– 2 –

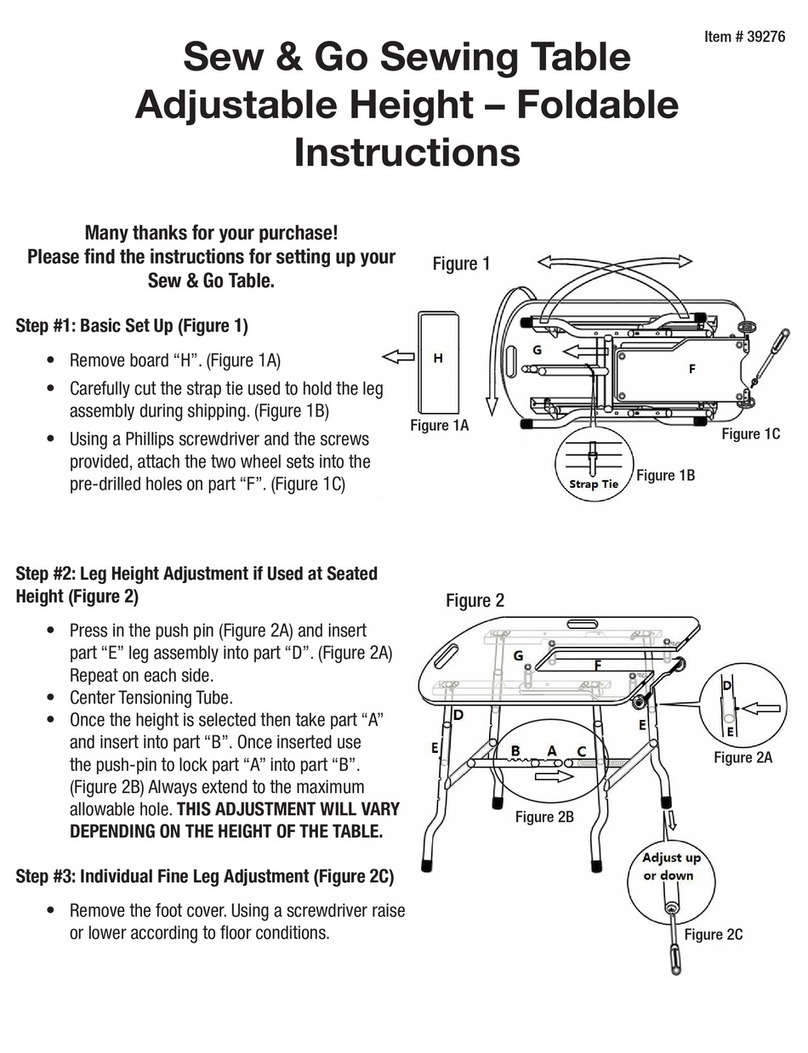

#. INSTALLING IP-200 ON TABLE/STAN AND CONTROL BOX

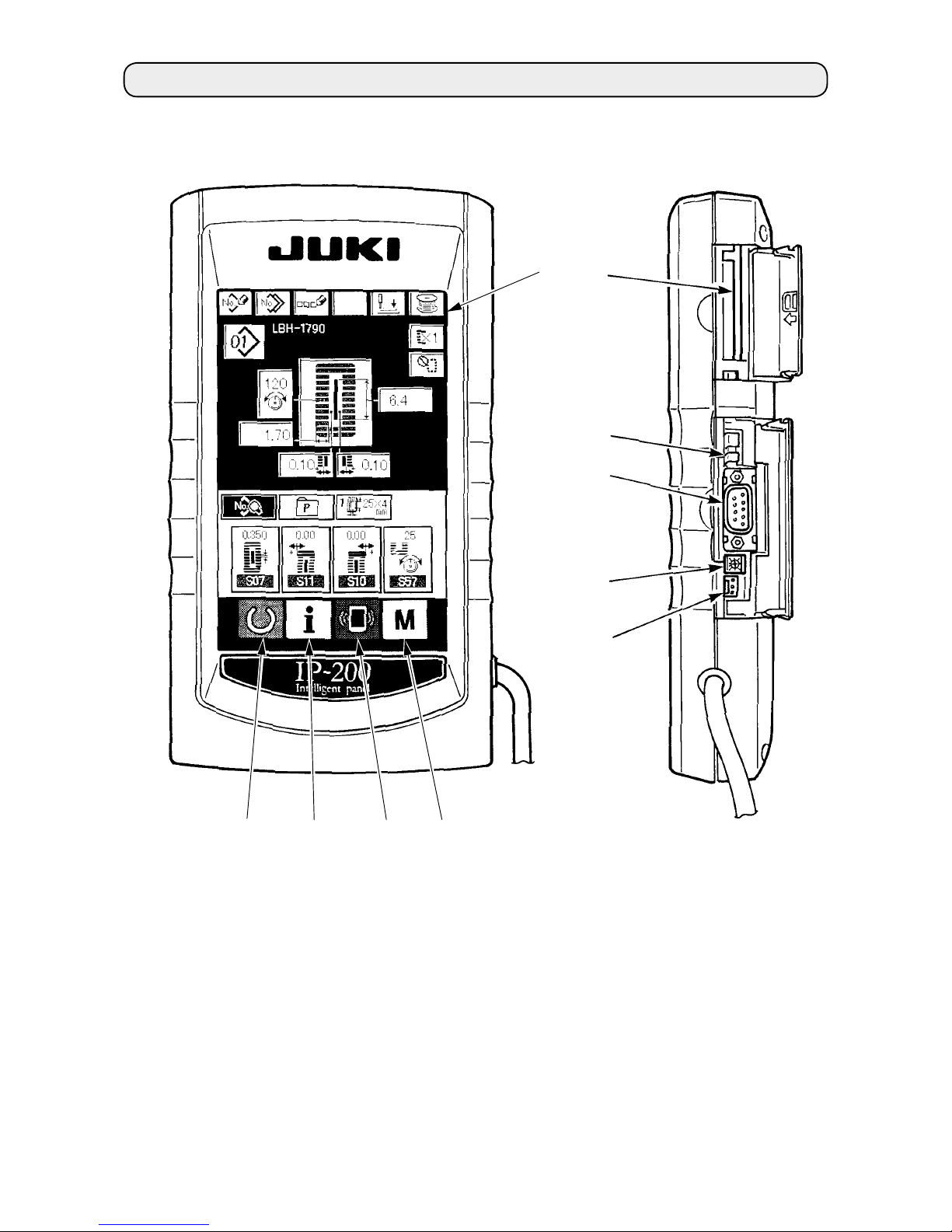

1. Installing procedure of the operation panel and the installing base

1) When installing the installing base, install it on the

table with the screws supplied as accessories.

At this time, consider the position of the hole for

wiring opened in the table to install the base.

In case of the table without the hole for wiring,

install the base at the position where there is no

trouble when the machine head is tilted or sewing

is performed.

2) Operation panel can be fixed to the installing

base since the magnet on the rear of the

operation panel adheres to the installing base.

Besides, operation panel can be installed on the

metal part such as the side of the control box to

which the magnet adheres.

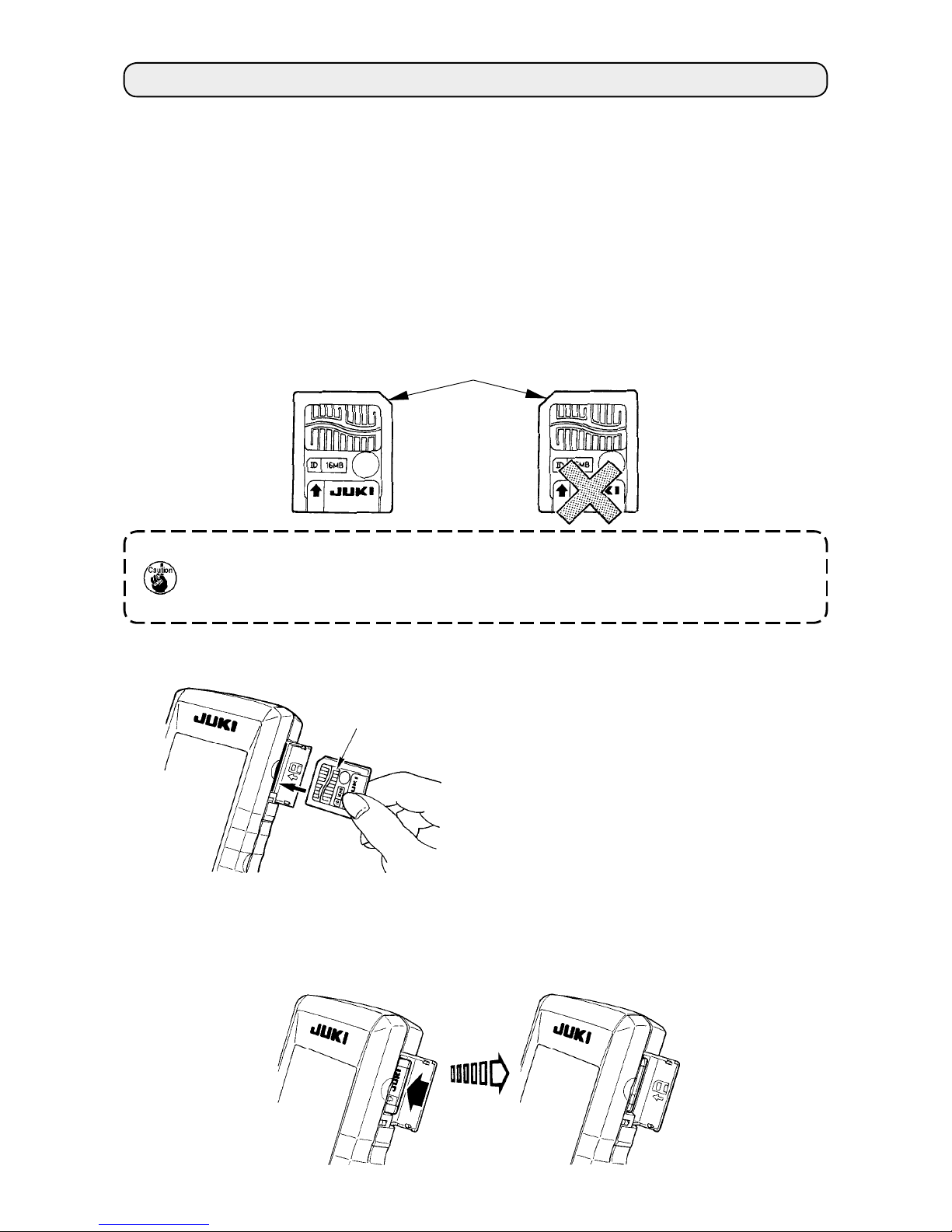

Do not put the articles which have little

resistance against the magnet near the

operation panel.

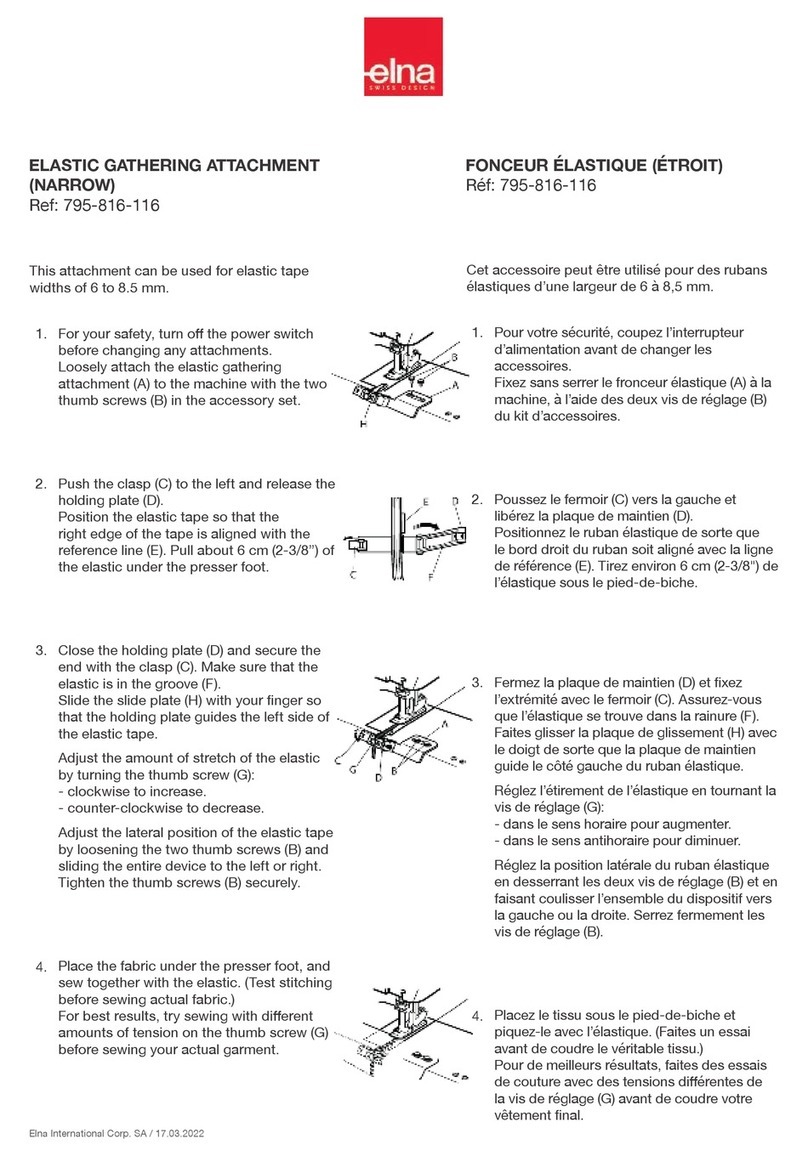

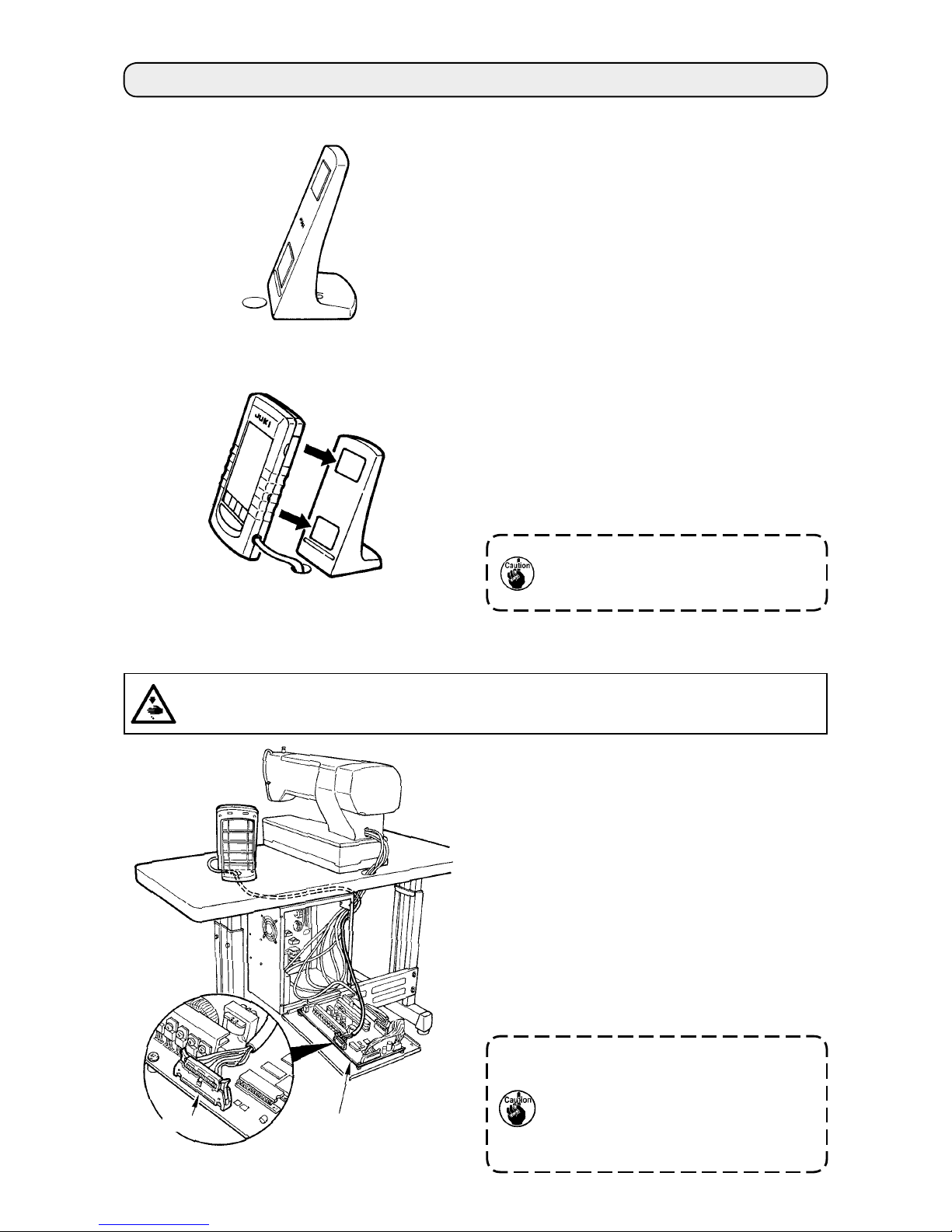

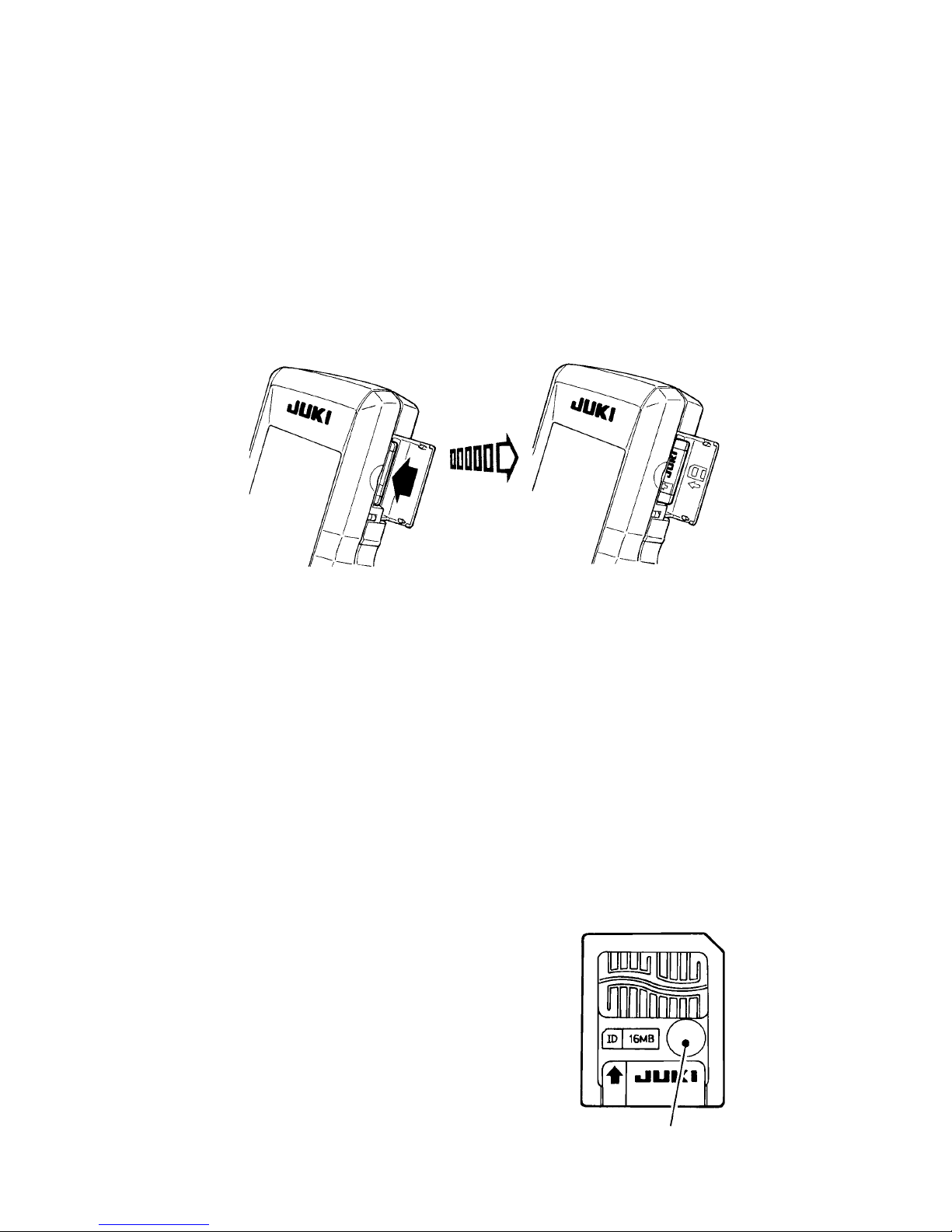

2. Connecting the cord and turning ON the power

1) Pass the cord of the operation panel through the

hole for wiring in the table and connect it with the

control box under the table. For the table without

the hole for wiring, wire the cord at the position

where there is no trouble when the machine head

is tilted or sewing is performed, and connect it

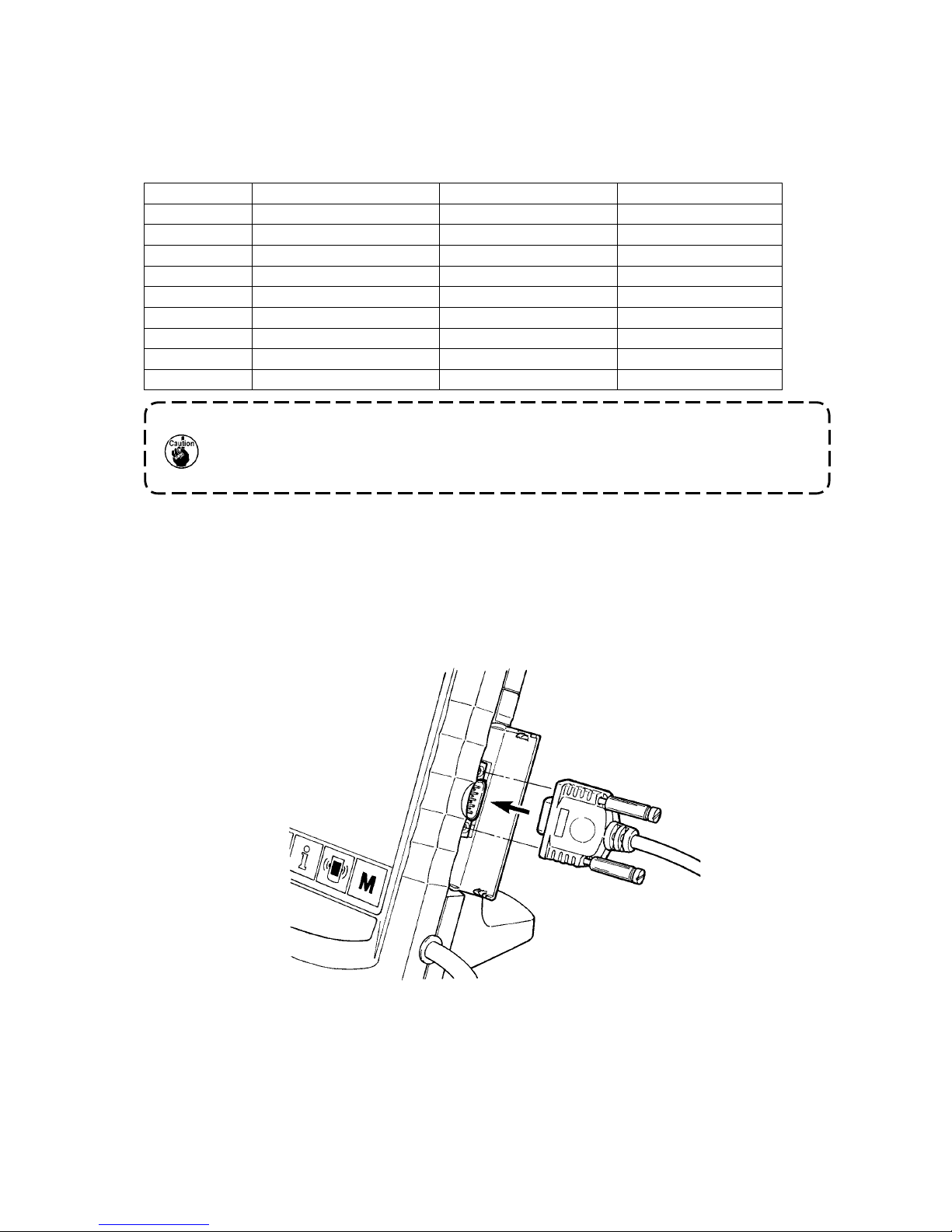

with the control box. For the connection of the

connector, connect it to CN34 of MAIN circuit

board in the control box or built in the machine

head. For the details, refer to the Instruction

Manual for the sewing machine main unit.

When the work above has been completed, turn

ON the power.

When connecting the cord, make

sure that the power of the main unit is

turned OFF. When connecting the cord

in the state that the power is turned

ON, trouble or breakage of the circuit

will be caused.

MAIN circuit board

CN34

WARNING :

Turn OFF the power before starting the connecting work so as to prevent accidents caused by abrupt

start of the sewing machine.