●Only well-trained people should perform routine daily

maintenance and/or repair the machine and/or device.

●Do not modify the machine and device yourself.

※Consult you local Pegasus' sales office or representative for

modification.

(2)Before operating the device

●Before operating the device, check the machine head, machine

unit and device to make sure they do not have any damage

and/or defects.

Repair or replace any defective parts immediately.

●To prevent accidents, always make sure the safety covers and

safety guards are properly secured.

Never remove the safety covers and safety guards.

(3)Training

●To prevent accidents, operators and service/maintenance

personnel should have proper knowledge and skills for safe

operation.

To ensure so, managers must design and conduct training for

these people.

4.Notes for each procedure

CAUTION

CAUTION

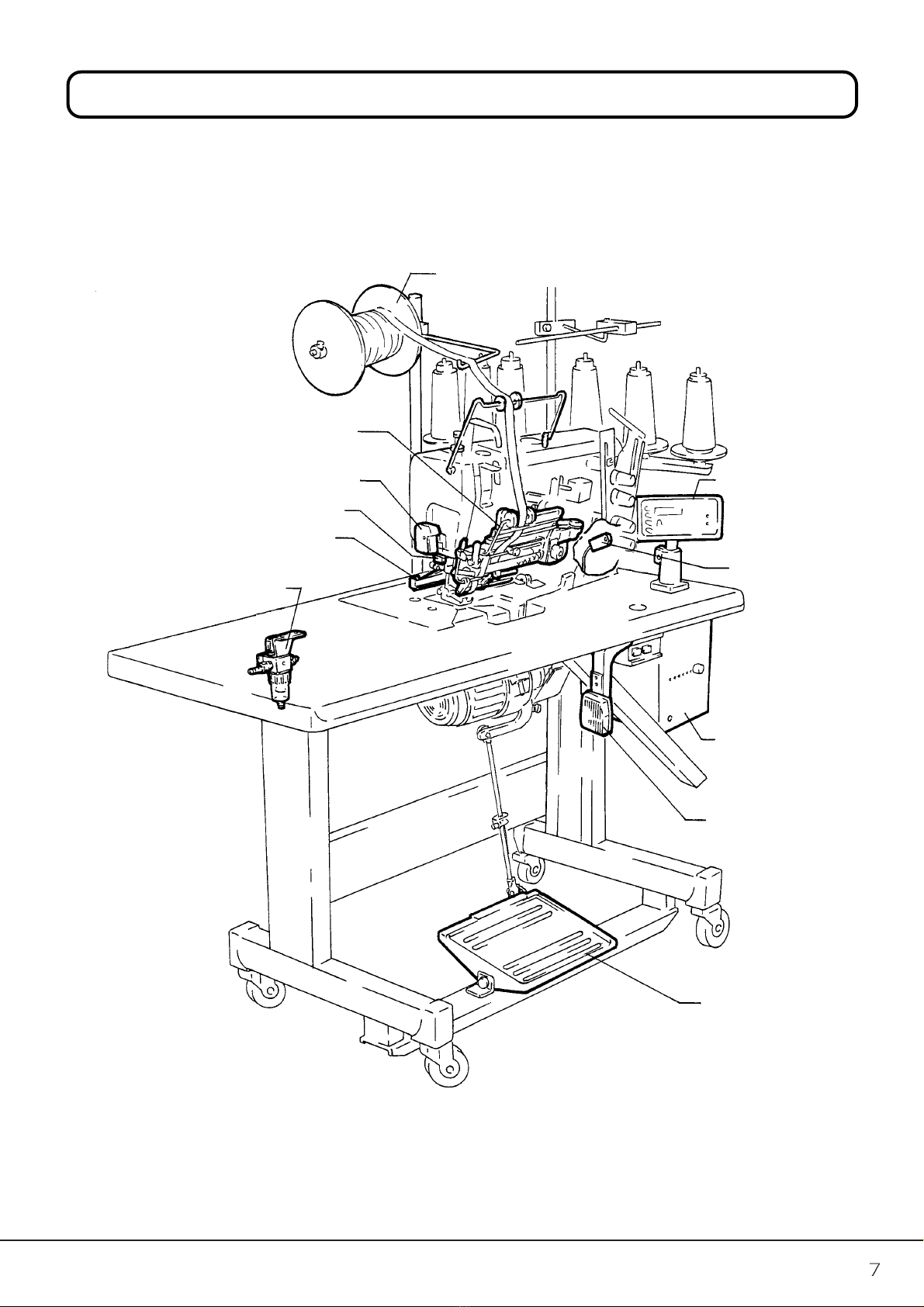

①Unpacking

The machine and device are packed in boxes (and plastic bags) in

the factory before shipment. Unpack the boxes and bags properly

and sequentially by following the instructions shown on them.

②Installation, preparation

CAUTION

CAUTION

Connecting the air lines

1.Always turn off the power first and then connect the air lines to

the joints. Be sure to connect all the air lines before connecting

them to the air source.

2.When connecting the air lines to the joints, be sure to insert the

joints to the proper depth of the air lines and fasten securely.

3.Do not allow excessive force to be exerted on the air lines while

using the device.

4. Do not bend the air lines too much.

5.If necessary, protect the air lines by positioning them safely

and/or using the cover.

6. Do not use staples to secure the air lines. Otherwise it may

cause damage.

W

WARNING

ARNING

Connecting the cords

1. When connecting the power cord, be sure to turn off the

power and disconnect the power plug from the outlet.

2. Check the voltage designation to make sure the power

relay cord matches the local supply voltage. The use of wrong

cord may cause damage to parts and/or fire.

3.Do not allow excessive force to be exerted on the cords while

using the device.

4. Do not bend the cords too much.

5.Confirm that the cord is at least 25mm away from moving part of

the machine and/or the device when you connect the cord.

6.If necessary, protect the cords by positioning them safely and/or

using the cover.

7. Do not use staples to secure the cords. Otherwise it may

cause damage.

Ground

1.Connect each of the ground wires in the sewing machine system

to the ground terminal. Do not connect one devices' ground wire

to another devices'.

2. Connect the ground wires securely to the indicated ground

points on the machine head.

W

WARNING

ARNING

③Before operation

1.Check the cords, connector and air lines to make sure they do

not have any damage, disconnections or tangles and then turn on

the power.

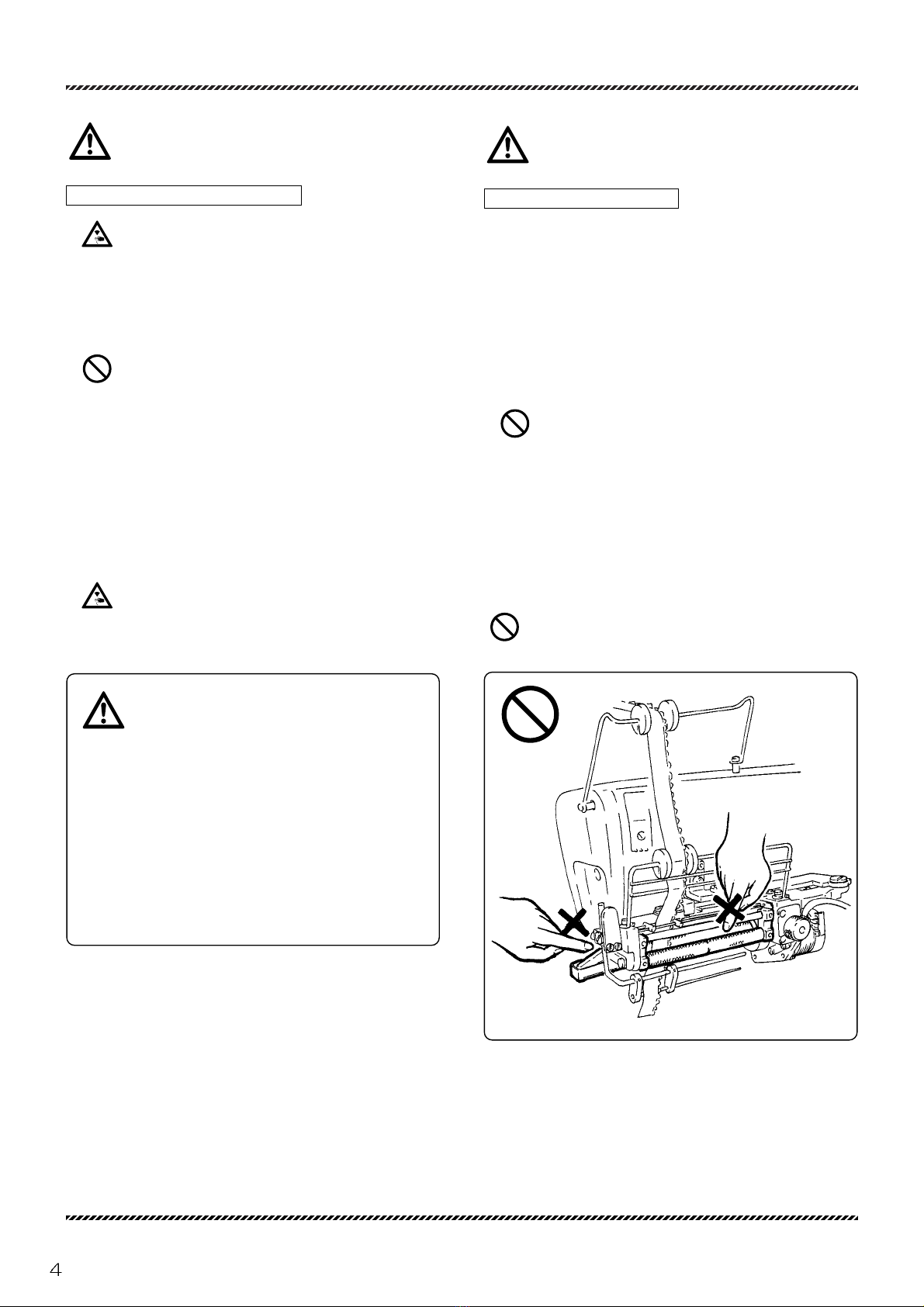

2. Do not bring your hands and/or any part of your body close

to the needle and pulley when turning on the power.

3.Well-trained people who studied this manual and the instruction

manual very carefully should use the machine with the labor

saving device.

4.Study the contents on "2. Indications of dangers, warnings and

cautions" very carefully and then provide users with safety

training as required.