2

Introduction ............................................................................................................................................................................3

Unpacking and Installation ....................................................................................................................................................4

Unpacking........................................................................................................................................................................4

Visible Loss or Damage ..................................................................................................................................................4

Concealed Loss or Damage............................................................................................................................................4

Packing List ....................................................................................................................................................................5

Selecting a Location ........................................................................................................................................................5

Leveling the Unit..............................................................................................................................................................5

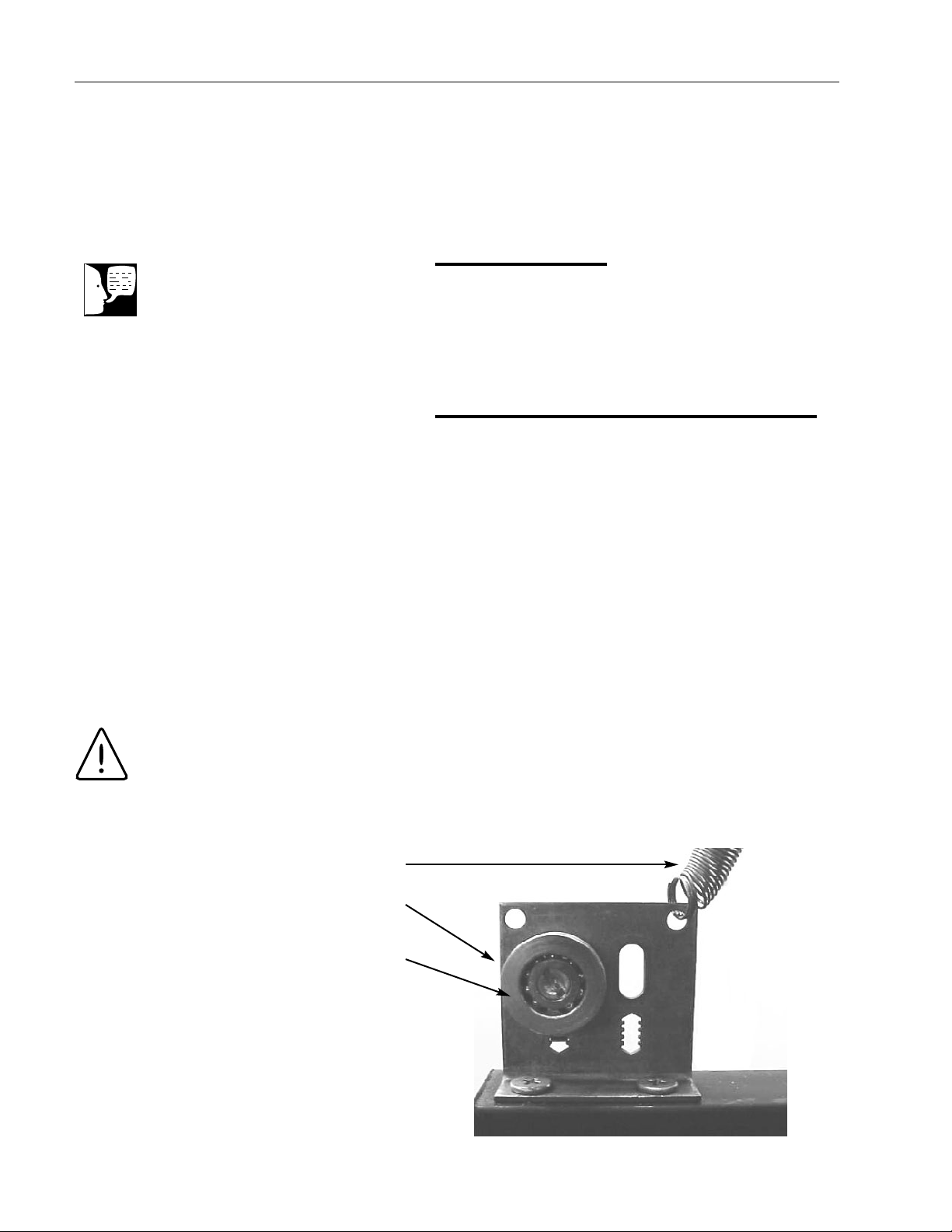

Door Handles ..................................................................................................................................................................6

Door Removal and Adjustment........................................................................................................................................6

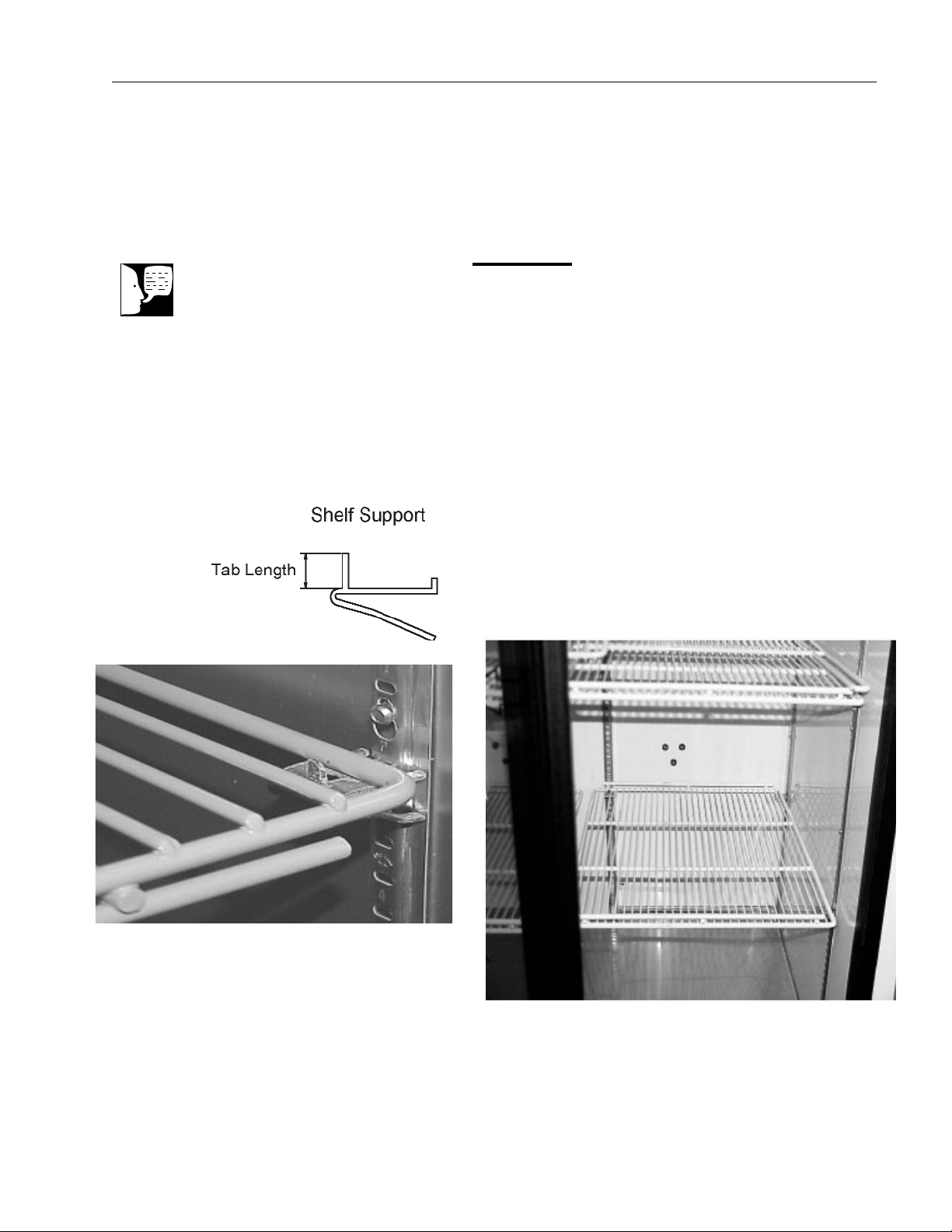

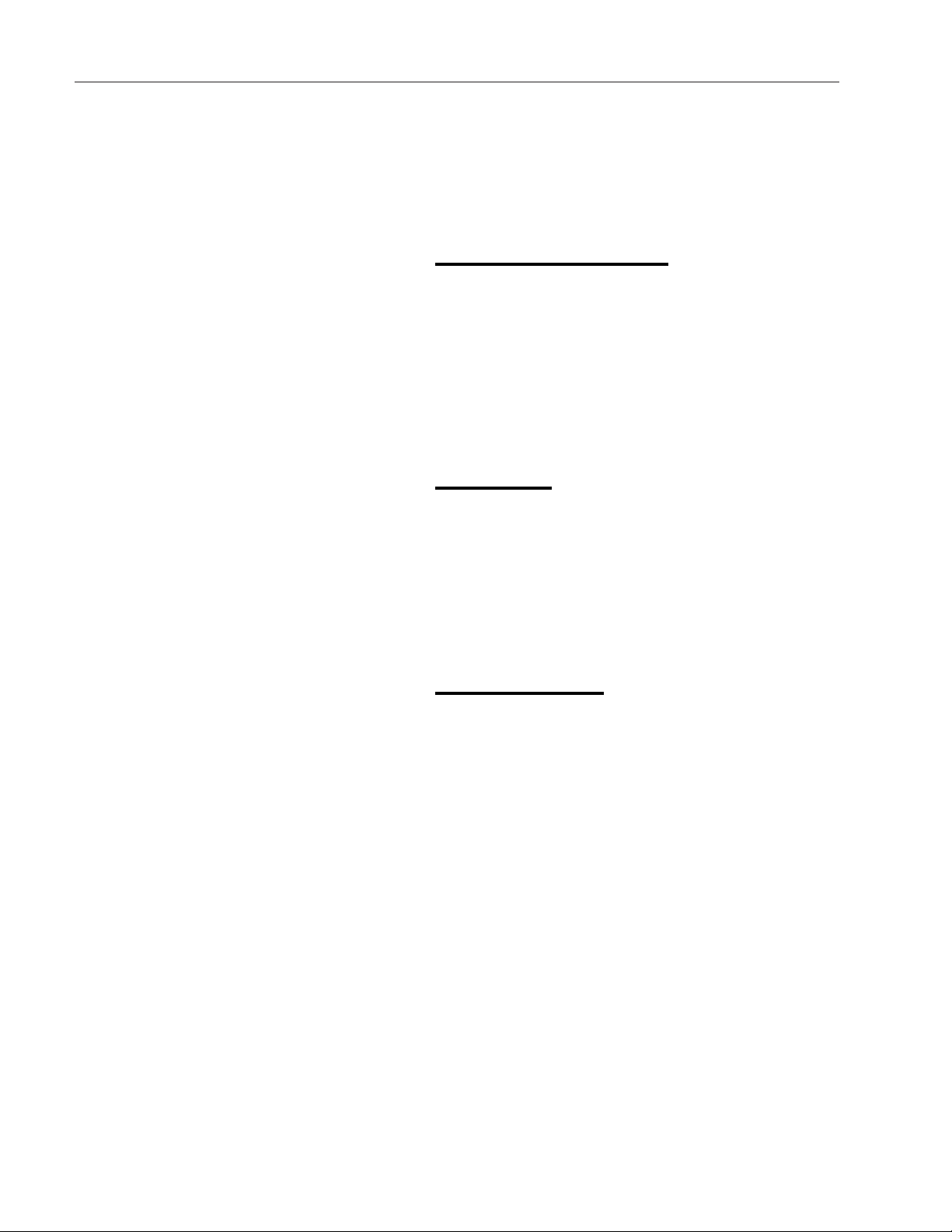

Shelves............................................................................................................................................................................7

Electrical Connection ......................................................................................................................................................8

Operation ................................................................................................................................................................................9

Controls Layout ..............................................................................................................................................................9

Temperature Controller....................................................................................................................................................9

Setting the Temperature ........................................................................................................................................10

Unit Select ..............................................................................................................................................................10

Calibration Offset....................................................................................................................................................10

Hold-Off Time ........................................................................................................................................................11

Error Codes ..................................................................................................................................................................11

Fluorescent Lamps........................................................................................................................................................11

Convenience Outlet ......................................................................................................................................................12

Manual/Automatic Condenser Fan................................................................................................................................12

Troubleshooting ....................................................................................................................................................................13

Maintenance ........................................................................................................................................................................14

Cabinet Cleaning ..........................................................................................................................................................14

Cleaning the Condensor................................................................................................................................................14

Condensate Evaporator Pan ........................................................................................................................................14

Replacement Parts ..............................................................................................................................................................15

Specifications........................................................................................................................................................................16

Performance Characteristics ........................................................................................................................................16

Power Requirements ....................................................................................................................................................16

Wiring Diagrams ..................................................................................................................................................................17

Warranty ..............................................................................................................................................................................20

Table of Contents