FISNAR RVC900N Series User manual

RVC900N Rotary Valve Controller Rev. A - Nov. 10

RVC900N Series

ROTARY VALVE CONTROLLER

U

Us

se

er

r

M

Ma

an

nu

ua

al

l

RVC900N Rotary Valve Controller Rev. A - Nov. 10

This page intentionally left blank

RVC900N Rotary Valve Controller Rev. A - Nov. 10

1

1. TABLE OF CONTENTS

1. Table of contents 1

2. Designated use 2

3. For your safety 2

4. Technisa data 3

4.1 Parts & description 4

5. Included parts 5

6. Start operation 5

7. Operation 6

7.1 Display 6

7.2 Status LED´s 6

7.3 Operation keys 7

8. Parameter 8

9. Service Menu 9

9.1 Display 9

9.2 Settings 9

10. Electrical connections 10

10.1 Rotary valve 10

10.2 Foot switch 10

10.3 I/O-port 10

10.4 Wiring diagrams 11

11. Maintenance and cleaning 12

12. Disposal 12

RVC900N Rotary Valve Controller Rev. A - Nov. 10

2

2. DESIGNATED USE

The digital rotary valve controller RVC900N is used for precise controlling of rotary

valves which work with a DC voltage of 0 –24V, for example the PDV-1000 valve. The

RVC900N controls the air pressure on the material, and also the voltage to the rotary

valve for setting the speed of the valve.

With the integrated precision air pressure regulator, the air pressure on the material can

be set precisely. There are two different air pressure outputs for the RVC900N. One

output is continuous air pressure, the second output is a pulsed air pressure, as long, as

the rotary valve dispenses. An integrated digital pressure sensor at the inlet air gives an

additional point for the process safety.

3. FOR YOUR SAFETY:

WARNING:

If the RVC900N is used for other functions as described below, it could come to

personal or material damage. Use the RVC900N controller only for the functions, which

are explained in this user manual. Fisnar Inc. is not responsible for personal or material

damages, which happen because of incorrect usage.

DO NOT modify the RVC900N.

DO NOT attempt to repair or use spare parts without first contacting Fisnar.

DO NOT use anything but recommended Fisnar accessories..

SAFETY PRECAUTIONS:

The RVC900N works with 100 –240V AC voltage. By touching the 100 –240V AC

voltage, there exists danger of life!! Because of this, the RVC900N must be

disconnected from the AC input cable, before opening the housing. It is only allowed for

authorized electrical experts to open the housing.

DO NOT exceed the maximum allowed power / settings.

Always wear protective gear.

Before using the RVC900N please review the safety datasheets of the dispensing

material

No smoking or fire by flammable materials.

The RVC900N is only allowed for use indoors.

Due to the electronic nature of this equipment and the potential for a spark or

generation of heat, note that this equipment most NOT be used with any explosive

material or in an explosive type environment.

RVC900N Rotary Valve Controller Rev. A - Nov. 10

3

4. TECHNICAL DATA

Measurements : 9 ¼” x 8 ¼” x 2 ¾” (235 x 210 x 70mm)

Weight : 3.6lbs. (1.65kg)

Power Supply : 100 –240V AC 50/60Hz

Internal Voltage : 24V DC

Voltage Rotary Valve : 0 ... 24V DC (PWM)

Dispense Time : 0.01 - 999 sec.

Air Inlet : 0-100psi (0-7bar) Display: digital

Air Outlet : 0-58 psi (0-4bar)precise pressure regulator

-continuous

-pulsed

Parameter Display : 128 x 64 Pixel graphical display

Programs : 8 programs

RVC900N Rotary Valve Controller Rev. A - Nov. 10

4

4.1 PARTS & DESCRIPTION

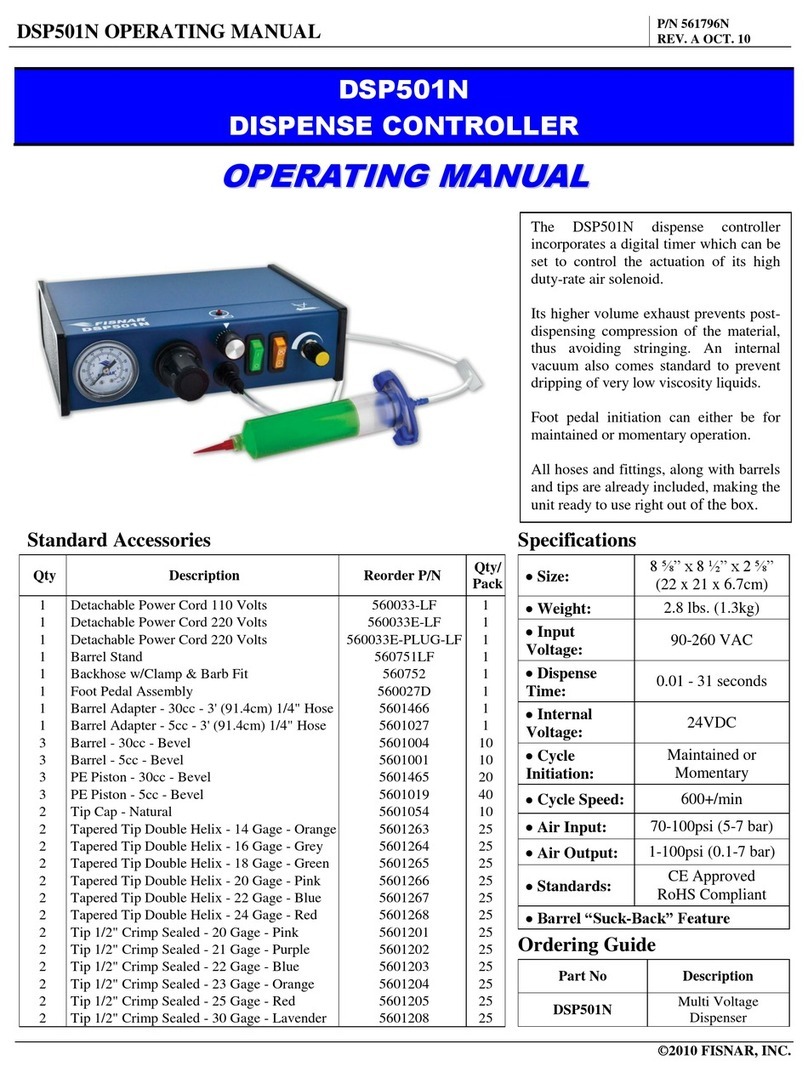

[Front Side]

[Back Side]

Pressure

gauge for

air outlets

Air pressure regulator

Operating keys

Status LED´s

Graphic display

Rotary valve

0-24V DC (PWM)

Footswitch

Power

switch

Air outlet

continuous

Air outlet

pulsed

Air inlet

0–7 bar (0-100psi)

I/O-Port

Fuse 2A T

Power inlet

RVC900N Rotary Valve Controller Rev. A - Nov. 10

5

5. INCLUDED PARTS:

RVC900N Controller

Power Inlet cable

Tube for Air Inlet

User Manual

Foot Pedal

6. START OPERATION:

Connect the power inlet cable to the power inlet connector on the backside.

Connect the air inlet tube from the compressor to the air inlet on the backside of the

RVC900N.

Connect the foot pedal or dispense cable to the footswitch connector on the backside of the

RVC900N. Also connect the rotary valve cable to the connector in the rear of the RVC900N

controller.

Depending on your application, use the continuous or pulsed air outlet for the air supply of

the material reservoir. Adjust the air outlet pressure with the pressure regulator on the front

side of the RVC900N. A typical air pressure is less then 30psi (2 bar)for standard

applications with a rotary valve. If material comes out of the tip, without dispensing with the

rotary valve, reduce the air pressure on the material reservoir.

Switch the RVC900N on. The display shows the initialization and the installed software

version. After 5 sec, the display switches automatically to the standard screen and is ready

for operation.

Check the pressure input (e.g. P-IN: 80psi (5.6bar)) in the display to be sure, that the air

input pressure is connected.

RVC900N Rotary Valve Controller Rev. A - Nov. 10

6

7. OPERATION:

7.1 Display: (values can be different)

7.2 Status LED´s

Below the display are the status-LED´s of the RVC900N.

RUN: The RUN LED will turn on when the motor of the rotary valve is running.

Independent to the rotation direction.

ALARM: The ALARM LED lights, during the following conditions:

Pressure alarm is active

Motor current overload (only active for speed >50)

External alarm signal on the I/O-Port

Dispense :

Speed :

Wait time :

Retract :

Mode :

CW C: 000027

*002.55 s

070

0.20 s

0.50 s

Prog: 1

P-IN 80psi

Parameters

Selected values

Program

/ Mode

Rotating

Direction

CW / CCW

Cyclecounter

volatile

Display:

air inlet pressure

Selected

Program

Marking

RVC900N Rotary Valve Controller Rev. A - Nov. 10

7

7.3 Operating keys:

PROG - switches to the next program

SAVE - saves the actual parameters.

Press the SAVE key for 2 sec. and select the wanted program with the UP

/ DOWN keys and press SAVE again to store the parameters. If no

different program is selected, the parameters get automatically saved in

the actual program.

PURGE - starts the dispensing procedure.

UP - increases the selected value.

DOWN - decreases the selected value

SELECT - Moves the marking to the next display line.

RVC900N Rotary Valve Controller Rev. A - Nov. 10

8

8. PARAMETER:

Select mode

Pressing the PROG key switches to the next program and to manual mode

Manual: In this mode, the dispense time does not get saved and the rotary valve

dispenses as long as the dispense signal is activated by one of the following:

footswitch / purge key / I/O-start.

After dispensing, the dispense time starts again at 0.00 sec.

PROG 1-7: If one of the programs 1 –7 is selected, the RVC900N dispenses as long as

the value of the dispense time is set for. This dispense cycle is activated by

one of the following: footswitch / purge key / I/O-start.

This mode should be selected, if the rotary valve should always dispense for

the same time.

Set the dispense time:

The dispense time can be selected with the UP / DOWN keys, and set from 0.01 - 999.99

sec.

Set the rotation speed:

The rotation speed of the rotary valve can be selected in linear steps.

The value from 001 - 100 is related to the rotary valve voltage 0 - 24V.

Set the wait time:

The wait time is the pause time between end of dispensing and starting the retract of the

rotary valve. This value is limited to max. 5 sec.

Set the retract:

The retract is the time, which the rotary valve moves in the inverted direction to the

dispense direction. With this function, dropping of material out of the dispense tip, after

finishing the dispense procedure can be prohibited. This value is limited to max. 5 sec.

Cycle counter:

The cycle counter counts the dispensing procedures after switching ON the RVC900N

controller. The memory of the cycle counter is volatile and gets reset to 000000 after

switching OFF the unit.

Rotation Direction:

The rotation direction of the rotary valve can be set for clockwise and counter clockwise.

The selected direction is shown in the display as follows:

CW: Clockwise - spindle moves clockwise

CCW: Counter clockwise - spindle moves counter clockwise

The rotation direction can be selected in the SERVICE MENU

RVC900N Rotary Valve Controller Rev. A - Nov. 10

9

Keylock:

By pressing SAVE + PRG at the same time, a key lock for the RVC900N can be activated.

An activated key lock is shown in the display (lower right hand corner) with the symbol:

By pressing SAVE + PRG again, the keylock is deactivated.

9. SERVICE MENU: (press the UP + DOWN keys during initialisation)

9.1 Display:

9.2 Settings:

Language:

Pressing UP / DOWN keys switches between English and German language.

Direction:

Pressing UP / DOWN keys switches between CW / CCW rotating direction for the rotary

valve:

CW: Clockwise - spindle moves clockwise

CCW: Counter clockwise - spindle moves counter clockwise

P-Unit:

Pressing UP / DOWN keys switches between PSI and BAR as unit for the digital displayed

pressure.

P-Alarm:

By pressing the UP / DOWN keys, the value for the low pressure alarm-limit can be

selected. If the input pressure is lower than the selected limit, the RVC900N controller

switches to ALARM mode and no new dispensing is possible.

Service:

Service counter –not resettable

NOTE: Press the save key to store new settings. The unit will reboot itself.

If you do not want to store new settings, turn off the power and turn on again.

SERVICE

Language : *

Direction :

P-Unit :

P-Alarm :

Service :

CW C: 000027

E

CW

PSI

80 PSI

000000239

Selected language

Selected rotation direction

Selected pressure unit

Selected pressure limit

Service counter

RVC900N Rotary Valve Controller Rev. A - Nov. 10

10

10. ELECTRICAL CONNECTIONS

10.1 Rotary Valve:

type: LEMO connector female 2-pol: EGG.00.302.CLL

pins: pin 1 (red) 0-24V rotary valve

Pin 2 0V (GND) rotary valve

mating connector: LEMO connector male 2-pol. FGG.00.302.CLAD35

10.2 Footswitch:

pins: connection between Pin 1 + 3 starts dispensing

10.3 I/O-Port:

type: 15-pol. SubD female 2-doublerow

pins: see following chart

pin no.

Input / Output

Description:

Comment:

1

--

Reserved

Reserved

2

--

GND

GND

3

--

24V DC

24V DC

4

Output

BUSY

Dispensing procedure active

5

--

GND

GND

6

Input

START

Starts dispensing

7

Input

PRG1

Program select Bit #1

8

Input

PRG3

Program select Bit #3

9

--

Reserved

Reserved

10

--

Reserved

Reserved

11

Output

READY

Ready signal

12

Output

ERROR

Error signal

13

Input

REMOTE

Remote active

14

Input

ERROR-IN

External Error input

15

Input

PRG2

Program select Bit#2

RVC900N Rotary Valve Controller Rev. A - Nov. 10

11

10.4 Wiring Diagrams:

Digital Inputs:

A digital input is active, if the opto coupler is ON. If the opto coupler is connected to GND, the

input is activated:

Digital Outputs:

If the digital output is active, the opto coupler is electro conductive.

RVC900N Rotary Valve Controller Rev. A - Nov. 10

12

11. Maintenance and cleaning

The RVC900N is maintenance free

Repairs should only be done by the manufacturer.

Clean the RVC900N controller only with a clean, smooth and dry cloth.

Do not use dissolvent material to clean the RVC900N controller. The foil at the front / back

plate or the housing paint can be destroyed.

12. Disposal

Dispose the product after the economic life-time according to the legal

requirements.

Table of contents

Other FISNAR Controllers manuals

Popular Controllers manuals by other brands

cashco

cashco 1164 Installation, operation & maintenance manual

Nordson

Nordson CoolWave 2 instruction sheet

Watlow

Watlow DIN-A-MITE C user manual

vanEE

vanEE VENMAR ADVANCED TOUCHSCREEN CONTROL Installation and user guide

Humboldt

Humboldt HM-5240.3F product manual

Homematic IP

Homematic IP HmIP-FSI6 Installation instructions and operating manual