Sewhacnm SI 560A User manual

Digital Weighing Indicator

SI 560A

User Manual

2014.06.25

- 2 -

SI 560A DIN SIZE WEIGHING INDICATOR

CONTENTS

1. Before Installation······························· - 3 -

2. Introduction ······································ - 4 -

3. Specification ······································ - 5 -

4. Installation ·······································- 10 -

4-1. Dimension & Cutting Size················· - 10 -

4-2. Installation Components··················· - 10 -

4-3. Load Cell Installation······················· - 11 -

5. Set-up·············································- 12 -

5-1. TEST Weight Calibration Mode ··········· - 12 -

5-2. Simulating Calibration Mode ············· - 16 -

5-3. F-FUNCTION Setting ······················· - 20 -

5-4. Test Mode ··································· - 31 -

6. Interface ··········································- 32 -

6-1. Serial Interface ······························ - 32 -

6-2. Relay output·································- 38 -

6-3. Analog Output Interface(4~20mA)········ -39 -

6-4. Analog Output Interface(0~10V) ········· - 40 -

6-5. Serial Print ··································· - 41 -

7. Error & Treatment······························- 42 -

- 3 -

SI 560A DIN SIZE WEIGHING INDICATOR

1. BEFORE INSTALLATION

Caution / Warning Marks

This mark warns the possibility to arrive death or serious injury

in case of wrongly used.

This mark cautions the possibility to arrive serious human body

injury or product lose in case of wrongly used.

Copy Rights

1. All Right and Authority for this Manual is belonged to SEWHA CNM CO., LTD.

2. Any kinds of copy or distribution without permission of SEWHA CNM CO., LTD. will be

prohibited.

3. This manual may be changed as the version is upgraded, without previous notice.

Inquiries

If you have any kinds of inquiries for this model, please contact your local agent or Head Office.

Head Office : SEWHACNM CO., LTD.

Website : http://www.sewhacnm.co.kr

Email : sales@sewhacnm.co.kr

- 4 -

SI 560A DIN SIZE WEIGHING INDICATOR

2. INTRODUCTION

2-1. Introduction

Thank you for your choice of this SI 460A Industrial Digital Weighing Indicator.

This SI 560A model is high-performance weighing Indicator.

Please review and learn this instruction Manual and enjoy your process efficiency

with “SI 560A”Weighing Indicator.

2-2. Cautions

1. Don’t drop on the ground and avoid serious external damage on item.

2. Don’t install under sunshine or heavy vibrated condition.

3. Don’t install place where high voltage or heavy electric noise condition.

4. When you connect with other devices, please turn off the power of item.

5. Avoid from water damage.

6. For the improvement of function or performance, we can change item specification without

previous notice or permission.

7. Item’s performance will be up-dated continuously base on previous version’s performance.

2-3. Features

1. SI 560A model is the square DIN SIZE and compact enough, so it is easy to install.

2. Front panel is covered with Polycarbonate film, strong against dust and water.

3. RS422, RS485 serial interface and Modbus(RTU) is standard installed.

4. User can choose various options; 4-20mA, 0-10V, RS232C and Extra RS422, RS485.

- 5 -

SI 560A DIN SIZE WEIGHING INDICATOR

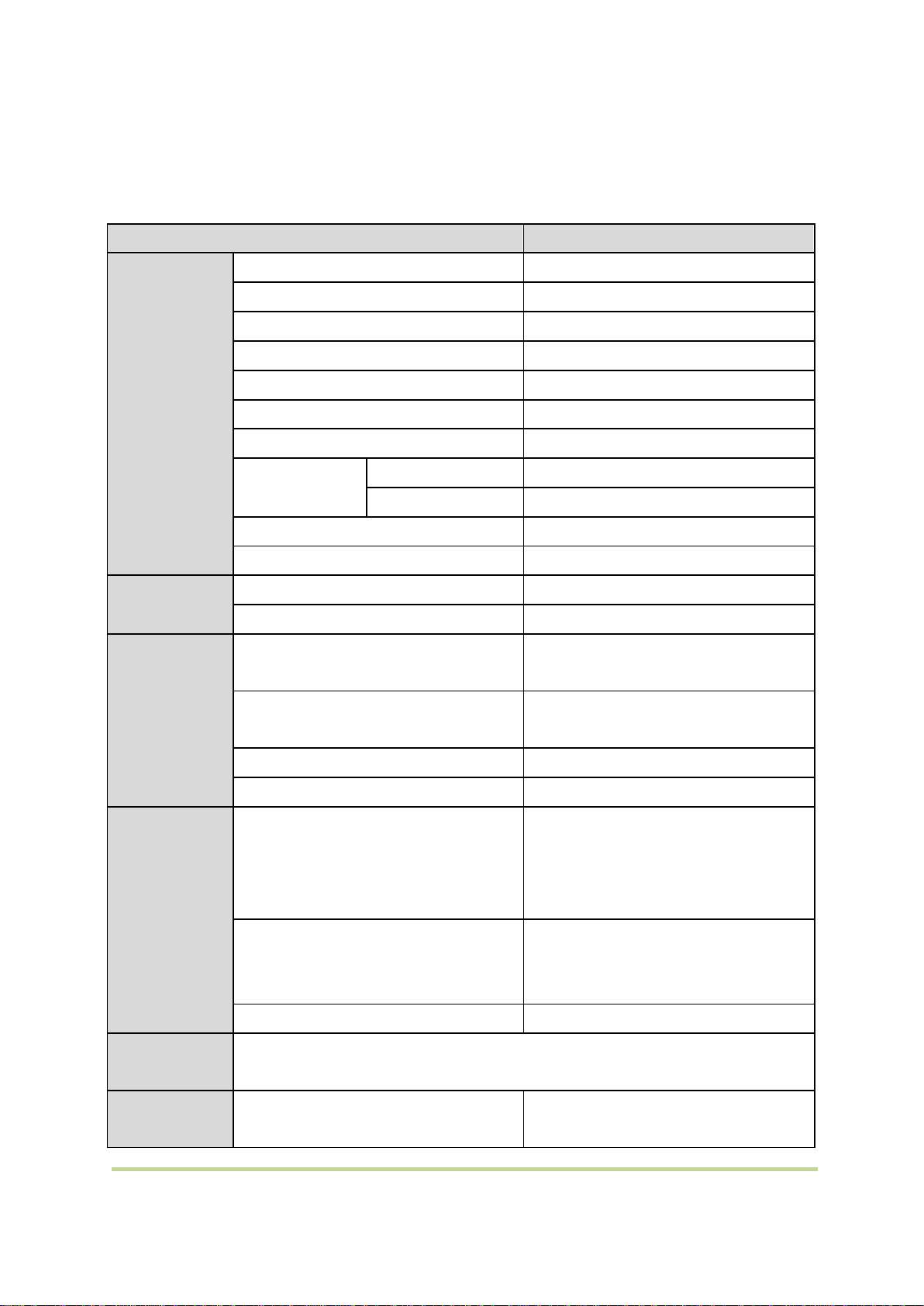

3. SPECIFICATION

3-1 Specification

Content

Specification

Performance

External Resolution

1/20,000

Internal Resolution

1/2,000,000 (±1,000,000)

Input Sensitivity

Min 0.1µV/V

Max Signal Input Voltage

3.0mV/V

Load cell Excitation

DC +5V

A/D Conversion Method

Sigma-Delta

Decimal Point

0, 0.0, 0.00, 0.000

Drift

Offset

10PPM/℃

Span

10PPM/℃

Linearity

0.001% of Full Scale

Analogue Sampling(sec)

Max 60times / sec

Environment

Operating Temperature Range

-10℃ ~ +40℃ [14℉ ~ 104℉]

Operation Humidity Range

40% ~ 85% RH, Non-condensing

Function

Calibration Mode

Test Weight Calibration Mode

Simulation Calibration Mode

Display

6 digit, 15mm(0.56inch) Red Color FND

10 digit, 13.5mm(0.36inch) Red Color FND

Key Pad

7pcs Standard Key pad

Additional Digital Input

4pcs external input key

Communi-

cation

Standard Serial Interface

(RS-422/485)

Data Transference

Command Mode

Serial Printer Mode

Modbus (RTU)

Option Serial Interface

(RS-232C)

Data Transference

Command Mode

Serial Printer Mode

Analog Output (Option)

0~10V, 4~20mA (Selectable)

Power

DC : 24V, Power Consumption 12W

AC (Option) : 110~220V, Power Consumption 12W

Size

96mm(W)ⅹ96mm(H)ⅹ116mm(D)

Weight : 500g (DC)

700g (AC.)

- 6 -

SI 560A DIN SIZE WEIGHING INDICATOR

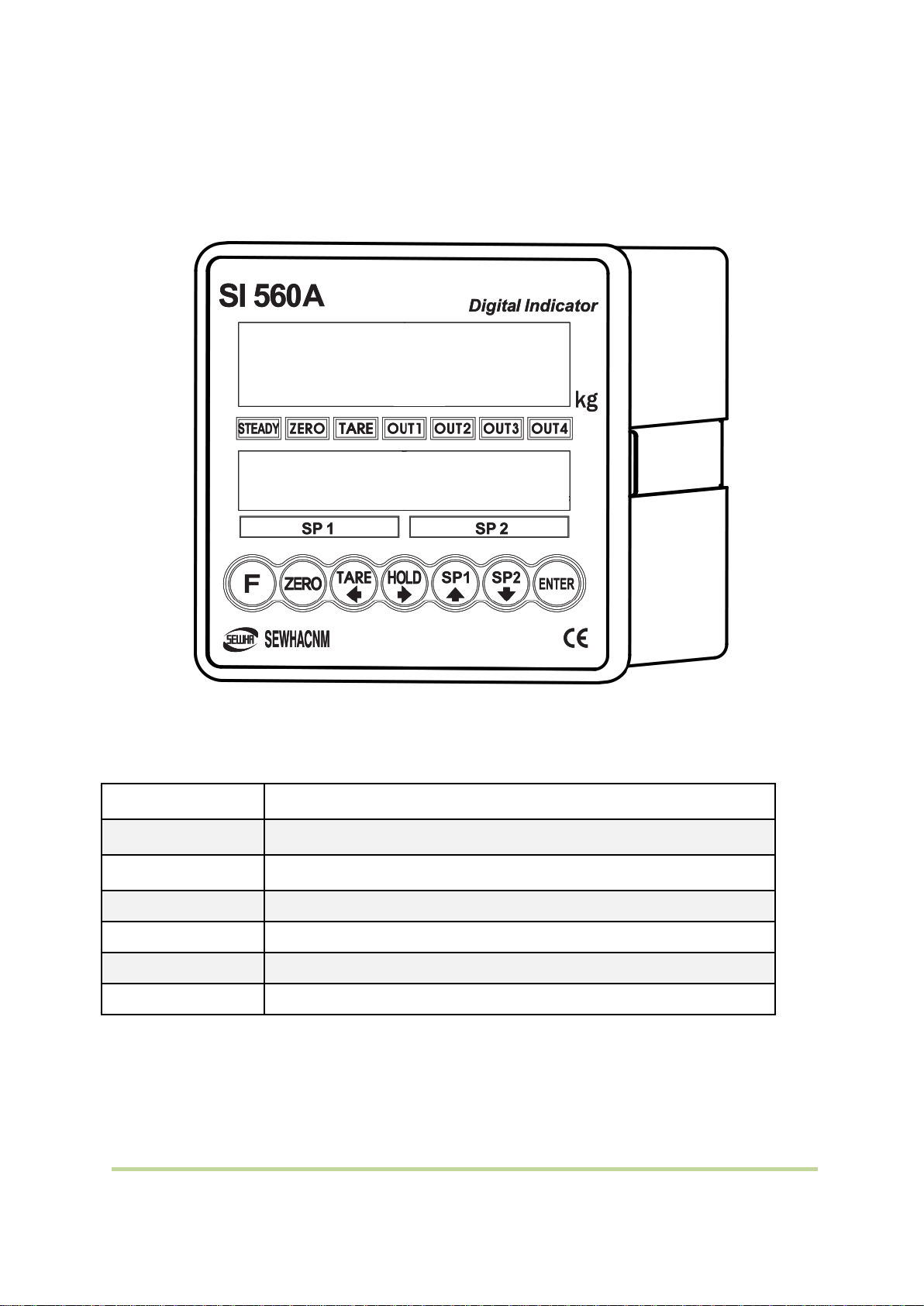

3-2. Front Panel

3-2-1 Front Panel (Display / Key Pad)

3-2-2. State LED

STEADY

When the weight is “STEADY”, ON.

ZERO

When the current weight is ”ZERO”, ON.

TARE

“TARE”function is set, ON.

OUT1

When OUT1 (Relay) is operated, ON.

OUT2

When OUT2 (Relay) is operated, ON.

OUT3

When OUT3 (Relay) is operated, ON.

OUT4

When OUT4 (Relay) is operated, ON.

- 7 -

SI 560A DIN SIZE WEIGHING INDICATOR

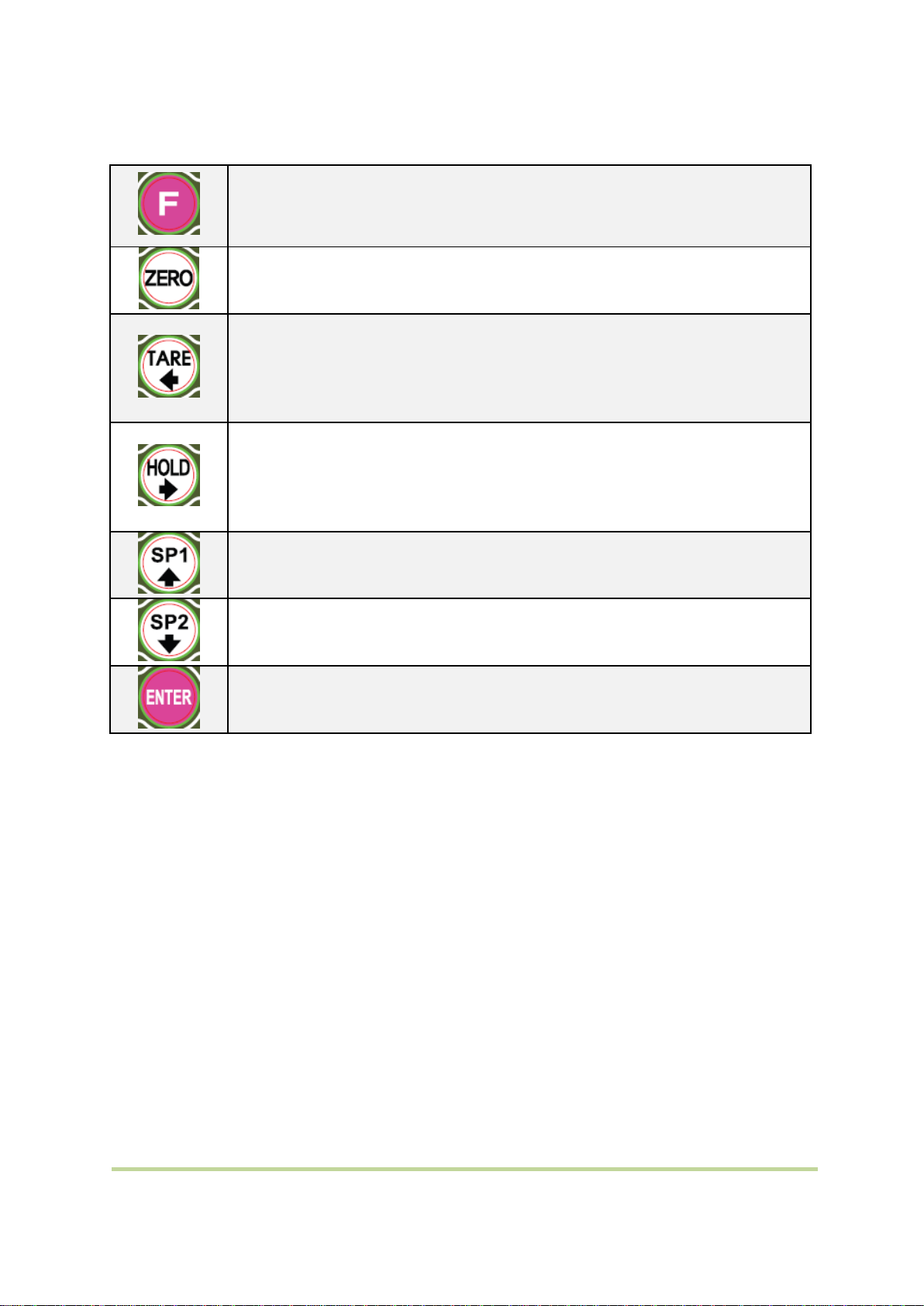

3-2-3. Key Operation

1. Press this key 4times, within 3secs, enter to “SET-UP”mode.

2. Press this key during 4secs, enter to “Hidden function”mode.

3. Cancel or ESC.

1. Make weight value to Zero.

2. Enter to P/N setting at the SP value setting stage

1. Set the TARE Function

1st input : “TARE”, 2nd input : “TARE Reset”

(When “HOLD”or weight value is ZERO, then this key doesn’t work.)

2. Moving the cursor to left.

1. Set the “HOLD”Function

1st input : “HOLD”, 2nd input : “HOLD Reset”

※When HOLD is on, “H”mark will be shown at the display.

2. Moving the cursor to right.

1. SP1 set value setting

2. Increase the value

1. SP2 set value setting

2. Decrease the value

1. Save

2. Manual print out key

- 8 -

SI 560A DIN SIZE WEIGHING INDICATOR

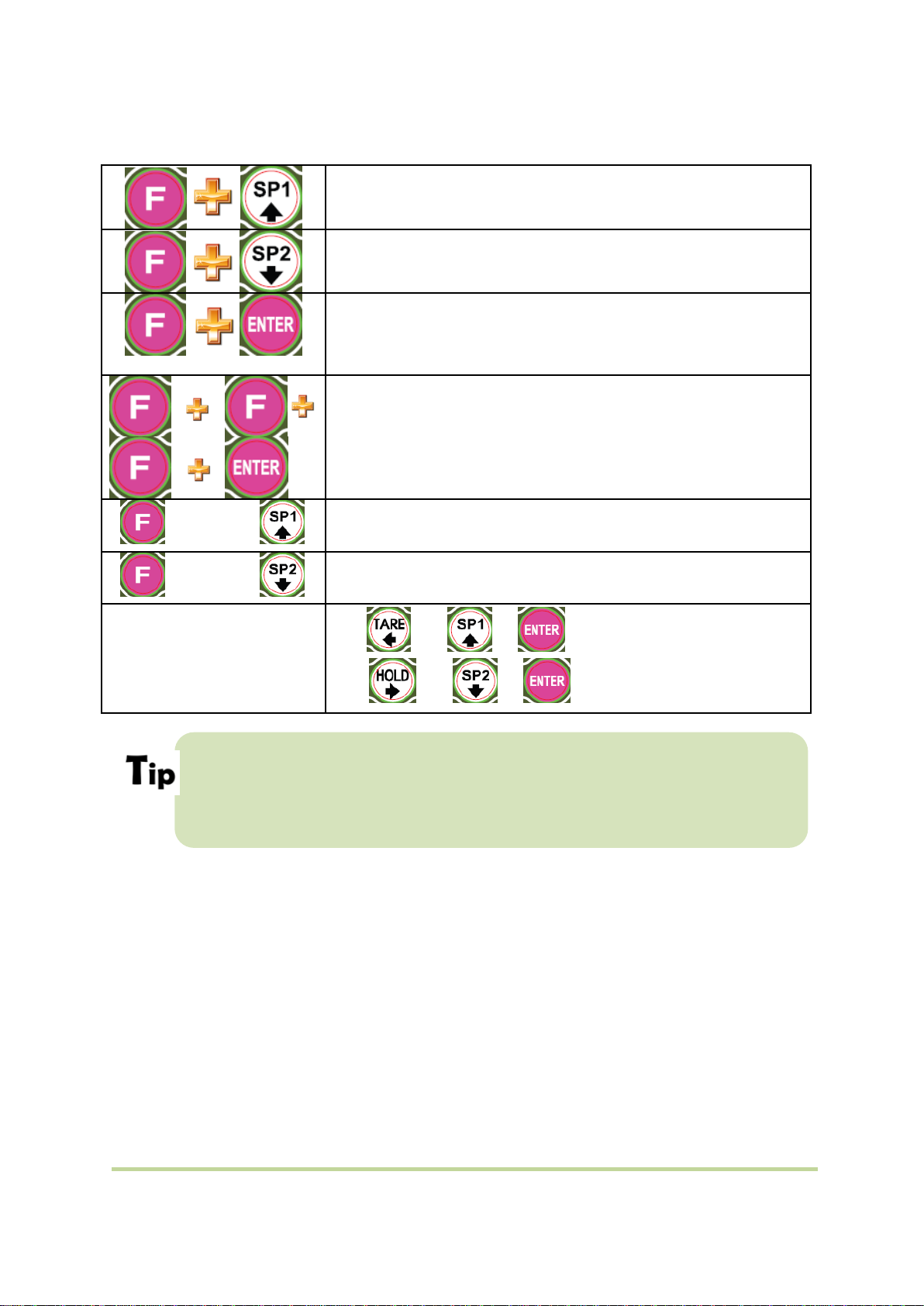

3-2-4. Hot key (Combine with F key)

SP3 Set value setting

SP4 Set value setting

If the Printer is installed,

You can print out the “Sub-total data”.

(Sub-total data cannot be displayed).

If the Printer is installed,

You can print out the “Grand-total data”.

(GRAND-total data cannot be displayed.)

key 4times

Delete Sub-total. (Sub-total data cannot be displayed).

key 4times

Delete Grand-total. (GRAND-total data cannot be displayed.)

At the deleting Sub-total

or Grand-total stage, key

operation for confirmation

question

No: OR +

Yes: OR +

Max accumulated weighing count : 999,999times

Over 999,999times return to “0” time

Max accumulated weight display : 999999999 (g, kg, ton)

Over 999,999,999 (g, kg, ton) return to “0” (g, kg, ton)

- 9 -

SI 560A DIN SIZE WEIGHING INDICATOR

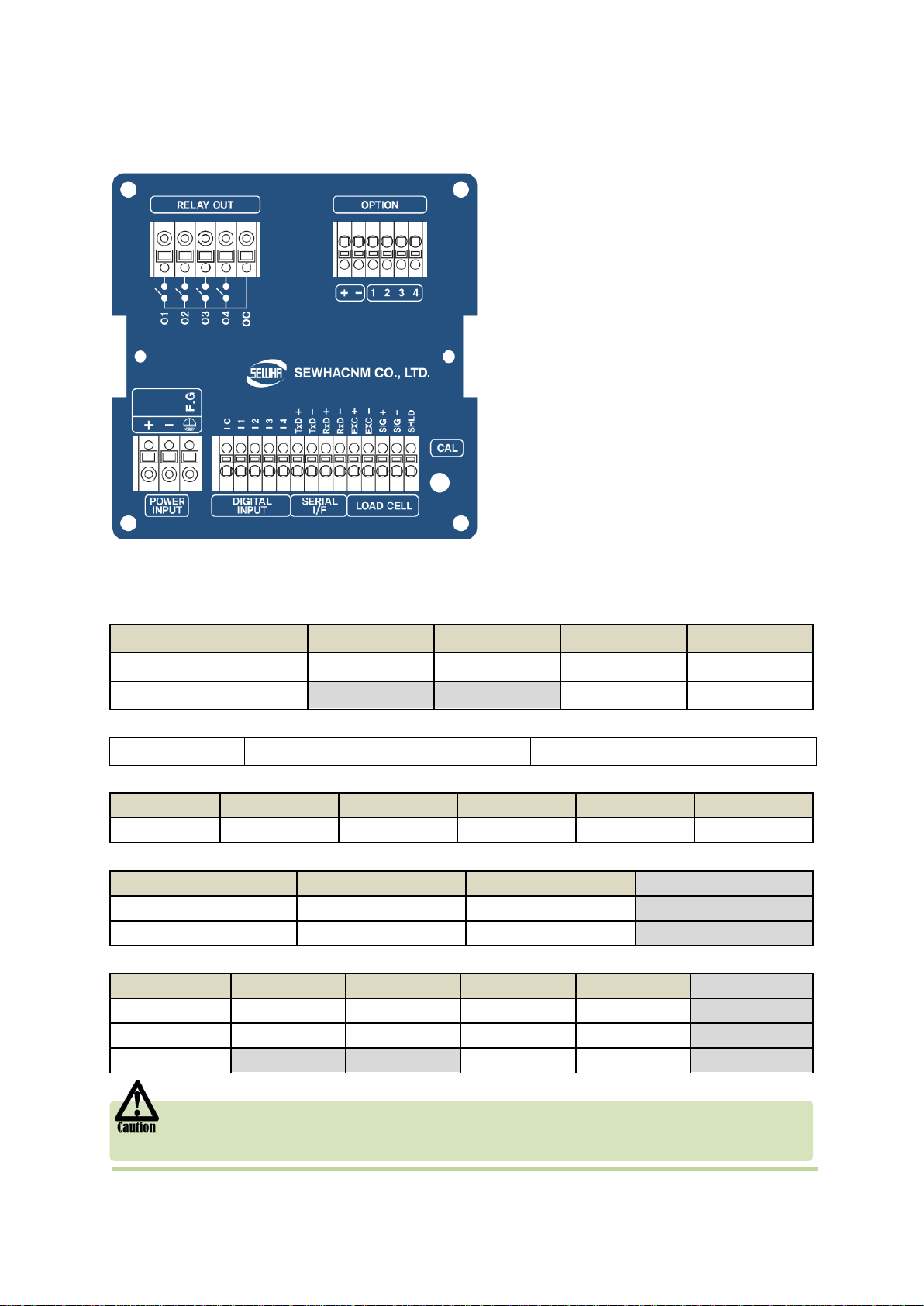

3-3. Rear Panel

1. Power DC IN: 24V (Power: 24V 1A recommended)

2. External Input terminal: Refer F-Function 231~234 to select each function.

3. Serial Interface terminal 1

Communication Method

TX+ Terminal

TX- Terminal

RX+ Terminal

RX- Terminal

RS –422(Standard)

TxD+

TxD-

RxD+

RxD-

RS –485(Standard)

Unuse

Unuse

RxD +

RxD-

4. Load cell Input

EXC+

EXC-

SIG+

SIG-

SHIELD

(5) Relay output terminal (COM terminal is common.)

Terminal

O1

O2

O3

O4

OC

Relay

OUT 1

OUT 2

OUT 3

OUT 4

COM

(6) Analogue Output terminal (Option)

Terminal

+

-

4~20mA

(+)

(-)

Option

0~10V

(+)

(-)

Option

(7) Serial Interface terminal 2

Terminal

1

2

3

4

RS –232C

GND

GND

Tx

Rx

Option

RS - 422

TxD+

TxD-

RxD+

RxD-

Option

RS - 485

Unuse

Unuse

D+

D-

Option

Please check the Comm. and other specification in the label, attached on the cover

plate first, and make connection according to that information.

(1)Power

(2)External

(3)Serial Port 1

(4)Loadcell

(5)Relay Output

(6)Analog Output

(7)Serial Port 2

- 10 -

SI 560A DIN SIZE WEIGHING INDICATOR

4. INSTALLATION

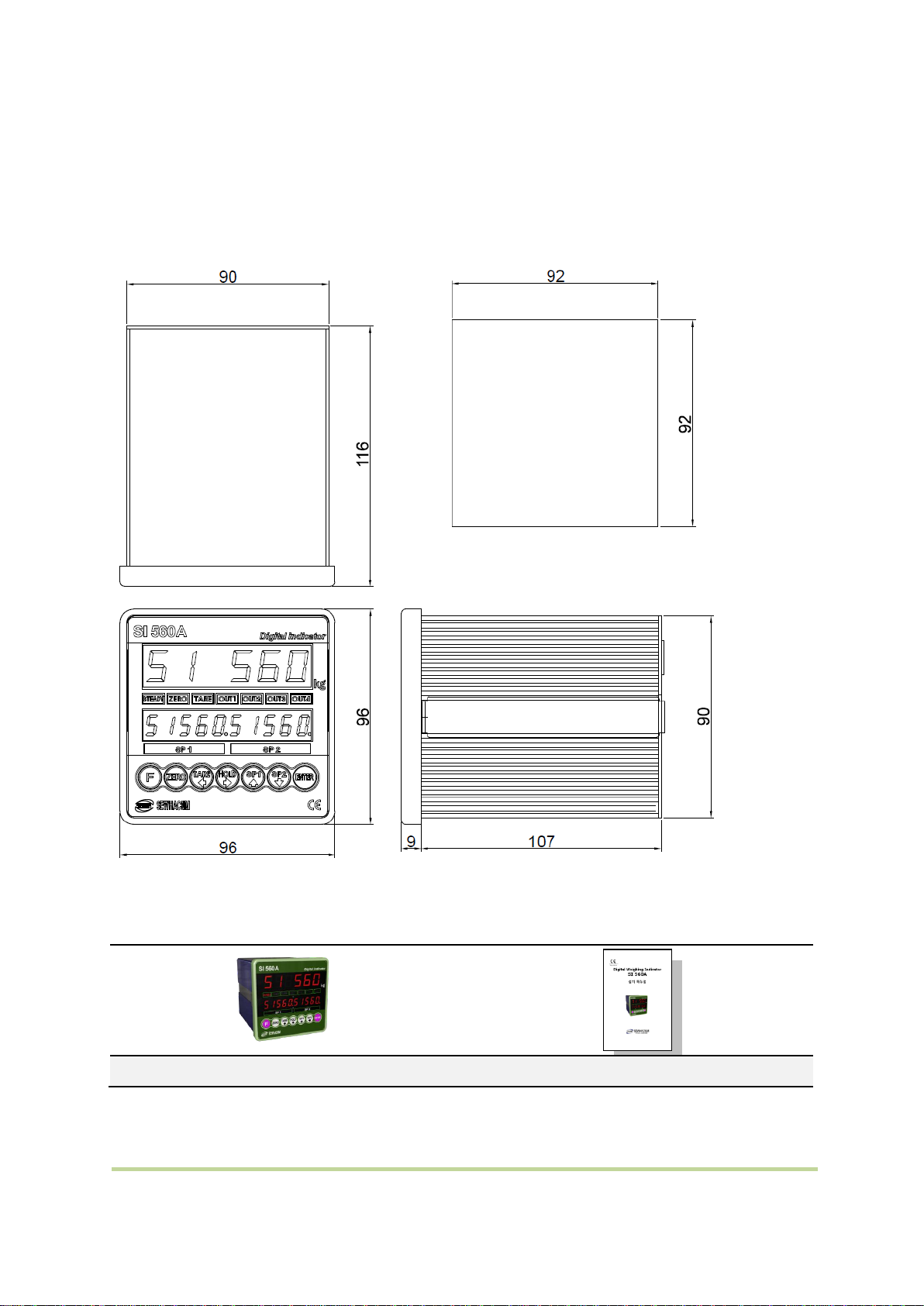

4-1. External Dimension & Cutting Size

4-2. Installation Components

SI 560A

User Manual

External Dimension (Unit : mm)

Cutting Size (Unit : mm)

- 11 -

SI 560A DIN SIZE WEIGHING INDICATOR

4-3 Load cell Installation

Load Cell Wire Connection (In case of SEWHACNM’s Load cell)

It depends on the manufacturer of load cell, please check the specification.

Under Set-up the Load cell, if EXC+ and EXC- have a short circuit,

It may cause damage in the indicator.(specially analogue board)

If you connect other wires to Load cell terminal wrongly, it may cause damage

in the analogue board.

Before connecting the load cell cable you have to power off and be sure to connect

the cable to the terminal correctly.

Do not weld near the load cells , Indicators or other devices.

■Load Cell Installation

1. You can connect Max 8pcs of same capacity Load cells at once. (350 Ω)

2. You have to make horizontal balance on the ground.

3. If you install more than 2pcs of load cells, use Summing box and adjust output signal

difference as minimum. It can make wrong weighing process caused by each load cell’s

variation.

4. If there is some temperature difference around Load cell, it can cause wrong weight

measurement.

5. Don’t do Welding job or Arc discharge around installation place. But, there is no

choice, please disconnect power cable and Load cell cable. If you measure static

electricity material, please make earth between down part and up part of Load cell.

- 12 -

SI 560A DIN SIZE WEIGHING INDICATOR

5. SET-UP

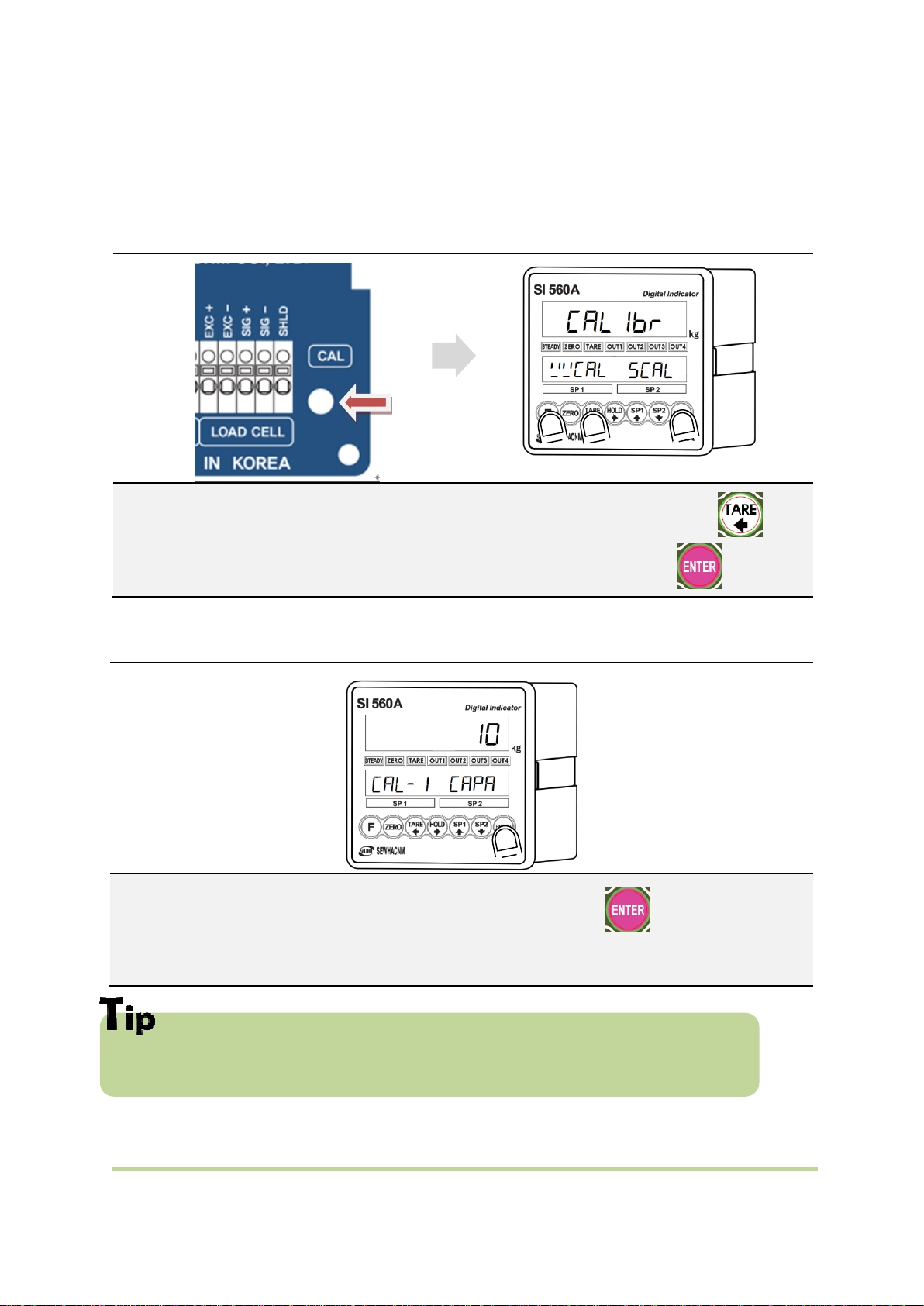

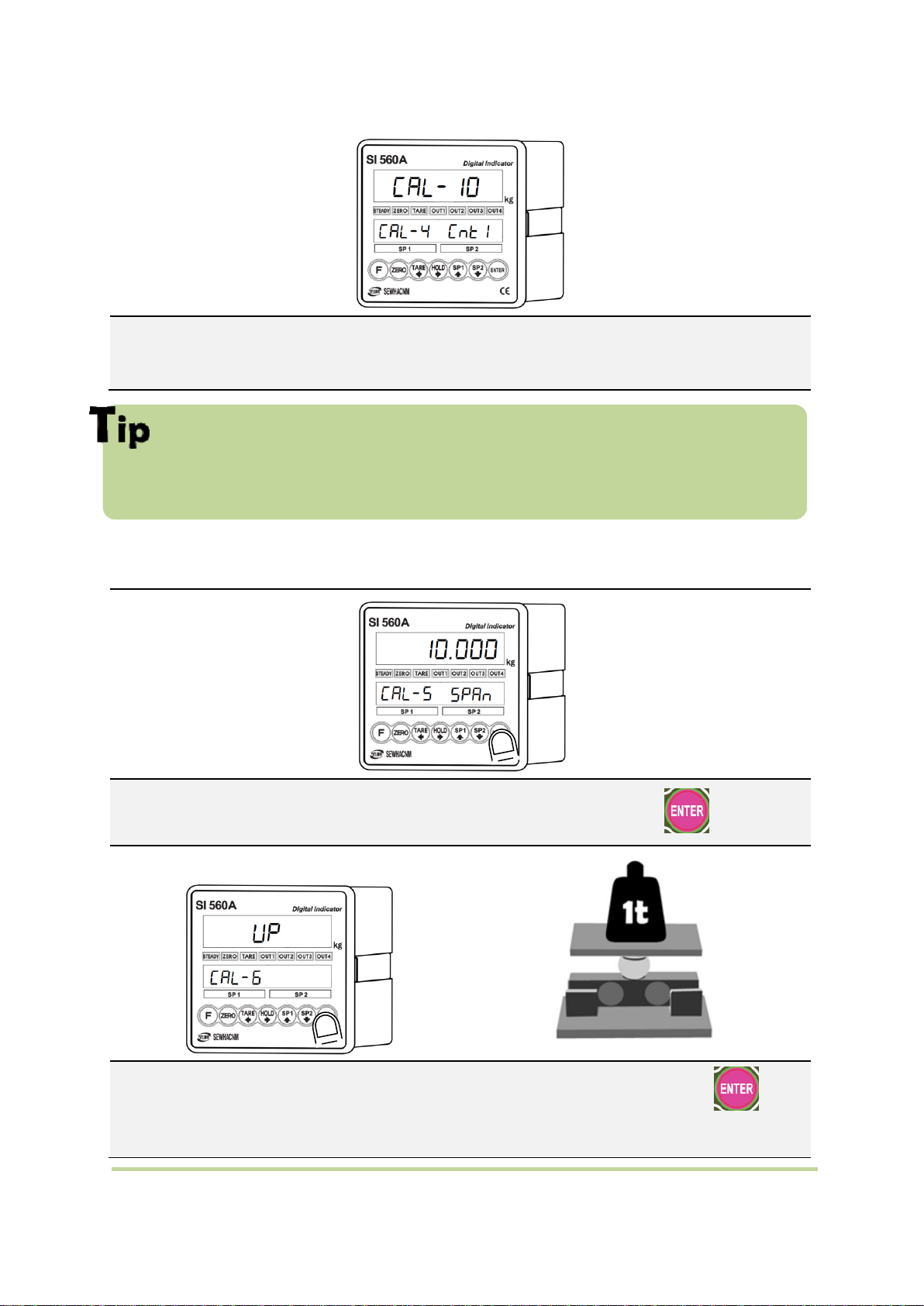

5-1. Test Weight Calibration Mode (Using test weight)

5-1-1. Start Test Weight Calibration Mode

5-1-2. Setting “Capacity of weighing Scale”

If you want to set Max capacity as 1,000kg and the division is

0.1 (100g), then just input “1000”.

Remove “CAL-BOLT” on the Front panel, .

and press “CAL - LOCK S/W” inside.

When “CALIBR”displays, press key,

select “WCAL”and press key.

After displaying “CAPA”, input max capacity with keys & Press key to save &

move to next step.

- 13 -

SI 560A DIN SIZE WEIGHING INDICATOR

5-1-3. “Decimal Point”and “Digit / Division”Value

Max decimal point will be 0.001, and digit can be selected among 1, 2, 5, 10, 20,

50. Digit and decimal point must be fulfilled under the below condition.

(division value / Max capacity value) cannot be over 1/20,000. If this condition is not

fulfilled, “err-1”will be displayed and move back to capacity setting mode.

5-1-4. Measuring the “DEAD”Weight of Weighing Scale.

After “DIVI”is displayed, locate decimal point with key and key. Set the

division with key and key, save key to save.

When “DEAD”displays, Press key, then indicator will calculate dead weight of

scale part automatically (While this process, there should be nothing on the scale part.)

- 14 -

SI 560A DIN SIZE WEIGHING INDICATOR

In this step, if there is unstable condition such as some forces or Vibration on the

scale part, “ErrorA”will be displayed, and “DEAD value”will not be calculated.

Please remove the cause of the force or vibration and process it again.

5-1-5. Calculating span value

Indicator will search “DEAE weight”during 10secs automatically to find the best

condition.

If the count is over, input the weight of your “Test Weight”and press key.

If “UP”is displayed, please load “Test Weight”on the scale part and press

key.

- 15 -

SI 560A DIN SIZE WEIGHING INDICATOR

After calculation, span value will be

displayed on the display. Then press

key.

When “CALEND”is displayed and

calibration is completed.

Calculate Span value during 10~20 secs.

- 16 -

SI 560A DIN SIZE WEIGHING INDICATOR

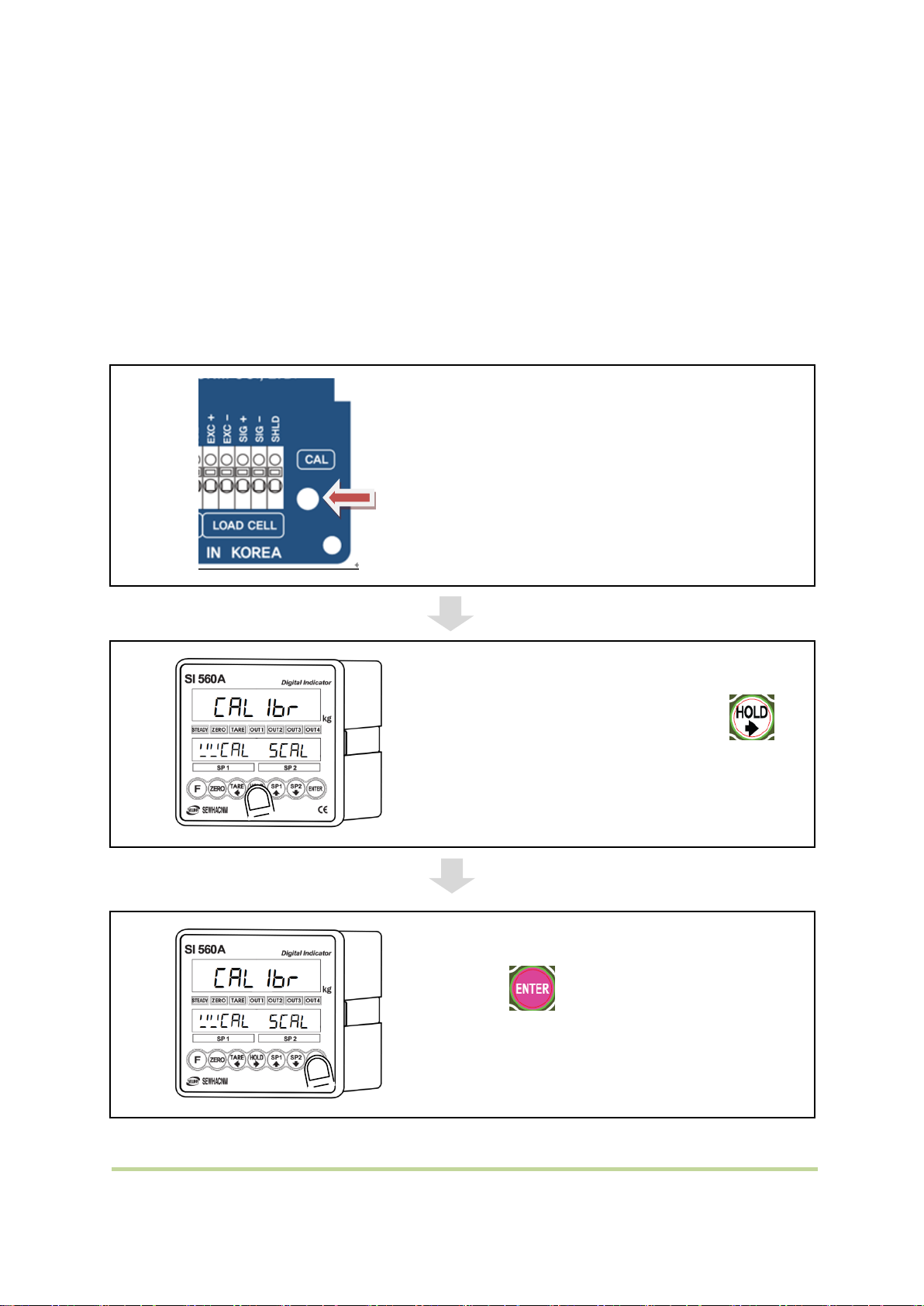

5-2. Simulation Calibration Mode(Calibrate without Test weight)

With this “Simulation Calibration Mode”you can make simple calibration without any

“TEST weight”This calibration mode uses “Load cells’max capacity”and “Max Output

Rate(mV)”, so the weight adjustment degree might be less than “Test weight Calibration”.

The guaranteed resolution of this “Simulation Calibration”is 1/3,000.

5-2-1. Simulation Calibration Mode Start

Remove “CAL-BOLT” on the Front panel,

and press “CAL - LOCK S/W” inside.

When “CALIBR”is displayed, press

key and select “SCAL”.

Press key to enter to simulation

calibration mode.

- 17 -

SI 560A DIN SIZE WEIGHING INDICATOR

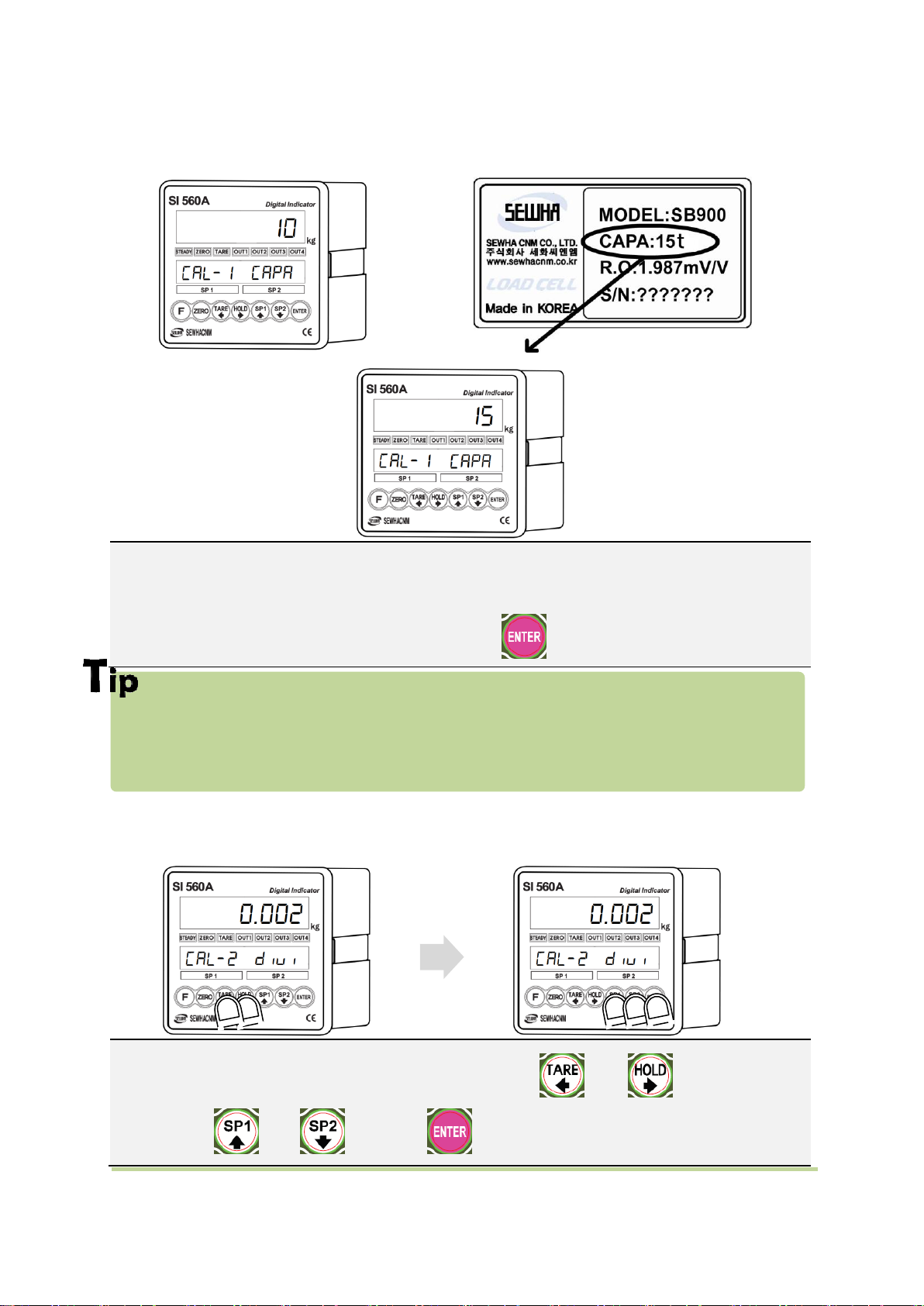

5-2-2. Setting “Capacity of Load Cell”

In case of multiple pieces of load cells are installed, Please make sum of each load

cell’s capacity and make setting with Max Capacity.

EX) There are 4pcs of load cells, and each load cell’s Max capacity is1,000kg.

Then, total Max Capacity will be 4,000kg(1,000 x 4) and you have to input 4,000.

5-2-3. Setting “Digit / Division”value

After “CAPA”displayed, Check Max Capacity of Load cell.

(refer the load cell label, or Test Report)

Input the Max Capacity of Load cell. And press key.

After “DIVI”is displayed select Decimal point with and key, and set the

division with and key. Press key to save.

- 18 -

SI 560A DIN SIZE WEIGHING INDICATOR

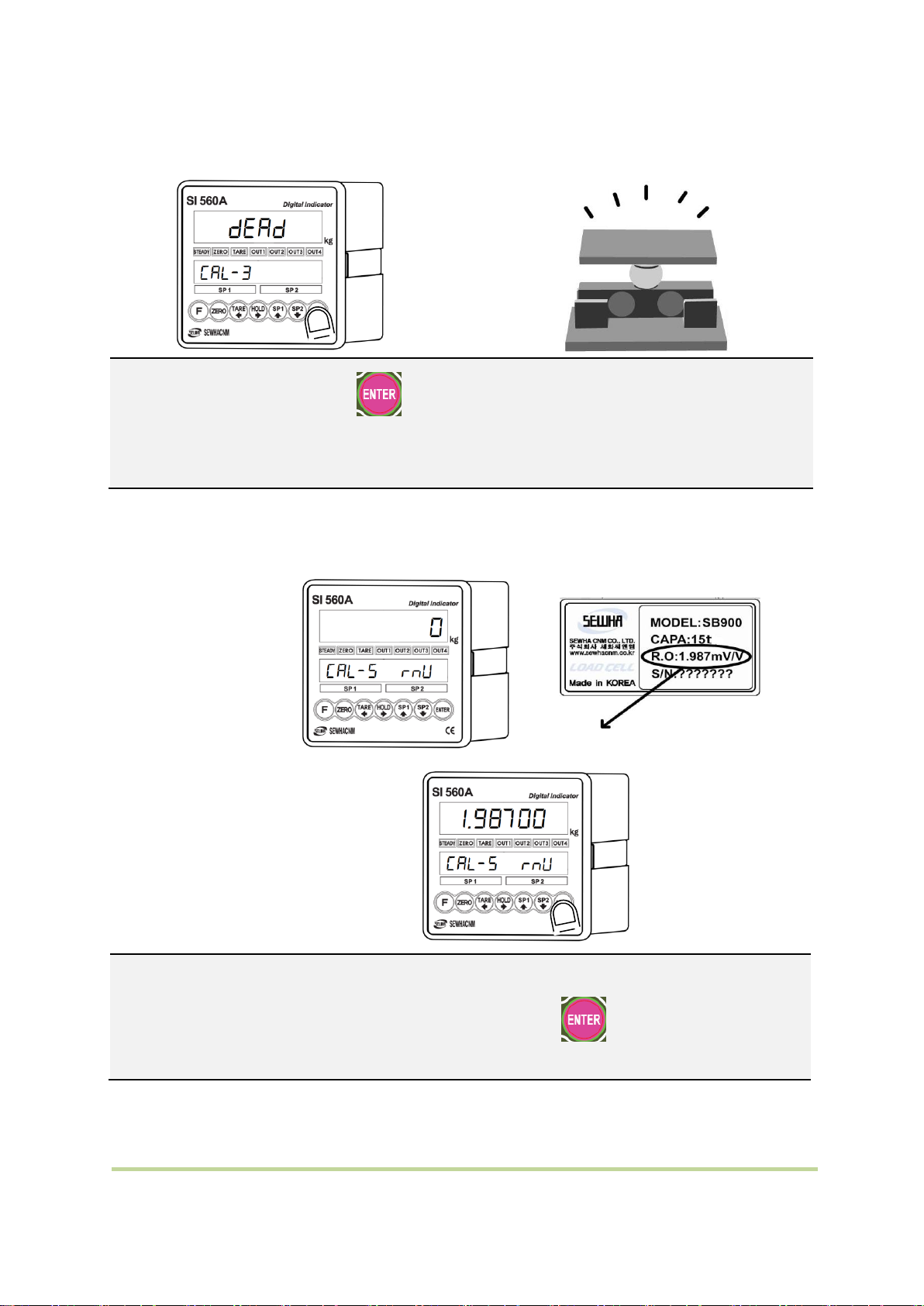

5-2-4. Measuring the “DEAD Weight”of Weighing Scale.

5-2-5. Inputting Max Output ( Rated Output Voltage / mV)

When “DEAD”displays, Press key, then indicator will calculate dead weight

of scale part automatically.

(While this process, there should be nothing on the scale part.)

After “mV”displayed, Check the Rated output value of Load cell.

(Refer to the load cell label, or Test Report) . And Press key to save and move to

next step.

- 19 -

SI 560A DIN SIZE WEIGHING INDICATOR

In case of multiple pieces of load cells are connected, the rated output will be

same as single load cell’s. (Because plural load cells are connected with parallel

connection, the sum of rated output voltage is same as single load cell’s rated output)

※Due to some variation between “State output rate” and “Real Output rate” of load

cell, there might be some weight difference after finishing calibration.

If you want to make more precise weighing process, please measure real output rate of

load cell and input the measured value. Then the weight measurement will be more

precise than before.

If input wrong value, there will display “Err-01”, please go back to Setting “Capacity of

Load Cell”.

After recheck the label of load cell and retry the process.

Calculated span value will be displayed.

Then press key to finish the

calibration step.

- 20 -

SI 560A DIN SIZE WEIGHING INDICATOR

5-3. F-FUNCTION Setting

5-3-1. Starting F-FUNCTION Mode

Press key 4 times When “SETUP”is displayed, press key.

Input the set value and press key.

Whenever press key, function No. is increased.

Enter the function No. that you want to move,

and Press key.

키로 바로 이동

Table of contents