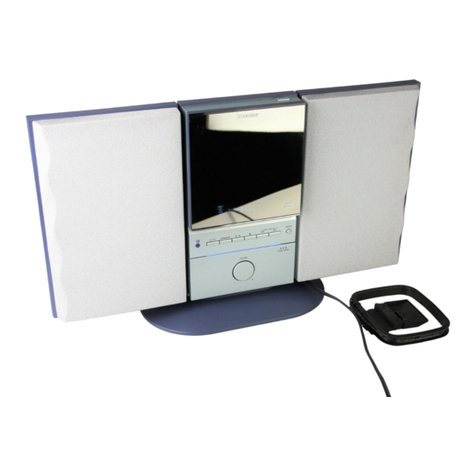

Fisher MC-715 User manual

Other Fisher Stereo System manuals

Fisher

Fisher Slim-1400 User manual

Fisher

Fisher SLIM-1700 User manual

Fisher

Fisher SLIM-1700 User manual

Fisher

Fisher SLIM-1600 User manual

Fisher

Fisher DCS-DA380 Assembly instructions

Fisher

Fisher SLIM-1600 User manual

Fisher

Fisher DCS-DTA200 User manual

Fisher

Fisher PH-DTA100 User manual

Fisher

Fisher MC-929 User manual

Fisher

Fisher TAD-9415 User manual

Fisher

Fisher PH-DTA100 User manual

Fisher

Fisher PH-DTA100 User manual

Fisher

Fisher digital slim -1400 User manual

Fisher

Fisher 510 series User manual

Fisher

Fisher DCS-DTA200 User manual

Fisher

Fisher PH-DTA300M User manual

Fisher

Fisher FM-P7 User manual

Fisher

Fisher DCS-DA380 User manual

Fisher

Fisher P7 User manual

Fisher

Fisher Ambassador IV User manual