1

www.fishman.com

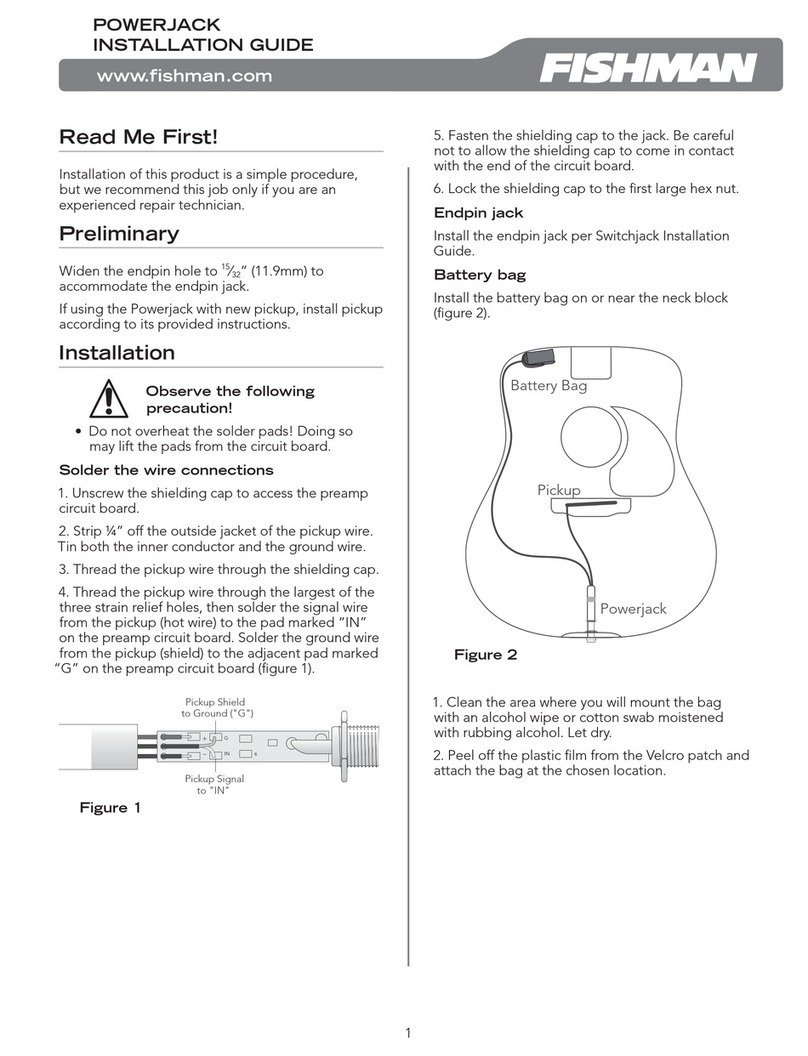

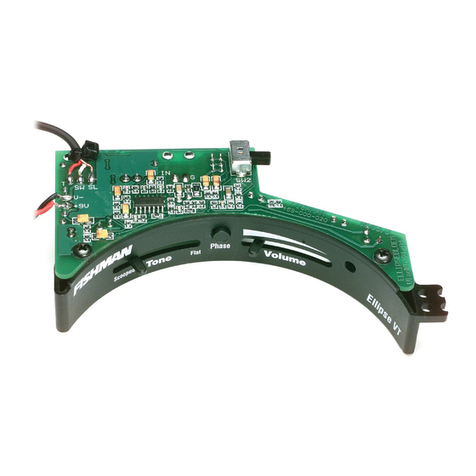

Read Me First!

Installation of this product is a simple procedure,

but we recommend this job only if you are an

experienced repair technician.

Requirements

The Full Circle is available in either ¼-20 or 6mm

thread format. Before you install the pickup,

confirm that the threads in the bridge will match

those on the Full Circle.

Installation

Observe the following

precautions!

• Before you install the Full Circle, confirm

that the wheels you are about to replace are

lined up well in the legs. The wheels must

be parallel and the posts perpendicular to

the cuts in the legs or the Full Circle may

become mechanically unstable on the

instrument (figure 1).

• Fishman Transducers will not be responsible

for damages to the pickup or the instrument

due to improperly installed wheels!

Retro-fit the Full Circle to a bridge with

installed wheels

The pickup is “hot” on the flat face of the wheel:

on the side with the non-threaded post. For good

performance it is crucial that the hot side of the

pickup lies absolutely flat with no gaps or voids

where it contacts the bridge. If necessary, sand the

wood flat where it contacts the wheel before you

install bridge on the bass (figure 1).

When you install the pickup, remove the RCA plug

from the back side of the output jack. Replace the

plug after the pickup is in place.

Setup

Once the wheels are mounted and the bass is tuned

up, thread the white wire through one of the wing

holes in the bridge and hold it in place with one of

the neoprene plugs from the kit (figure 2).

Fasten the output jack behind the bridge and

between two adjacent pairs of strings. Then fasten

the RCA plug into the back of the output jack.

Mind the gap!

For good pickup performance, leave a slight gap

between the threaded side of the wheel and the

wood. If you close the gap, the amplified sound will

become choked and muted (figure 2).

Height adjustment

Remove the RCA plug from the back of the output

jack so the white wire does not wrap around the

leg as you turn the wheel. Turn both wheels equal

amounts for good contact with the pickup. To pro-

long the life of the pickup, do not pinch the white

wire where it joins the wheel.

Tonal adjustments (figure 3)

Turn the wheel so the wire is perpendicular to the

leg and the pickup will have an open, resonant

response.

Turn the wheel 45 degrees so the wire faces one of

the corners and the tone will be somewhat drier and

more focused, with less output.

Fit the Full Circle to a bridge without

wheels

For maximum reliability and performance, the

wheels should be centered precisely within the

taper of the bridge.

Fit the bridge to the bass before you install the

wheels. Note that the wheel with the white wire

belongs under the E string.

There is a subtle tonal difference between “threads

up” and “threads down” position for the pickup.

FULL CIRCLE

INSTALLATION GUIDE

Hot Side

Good Bad

Gap

Figure 1

Figure 2