FISCHBEIN 10,300 Technical reference manual

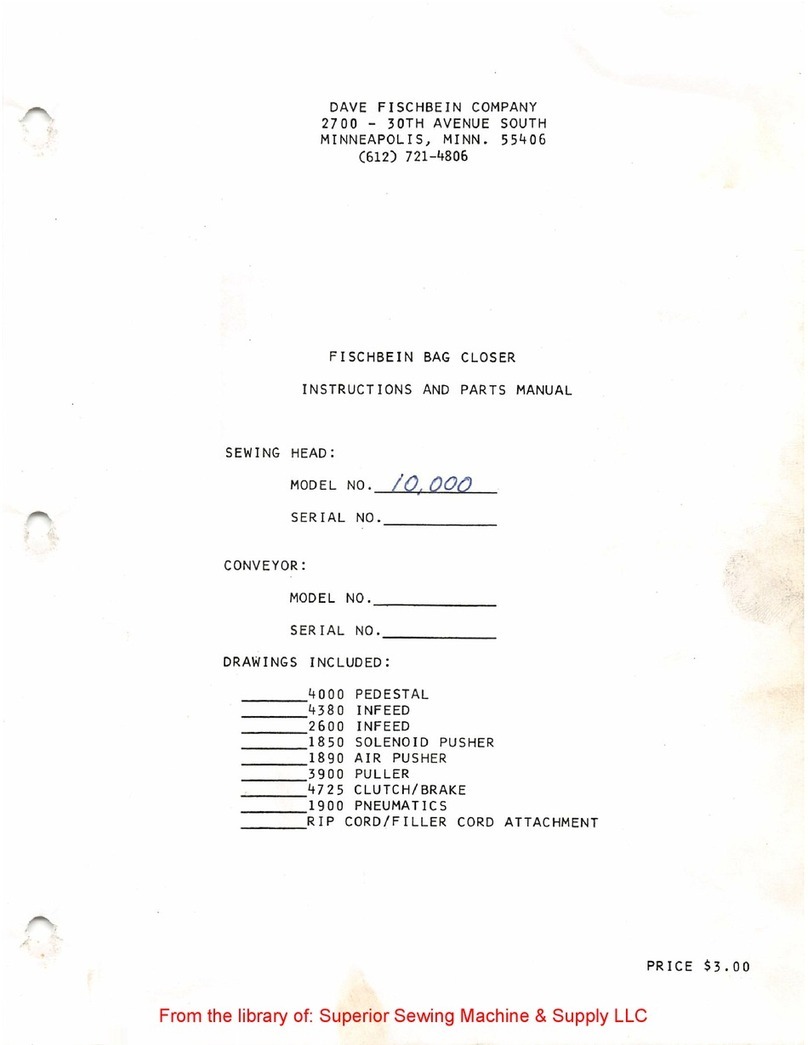

DAVE

FISCHBEIN

COMPANY

2700

-

30TH

AVENUE

SOUTH

MINNEAPOLIS,

MINN.

55406

(612)

721-4806

FISCHBEIN

BAG

CLOSER

INSTRUCTIONS

AND

PARTS

MANUAL

SEWING

HEAD:

model no.

/O.

^OO

%

SERIAL

NO.

K

"j:

CONVEYOR:

MODEL

NO.

SERIAL

NO.

DRAWINGS

INCLUDED:

4000

PEDESTAL

4380

INFEED

_2600

INFEED

.1850

SOLENOID

PUSHER

.1890

AIR

PUSHER

3900

PULLER

.4725

CLUTCH/BRAKE

.1900

PNEUMATICS

RIP

CORD/FILLER

CORD

ATTACHMENT

PRICE

$3.00

From the library of: Superior Sewing Machine & Supply LLC

INSTALLATION

MOTOR

RECOMMENDATIONS

USE

A

1/2

H.P.

1725

R.P.M.

MOTOR.

THE

VARIABLE

PULLEY

ON

THE

SEWING

HEAD

PERMITS

SPEED

ADJUSTMENT.

SEWING

HEAD

PULLEY

MUST

ROTATE

CLOCKWISE.

INITIAL

LUBRICATION

THE

SEWING

HEAD

IS

SHIPPED

FROM

THE

FACTORY

OIL

FILLED.

AT

THE

BEGIN

NING

OF EACH DAY OR

SHIFT,

MAKE

SURE

THE

OIL

LEVEL

WINDOW AT

THE

LOWER

PORTION

OF

THE

SEWING

HEAD

SHOWS

OIL

AT

THE

"OIL

LEVEL"

LINE.

AFTER

ABOUT

30

SECONDS,

THE

OIL

PRESSURE

GAUGE SHOULD READ

IN

THE

NORMAL

3-9

POUND

RANGE.

WHILE

THE MACHINE

IS

RUNNING,

THE

OIL

LEVEL

WINDOW

WILL

SHOW

LITTLE

OR

NO

OIL.

NEVER

RUN

MACHINE

IF

OIL

PRESSURE

GAUGE

IS

IN

THE

RED

WARNING

AREA.

MAINTENANCE

OIL

USE

SPECIAL

LUBRICATION

OIL

FOR

THE

SERIES

10,000

SEWING

HEAD

AVAILABLE

FROM

THE

DAVE

FISCHBEIN

COMPANY

OR

ITS

AUTHORIZED

REPRESENTATIVES.

AS

A

SUBSTITUTE,

ANY

GOOD

GRADE OF SAE

20

MOTOR

OIL

OR

ITS

EQUIVALENT

MAY

BE

USED.

EIGHT

OUNCES OF

OIL

WILL

ADEQUATELY

FILL

THE

MACHINE.

WHEN

ADDING OR CHANGING

OIL,

REMOVE BREATHER PLUG

AND

POUR

OIL

INTO

BREATHER

PLUG

HOLE.

FILL

UNTIL

OIL

REACHES

"OIL

LEVEL"

LINE

ON

THE

OIL

WINDOW.

NEVER

RUN

MACHINE

IF

OIL

PRESSURE

GAUGE

IS

IN

THE

RED

WARNING

AREA.

SEE

DRAWING

1.

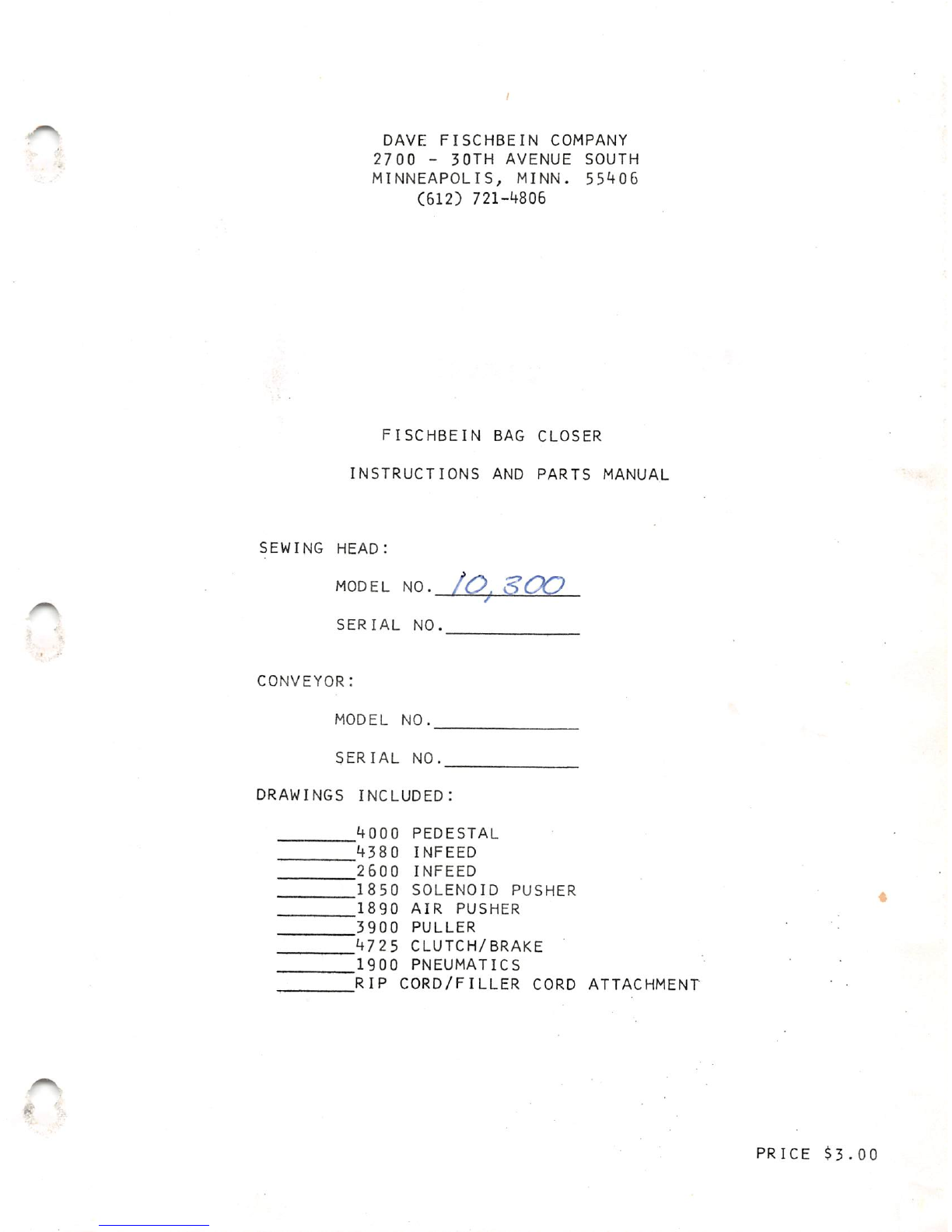

OIL INTAKE TUBE

GIL INTAKE FILTER

MAGNETIC DRAIN PLUG

OIL

LEVEL

WINDOW

DRAWING

1

BAFFLE

BREATHER PLUG

FILTER

OIL PRESSURE GAUGE

SNAP

RING

BREATHER PLUG

PAGE

1

From the library of: Superior Sewing Machine & Supply LLC

TO

DRAIN

OIL,

REMOVE

MAGNETIC

DRAIN

PLUG

AND ALLOW

OIL

TO

DRAIN.

AT

OIL

CHANGE

INTERVALS,

ALSO

CLEAN

OIL

INTAKE

FILTER

AND

WIPE

ANY ACCUMU

LATION

OF

PARTICLES

OFF

MAGNETIC

DRAIN

PLUG.

INSPECT

BREATHER

PLUG

AT

LEAST

ONCE

A

YEAR

AND

CLEAN

OR

REPLACE

FOAM

FILTER

ELEMENT.

CHANGE

OIL

EVERY

TWO

MONTHS OR

500

HOURS OF

OPERATION,

WHICHEVER COMES

FIRST.

SEALS

ALL

SEALS

MUST

BE

HANDLED

WITH

EXTREME

CAUTION.

ANY

SMALL

AMOUNT

OF

DAMAGE

IN

HANDLING

OR

INSTALLATION

WILL

PERMIT

LEAKAGE.

WHEN

REPLACING

A

SEAL,

SATURATE

BOTH

IT

AND

THE

SHAFT

THOROUGHLY

WITH

OIL

BEFORE

ASSEMBLING.

NEVER

INSTALL

A

DRY

SEAL

OVER

A

DRY

SHAFT.

CLEANING

REMOVE

ACCUMULATIONS

OF

LINT

FROM

LOOPER

AREA.

IF

PERMITTED

TO

REMAIN

FOR

LONG

PERIODS

OF

TIME,

THESE

CAN

SET

UP A

WICKING

ACTION

WHICH

WILL

ABSORB

OIL

FROM

THE

MACHINE.

IF

THE

MACHINE

IS

OPERATED

AROUND

CORROSIVE

OR

STICKY

PRODUCTS,

OCCASIONALLY

BLOW

OFF

OR

SCRAPE

SUCH

EXPOSED

PARTS

AS

THE

FEED

DOG,

THROAT

PLATE

AND

PRESSER

FOOT.

ALSO

RECOMMENDED

IS

PERIODIC

HAND

OILING

OF

PRESSER

FOOT

HINGE

BOLT

AND

SURFACES

OF

CUTTING

KNIFE.

COLD

AREA

OPERATION

IN

VERY

COLD

AREAS

ALLOW

MACHINE

TO

WARM

UP

BY

RUNNING

STEADILY

FOR

A

FEW

MINUTES

BEFORE

CLOSING

ANY

BAGS.

FAILURE

TO DO

THIS,

ESPECIALLY

WITH

UNITS

RUNNING ON

SINGLE

PHASE

CURRENT,

CAN

RESULT

IN SLOW

STARTING

AND

RUNNING

OF

SEWING

HEAD.

THIS

CAUSES

MIS-SYNCHRONIZATION

WITH.THE

SPEED

OF

THE

CONVEYOR

BELT

WHICH

WILL

BREAK

THREAD

AND

CAUSE

SEWING

PROBLEMS

UNTIL

THE

SEWING

HEAD

AND

MOTOR

WARM

UP

AND

ATTAIN

PROPER

SPEED.

RUNNING

AFTER

PROLONGED

SHUT-DOWN

AFTER

PROLONGED SHUT-DOWN

PERIODS,

THE SEWING HEAD

OIL

SHOULD BE

PUMPING

PROPERLY

AND

THE

SEWING

HEAD

AND

MOTOR

WARMED

UP

BEFORE

CLOSING

ANY

BAGS

THIS

IS

EASILY

ACCOMPLISHED

BY

RUNNING

THE

SEWING

HEAD

IN

SHORT

2-3

SECOND

CYCLES

UNTIL

THE

OIL

PRESSURE

GAUGE

READS

IN

THE

NORMAL

3-9

POUND

RANGE.

ADJUSTMENTS

INITIAL

SEWING

WHEN

THERE

IS

NO

THREAD

CHAIN

FORMATION,

SEWING

MUST

BEGIN

ON

MATERIAL.

RAISE

THE

PRESSER

FOOT

BY

PUSHING

THE

LIFTER

LEVER

AND

PLACE

MATERIAL

UNDER

THE

PRESSER

FOOT.

CHECK

THE

LOOPER

TO

MAKE

SURE

NO

THREAD

IS

TANGLED

AROUND

IT

AS

A

RESULT

OF

RUNNING

THE

MACHINE

WITHOUT

A

THREAD

CHAIN

FORMATION.

PAGE

2

From the library of: Superior Sewing Machine & Supply LLC

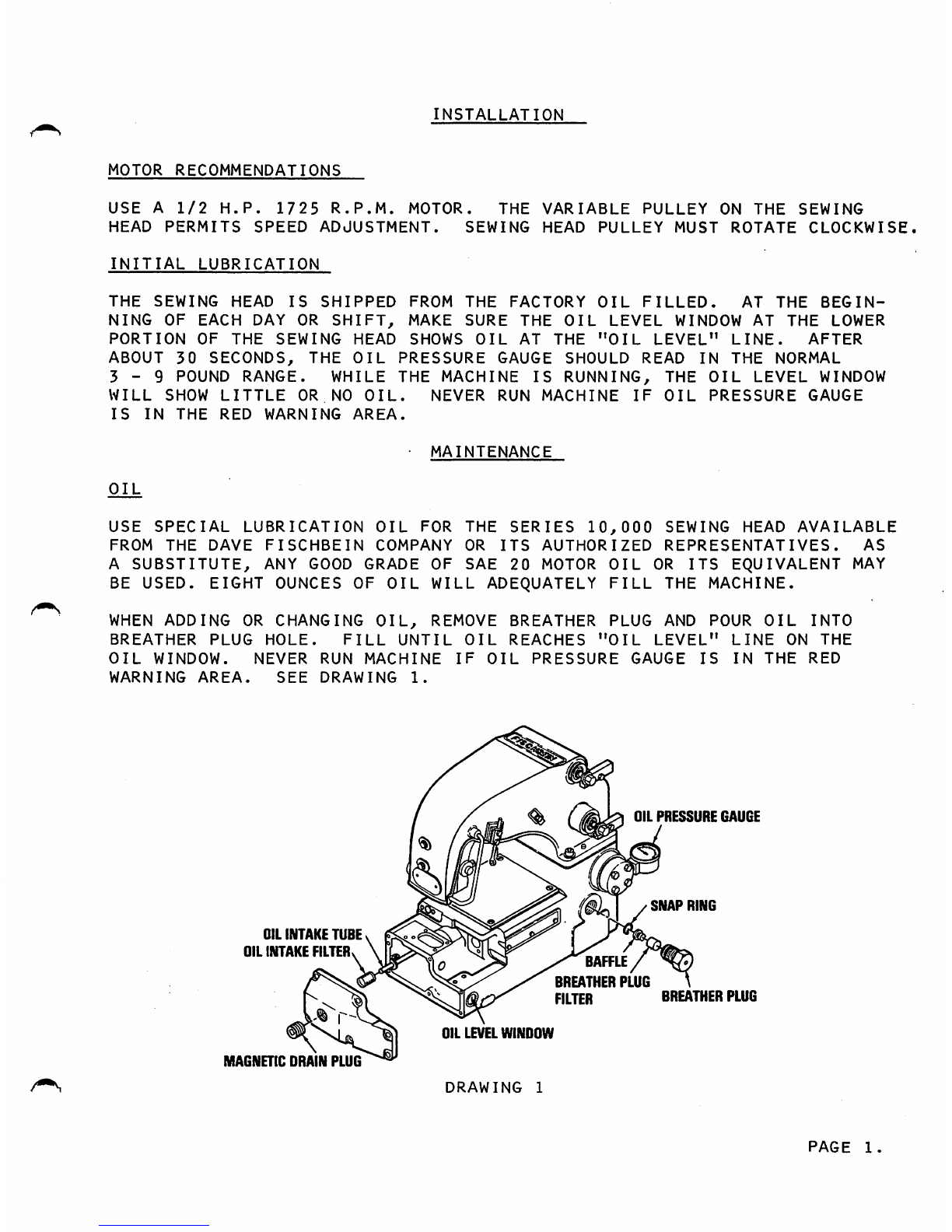

HREADING

FOLLOW

THE

THREADING

DIAGRAM

BELOW

FOR

PROPER

THREADING

LOOPER

THREAD

PASSES

THROUGH

BOTH

HOLES

OF

THE

LOOPER.

BE

SURE

NEEDLE

THREAD

TENSION

NEEDLE

LEVER

TENSION ASSEMBLY

NEEDLE

THREAD

PULL-OFF

LOOPER

THREAD

TENSION

THREADING

DIAGRAM

DRAWING

2

TENSIONS

THE

LOOPER

TENSION

MUST

BE

VERY

LIGHT,

BARELY

DISCERNIBLE

WHEN

PULLING

THREAD

BY

HAND.

THE NEEDLE

THREAD

TENSION

SHOULD

BE

VERY

FIRM

AND

PUT

ANOTICEABLE

DRAG

ON

THE THREAD. THE TENSION ASSEMBLY

LOCATED

ON

THE

NEEDLE

LEVER

MUST

PUT

ONLY

LIGHT PRESSURE,

ABOUT

THE

SAME

AS THE

LOOPER

TENSION,

ON THE

THREAD.

NEEDLE

REPLACEMENT

BE SURE

NEW

NEEDLE

IS

INSERTED INTO

THE

NEEDLE

CHUCK

AS

FAR

AS IT WILL

GO.

LOCK

NEEDLE

SET

SCREW

AGAINST

FLAT

OF

NEEDLE

SHANK.

CAUTION: USE

THE

SMALL

NEEDLE

WRENCH

PROVIDED

WITH

THE

MACHINE.

EXCESSIVE

PRESSURE

ON NEEDLE

SET

SCREW CAN

DAMAGE

SCREW OR NEEDLE CHUCK.

PAGE

3.

From the library of: Superior Sewing Machine & Supply LLC

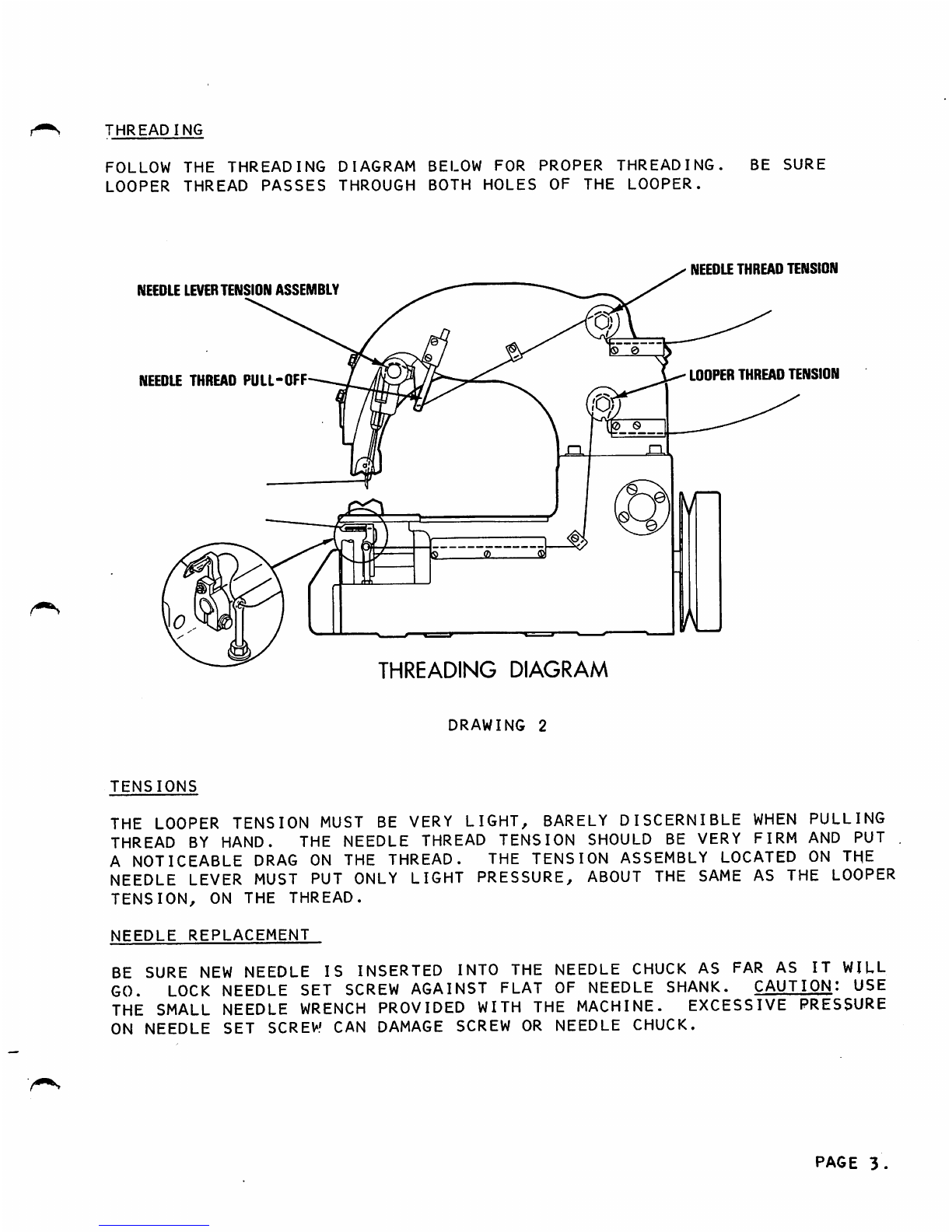

STITCH

LENGTH

TO

ADJUST

STITCH

LENGTH,

REMOVE

THE MAGNETIC DRAIN PLUG ON THE

BOTTOM

COVER. REACH THROUGH THE DRAIN PLUG HOLE WITH A

3/16

INCH

ALLEN

WRENCH AND

LOOSEN

THE

SOCKET

CAP

SCREW ON

THE

FEED

ROCKER.

DO NOT

COMPLETELY

REMOVE

CAP

SCREW.

TO

SHORTEN

STITCH

LENGTH,

SLIDE

LOOSENED

CAP

SCREW TOWARDS THE THROAT

PLATE.

TO LENGTHEN

STITCH, SLIDE

AWAY

FROM

THROAT

PLATE.

ALWAYS

MAKE

SURE

ADJUSTING

SCREW

IS

SECURELY

RE-TIGHTENED.

FOR

STITCH

LENGTH OF

TWO

STITCHES

PER INCH, USE OPTIONAL

THROAT

PLATE

B-10302

AND

FEED

DOG

A-10079.

SEE

DRAWING

3.

NEEDLE

GUARD

SOCKETCAP SCREW

MAGNETIC

DRAIN

PLUG

HOLE

NEEDLE

THREAD

PULL-OFF

FEED ROCKER

DRAWING

3

LOOPER

SHAFT

LOOPER

LOOPER HOLDER

THIS

ADJUSTMENT CAN VARY WITH

DIFFERENT

LENGTHS OF

STITCH,

BAG

THICKNESS

AND

TYPE OF THREAD. THE

NORMAL

SETTING

IS

l-l/h

INCHES

FROM

CENTER

OF THREAD HOLE

IN

PULL-OFF

TO THE BOTTOM OF

PULL-OFF

CLAMP.

PAGE

k

From the library of: Superior Sewing Machine & Supply LLC

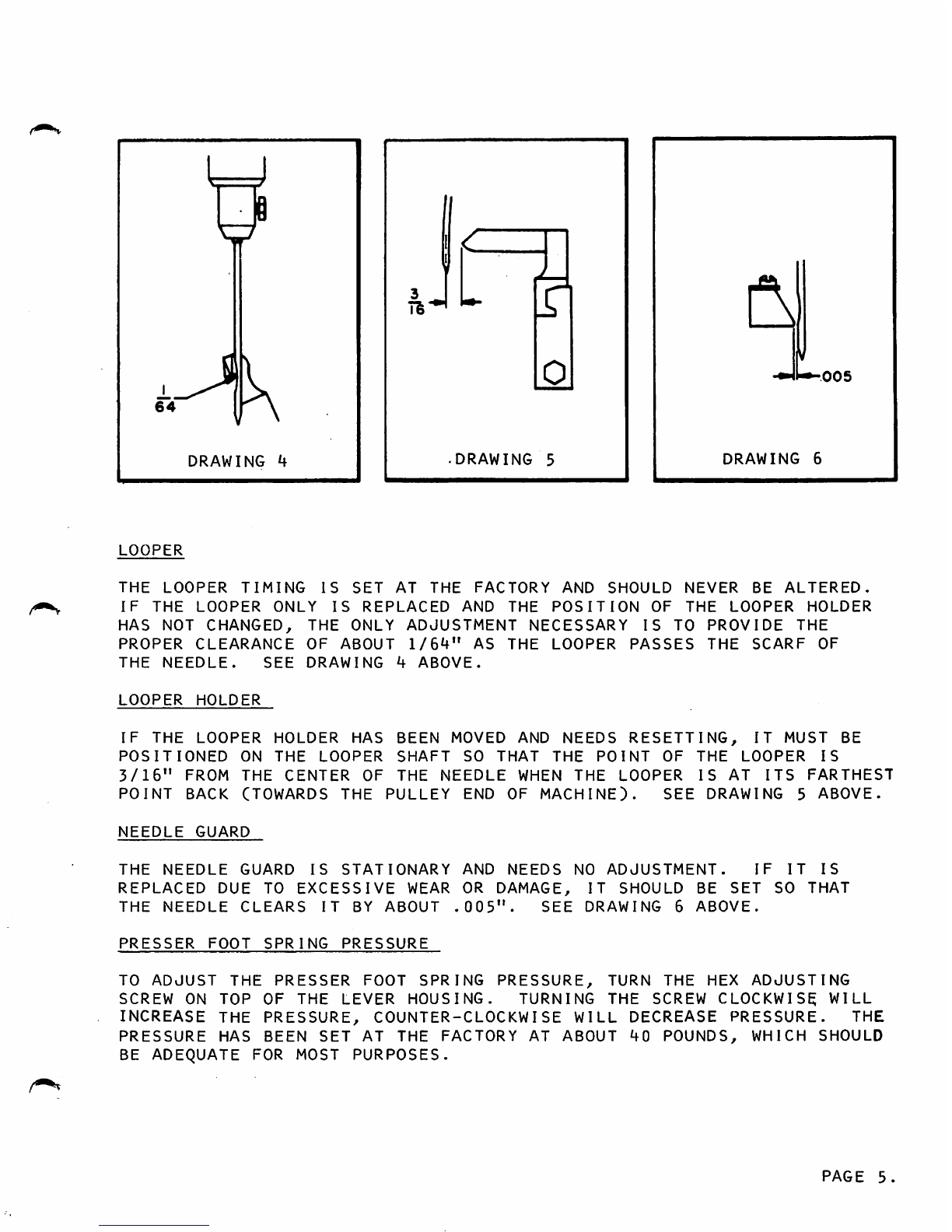

QLaJL

DRAWING

A

DRAWING

5

DRAWING

6

LOQPER

THE

LOOPER

TIMING

IS

SET

AT

THE

FACTORY

AND

SHOULD

NEVER

BE

ALTERED.

IF

THE

LOOPER

ONLY

IS

REPLACED

AND

THE

POSITION

OF

THE

LOOPER

HOLDER

HAS NOT

CHANGED,

THE

ONLY

ADJUSTMENT

NECESSARY

IS

TO

PROVIDE

THE

PROPER

CLEARANCE

OF

ABOUT

AS

THE

LOOPER

PASSES

THE

SCARF

OF

THE

NEEDLE.

SEE

DRAWING

k

ABOVE.

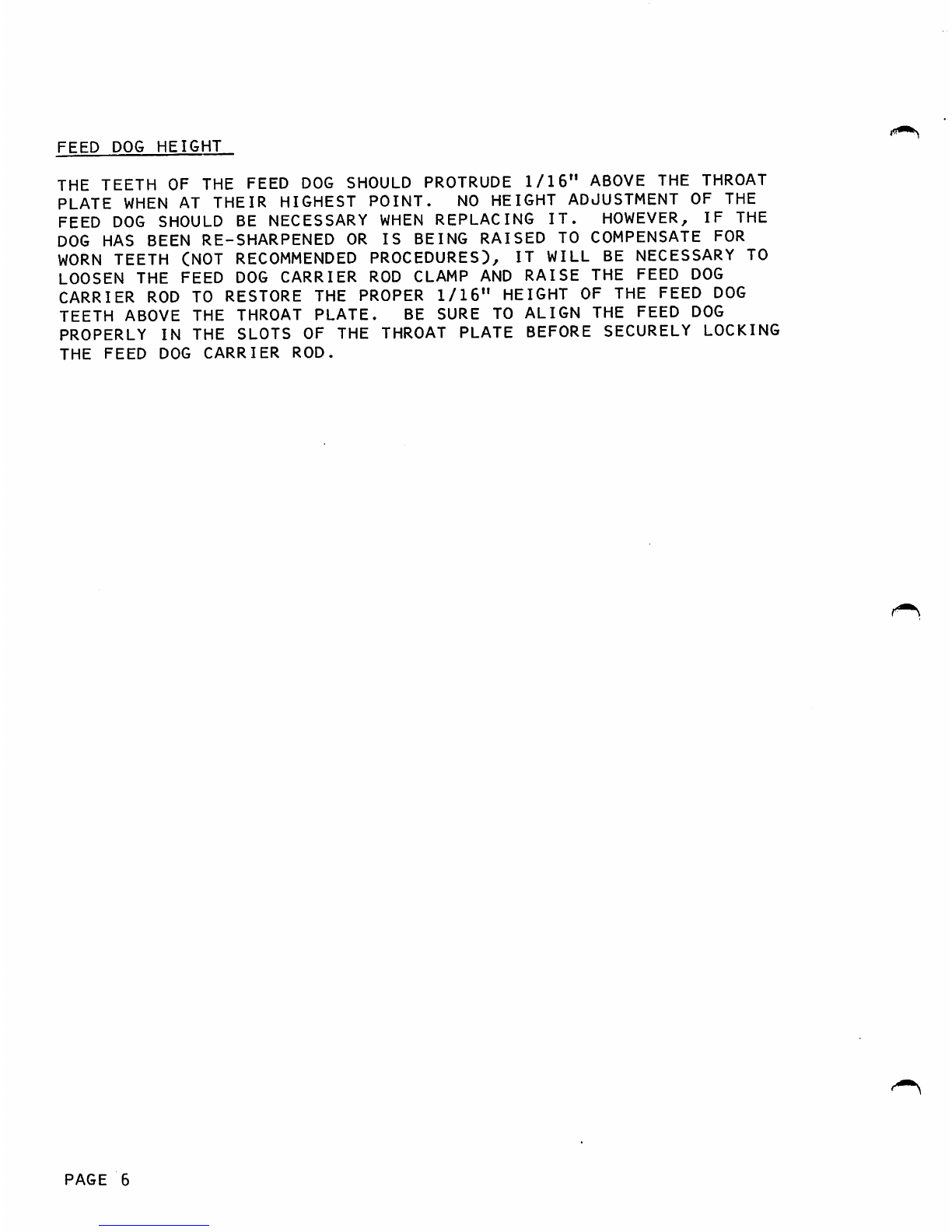

LOOPER

HOLDER

IF

THE

LOOPER

HOLDER

HAS

BEEN

MOVED AND

NEEDS

RESETTING,

IT

MUST

BE

POSITIONED

ON

THE

LOOPER

SHAFT

SO

THAT

THE

POINT

OF

THE

LOOPER

IS

3/16"

FROM

THE

CENTER

OF

THE

NEEDLE

WHEN

THE

LOOPER

IS

AT

ITS

FARTHEST

POINT

BACK

(TOWARDS

THE

PULLEY

END OF

MACHINE).

SEE

DRAWING

5

ABOVE.

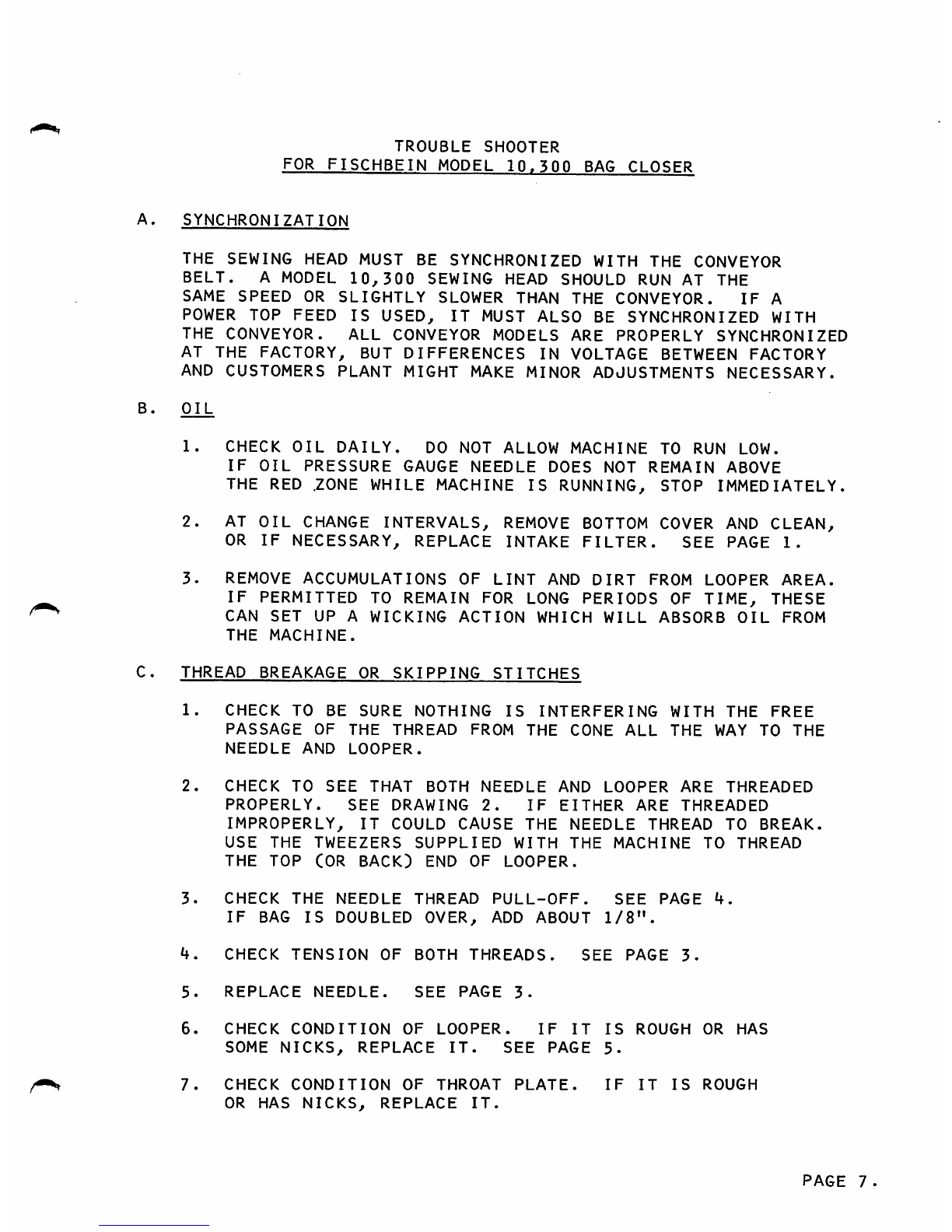

NEEDLE

GUARD

THE

NEEDLE

GUARD

IS

STATIONARY

AND

NEEDS

NO

ADJUSTMENT.

IF

IT

IS

REPLACED

DUE

TO

EXCESSIVE

WEAR OR

DAMAGE,

IT

SHOULD

BE

SET

SO

THAT

THE

NEEDLE

CLEARS

IT

BY

ABOUT

.005".

SEE

DRAWING

6

ABOVE.

PRESSER

FOOT

SPRING

PRESSURE

TO

ADJUST

THE

PRESSER

FOOT

SPRING

PRESSURE,

TURN THE HEX

ADJUSTING

SCREW

ON

TOP

OF

THE

LEVER

HOUSING.

TURNING

THE

SCREW

CLOCKWISE

WILL

INCREASE

THE

PRESSURE,

COUNTER-CLOCKWISE

WILL

DECREASE

PRESSURE.

THE

PRESSURE

HAS

BEEN

SET

AT

THE

FACTORY

AT

ABOUT

^tO

POUNDS,

WHICH

SHOULD

BE ADEQUATE FOR MOST

PURPOSES.

PAGE

5.

From the library of: Superior Sewing Machine & Supply LLC

FEED

DOG

HEIGHT

THE TEETH OF THE FEED

DOG

SHOULD

PROTRUDE

1/16"

ABOVE

THE

THROAT

PLATE

WHEN

AT THEIR HIGHEST

POINT.

NO

HEIGHT ADJUSTMENT OF THE

FEED

DOG

SHOULD

BE NECESSARY

WHEN

REPLACING

IT.

HOWEVER,

IF

THE

DOG

HAS BEEN RE-SHARPENED OR

IS

BEING

RAISED

TO COMPENSATE FOR

WORN

TEETH (NOT

RECOMMENDED

PROCEDURES), IT WILL BE

NECESSARY

TO

LOOSEN

THE FEED

DOG

CARRIER

ROD

CLAMP

AND

RAISE

THE FEED

DOG

CARRIER

ROD

TO RESTORE THE PROPER

1/16"

HEIGHT OF THE FEED

DOG

TEETH ABOVE THE THROAT

PLATE.

BE SURE TO

ALIGN

THE FEED

DOG

PROPERLY IN THE SLOTS OF THE

THROAT

PLATE BEFORE SECURELY LOCKING

THE

FEED

DOG

CARRIER

ROD.

PAGE

6

From the library of: Superior Sewing Machine & Supply LLC

TROUBLE

SHOOTER

FOR

FISCHBEIN

MODEL

10.300

BAG

CLOSER

A.

SYNCHRONIZATION

THE

SEWING

HEAD MUST BE

SYNCHRONIZED

WITH

THE CONVEYOR

BELT.

A

MODEL

10,300

SEWING

HEAD

SHOULD RUN AT THE

SAME

SPEED

OR

SLIGHTLY

SLOWER THAN

THE

CONVEYOR.

IF

A

POWER

TOP FEED

IS

USED,

IT

MUST ALSO BE SYNCHRONIZED WITH

THE

CONVEYOR.

ALL

CONVEYOR

MODELS

ARE

PROPERLY

SYNCHRONIZED

AT THE

FACTORY,

BUT

DIFFERENCES

IN

VOLTAGE BETWEEN FACTORY

AND

CUSTOMERS

PLANT

MIGHT

MAKE

MINOR

ADJUSTMENTS

NECESSARY.

B.

OI_L

1.

CHECK

OIL

DAILY.

DO NOT ALLOW

MACHINE

TO RUN LOW.

IF

OIL

PRESSURE

GAUGE

NEEDLE

DOES

NOT

REMAIN

ABOVE

THE RED .ZONE WHILE MACHINE

IS

RUNNING,

STOP

IMMEDIATELY.

2.

AT

OIL

CHANGE

INTERVALS,

REMOVE

BOTTOM

COVER

AND

CLEAN,

OR

IF

NECESSARY,

REPLACE

INTAKE

FILTER.

SEE

PAGE

1.

3.

REMOVE

ACCUMULATIONS

OF

LINT

AND

DIRT

FROM

LOOPER

AREA.

IF

PERMITTED TO REMAIN FOR

LONG

PERIODS

OF

TIME,

THESE

CAN

SET

UP

A

WICKING

ACTION

WHICH

WILL

ABSORB

OIL

FROM

THE

MACHINE.

C.

THREAD

BREAKAGE

OR

SKIPPING

STITCHES

1.

CHECK

TO

BE

SURE

NOTHING

IS

INTERFERING

WITH

THE

FREE

PASSAGE

OF

THE

THREAD

FROM

THE

CONE

ALL

THE

WAY

TO

THE

NEEDLE

AND

LOOPER.

2.

CHECK

TO

SEE

THAT

BOTH

NEEDLE

AND

LOOPER

ARE

THREADED

PROPERLY.

SEE

DRAWING

2.

IF

EITHER

ARE

THREADED

IMPROPERLY,

IT

COULD

CAUSE

THE

NEEDLE

THREAD TO

BREAK.

USE

THE

TWEEZERS

SUPPLIED

WITH

THE

MACHINE

TO

THREAD

THE

TOP

COR

BACK)

END OF

LOOPER.

3.

CHECK

THE

NEEDLE

THREAD

PULL-OFF.

SEE

PAGE

k.

IF

BAG

IS

DOUBLED

OVER,

ADD ABOUT

1/8".

CHECK

TENSION

OF

BOTH

THREADS.

SEE

PAGE

3.

5.

REPLACE

NEEDLE.

SEE

PAGE

3.

6.

CHECK

CONDITION

OF

LOOPER.

IF

IT

IS

ROUGH

OR

HAS

SOME

NICKS,

REPLACE

IT.

SEE

PAGE

5.

7.

CHECK

CONDITION

OF

THROAT

PLATE.

IF

IT

IS

ROUGH

OR HAS

NICKS,

REPLACE

IT.

PAGE

7

From the library of: Superior Sewing Machine & Supply LLC

8.

CHECK SHARPNESS OF FEED DOG.

IF

DULL, REPLACE

IT.

note:

only

the

outside

rows

of

teeth

should

be

SHARP.

DO

NOT

SHARPEN

CENTER

TEETH.

D.

FAILURE

TO

CHAIN

OFF

AFTER

BAG

IS

SEWN

1.

CHECK

ITEMS

LISTED

UNDER

THREAD

BREAKAGE

ABOVE.

2.

CHECK

PRESSER

FOOT

PRESSURE.

IT

SHOULD BE « "

APPROXIMATELY

kO

POUNDS.

SEE

PAGE

5.

E.

UNEVEN

STITCH

LENGTH

OR

POOR

FEEDING

CHECK

SHARPNESS

OF

FEED

DOG

AND

PRESSER

FOOT

PRESSURE.

F.

EXCESSIVE

NEEDLE

BREAKAGE

1.

OPERATOR

MAY

BE

PULLING

BAG

THROUGH

MACHINE.

2.

SEWING

MAY

BE

TOO

CLOSE

TO

CONTENTS

OF

BAG.

3.

CHECK

ALIGNMENT

OF

NEEDLE

SLOT

IN

PRESSER

FOOT

TO

BE

SURE

NEEDLE

DOES

NOT

RUB.

PAGE

8.

if.

CHECK

TO

SEE

THAT

THE

NEEDLE

CHUCK

IS

PARALLEL

WITH

SIDE

OF

MACHINE.

5.

CHECK

SHARPNESS

OF

FEED

DOG.

6.

CHECK

SYNCHRONIZATION.

From the library of: Superior Sewing Machine & Supply LLC

OIL

PUMP

6

COUNTERWEIGHT

ASSEMBLY

ITEM

PART

QTY.

NO. NO.

DESCRIPTION

1

A-10191

ASS'Y,

FILTER

-INTAKE 1

2

P-10192

RING,

"0"

- INTAKE

FILTER

1

3

A-10204

RETAINER,

TUBE

-

INTAKE

1

8103212

SCREW,

BINDING

HD 1

WN8

WASHER,

NYLON 1

NJIO

NUT

1

k

A-10105

ASS'Y,

TUBE - INTAKE 1

P-10107

RING,

"0"

- INTAKE TUBE 1

5

A-10178

INSERT,

BODY - PUMP

SC63278

SCREW, SOCKET HD CAP

6

P-10104

LINK,

CONNECTING -

PUMP

DRIVE 1

7

A-10103

PIN,

PIVOT

- PUMP

DRIVE

8

A-10061

ECCENTRIC,

STROKE - PUMP 1

SSltf2038

SCREW,

SET

1

SS142038CP

SCREW,

SET

- CONE

POINT

1

9

A-10101

COUNTERWEIGHT

6

PUMP

DRIVE

1

10

A-10102

LINK,

CONTROL - PUMP DRIVE 1

SS1032316

SCREW,

SET

11

A-10106

ASS'Y,

TUBE -

PRESSURE

1

NUT,

HEX 1

P-10107

RING,

"0"

- TUBE TERMINAL

12

A-10169

PISTON,

PUMP 1

13

P-10051

BALL,

VALVE 3

Itt

A-10130

SPRING,

RELIEF

-

OIL

PRESSURE

1

15

A-10053

PLUG,

SPRING

- VALVE 3

16

P-lOOO^f

RING,

"0"

1

17

B-10167

BODY, PUMP 1

H103212

SCREW,

HEX HD

18

A-10168

CYLINDER,

PUMP 1

19

A-10049

GASKET,

BLOCK - VALVE 1

20

B-10050

BLOCK,

VALVE 1

H103211't

SCREW,

HEX

HD

(LONG) 2

H10321

SCREW,

HEX

HD

(SHORT) 1

21

A-10127

SPRING,

BLOCK - VALVE 2

22

A-10052

SEAL,

WASHER

- VALVE PLUG 2

PAGE

9

From the library of: Superior Sewing Machine & Supply LLC

PAGE

10

From the library of: Superior Sewing Machine & Supply LLC

MAIN

HOUSING

ITEM

PART

NO.

NO.

DESCRIPTION

QTY.

1

B-10302

PLATE,

THROAT

-

RAMP

CUTTER (LONG

STITCH)

1

B-10303

PLATE,

THROAT - RAMP

CUTTER

1

F103258

SCREW, FLAT

HD

(LONG)

F103238

SCREW, FLAT

HD

(SHORT)

2

B-10304

RAMP

1

F103238

SCREW,

FLAT

HD 1

3

A-10015

POST,

SHORT - THROAT

PLATE

1

H103212

SCREW,

HEX HD 1

WN8

WASHER

-

NYLON

1

D208

WASHER

1

if

B103238

SCREW,

BINDING

HD

WN8

WASHER

5

P-10111

PLUG,

DRAIN

-MAGNETIC 1

6

B-10022

COVER,

BOTTOM 1

F1032114

SCREW, FLAT

HD

(LONG)

F103258

SCREW,

FlIt

HD

(SHORT)

7

A-10170

PULL-OFF

LOOPER

THREAD

1

NH1420

NUT,

HEX ; 1

WF14

WASHER

1

WN14

WASHER

-

NYLON

1

8

A-10093

GASKET,

COVER - BOTTOM 1

9

A-10016

POST,

LONG - THROAT

PLATE

1

H103212

SCREW,

HEX HD 1

WN8

WASHER

-

NYLON

1

D208

WASHER

1

10

A-10005

DOOR,

LOOPER

1

11

A-10021

KNOB, LATCH - LOOPER DOOR 1

F63234

SCREW,

FLAT

HD 1

12

A-10019

SPRING,

LATCH - LOOPER

DOOR

1

13

A-10020

LATCH,

DOOR - LOOPER 1

14

P-10112

WINDOW,

OIL

LEVEL

1

15

A-10097

PLATE,

LATCH - LOOPER DOOR 1

H103212

SCREW,

HEX HD 1

D208

WASHER

1

16

A-10098

COVER,

GROOVE - THREAD 1

B632316

SCREW,

BINDING

HD

17

A-10164

EYELET,

THREAD - SHORT 1

H103234

SCREW,

HEX HD 1

18

A-10134

RING,

SNAP -

BREATHER

BAFFLE RETAINER 1

19

A-10179

BAFFLE,

PLUG - BREATHER 1

20

A-10116

ASS'Y,

PLUG - BREATHER 1

21

A-10121

FILTER,

PLUG - BREATHER 1

22

P-10227

GAUGE,

OIL

PRESSURE

1

23

P-10226

ADAPTER, GAUGE -

OIL

PRESSURE 1

H10321

SCREW,

HEX HD

24

A-10094

GASKET,

MAIN SHAFT SEAL 1

25

D-lOOOl

HOUSING,

MAIN 1

26

A-10095

GASKET,

COVER - MANIFOLD 1

27

A-lOlOO

COVER,

MANIFOLD 1

H103212

SCREW,

HEX

HD

5

28

A-10092

GASKET,

COVER -

TOP

1

29

A-10014

PLATE,

COVER -

TOP

1

F103238

SCREW,

FLAT

HD 4

PAGE

11

From the library of: Superior Sewing Machine & Supply LLC

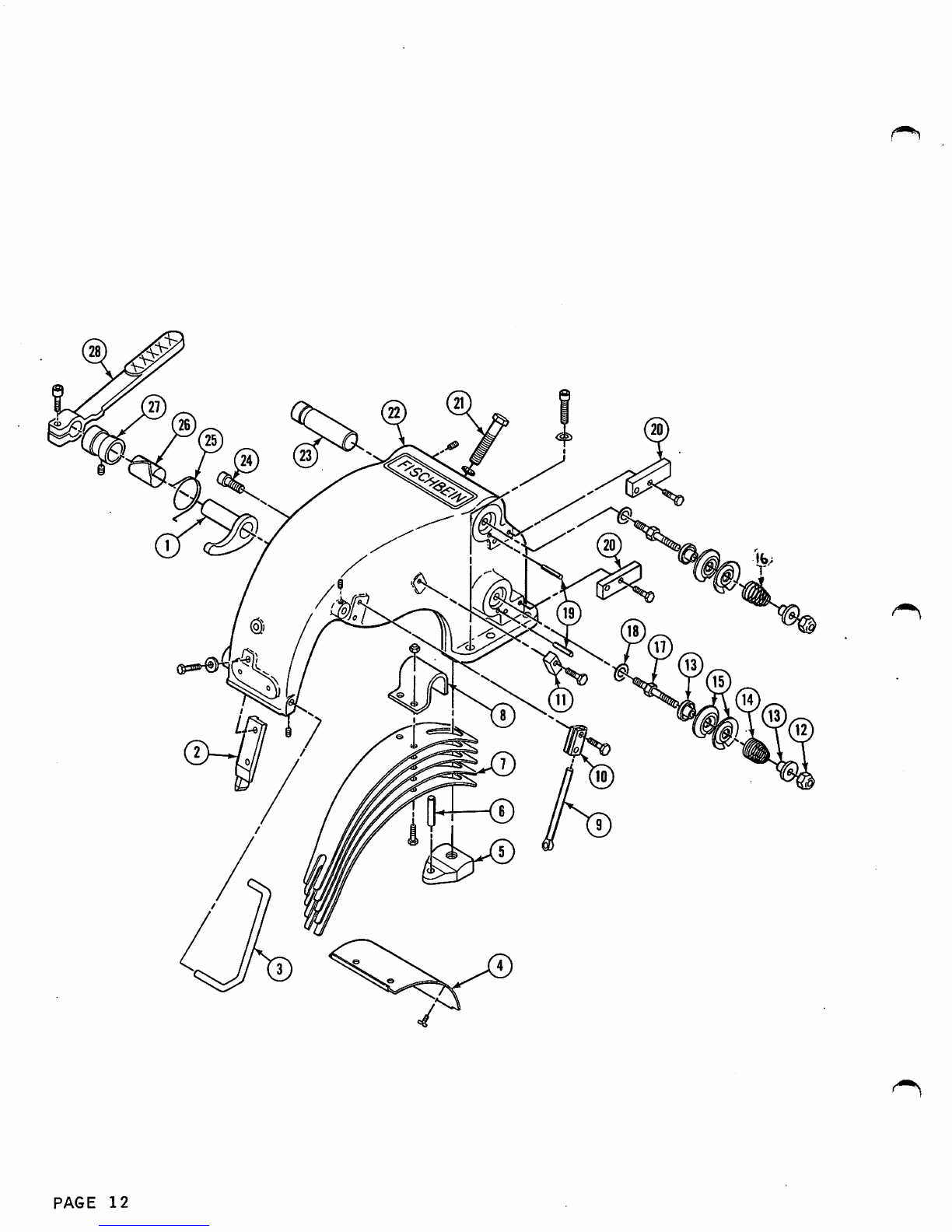

PAGE

12

From the library of: Superior Sewing Machine & Supply LLC

ITEM

NO.

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

PART

NO.

A-10142

A-10161

H10327B

WFIO

A-10188

SS1032516

B-10123

B103238

A-10146

p-ioai3

B-10145

H103234

1-178

A-10144

A-10171

A-10172

H103234

A-10164

H103234

NH1428L

A-10114

A-10008

A-10120

A-10007

A-10115

D-120

P-10010

A-10165

H103234

H3824134

WF38

D-10002

SC516181

WS516

A-10143

SS142038

SC5161858

A-10187

A-10186

A-10139

SS142014

8-10141

SC142034

LEVERS

HOUSING

DESCRIPTION

CAM,

LIFTER - PRESSER

FOOT

GUIDE,

LEVER - PRESSER FOOT

SCREW,

HEX HD

WASHER

TENSION

-

NEEDLE

SCREW,

SET

GUARD

-

LEVERS

SCREW,

BINDING

HD

PRESSER

FOOT

SPRING

-

TAPPED

PIN,

ROLL

SPRING,

PRESSER

FOOT

SCREW,

HEX HD

NUT,

LOCK

CLAMP, SPRING - PRESSER FOOT

PULL-OFF,

NEEDLE THREAD

CLAMP,

NEEDLE

THREAD

PULL-OFF

SCREW,

HEX HD

EYELET,

THREAD - SHORT

SCREW,

HEX

HD

NUT

GUARD,

COVER,

PLATE,

SLEEVE,

TENSION

SPRING, TENSION -

LOOPER

THREAD

DISC,

TENSION -

LARGE

SPRING, TENSION -

NEEDLE

THREAD

STUD,

TENSION

WASHER,

LOCK

PIN,

RETAINING -TENSION

DISC..

EYELET,

THREAD

-

LONG

SCREW,

HEX HD

SCREW, ADJUSTING

WASHER

HOUSING,

LEVERS

SCREW, SOCKET

HD

CAP

WASHER,

SPRING

SHAFT,

SPRING

-PRESSER

FOOT...

SCREW,

SET

SCREW, STOP -

LIFTER

LEVER

SPRING,

LIFTER

LEVER

LINER,

BUSHING

- LIFTER LEVER..

BUSHING, LIFTER - PRESSER FOOT.

SCREW,

SET

LEVER, LIFTER - PRESSER

FOOT...

SCREW, SOCKET

HD

CAP....

QTY

1

1

2

2

1

2

1

2

1

1

5

2

2

1

1

1

2

1

1

2

4

1

4

1

2

2

2

2

4

1

1

1

4

4

1

1

1

1

1

1

1

1

1

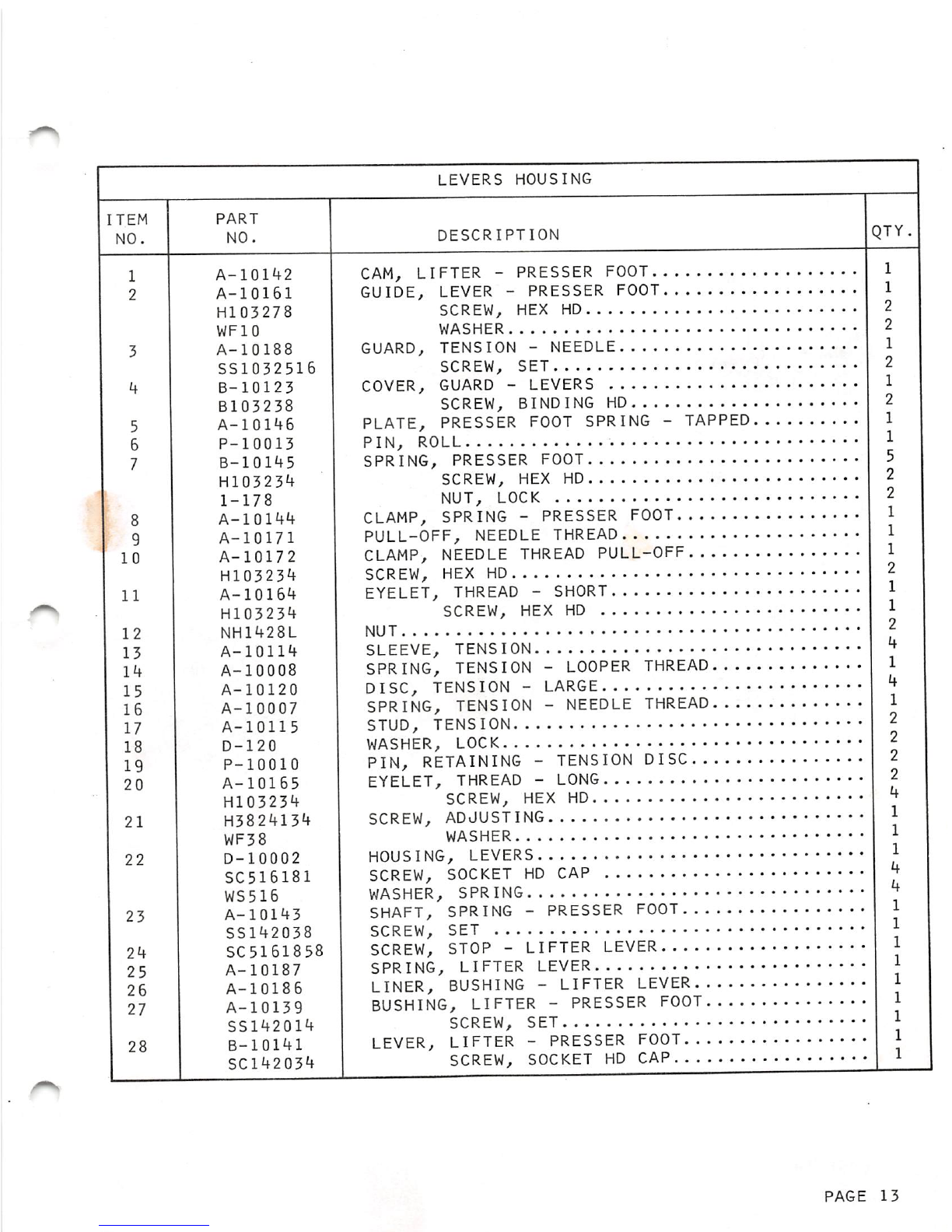

PAGE

13

From the library of: Superior Sewing Machine & Supply LLC

1 y > (16

PAGE

lA

From the library of: Superior Sewing Machine & Supply LLC

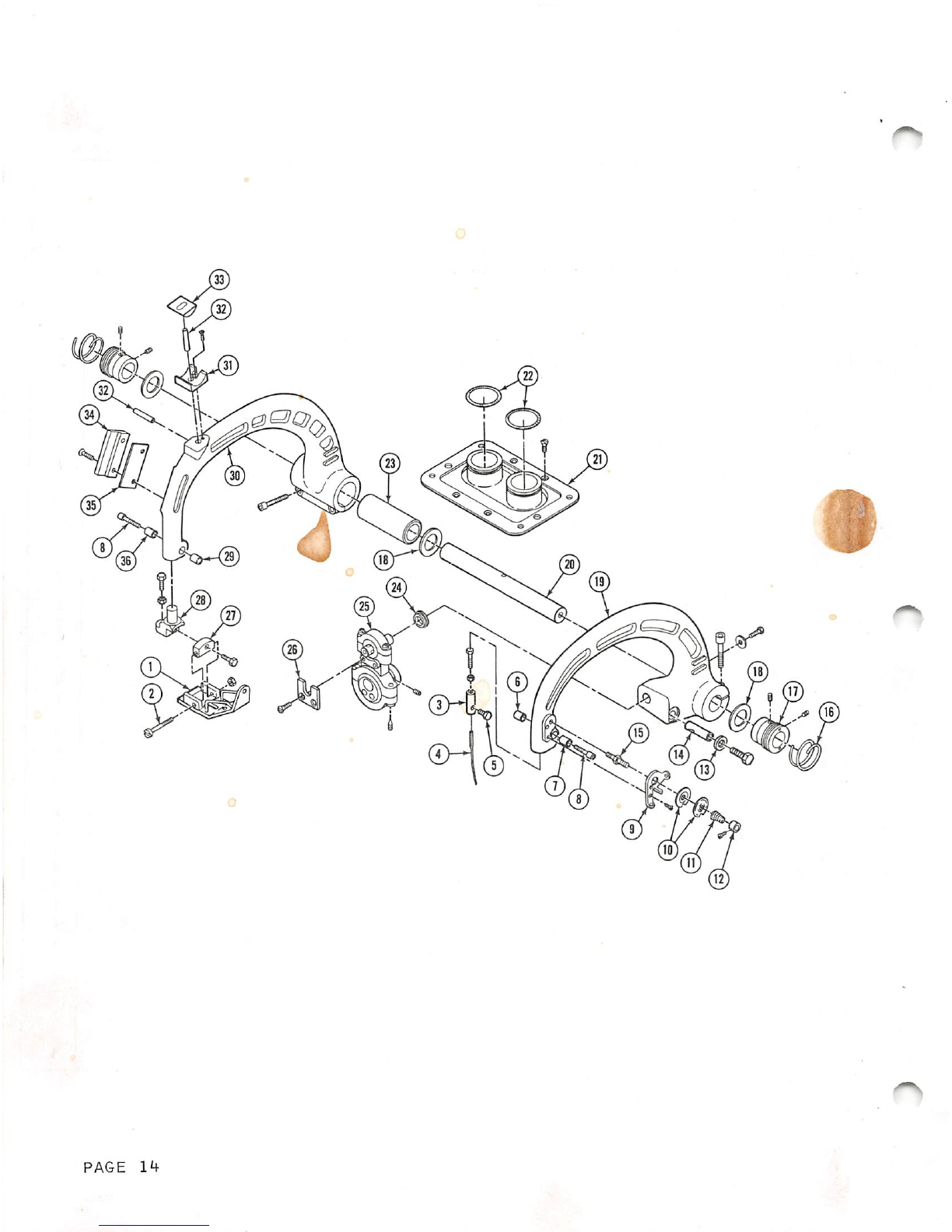

/

NEEDLE

S

PRESSER

FOOT

LEVER

ASSEMBLIES

ITEM

NO.

PART

NO.

1

A-10185

2

A-10182

NJIO

3

A-10031

H103234

NJIO

4

C-IOO-S

5

A-10011

6

A-10212

7

A-102

11

8

SC63234

9

A-10166

F54038

10

A-iail9

11

A-10009

12

A-10181

B632315

13

A-10231

H1032ia

l^f

A-10232

15

A-10113

16

A-10023

17

A-10025

SS1032316

SS103238

IS

T3129

19

C-10003

SC1420114

20

A-10026

21

B-10137

F103238

22

A-10128

23

A-10028

2k

A-10159

25

B-10047

SS142038CP

SS142014

H103238

WSIO

26

A-10048

~ —

F103238

27

A-10155

H1Q3234

28

A-10155

H103234

NJIO

29

A-10214

30

C-10004

SC1420114

31

A-10189

F63212

32

P10193

33

A-10190

34

A-10163

F103258

35

A-10162

36

A-10213

DESCRIPTION

PRESSER

FOOT

BOLT,

HINGING

-

PRESSER

FOOT

NUT

CHUCK,

NEEDLE

SCR:EW,

HEX

HD

NUT,

HEX HD

NEEDLE

•

SCREW,

CLAMP

NEEDLE,

PLUG,

CLAMP-TAPPED

(NEEliE

LEVER)

PLUG,

CLAMP-DRILLED

CN^LE

LEVER)

SCREW, SOCKET HD.

CAf^

GUIDE,

THREAD

-

NEEDLE

LEVER

SCREW,

FLAT

HD

DISC,

TENSION

-

SMALL

SPRING,

TENSION

-

NEEDLE

LEVER

COLLAR,

TENSION

-

NEEDLE

LEVER

SCREW,

BINDING

HD

WASHER,

HEAVY -

NEEDLE

LEVER

SCREW,

HEX HD

ROD,

CLAMP

-

NEEDLE

LEVER

STUD,

TENSION

-

NEEDLE

LEVER

INSERT,

THREAD -

LEVERS

SHAFT

BUSHING

BUSHING,

SHAFT

LEVERS

SCREW, SET

(SHORT)

SCREW, SET

(LONG)

.

WASHER,

THRUST

LEVER,

NEEDLE

SCREW,

SOCKET HD. CAP

SHAFT,

LEVERS

SEAL,

LEVERS

SCREW,

FLAT

HD

SPRING,

GARTER -LEVER

SEAL

BUSHING,

LEVER -

PRESSER

FOOT

SPACER,

STUD

-

BALL

ROD,

CONNECTING

-NEEDLE

DRIVE

SCREW,

SET

-

CONE

POINT

SCREW,

SET

SCREW,

HEX HD

WASHER,

SPRING

RETAINER,

ROD - CONNECTING

SCREW,

FLAT

HD

BLOCK,

HINGE

-

PRESSER

FOOT

SCREW,

HEX HD

SHANK,

PRESSER

FOOT

SCREW,

HEX HD

NUT,

HEX

PLUG,

CLAMP

- TAPPED

(PRESSER

FOOT)

LEVER,

PRESSER

FOOT

SCREW,

SOCKET HD.

CAP

CRADLE,

PAD -

PRESSER

FOOT

SPRING

SCREW,

FLAT

HD

PIN,

ROLL

PAD,

SPRING

-

PRESSER

FOOT

CLAMP,

BEARING

-

SHEET

SCREW,

FLAT

HD

SHEET,

BEARING - PRESSER FOOT LEVER GUIDE

PLUG,

CLAMP

- DRILLED (PRESSER FOOT)

QTY

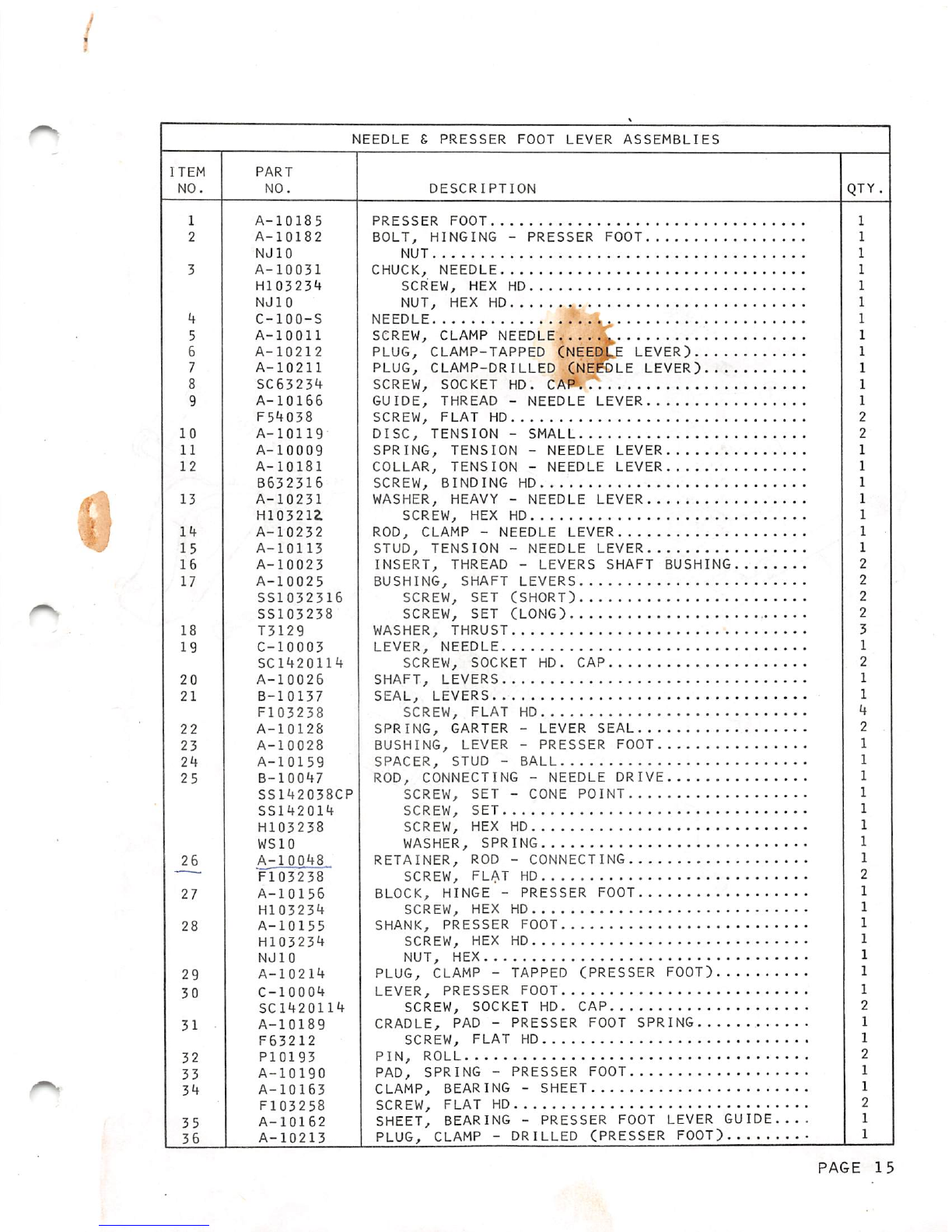

PAGE

15

From the library of: Superior Sewing Machine & Supply LLC

y J j

f .

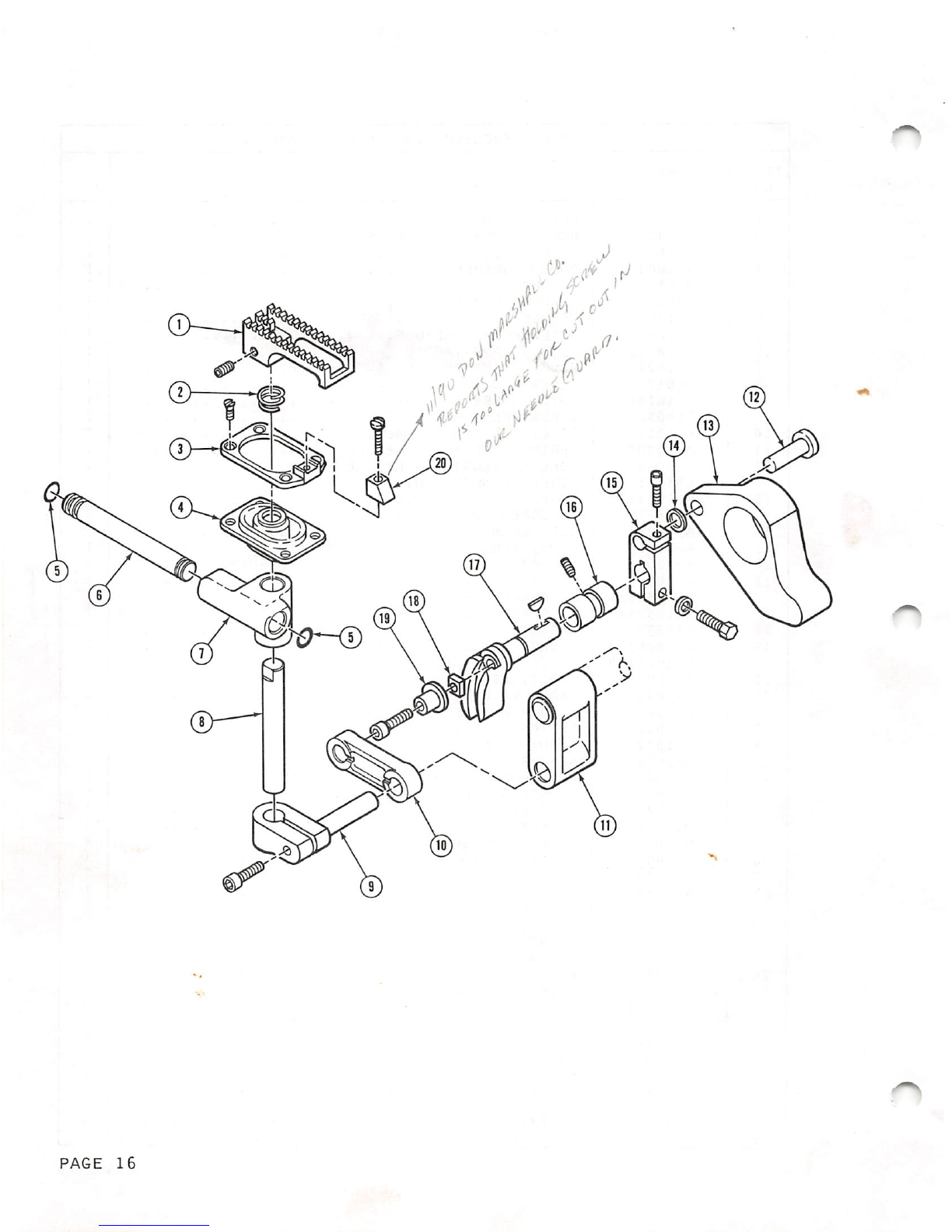

PAGE

16

From the library of: Superior Sewing Machine & Supply LLC

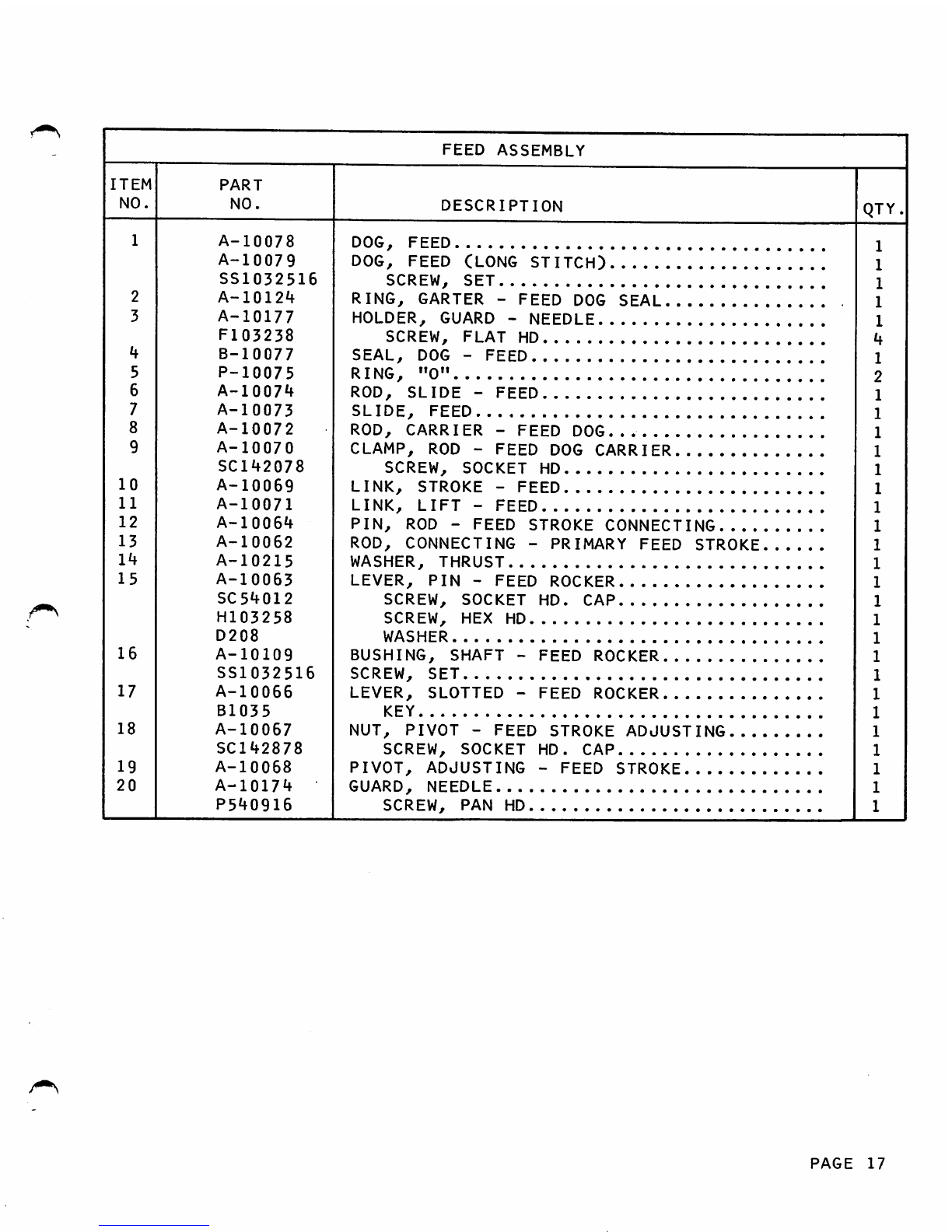

FEED

ASSEMBLY

ITEM

PART

NO.

NO.

DESCRIPTION

QTY.

1

A-10078

DOG,

FEED

1

A-10079

DOG, FEED

CLONG

STITCH)

1

SS1032516

SCREW,

SET

1

2

A-1012if

RING,

GARTER -

FEED

DOG

SEAL

.1

3

A-10177

HOLDER,

GUARD -

NEEDLE

1

F103238

SCREW,

FLAT

HD if

B-10077

SEAL,

DOG -

FEED

1

5

P-10075

RING,

"0"

6

A-lOOT'f

ROD,

SLIDE

-

FEED

1

7

A-10073

SLIDE,

FEED

1

8

A-10072

ROD,

CARRIER

-

FEED

DOG...

1

9

A-10070

CLAMP,

ROD -

FEED

DOG

CARRIER

1

SClif2078

SCREW,

SOCKET

HD 1

10

A-10069

LINK,

STROKE

-

FEED

1

11

A-10071

LINK,

LIFT

-

FEED

1

12

A-1006if

PIN,

ROD -

FEED

STROKE

CONNECTING

1

13

A-10062

ROD,

CONNECTING

-

PRIMARY

FEED

STROKE

1

lA

A-10215

WASHER,

THRUST

1

15

A-10063

LEVER,

PIN

-

FEED

ROCKER 1

SC5^012

SCREW,

SOCKET

HD.

CAP

1

H103258

SCREW,

HEX HD 1

D208

WASHER

1

16

A-10109

BUSHING,

SHAFT

-

FEED

ROCKER

1

SS1032516

SCREW,

SET

1

17

A-10066

LEVER,

SLOTTED

-

FEED

ROCKER

1

B1035

KEY

1

18

A-10067

NUT,

PIVOT

-

FEED

STROKE

ADJUSTING

1

SClif2878

SCREW,

SOCKET

HD.

CAP

1

19

A-10068

PIVOT,

ADJUSTING

-

FEED

STROKE

1

20

A-1017if

GUARD,

NEEDLE

1

P540916

SCREW,

PAN HD 1

PAGE

17

From the library of: Superior Sewing Machine & Supply LLC

PAGE

18

From the library of: Superior Sewing Machine & Supply LLC

MAIN

SHAFT

£

KNIFE

ASSEMBLY

ITEM

PART

NO. NO.

DESCRIPTION

QTY.

1

1-178

NUT,

LOCK

1

2

A-10305

STUD,

PIVOT

1

3

B-20if3

WASHER,

SPRING

3

if

A-10307

KNIFE,

MOVING

1

5

A-10306

KNIFE,

BED 1

6

SCS^Olif

SCREW,

SET

1

7

B-1030i+

1

8

C-100if5

SHAFT,

MAIN

1

g

B-1035

key

1

10

P-10125

PLUG,

PIPE

-MAIN

SHAFT

1

11

A-lOOi+if

BUSHING,

MAIN

SHAFT

-

NEEDLE

END 1

SS1032516

SCREW,

SET

1

12

T-3129

WASHER,

THRUST

13

A-10062

ROD,

CONNECTING

-

PRIMARY

FEED

STROKE

1

lif

A-10061

ECCENTRIC,

STROKE

-

FEED

1

SSm2038

SCREW,

SET

1

SSlif2038-CP

SCREW,

SET

-CONE

POINT

1

15

A-10158

COLLAR,

LOCK - MAIN

SHAFT

1

SC103258

SCREW,

SOCKET

HD.

CAP 1

16

A-lOOi+3

BUSHING,

MAIN

SHAFT

DRIVE

END 1

SS1032516

SCREW,

SET

1

17

A-1009it

GASKET,

MAIN

SHAFT

SEAL

1

18

A-10035

ASSY,

SEAL

-

MAIN

SHAFT

,1

H103212

SCREW,

HEX HD

19

A-10038

HUB,

PULLEY

1

S51if2038

SCREW,

SET

20

A-10199

PULLEY,

ADJUSTABLE

1

SSlif2038

SCREW,

SET

F103258

SCREW,

FLAT

HD 3

21

A-1006if

PIN,

ROD

- FEED STROKE CONNECTING 1

22

A-10080

ASSY,

CONNECTING

ROD -

KNIFE

1

H103212

SCREW,

HEX HD 1

H103258

SCREW,

HEX HD 1

23

A-10082

CRANK, BELT -

KNIFE

1

55590316

SCREW

SET

1

2it

P-1008if

RING,

"0"

1

25

A-10083

SHAFT,

BELL

CRANK

-KNIFE 1

26

B-10085

BRACKET,

PIVOT

-

KNIFE

1

H103212

SCREW,

HEX HD 9

27

A-10087

SCREW,

PIVOT

-

KNIFE

1

D120

WASHER,

LOCK 1

28

A-10086

LINK,

KNIFE

1

29

A-10056

BUSHING,

SHAFT

-

KNIFE

1

SS1032516

SCREW,

SET

1

30

A-10311

ASSY,

SHAFT

8

LINK

1

31

A-10058

GASKET,

SEAL -

KNIFE

SHAFT 1

32

A-10076

ASSY,

SEAL -

KNIFE

SHAFT 1

H103212

SCREW,

HEX HD

33

F103238

SCREW,

FLAT

HD. . ; 1

3if

B-10303

PLATE,

THROAT -

RAMP

CUTTER 1

B-i0302

PLATE,

THROAT-

RAMP

CUTTER

(LONG

STITCH) 1

PAGE

19

M:

From the library of: Superior Sewing Machine & Supply LLC

Table of contents

Other FISCHBEIN Sewing Machine manuals