FISNAR DSP501N User manual

DSP501N OPERATING MANUAL

P/N 561796N

REV. A OCT. 10

©2010 FISNAR, INC.

Specifications

Size:

8 ⅝” x 8 ½” x 2 ⅝”

(22 x 21 x 6.7cm)

Weight:

2.8 lbs. (1.3kg)

Input

Voltage:

90-260 VAC

Dispense

Time:

0.01 - 31 seconds

Internal

Voltage:

24VDC

Cycle

Initiation:

Maintained or

Momentary

Cycle Speed:

600+/min

Air Input:

70-100psi (5-7 bar)

Air Output:

1-100psi (0.1-7 bar)

Standards:

CE Approved

RoHS Compliant

Barrel “Suck-Back” Feature

Ordering Guide

Part No

Description

DSP501N

Multi Voltage

Dispenser

Standard Accessories

Qty

Description

Reorder P/N

Qty/

Pack

1

1

1

1

1

1

1

1

3

3

3

3

2

2

2

2

2

2

2

2

2

2

2

2

2

Detachable Power Cord 110 Volts

Detachable Power Cord 220 Volts

Detachable Power Cord 220 Volts

Barrel Stand

Backhose w/Clamp & Barb Fit

Foot Pedal Assembly

Barrel Adapter - 30cc - 3' (91.4cm) 1/4" Hose

Barrel Adapter - 5cc - 3' (91.4cm) 1/4" Hose

Barrel - 30cc - Bevel

Barrel - 5cc - Bevel

PE Piston - 30cc - Bevel

PE Piston - 5cc - Bevel

Tip Cap - Natural

Tapered Tip Double Helix - 14 Gage - Orange

Tapered Tip Double Helix - 16 Gage - Grey

Tapered Tip Double Helix - 18 Gage - Green

Tapered Tip Double Helix - 20 Gage - Pink

Tapered Tip Double Helix - 22 Gage - Blue

Tapered Tip Double Helix - 24 Gage - Red

Tip 1/2" Crimp Sealed - 20 Gage - Pink

Tip 1/2" Crimp Sealed - 21 Gage - Purple

Tip 1/2" Crimp Sealed - 22 Gage - Blue

Tip 1/2" Crimp Sealed - 23 Gage - Orange

Tip 1/2" Crimp Sealed - 25 Gage - Red

Tip 1/2" Crimp Sealed - 30 Gage - Lavender

560033-LF

560033E-LF

560033E-PLUG-LF

560751LF

560752

560027D

5601466

5601027

5601004

5601001

5601465

5601019

5601054

5601263

5601264

5601265

5601266

5601267

5601268

5601201

5601202

5601203

5601204

5601205

5601208

1

1

1

1

1

1

1

1

10

10

20

40

10

25

25

25

25

25

25

25

25

25

25

25

25

DSP501N

DISPENSE CONTROLLER

O

OP

PE

ER

RA

AT

TI

IN

NG

G

M

MA

AN

NU

UA

AL

L

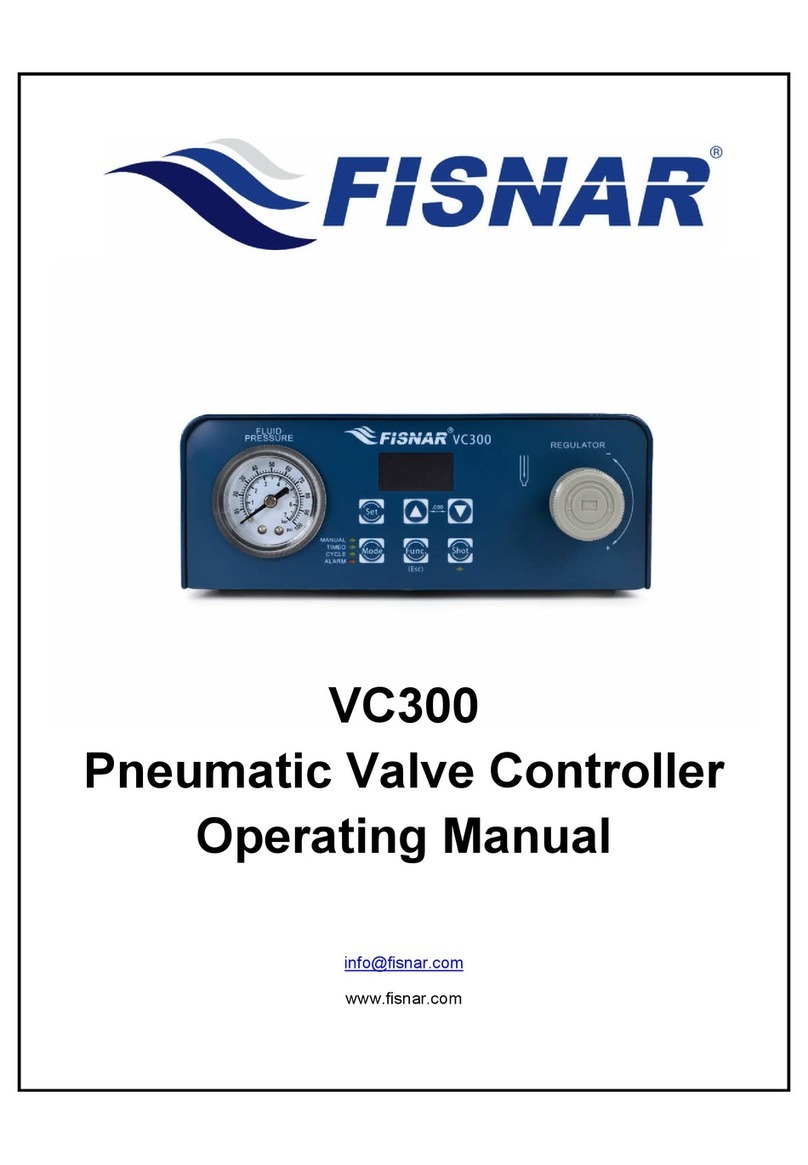

The DSP501N dispense controller

incorporates a digital timer which can be

set to control the actuation of its high

duty-rate air solenoid.

Its higher volume exhaust prevents post-

dispensing compression of the material,

thus avoiding stringing. An internal

vacuum also comes standard to prevent

dripping of very low viscosity liquids.

Foot pedal initiation can either be for

maintained or momentary operation.

All hoses and fittings, along with barrels

and tips are already included, making the

unit ready to use right out of the box.

DSP501N OPERATING MANUAL

P/N 561796N

REV. A OCT. 10

©2010 FISNAR, INC.

SETUP

Instructions:

1.Connect the air hose to filtered compressed air of

70-100 psi (5-7 bar) pressure. Connect the coupling

to the dispenser.

2.Insert the foot switch plug to the controller through

the connector at the back.

3.Insert and twist male quick connect into dispenser.

4.Insert power cord female plug into dispenser and

insert the male plug into a grounded outlet.

5.Fill barrel (with barrel tip cap on the barrel) with

material to be dispensed and lock the barrel to the

adapter assembly as shown.

DSP501N

DSP501N OPERATING MANUAL

P/N 561796N

REV. A OCT. 10

©2010 FISNAR, INC.

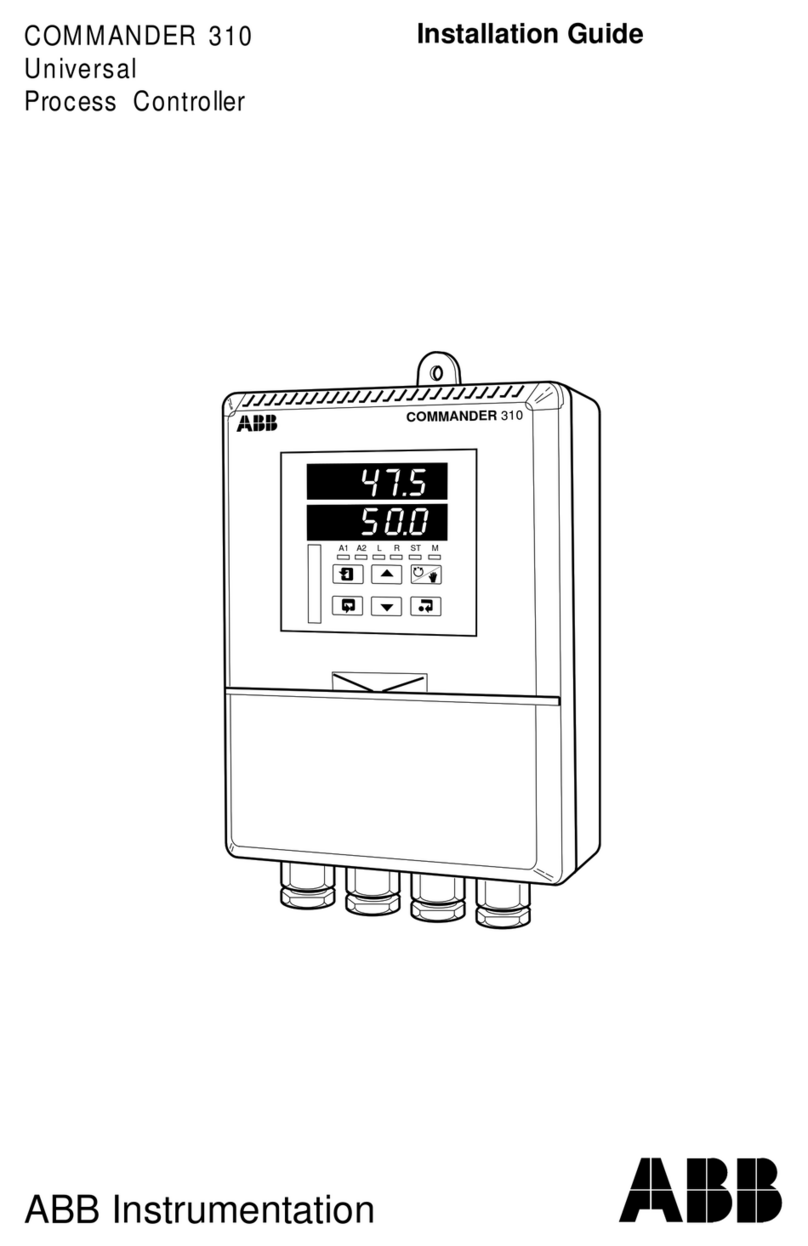

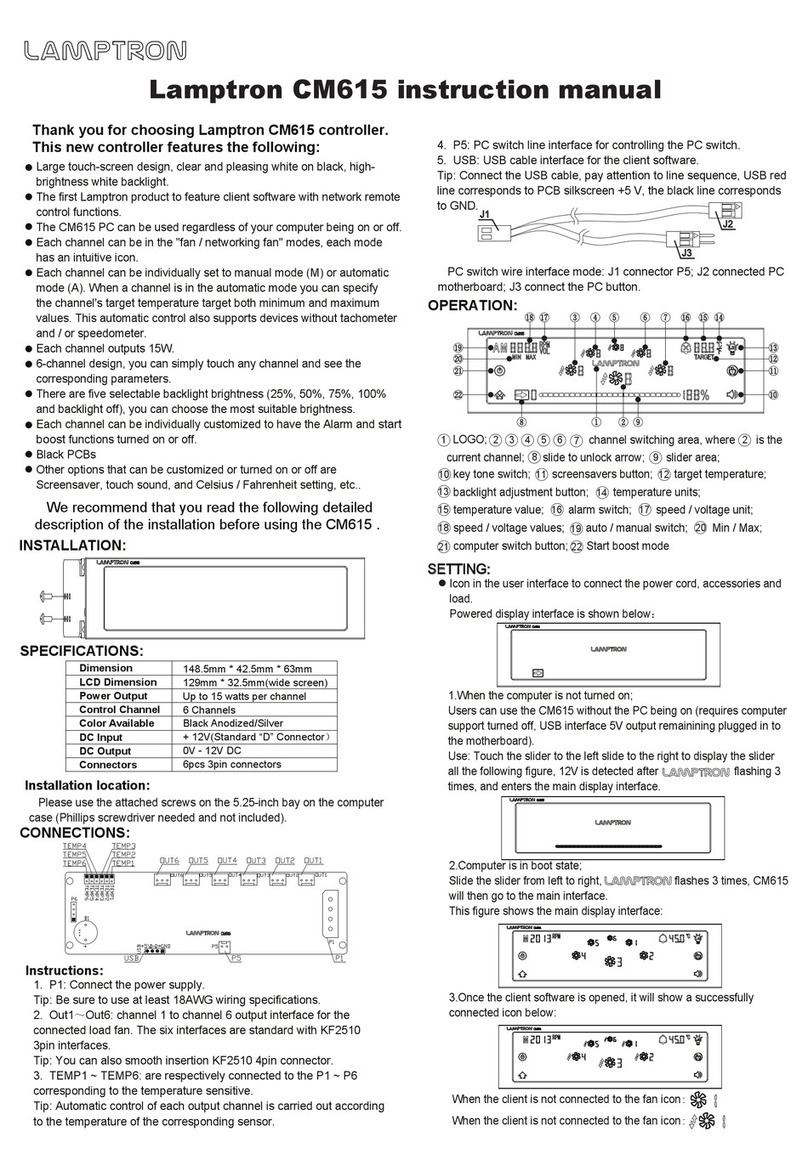

FIG. 3

A Pressure Gauge

- Displays the current pressure setting.

B Pressure Regulator

- Sets the required pressure setting. Turn the

knob clockwise to increase and counter-

clockwise to decrease pressure as needed.

C Timer Setting

- Sets the required time setting when Timer

Mode is on. Please note that the numbers

indicated on the knob are for reference only.

D Power Switch

- Turns the unit on or off.

E Timer Mode Switch

- Toggles between operator control mode

(light on) and timer mode (light off)

F Vacuum Control

-Turns on the vacuum.

G Foot Pedal

- Actuates the dispenser controller.

A B CD EF

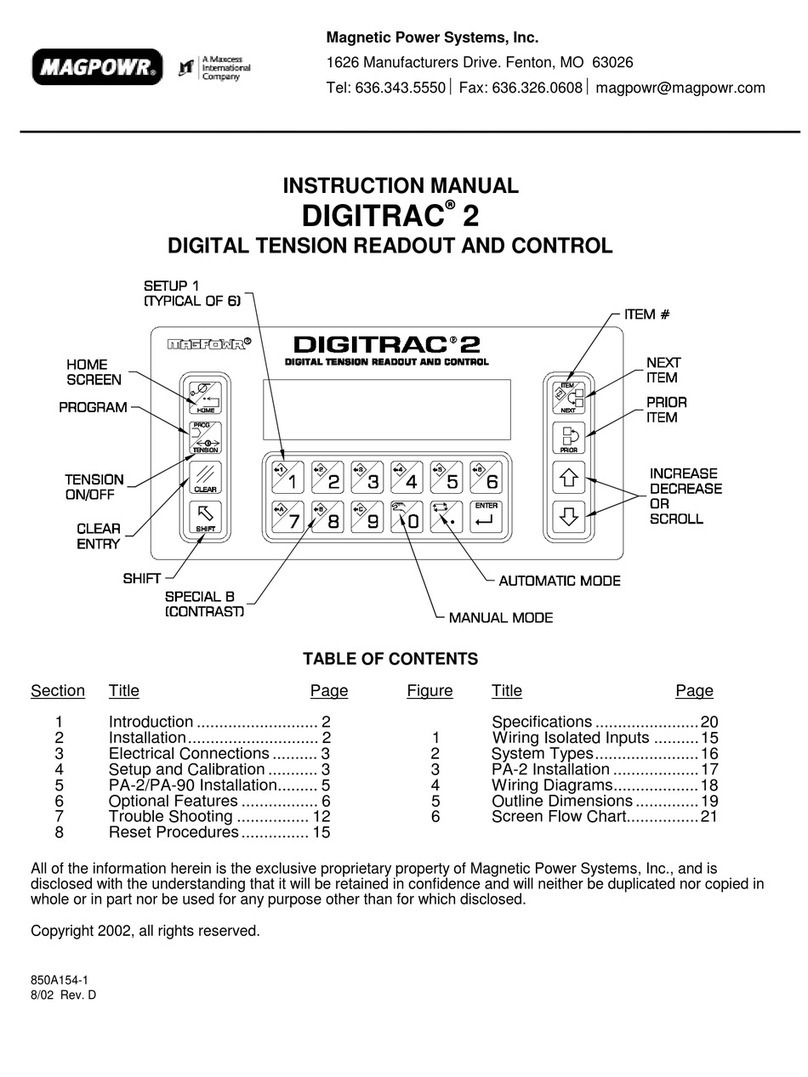

1. Hold the barrel at an approximately 60º (±20º) angle (Fig. 1).

2. Lift the tip as vertical as possible (Fig. 2) after making the deposit.

3. Do not let the liquid flow back into the controller (Fig. 3.)

HELPFUL HINTS FOR MAKING DEPOSITS

4. You may vary the shot size by doing one or a combination of the following:

Increasing or decreasing time only (C)

Increasing or decreasing pressure only (A) (B)

Increasing or decreasing size of tip

5. To increase pressure, turn the pressure regulator knob (B) clockwise and

counter-clockwise to decrease it. When decreasing pressure, set the gauge first to

less than the value desired and then just increase it as needed.

6. For thin liquids like water, you can prevent dripping by slowly turning the

vacuum control (F) counter clockwise.

WARNING: Too much vacuum will cause air bubbles and suck liquid back

into the controller thus creating permanent damage to the unit.

UNDERSTANDING THE FUNCTIONS

OF YOUR DISPENSER DISPLAY

G

FIG. 1

FIG. 2

60º

DSP501N OPERATING MANUAL

P/N 561796N

REV. A OCT. 10

©2010 FISNAR, INC.

LIMITED WARRANTY

Manufacturer warrants this product to the original purchaser for a period of two (2) years from the

date of purchase to be free from defects in material and workmanship, but not against damages

caused by misuse, negligence, accident, faulty installation, abrasion, corrosion or by not operating in

accordance with factory recommendations and instructions.

Manufacturer will repair or replace (at factory's option) free of charge, any component of the

equipment thus found to be defective upon prepaid return of the equipment to the factory during the

warranty period of the equipment. In no event shall any liability or obligation of Manufacturer arising

from this warranty exceed the purchase price of the equipment. This warranty is valid only when the

5 micron filtered air is used.

The manufacturer's written liability, as stated herein, cannot be altered or enlarged except by a written

statement signed by an officer of the company. In no event shall manufacturer be liable for

consequential or incidental damages. A return authorization is required from FISNAR prior to shipping

a defective unit to the factory.

Manufacturer reserves the right to make engineering or product modifications without notice.

Other FISNAR Controllers manuals