Table of Contents

Section 1 Introduction................................................................................................................1

Intended Use.............................................................................................................. 1

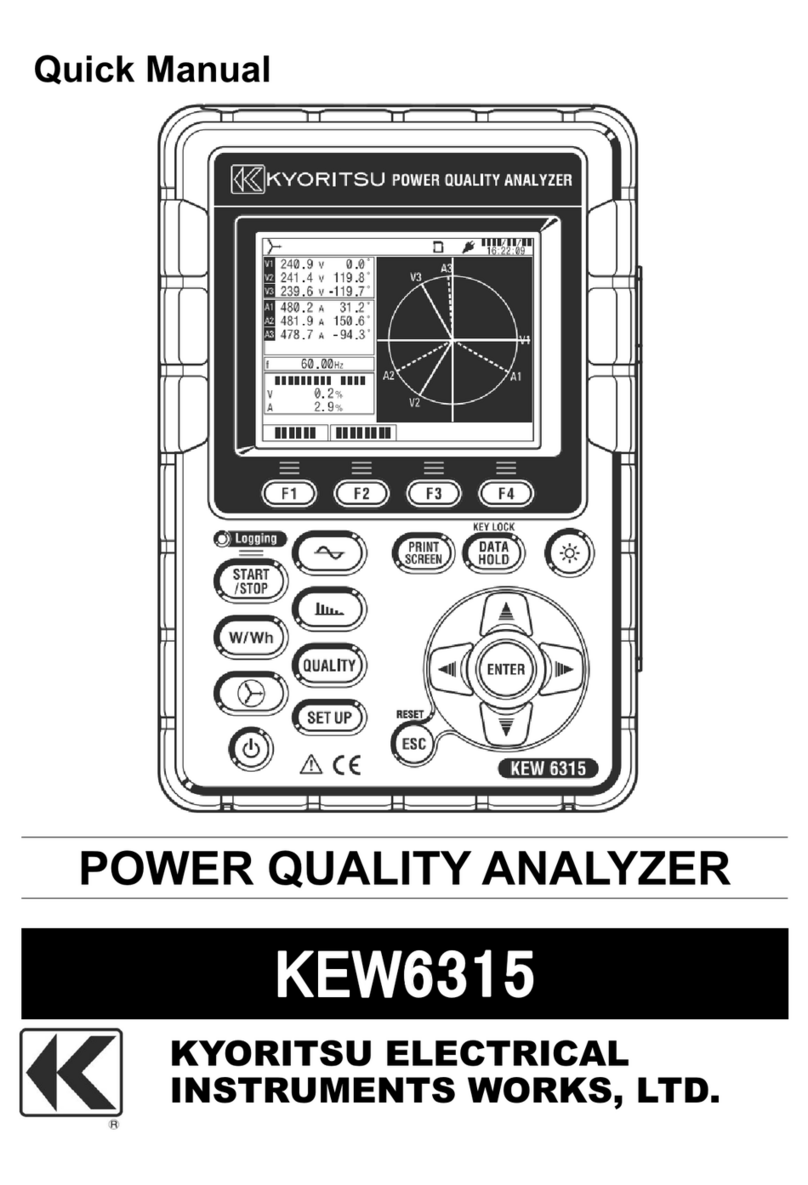

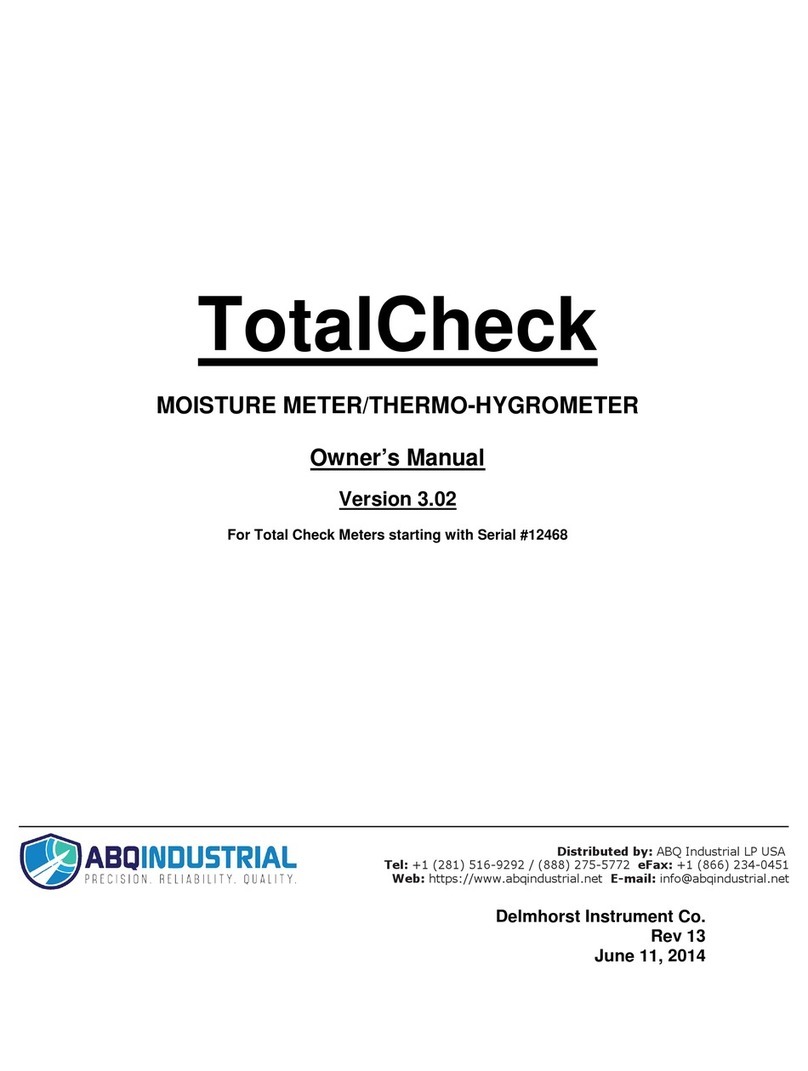

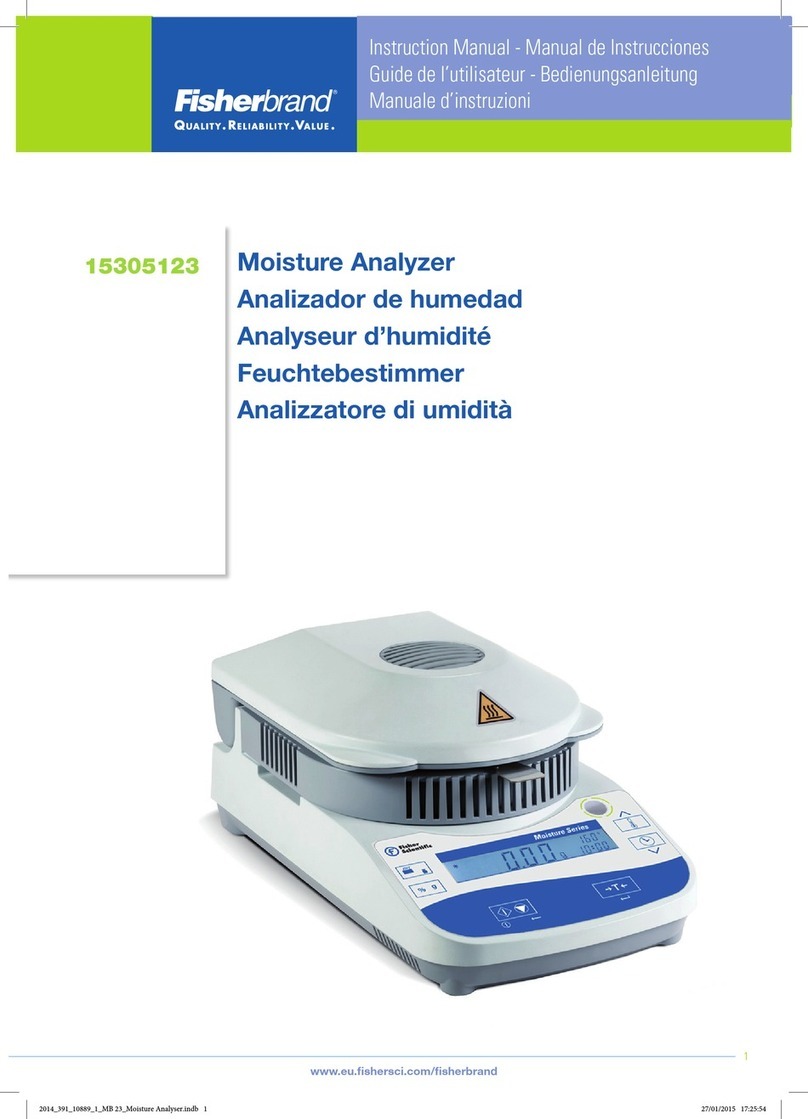

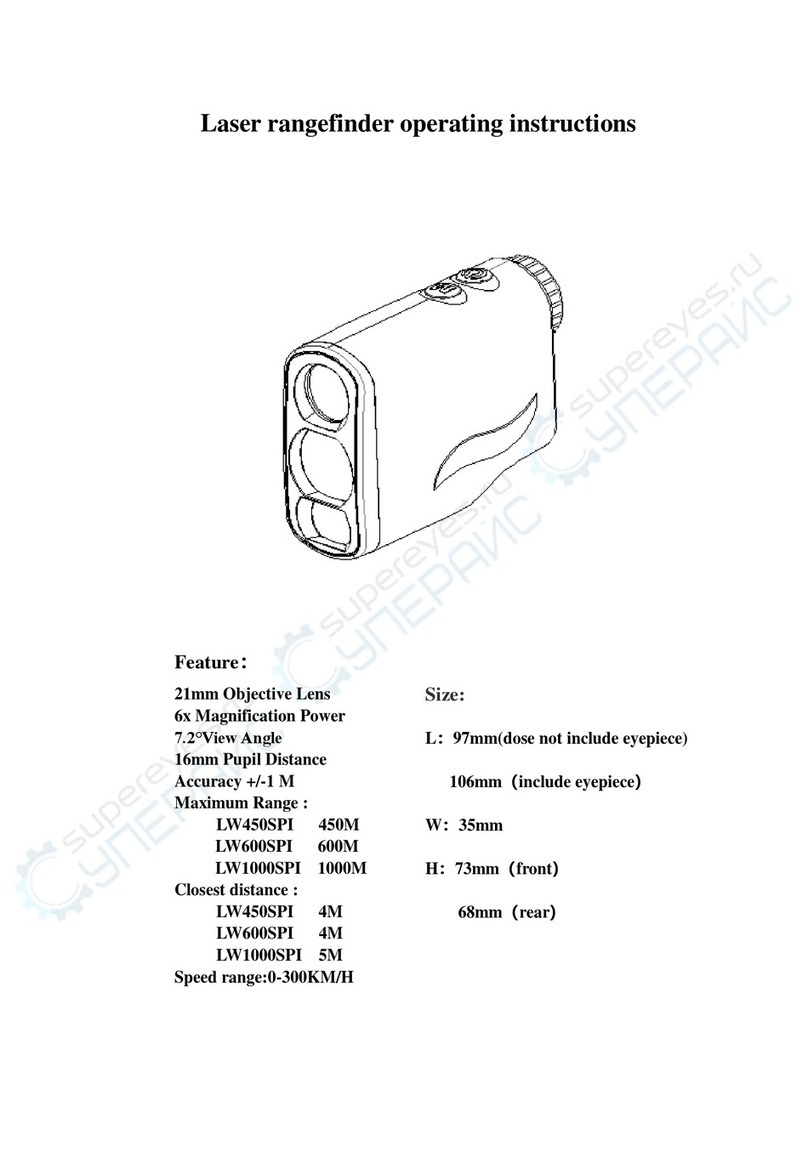

Section 2 Analyzer Components...............................................................................................2

Analyzer Component Illustrations............................................................................... 2

Section 3 Initial Startup..............................................................................................................3

Section 4 Analyzer Setup...........................................................................................................5

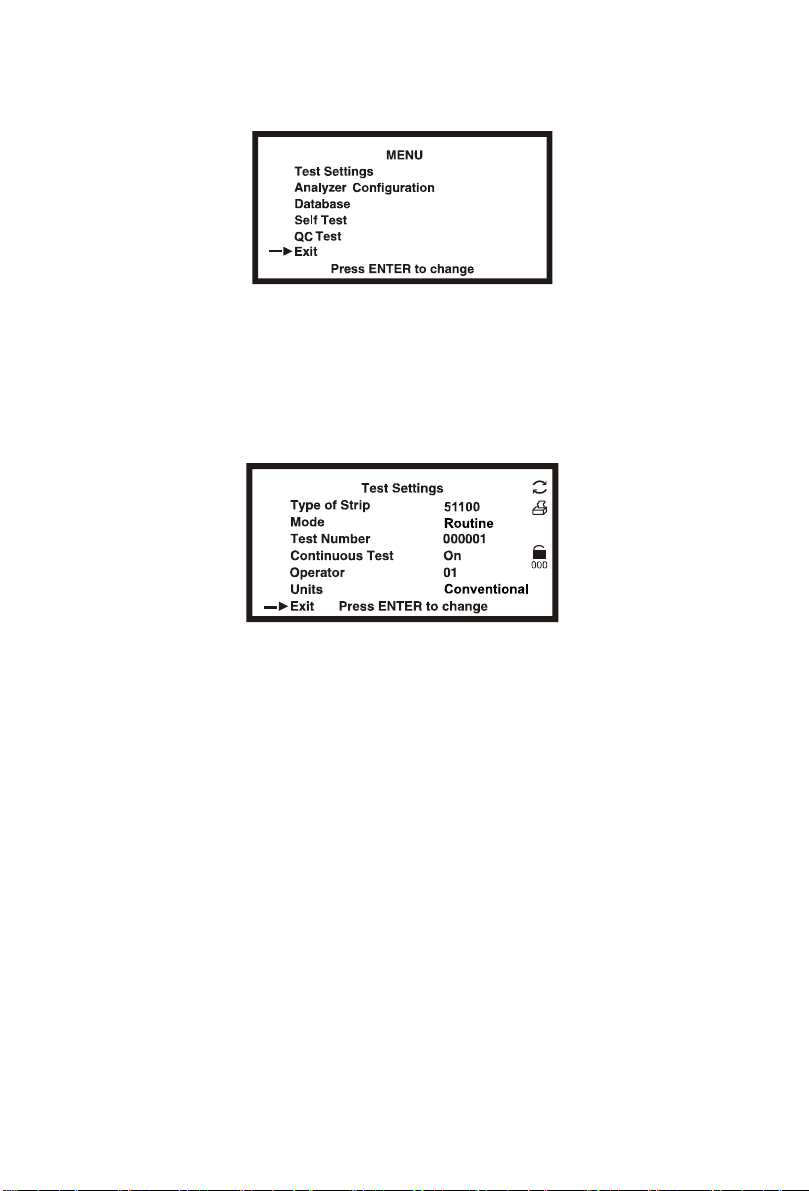

Test Settings..........................................................................................................5

Type of Strip............................................................................................................... 5

Mode.......................................................................................................................... 6

Test Number............................................................................................................... 6

Continuous Test ......................................................................................................... 7

Operator ID................................................................................................................ 7

Units...........................................................................................................................7

Analyzer Configuration.........................................................................................7

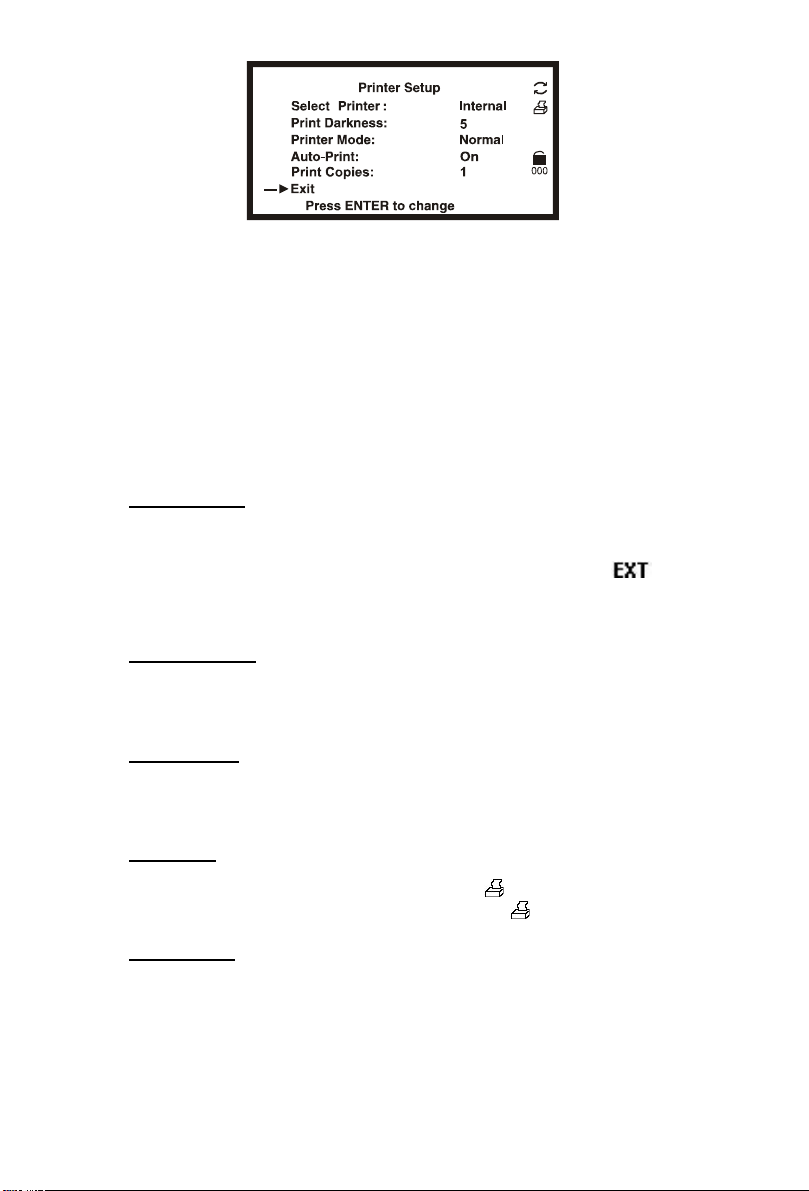

Printer Setup.............................................................................................................. 7

Sound......................................................................................................................... 8

Barcode reader.......................................................................................................... 9

Language................................................................................................................... 9

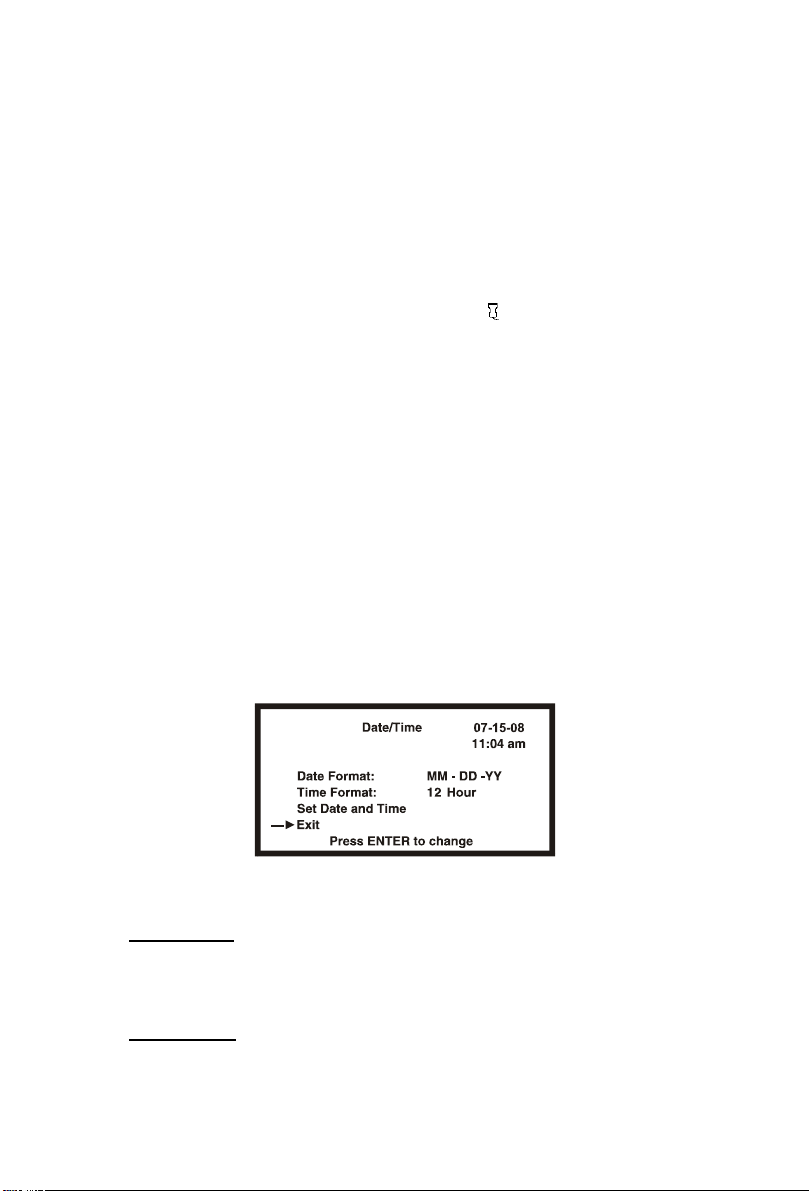

Date/Time................................................................................................................... 9

Auto Number Reset.................................................................................................. 10

Database...............................................................................................................10

Clear all Records.......................................................................................................11

Locate Record...........................................................................................................11

View Current Record.................................................................................................11

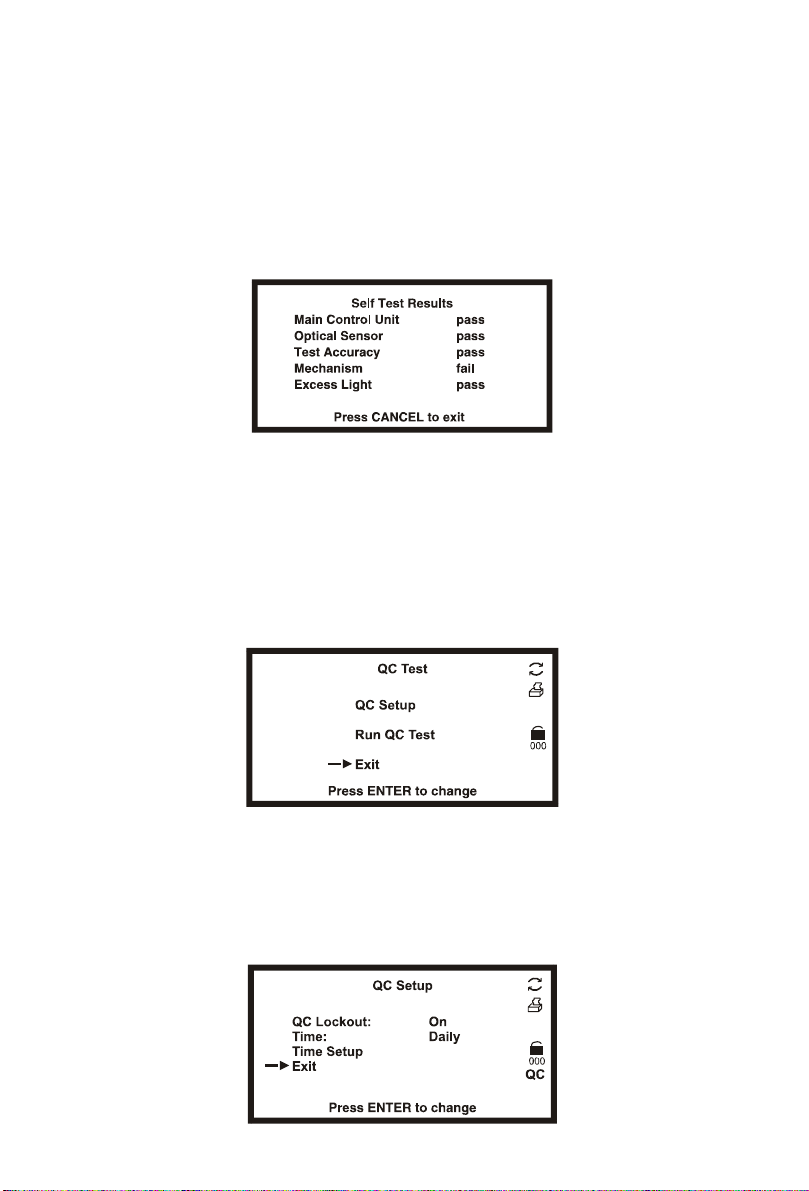

Self Test................................................................................................................12

QC Test.................................................................................................................12

QC Setup................................................................................................................. 12

Run QC Test............................................................................................................. 13

Setting the QC Values.............................................................................................. 14

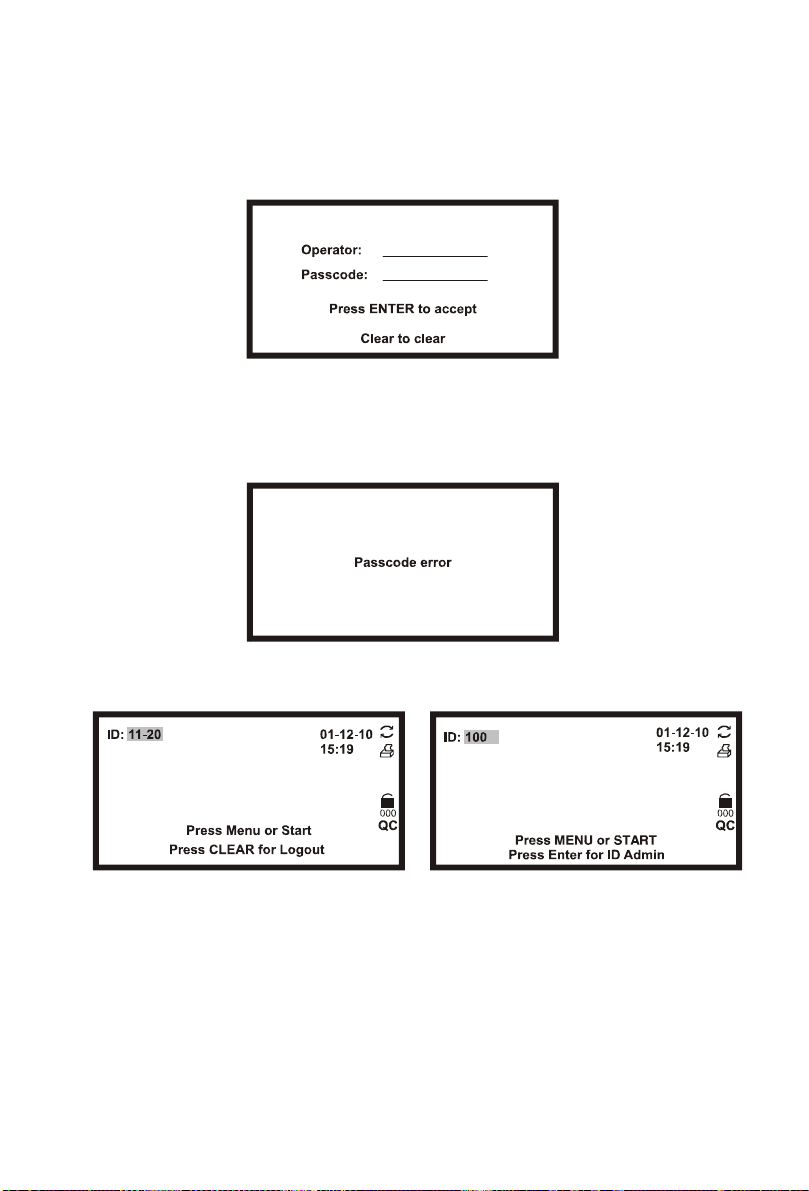

User Login............................................................................................................14

ID Admin .................................................................................................................. 14

Section 5 Analyzer Operation..................................................................................................17

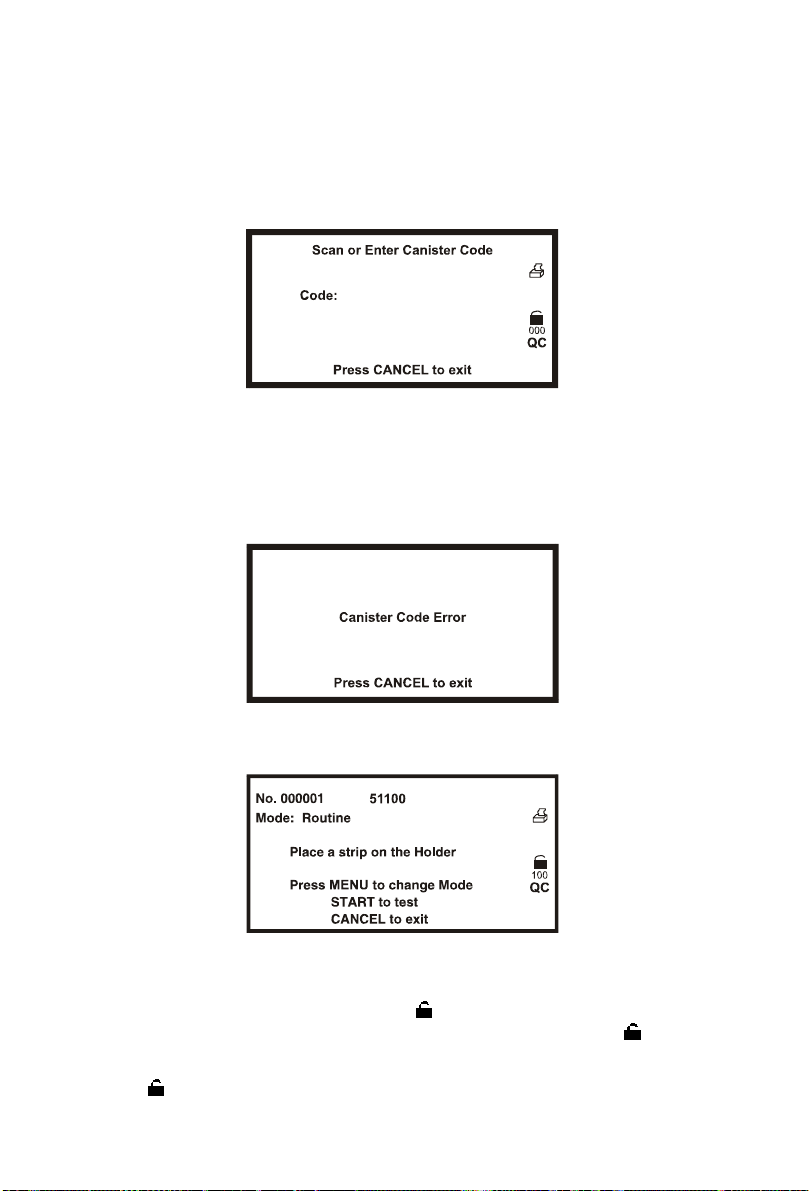

Entering Canister Code ......................................................................................19

Normal Operation, no Barcode reader ..............................................................20

Sample/Strip Preparation......................................................................................... 20

Strip Test – Single Test Mode................................................................................... 20

Strip Test – Continuous Test Mode........................................................................... 22

Normal Operation, Barcode reader installed....................................................23

Strip Test – Single Test Mode with Barcode reader.................................................. 23

Strip Test – Continuous Test Mode with Barcode reader.......................................... 24

Urine Controls QC Testing .................................................................................26

Strip Preparation ...................................................................................................... 26

Urine Control Test Procedures................................................................................. 27

QC lockout ...........................................................................................................27

Section 6 Data/Communication...............................................................................................29

External Printer ........................................................................................................ 29

Barcode reader........................................................................................................ 29

Section 7 Quality Control.........................................................................................................30

Section 8 Maintenance.............................................................................................................31

Loading Printer Paper.........................................................................................31

General Cleaning.................................................................................................32

Daily Cleaning......................................................................................................32

Remove the Strip Holder.......................................................................................... 32

Clean the Strip Holder.............................................................................................. 32

Load the Strip Holder............................................................................................... 32

Return the Strip Holder/Mount to its Internal Position............................................... 33

Sample Deposit Cleaning ...................................................................................33

Strip Holder Sterilization.....................................................................................33

Section 9 Precautions ..............................................................................................................34

Section 10 Troubleshooting.....................................................................................................35

Appendix 1 Urine Analyzer Specifications.............................................................................36

Appendix 2 Compatible Urinalysis Reagent Strips................................................................37

Appendix 3 Urinalysis Reagent Strips Parameter Table .......................................................43

Appendix 4 Result Print-Out....................................................................................................44

Appendix 5 Barcode reader.....................................................................................................45

Appendix 6 Catalog ..................................................................................................................46

Appendix 7 Index of Symbols..................................................................................................47

Appendix 8 Warranty................................................................................................................48