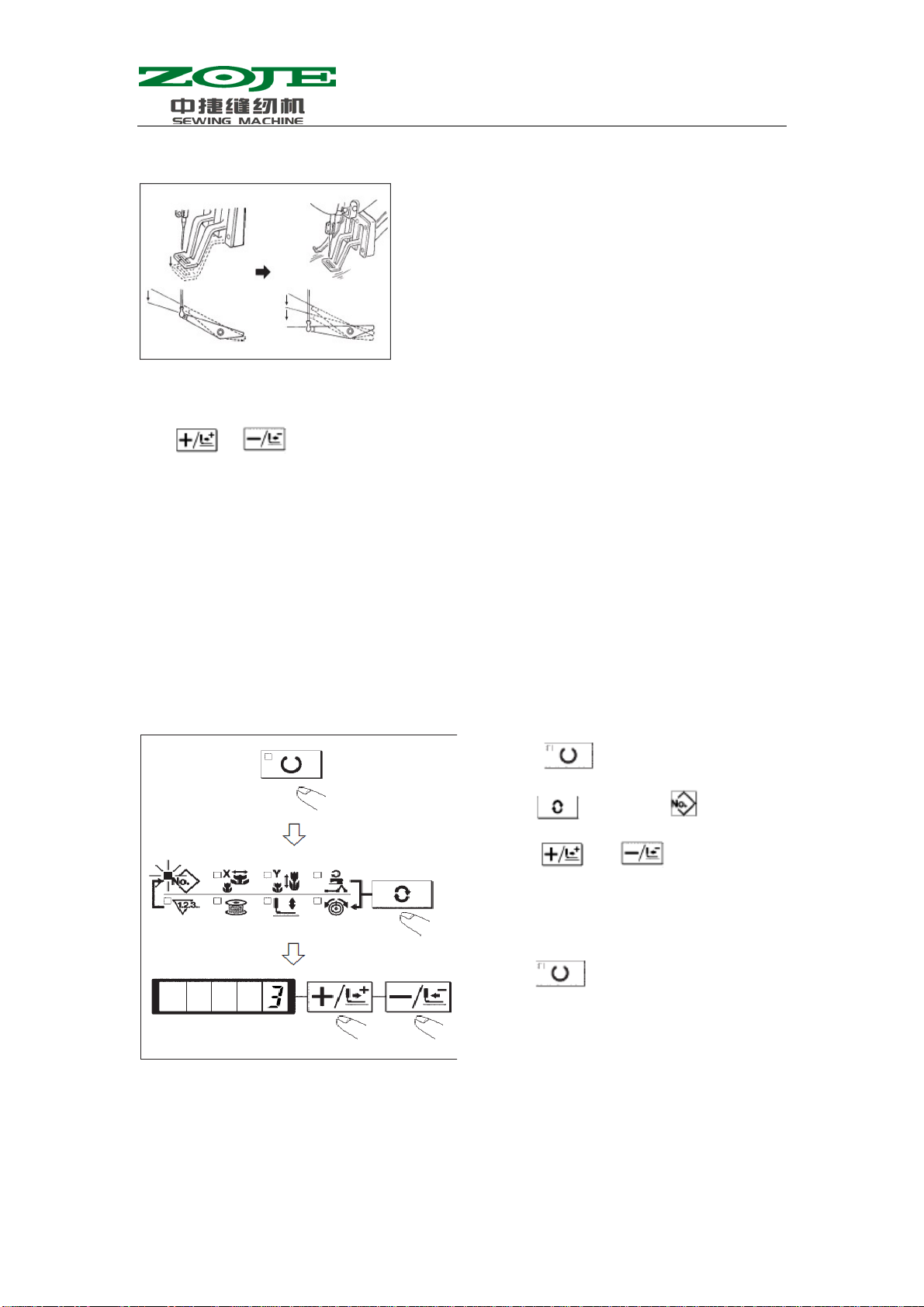

2.2.3 Sewing.....................................................................................................................6

2.2.4 Change to Other Patterns ........................................................................................6

2.2.5 Winding...................................................................................................................7

2.2.6 Independent Thread-trimming Device....................................................................7

2.2.7 Thread-catching Device ..........................................................................................7

2.2.8 Bottom Thread Counter...........................................................................................9

2.2.9 Pause.......................................................................................................................9

2.3 Set P Pattern & C Pattern..................................................................................................10

2.3.1 Use Pattern Key()for Sewing.............................10

2.3.2 Sewing with Combination Functions....................................................................12

2.4 Debugging Mode...............................................................................................................14

2.4.1 CP-1(Input Signal Test)...................................................................................17

2.4.2 CP-2(Check X/Y Motor/Origin Sensor)..........................................................18

2.4.4 CP-4(Test Main Motor Speed).........................................................................20

2.4.6 CP-6(Test Presser Origin Sensor)....................................................................24

2.4.7 CP-7(Test Thread-catching Motor/ Origin Sensor)..........................................24

2.5 Parameter Setting..............................................................................................................26

2.5.1 Specific Operations on Setting Parameters...........................................................26

2.5.2 Example for Setting Parameters............................................................................26

2.5.3 Table for Parameter Setting...................................................................................30

3 Setting of Service Parameter........................................................................................................33

3.1 Activation & Modification of Service Parameter..............................................................33

3.2 Table of Service Parameters..............................................................................................33

3.3 Recovery to Default Setting..............................................................................................35

3.3 List of Standard Figure......................................................................................................37

4 Function of Button Sewing..........................................................................................................41

4.1 Settings..............................................................................................................................41

4.2 List of Standard Pattern in Sewing Button........................................................................42

5 Appendix......................................................................................................................................44