Cloth Puller Optional device

Please note when placing orders, that the model name should be written as follows:

Cloth Puller Optional device

Code

M

Application

For light-weight

materials (standard)

For medium-weight

materials

Code

B

C

D

E

F

H

Needle gauge

3.2mm (1/8")

4.0mm (5/32")

4.8mm (3/16")

5.6mm (7/32")

6.4mm (1/4")

7.9mm (5/16")

Code

M

Application

For extra heavy-weight

materials (standard)

For medium-weight

materials

Code

E

F

G

H

K

Needle gauge

5.6mm (7/32")

6.4mm (1/4")

7.2mm (9/32")

8.0mm (5/16")

9.6mm (3/8")

*1 The knee switch for the chain-off thread cutter AT27 and that for the

pneumatic auto-lifter AK81 cannot be installed simultaneously.

*2 Codes "04" and "05" represent the combination for the MS-1261.

When you need to use your machine in combination with other options,

please contact your distributor.

MS-1190Model name

SCHMETZ B-64 (Nm100)

Nm80〜Nm120

ORGAN TV×64-NY (#16)

#12〜#19

SCHMETZ B-64 (Nm80)

Nm60〜Nm90

ORGAN TV×64-NY (#12)

#8〜#14

SCHMETZ UY128GAS (Nm120)

Nm100〜Nm140

ORGAN UY×128GAS-NY (#19)

#16〜#22

SCHMETZ UY128GAS (Nm130)

Nm100〜Nm140

ORGAN UY×128GAS-NY (#21)

#16〜#22

MS-1190M

Thread pulling cam type

thread take-up lever Needle bar thread take-up lever

For light-weight

materials

For medium-weight

materials

For medium- to heavy-weight

materials

For extra heavy-weight

materials for jeans

3,600sti/min (normal 3,000sti/min)

33.2mm

Longitudinally-fixed needle guard Backward travelling needle guard

4,000sti/min (normal 3,500sti/min)

28.0mm

23

1.2〜3.2mm

171mm

MS-1261M

1.4〜4.2mm

10mm

190mm

3.2mm (1/8"), 4.0mm (5/32"), 4.8mm (3/16"),

5.6mm (7/32"), 6.4mm (1/4")

5.6mm (7/32"), 6.4mm (1/4"), 7.2mm (9/32"),

8.0mm (5/16"), 9.6mm (3/8")

MS-1261

By push-button (with locking mechanism)

Semi-automatic lubrication

JUKI New Defrix Oil No.1 (equivalent to ISO VG7)

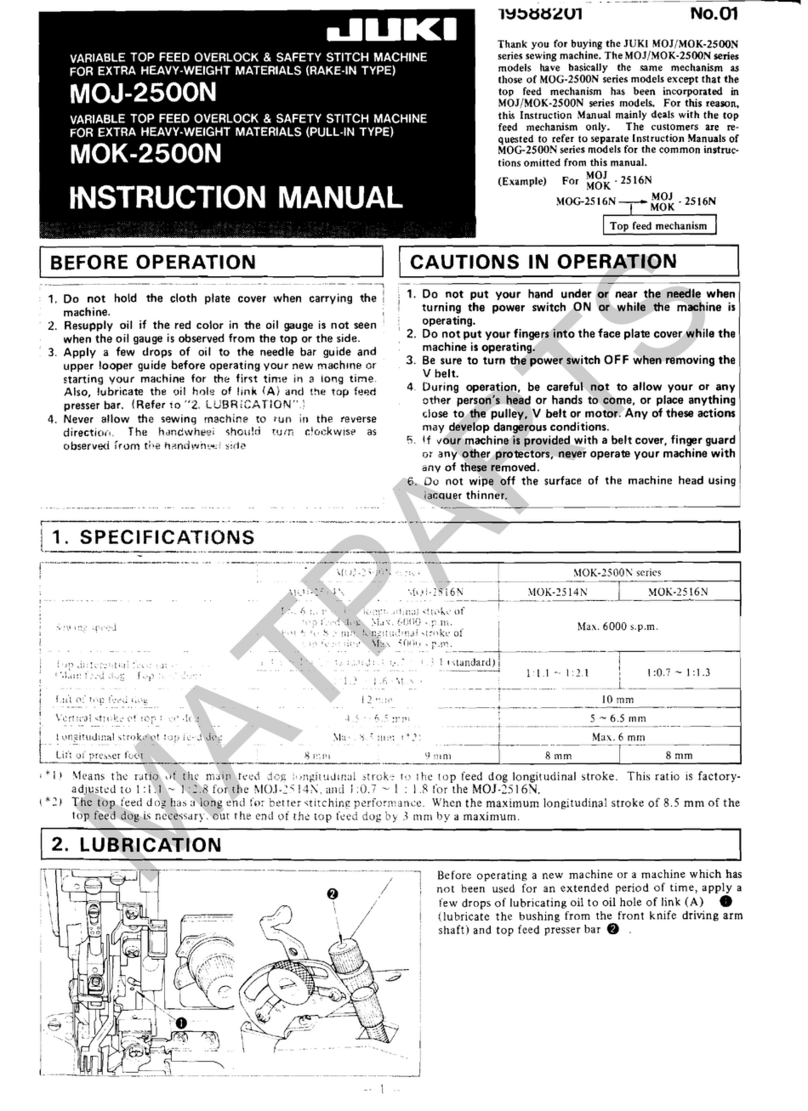

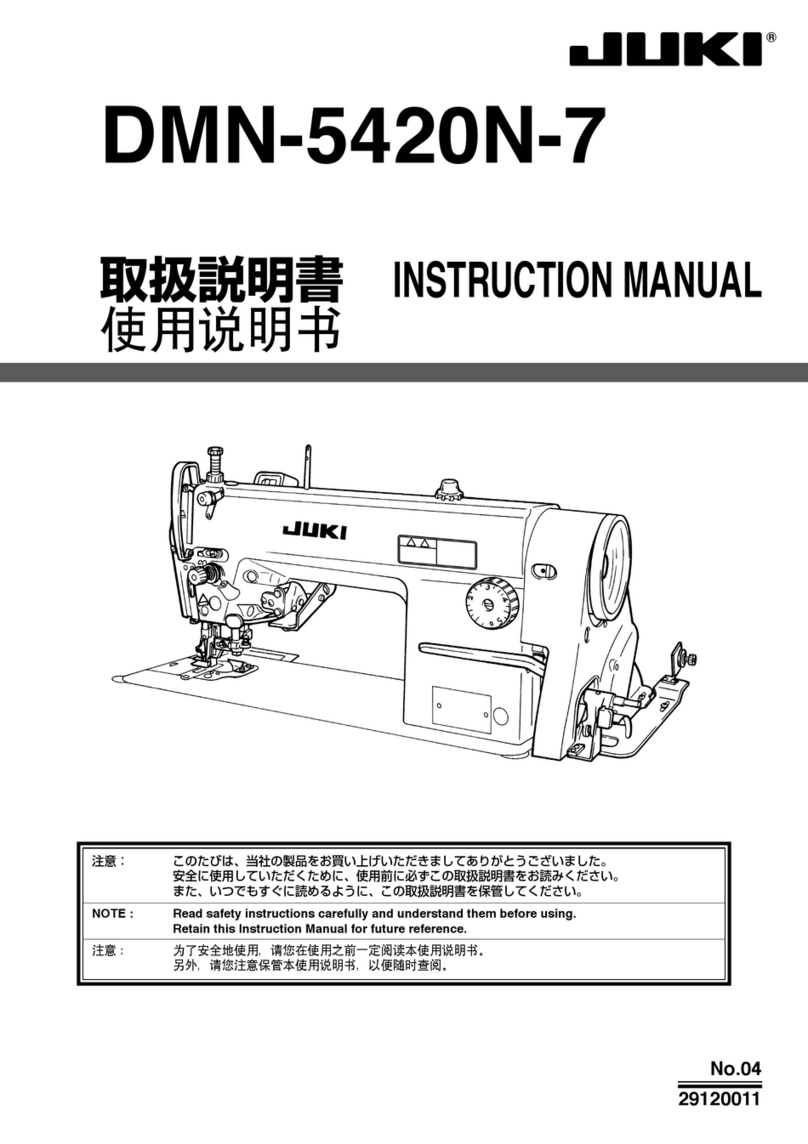

Application

No. of needle

Max. sewing speed

Needle bar stroke

Needle gauge

Stitch length

Lift of the presser foot

Thread take-up lever

Circumference of tube at

the needle entry

Needle guard

Stitch adjusting system

Lubrication

Lubricating oil

Needle

(at the time of delivery)

MS1190

M S12 61

Code

V045R

V045S

V046R

V046S

Rubber

Steel

Rubber

Steel

Cloth Puller

Not provided

V045

V046

Code

F

G

A

H

B

J

C

D

E

P

K

01

02

03

04*2

05*2

Optional device

Not provided

Chain-off

thread cutter

AT27*1

Needle cooler (CL-3)

Needle cooler with folder air blow type

Silicon oil lubricating

Pneumatic auto-lifter

AK81

A + C + E + K

A + D + E + K

A + C + P

H + C + E + P

J + C + P

Pedal switch type

Knee switch type

Pedal switch type

Knee switch type

Pedal switch type

Knee switch type

Pedal switch type

Knee switch type

Without

cloth puller

For V045

For V046

To order, please contact your nearest JUKI distributor.

WHEN YOU PLACE ORDERS

SPECIFICATIONS

*"sti/min" stands for "Stitches per Minute."

SEWING MACHINERY BUSINESS UNIT

MARCH, 2012 Printed in Japan(C)

2-11-1, TSURUMAKI, TAMA-SHI,

TOKYO

206-8551, JAPAN

PHONE : (81)42-357-2254

FAX : (81)42-357-2274

http://www.juki.com

✽

Specifications and appearance are subject to change without prior notice for improvement.

✽

Read the instruction manual before putting the machine into service to ensure safety.

✽

This catalogue prints with environment-friendly soyink on recycle paper.

Juki Corporation operates an environmental management system

to promote and conduct the following as the company engages in

the research, development, design, sales, distribution,and

maintenance of industrial sewing machines, household sewing

machines, industrial robots, etc., and in the provision of sales and

maintenance services for data entry systems:

(1) The development of products and engineering processes

that are safe to the environment

(2) Green procurement and green purchasing

(3)

Energy conservation (reduction in carbon-dioxide emissions)

(4) Resource saving (reduction of papers purchased, etc.)

(5) Reduction and recycling of waste

(6) Improvement of logistics efficiency (modal shift and

improvement of packaging, packing, etc.)