Introduction ..................................................................................................................................................................3

Installation ....................................................................................................................................................................4

Shipping Carton ....................................................................................................................................................4

Location ................................................................................................................................................................4

Electrical ................................................................................................................................................................4

Be Advised ............................................................................................................................................................5

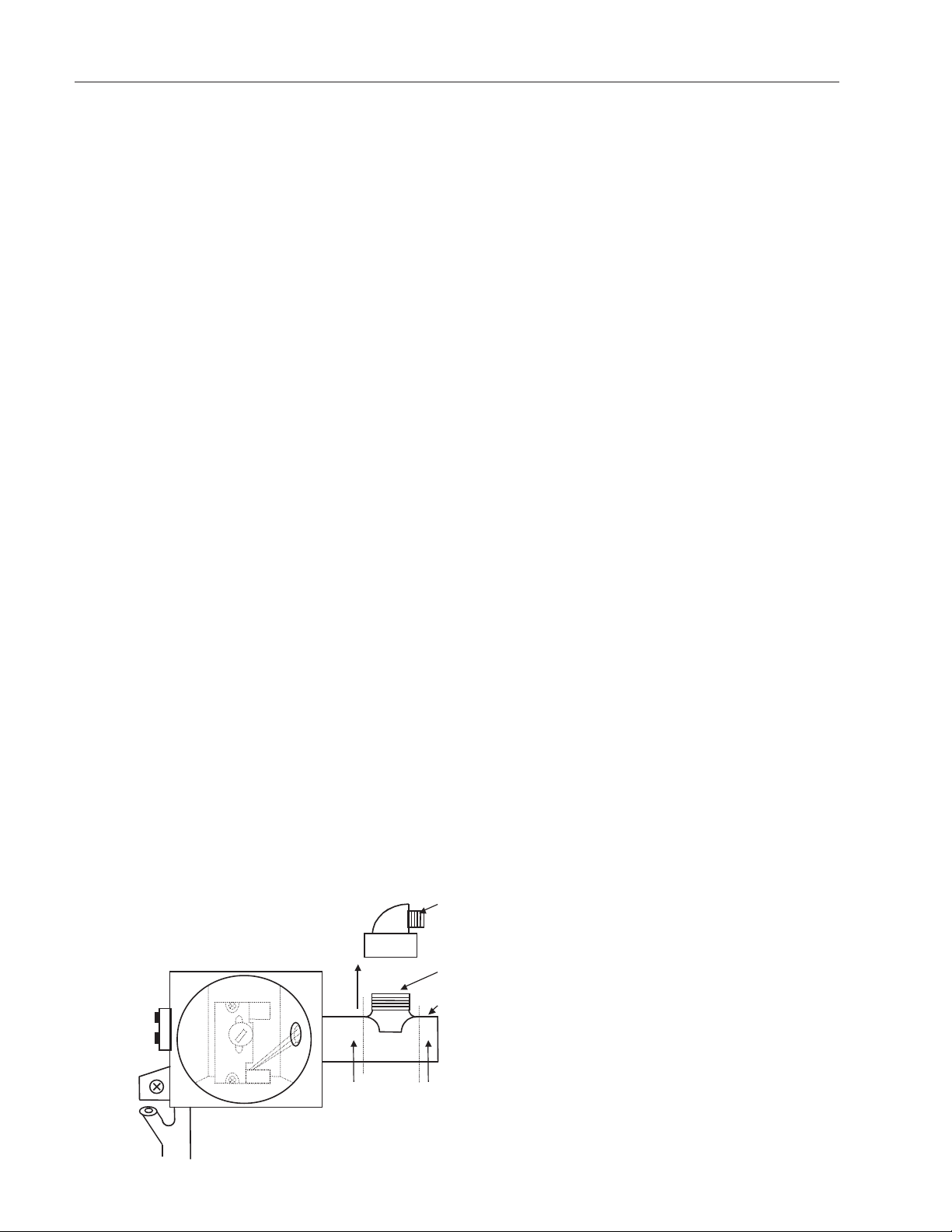

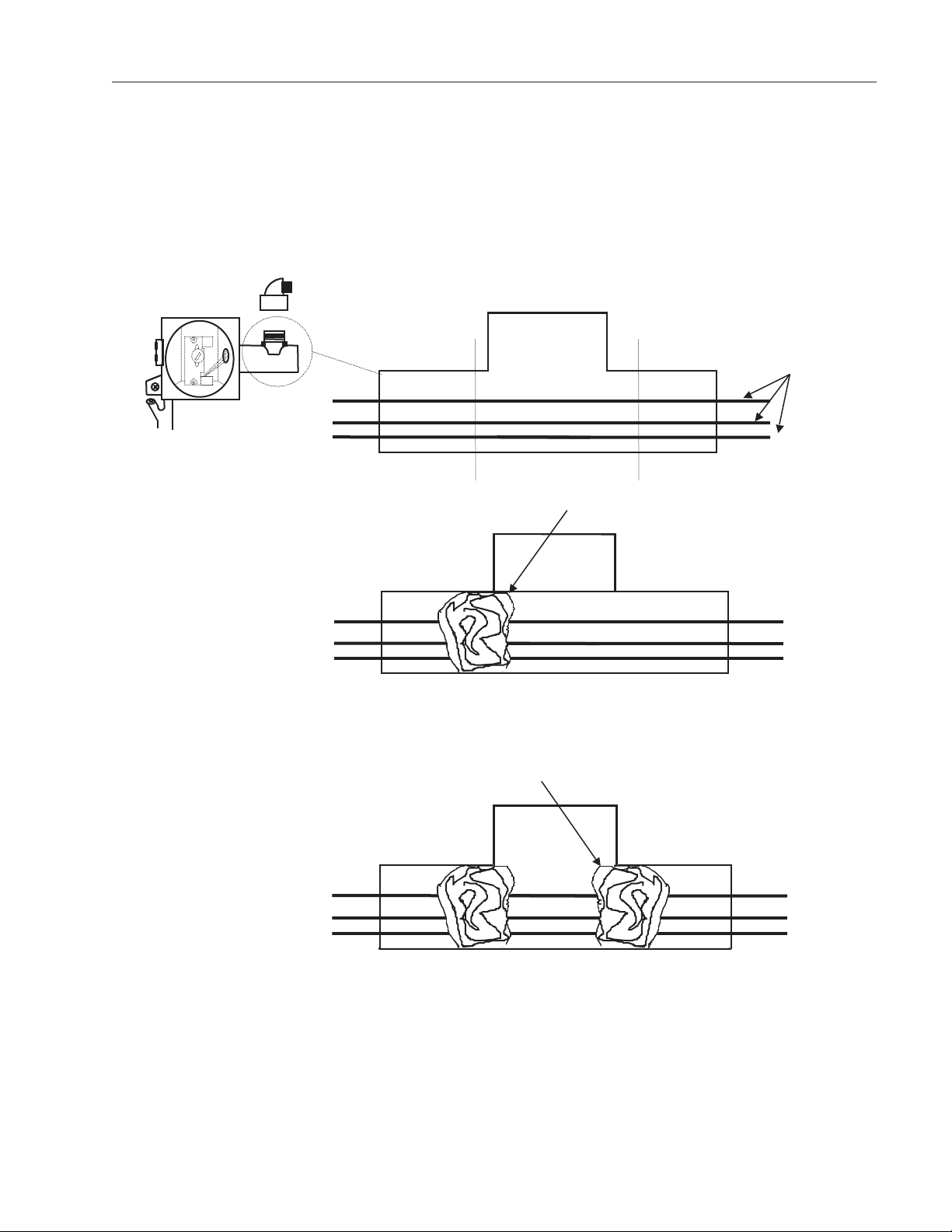

Sealing Killark Box Conduit to Help Protect Against Explosions ..........................................................................6

Operation......................................................................................................................................................................9

Environmental Operating Conditions ....................................................................................................................9

Child Entrapment Warning ....................................................................................................................................9

Start-Up Procedure................................................................................................................................................9

Restart Procedure................................................................................................................................................10

Manual Defrost Procedure ..................................................................................................................................10

How to Save Energy ............................................................................................................................................11

Safety Tips ..........................................................................................................................................................11

Reversing the Front Door (Model 97-920-1) ......................................................................................................12

eneral Purpose Laboratory Units ............................................................................................................................13

Model 97-920-1....................................................................................................................................................13

Model 97-915-1....................................................................................................................................................14

Model 97-960-1....................................................................................................................................................15

Model 97-926-1....................................................................................................................................................16

Flammable Materials Storage Units ..........................................................................................................................17

Overview..............................................................................................................................................................17

Model 97-925-1....................................................................................................................................................18

Model 97-938-1 ....................................................................................................................................................19

Model 97-935-1....................................................................................................................................................20

Explosion-Proof Units ................................................................................................................................................21

Model 97-952-1....................................................................................................................................................21

Model 97-928-1....................................................................................................................................................22

Model 97-950-1....................................................................................................................................................23

Options ......................................................................................................................................................................24

Optional Dolly ......................................................................................................................................................24

Installation Instructions ................................................................................................................................24

Optional Buzzer Alarm ........................................................................................................................................25

Maintenance ..............................................................................................................................................................27

Be Advised ..........................................................................................................................................................27

Cleaning of Units ................................................................................................................................................27

Interior/Exterior and Door askets ..............................................................................................................27

Condenser ....................................................................................................................................................27

Troubleshooting ..........................................................................................................................................................28

Replacement Parts ....................................................................................................................................................29

Warranty ....................................................................................................................................................................31

2

Table of Contents