PARTS LIST

• Slider Bezel • Preamp

• Acoustic Matrix Pickup • 1/4" Stereo Jack, with hardware

• 4-40 Screws (4), 3/16" length, with Star Washers • 4-40 Screws (4), 7/16" length

• 1/4" Aluminum Hex Standoffs (4), 9/16" length • 3/16" Brass Hex Jack Screws (4), 1/2" length

• (3) Adhesive-backed Plastic Wire Guides • Preamp Cutout Template

• (5) Slider Knobs • Back Plate with Battery Clip

TOOLS

• Caliper

• Router with 1/8" (3 mm) (or .9375" Plunging Cutter for Narrow Format)

• 400 Grit Sandpaper or Scraper

• Flex Shaft Tool with 1" (25.4 mm) Diameter Saw Blade or Router with 1/4" (6.30 mm) cutter.

• Soldering Iron (30 watt max) • Rosin Core Solder

• Wire Strippers • #1 Phillips Screwdriver

• Variable Speed Drill • Center Punch

• 1/8" Twist Drill • 15/32" Spade Bit Drill

• 1/2" Open End Wrench • 3/32" Allen Wrench

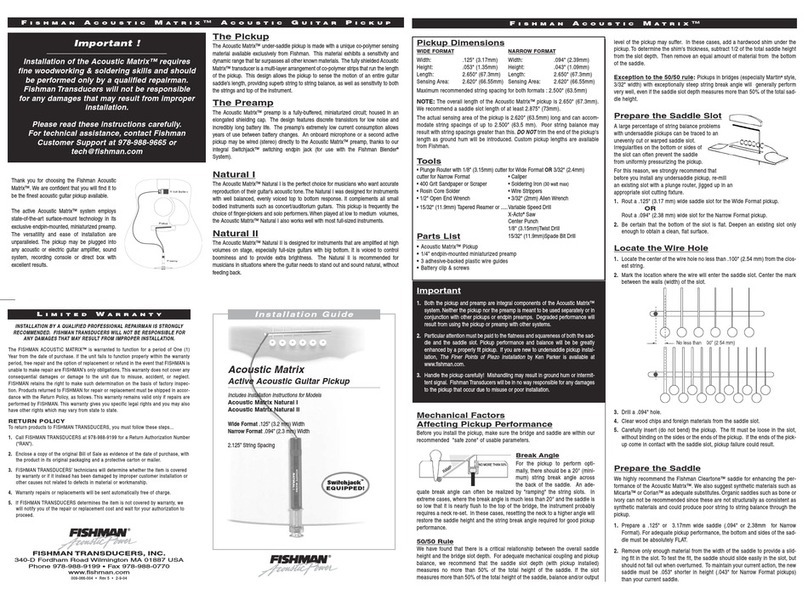

PICKUP DIMENSIONS

WIDE Format

Width: .125" (3.2 mm)

Height: .053" (1.35 mm)

Length: 2.650" (67.3 mm)

Sensing Area: 2.670" (67.8 mm)

Max. recommended string spacing: 2.500" (63.5 mm)

Narrow Format

Width: .09375" (2.4 mm)

Height: .043" (1.1 mm)

Length: 2.650" (67.3 mm)

Sensing Area: 2.670" (67.8 mm)

Max. recommended string spacing: 2.500" (63.5 mm)

NOTE: The overall length of the Matrix pickup is 2.700" (68.58mm). We recommend a saddle slot length

of at least 2.875" (73mm).

The actual sensing area of the pickup is 2.670" long and can accommodate string spacings of up to 2.500"

(63.5 mm). Poor string balance may result with string spacings greater than this.

DO NOT trim the end of the pickups length as ground hum will occur. Custom pickup lengths are available

from Fishman.

MECHANICAL FACTORS AFFECTING PICKUP PERFORMANCE

BREAK ANGLE

There must be an adequate amount of downbearing pres-

sure on the pickup in order for it to perform optimally. The

pickup will "see" an acceptable amount of downbearing

pressure when there is a 20° (minimum) break angle

across the saddle.

A pickup in a Guitar with less than a 20° break angle will often have string balance problems as well as

poor tone. For such instruments, an adequate break angle can be realized by "ramping" the string slots or

(in extreme cases) raising the saddle height and resetting the neck angle.

THE 50/50 RULE

For adequate coupling between string, saddle and pickup, we recommend that the saddle slot depth (with

pickup installed) should equal no more than 50% of the total height of the saddle.

ADJUSTING FOR TOO DEEP A SADDLE SLOT

If the slot (with pickup installed) measures more than 50% of the total saddle height, the pickup perfor-

mance will often suffer. To correct for too deep a slot, place a wood shim under the pickup. Determine the

proper thickness of the shim by subtracting 1/2 of the total saddle height from the slot depth (with pickup

installed). Then, remove an amount of material equal to the thickness of the shim from the bottom of the

saddle.

EXCEPTION: Pickups in guitars with a very steep string break angle (25° or more), will generally perform

well, even if the saddle slot depth measures more than 50% of the total saddle height.

COMPENSATED SADDLES

We do not recommend compensating the saddle under the "B" string. Doing so may twist the saddle and

cause uneven pickup response.

PREPARE THE SADDLE SLOT

1. Rout a .125" (3.2 mm) wide saddle slot for the Acoustic Matrix Wide Format

pickup.

OR

Rout a .09375" (2.3 mm) wide slot for the Acoustic Matrix Narrow Format pickup.

2. Be certain that the bottom of the slot is flat.

Deepen an existing slot only enough to obtain a clean, flat surface.

LOCATE THE WIREHOLE

1. Locate the center of the wire hole no less than .100" (2.5 mm) from the closest string.

2. Mark the location where the wire will enter the saddle slot. Center the mark between the walls (width)

of the slot.

3. Drill a .09375" hole.

4. Clear wood chips and foreign materials from the saddle slot.

5. Carefully insert (do not bend) the pickup.

PREPARE THE SADDLE

We recommend synthetic materials such as Micarta or Corian as excellent saddle materials for the

Acoustic Matrix. Organic materials such as bone or ivory are not as consistent and may result in poor string

balance.

1. Prepare a .125" wide saddle (.09375" for Narrow Format) The bottom of the saddle must be flat.

2. Remove only enough material from the width of the saddle to provide a sliding fit in the slot. To test the

fit, the saddle should slide easily in the slot, but should not fall out when overturned. To maintain your

current action, the new saddle must be .053" shorter in height (.043" for Narrow Format pickups) than

your current saddle.

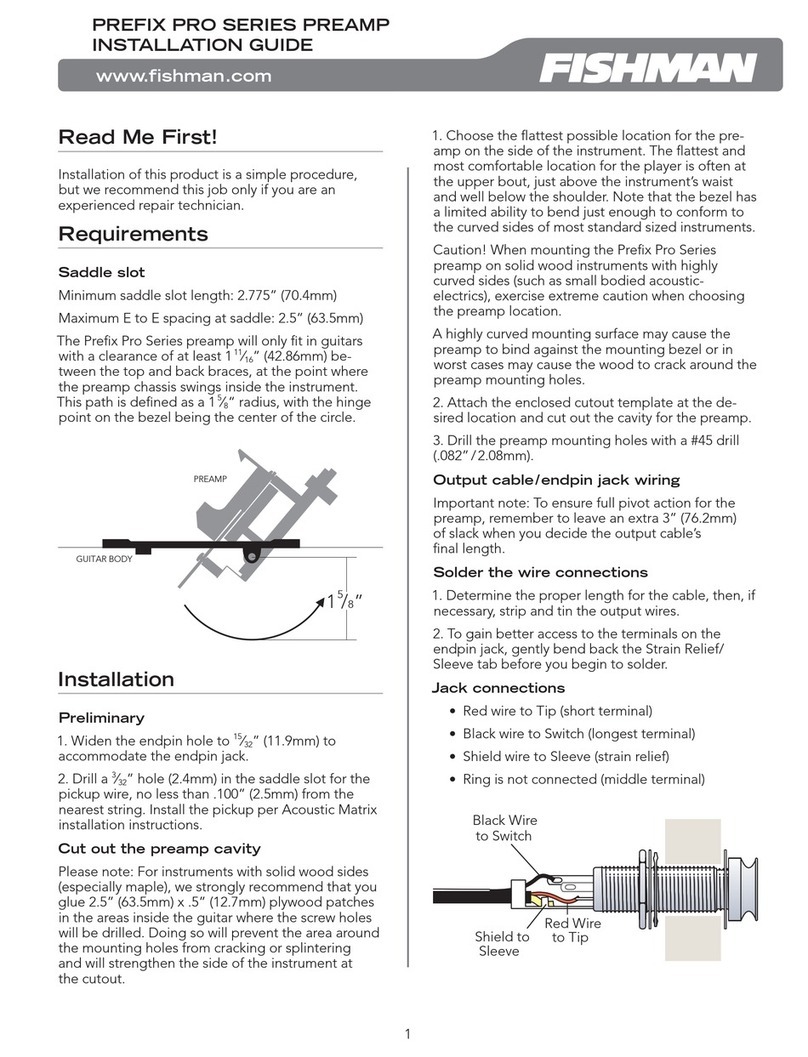

PREAMP CUTOUT

For guitars with non-laminated sides, we strongly recommend gluing a thin plywood patch inside the guitar

before cutting out the cavity. This will prevent cracking and splintering of the cut-out area during cutting,

and provide adequate structural support for the preamp.

1. Choose the preamp location on the side of the instrument. Note that the bezel has the ability to con-

form to most curved surfaces on standard size guitars.

2. Tape the enclosed Cutout Template to the desired location. Use the flex shaft tool (with 1/2" blade) or

the router (with 1/4" cutter) to make the cut-out.

3. Drill the screw mounting holes using the 1/8" drill.

PREPARE THE ENDPIN BLOCK

TOOLS

• Masking Tape • X-Acto Fine-toothed Saw

• Variable Speed Drill • Center Punch

• 1/8" Twist Drill • 15/32" Spade Bit Drill

• 1/2" Open End Wrench • 3/32" Allen Wrench

The objective of this method is to drill a hole in the endblock, with the endpin in place. You may remove a

loose endpin and refasten it in the endblock with cyanoacrylate glue before starting this procedure.

F

ISHMAN

®A

COUSTIC

M

ATRIX

™ P

ROFESSIONAL

S

YSTEM

P

REAMP

I

NSTALLATION

No less than .100" (2.54 mm)

2.2511"

57.18MM

1.7490"

44.42MM

1.5700"

39.88MM

0.1780"

4.52MM

0.1579"

4.01MM

D 0.1250"

3.18MM

4 HOLES

VOLUME CONTROL ON THIS END

R 0.1250"

3.18MM