Safety Information

Your satisfaction and safety are important to Fisher Scientific and a complete understanding of this unit

is necessary to attain these objectives.

As the ultimate user of this apparatus, it is your responsibility to understand its proper function and

operational characteristics. This instruction manual should be thoroughly read and all operators given

adequate training before attempting to place this unit in service. Awareness of the stated cautions and

warnings, and compliance with recommended operating parameters – together with maintenance

requirements – are important for safe and satisfactory operation. The unit should be used for its intended

application; alterations or modifications will void the Warranty.

This product is not intended, nor can it be used, as a sterile or patient connected device. In addition, this

apparatus is not designed for use in Class I, II or III locations as defined by the US National Electrical

Code, unless otherwise noted.

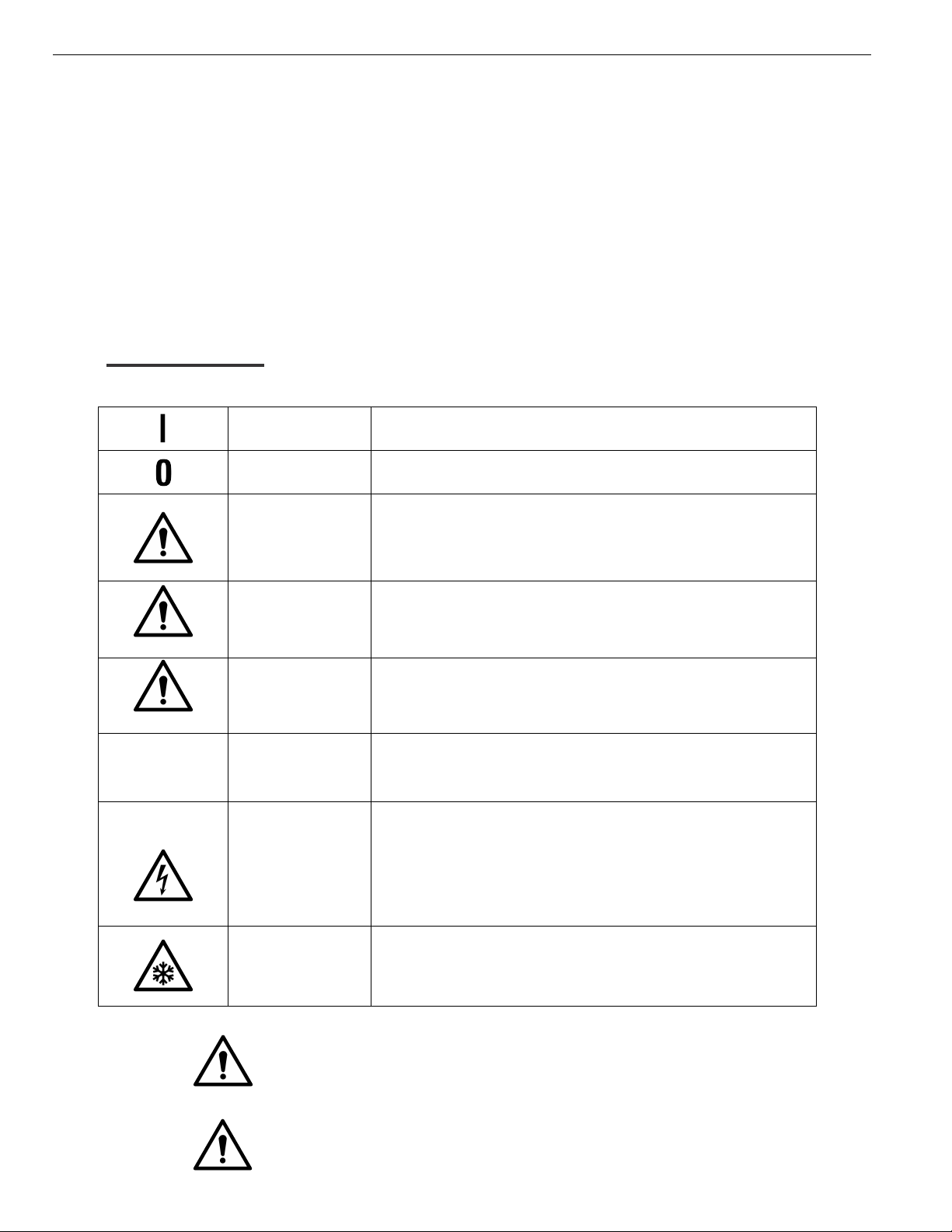

Alert Signals

DANGER RISK OF CHILD ENTRAPMENT

Before you throw away your old refrigerator or freezer:

Take off doors

Leave the shelves in the place so that children may not easily climb inside.

If the equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

ON

OFF

Safety Alert

Important operating instructions. To reduce the risk of injury

or poor performance of the unit. Read the user manual before

putting the equipment into operation.

WARNING

Indicates an immediately hazardous situation, which if

not avoided, will result in death or serious injury.

CAUTION

Indicates an immediately hazardous situation, which if

not avoided, may result in minor to moderate injury.

(No symbol)

CAUTION

(Without Safety Alert Symbol) indicates a situation that

may result in property damage.

Shock Hazard

Use of this equipment involves power supplies which convert

line voltage to low voltage power. Do not modify or use power

supplies other than OEM equipment. Connection of the

power supply may require a properly grounded receptacle.

Potential for electrical shock or equipment damage exists if

precautions are not followed.

Frost bite/

Low

Temperature

Avoid contact with cold freezer surfaces potential for

cold burns or skin sticking to cold surfaces.

3