FISNAR VC300 User manual

VC300 Pneumatic Valve Controller Operating Manual

© 2021 Fisnar - 2 - VC300 Rev 01

Table of Contents

Machine Overview 3

Product Safety Statements 4

Specifications 6

Accessories 6

External Controls 7

Front

8

Back

11

Control Buttons

13

Machine Setup 15

Dispense Setup 17

Timing Diagram 19

Dispense Modes 20

Manual Mode

20

Timed Mode

22

Cycle Mode

26

Function Menu 29

Auto Cycle Stop

30

Low Pressure Alarm

31

Low Pressure Limit

32

P-Unit

33

Program Version

34

External Machine Actuation 35

I/O Specification 36

Schematic

36

Output Signal Logic

37

Input Signal Logic

38

Output Signal Definition

39

Input Signal Definition

40

Spare Part List 41

Troubleshooting 42

VC300 Pneumatic Valve Controller Operating Manual

© 2021 Fisnar - 3 - VC300 Rev 01

OVERVIEW

Model VC300 Pneumatic Valve Controller

The VC300 is a sophisticated controller able to control the operation of pneumatic dispensing

valves with a spring return closing action or air actuated closing action. The high speed,

internal 5/2 way pneumatic solenoid valve is able to rapidly actuate and shut off the dispense

valve, to prevent drooling and achieve consistent and repeatable dispense results.

The plug & play pneumatic push-in style fittings on the back of the controller, ensure it can be

quickly and easily configured when actuating a pneumatic dispense valve fitted with a

mechanical spring return closing action.

The controllers bright multi-line LED display provides easy user-friendly programming and

visualization of the dispense parameters and conditions. While an integrated pressure

regulator and gauge offer the added benefit in allowing the controller to control both dispense

valve actuation and the fluid pressure being supplied to the dispense valve. This results in a

simple and compact valve system setup, with less external fittings & components being used

at risk of damage and leakages.

Three Operation Modes

A manual mode – The dispense operation is manually controlled by a foot pedal.

A timed mode – Dispenses at a pre-set time for controlled, repeatable shot sizes.

A cycle mode – Continually dispenses at a pre-set time and at a pre-set interval.

One programmable memory slot.

Adjustable fluid output pressure (0-100psi) for setting and controlling pressure of fluid reservoir

connected to the dispense valve.

Compatible with pneumatic dispense valves fitted with a spring return or air actuated closing action

Digital timer display (0.008-99.99 seconds).

7 channel I/O circuit for external control and robot integration

Air input alarm for monitoring consistent system input pressure

Industry standard ¼” air-output connector ensures easy system installation and integration into

workplace environments

Compact & durable aluminum housing designed for industrial work environments.

Worldwide compatible power supply.

VC300 Pneumatic Valve Controller Operating Manual

© 2021 Fisnar - 4 - VC300 Rev 01

General Precautions

Do not operate the machine in excess of its maximum ratings / settings.

Make sure that the input air supply is clean and dry. A 5 micron air filter/regulator

(item number 560567) is supplied and recommended to use, so as to ensure the

input air supply is clean and dry.

If Cyanoacrylates adhesives or other moisture sensitive fluids are being used,

an inline coalescing filter (item number 560779C) must be installed to maintain

dispensing system performance

The fluid being dispensed may be toxic and / or hazardous. Refer to the Material

Safety Data Sheet for proper handling and safety precautions.

Do not smoke or use near an open flame when flammable materials are being

dispensed.

Do not expose the machine directly to sunlight.

Avoid cleaning the machine with aggressive solvents – neutral detergents are

preferred.

VC300 Malfunction

If the machine malfunctions, shut down the machine immediately. This can be

done by either pushing the power switch at the back of the unit into the off

position or disconnecting the power cord.

Isolate pneumatic air supply to the controller.

Identify the cause of machine malfunction and fix accordingly before switching

back on.

SAFETY

VC300 Pneumatic Valve Controller Operating Manual

© 2021 Fisnar - 5 - VC300 Rev 01

Inappropriate Use

If the machine is used in a way other than described in this manual, it may cause damage

to self or property.

Do not use any components with the machine other than Fisnar authorized

components.

Do not use incompatible materials.

Do not make any modifications to the machine.

All repairs are to be done using Fisnar specified spare parts.

Do not operate the machine in excess of its maximum ratings / settings.

Fire Prevention

Refer to the following instructions to avoid any fire or explosion.

Assess your surroundings and the location of the nearest fire extinguisher and

Emergency Exit.

Do not smoke or use near an open flame when flammable materials are being

dispensed.

Immediately disconnect power if any sparking or smoke appears.

Do not expose the machine directly to sunlight.

Maintenance

The VC300 is generally a maintenance free machine. However, to ensure smooth

operation please follow the below instructions.

Only use non-woven cleaners on the machine.

Periodically inspect pneumatic and fluid tubing for signs of fatigue and replace

as necessary

Ensure that compressed air supply to the machine is clean and moisture free.

Periodically check electrical connections and pneumatic fittings are secure.

SAFETY

VC300 Pneumatic Valve Controller Operating Manual

© 2021 Fisnar - 6 - VC300 Rev 01

ACCESSORIES

Item Description Quantity

5601911 Power Adaptor (Input: 100 – 240 VAC / Output: 24 VDC) 1

5601888 Foot Pedal 1

560567 5 Micron Air Filter 1

5801060-10FT 1/4" OD x 1/8” ID Polyurethane Tubing – 10FT 1

560746A Straight 1/4" OD Push Connector x 1/4" NPT Male 3

560716 Nipple ¼” NPT Male 1

560945 Street T 1/4” NPT Male x 1/4" NPT Female 1

580057 Female Quick Connect x 1/4” NPT Male Fitting 1

51495K173 1/4” OD Push to Connect Air Plug 2

5779K712 Push To Connect Air Fitting 1/4" Stem OD X 5/32" Tube OD 3

2146T13 15 Pin D-Sub Connector Plug 1

SPECIFICATIONS

Dimensions (W x D x H): 7.56” x 5.04” x 3.00” (192 x 128 x 76 mm)

Weight: 2.36 lbs (1.07 kg)

Input AC to Power

Supply:

100 – 240 VAC, 50 / 60 Hz

Output DC from Power

Supply: 24 VDC – 1 Amp

Cycle Rate: Up to 600 cycles / min

Relative Humidity: 20 – 90% (No Condensation)

Operating Temperature: 50 – 104

℉ (

10 – 40

℃)

Timer: 0.008 – 99.99 seconds

Air Input: 100 psi (7 bar) max

Air Output: 1 – 100 psi (0.07 – 7 bar)

Standards: CE Approved, UKCA Approved, EMC Compliant,

RoHS Compliant

VC300 Pneumatic Valve Controller Operating Manual

© 2021 Fisnar - 7 - VC300 Rev 01

EXTERNAL CONTROLS

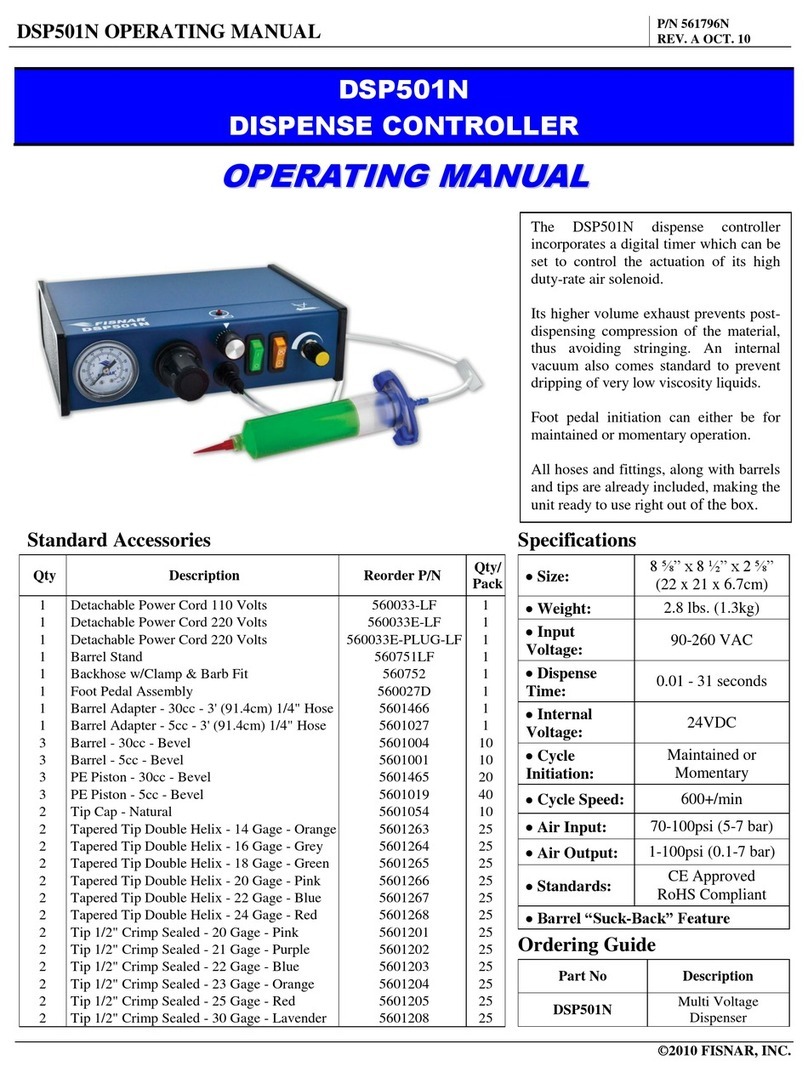

FIG. 1: External Controls - Overview

Item

Illustration Item Illustration Item Illustration

1 Air Pressure Gauge 7 Scroll Down Button 13 Power On/Off Switch

2 Set Button 8 Air Pressure Regulator 14 Valve Close Air Out

Port

3 Mode Button 9 Display 15 Exhaust Port

4 Function Button 10 Foot Switch Connector 16 Fluid Air Out Port

5

Scroll Up Button

11

Power Input Connector

17

Air Inlet Port

6 Shot Button 12 I/O Connector 18 Valve Open Air Out

Port

REAR

FRONT

9

7

1

8

2

4

6

3

5

17

13

18

10

11

12

14

15

16

VC300 Pneumatic Valve Controller Operating Manual

© 2021 Fisnar - 8 - VC300 Rev 01

EXTERNAL CONTROLS

FIG. 2: External Controls – Front

1. Air Pressure

Gauge

Shows the amount of pressure being used to pressurize the fluid feed

system that is feeding the dispense fluid into the valve.

The pressure gauge value is set and controlled by the pressure regulator

(3).

The set pressure is fed out of the machine to the external fluid feed

system from the “Fluid Air Out” port (16).

1

3

2

TIM AL1 IN 0 psi

1.

234 s

A

B

C

D

VC300 Pneumatic Valve Controller Operating Manual

© 2021 Fisnar - 9 - VC300 Rev 01

2A. Digital Display

Screen

In MANUAL mode, when the foot pedal switch or shot button is pressed

or an external machine actuation input signal is received, the dispense

valve will be actuated to start dispensing fluid. The machine will also

begin counting up from 0.000 seconds.

When the foot pedal switch or shot button is released or an external

machine actuation input signal is removed, the dispense valve will stop

being actuated and dispensing of fluid will stop. The machine will display

and hold the dispense cycle time until the next actuation cycle.

When the foot pedal switch or shot button is pressed again or an external

machine actuation input signal is received again, the timer will

automatically reset and start counting up from 0.000 seconds, and the

dispense valve will be actuated to start dispensing fluid again.

When in TIMED mode, the saved dispense time (seconds) will be

displayed. When the foot pedal switch or shot button is pressed or an

external machine actuation input signal is received, the dispense valve

will be actuated to start dispensing fluid. The machine will also begin

counting up from 0.000 seconds until it reaches the saved dispense time.

Once the saved dispense time has been reached, the dispense valve

will stop being actuated and dispensing of fluid will stop. The machine

will display and hold the dispense cycle time until the next actuation

cycle.

One (1) individual program is saved to the machine and automatically

recalled when the machine is powered back on.

When in CYCLE mode, the saved dispense time (seconds) will be

displayed. When the foot pedal switch or shot button is pressed or an

external machine actuation input signal is received, the dispense valve

will be actuated to start dispensing fluid. The machine will also begin

counting up from 0.000 seconds until it reaches the saved dispense time.

Once the saved dispense time has been reached, the dispense valve

will stop being actuated and dispensing of fluid will stop. The machine

will then automatically start counting down from the time set in the “P00.

Auto Cycle Stop” function setting to 0.000 seconds.

Once the machine has counted down to 0.000 seconds, the dispense

valve will automatically be actuated to start dispensing fluid again. The

machine will also automatically begin counting up from 0.000 seconds

until it reaches the saved dispense time.

This looping cycle will continue to be repeated until the foot pedal switch

or shot button is pressed again or an external machine actuation input

signal is received again.

VC300 Pneumatic Valve Controller Operating Manual

© 2021 Fisnar - 10 - VC300 Rev 01

2B. Digital Display

Screen – Mode

The current mode that the machine is operating in, is displayed here.

MAN = Manual Mode

TIM = Timed Mode

CYC = Cycle Mode

2C. Digital Display

Screen - Alarm

If an alarm circuit is activated, it will be displayed here.

AL 1 = Input Pressure Alarm

AL2 = External Error Input Alarm

A red LED light will alight next to the text “ALARM” on the front panel of

the controller, to identify the “Alarm Out” signal has been activated.

If the “Alarm Out” signal is activated during a program cycle, the

program cycle will be automatically stopped.

It will also not be possible to actuate a new program cycle until the “Alarm

Out” signal has been switched off.

2D.

Digital Display

Screen –

Pressure In

Shows the amount of pressure being supplied into the machine and

being used to actuate the connected dispense valve.

Pneumatically operated dispense valves are designed to be actuated

at a minimum pressure of 70psi (4.8bar).

3. Pressure

Regulator

Adjusts the amount of pressure being used to pressurize the fluid feed

system that is feeding the dispense fluid into the valve.

To reach the desired pressure, turn the knob counterclockwise to a point

below the required pressure, and then turn the knob clockwise to reach

the required pressure.

The regulator can be locked into position by tightening the jam nut

behind the knob against the fitting on the front panel of the machine.

VC300 Pneumatic Valve Controller Operating Manual

© 2021 Fisnar - 11 - VC300 Rev 01

EXTERNAL CONTROLS

FIG. 3: External Controls - Back

1. Foot Switch

Connector

The foot pedal switch is connected here. Or it can be used for connecting

to an external device (e.g. Fisnar dispense robot) that will send the

dispense start actuation signal to the machine.

2. Power Input

Connector Power input cable from the external power supply is connected here.

3. I/O Connector

Where the external machine I/O input signals and output signals are

connected.

A courtesy 24V + output is also included on the I/O Connector.

4. On / Off Switch Used to switch the machine on or off.

5. Valve Close

Air Out Port

At the end of a dispensing cycle, pressurized air will exit this port. It is

used for closing the dispense valve via the “Operating Air Close” / “2

nd

Operating Air Inlet” port on the dispense valve.

The pressurized air that exits this port is equal to the air pressure that is

being supplied to the “Main Air In” port

This port is only designed for optional use when the machine is

connected to a 790HP, VDP150, VMS400, VMP30H, VP300 Fisnar

dispense valve.

Typically, this is only needed when using a high viscosity fluid material,

which prevents the return spring fitted inside the dispense valve, from

creating a fast and positive shut-off actuation.

8

4

9

1

2

3

5

6

7

VC300 Pneumatic Valve Controller Operating Manual

© 2021 Fisnar - 12 - VC300 Rev 01

If this function is not required or cannot be used due to the dispense

valve model connected to the machine, then a blanking plug MUST be

inserted into the port.

6. Exhaust Port

At the end of a dispensing cycle, pressurized air that was used to control

the dispense valve actuation will be exhausted from this Exhaust Port.

7. Fluid Air Out Port

The regulated compressed air set by the pressure regulator and

displayed on the pressure gauge on the machine, will exit from this port.

It is used to allow the safe pressurization of the connected fluid feed

system (e.g. syringe barrel, cartridge, etc.)

If this connection is not required for use (e.g. a fluid reservoir tank is

being used as the fluid feed system with its own individual pressure

supply and regulator), it is recommended that the pressure regulator on

the machine be set to 0psi and a blanking plug be inserted into this port.

8. Main Air In Port

External Compressed air 70-100 psi (5-7 bar) is to be connected here.

To prevent damage to internal pneumatic components of the machine,

make sure that the input air supply is clean and dry.

A 5-micron air filter/regulator (item number 560567) is supplied and

recommended to be used, to ensure the input air supply is clean and

dry.

9. Valve Open

Air Out Port

At the start of a dispensing cycle, pressurized air will exit this port. It is

used for opening the dispense valve via the “Operating Air Open” /

“Operating Air Inlet” port on the dispense valve.

The pressurized air that exits this port is equal to the air pressure that is

being supplied to the “Main Air In” port

Pneumatically operated dispense valves are designed to be actuated

at a minimum pressure of 70psi (4.8bar).

To prevent actuation of the connected dispense valve below the

minimum specified working pressure that may have a negative effect on

the dispense result, we recommend enabling the “Low Pressure Alarm”

function (P10) on the machine and setting the “Low Pressure Limit” (P11)

value to 70psi.

VC300 Pneumatic Valve Controller Operating Manual

© 2021 Fisnar - 13 - VC300 Rev 01

EXTERNAL CONTROLS

FIG. 4: Control Buttons

Mode

Press the button to switch between the three different dispense modes

(MANUAL, TIMED or CYCLE). A green LED light will alight next to the text

“MANUAL”, “TIMED” or “CYCLE”, to identify the current dispense mode that the

machine is operating in.

Set

When in “TIMED” or “CYCLE” mode Press the button to change the

dispense time using the and/or button.

When adjusting the dispense time, the button is used as a scroll button

to move between the numerical digits showing on the digital display screen.

When the machine is in the “FUNCTION” menu, the button is used to go

into and out of the selected function setting.

UP and DOWN

When in “TIMED” or “CYCLE” mode, press the and/or button to

make on the fly adjustments by increasing or decreasing the dispense time.

VC300 Pneumatic Valve Controller Operating Manual

© 2021 Fisnar - 14 - VC300 Rev 01

The numerical digit adjusted will be the last numerical digit that was flashing,

when the dispense time was set using the button.

When the machine is in the “FUNCTION” menu, the and/or button is

used to scroll though the different Function settings.

When the machine is in a function setting, press the and/or button to

adjust the function setting value as required.

Shot

Press the button to actuate the machine and begin dispensing fluid from

the connected dispense valve.

Func. (Esc)

Press and hold the button for 5 seconds to enter the Function Menu to

make changes to the Function settings, which provide additional control and

adjustment to the dispense application and machine settings.

VC300 Pneumatic Valve Controller Operating Manual

© 2021 Fisnar - 15 - VC300 Rev 01

MACHINE SET UP

FIG. 5: Machine Setup

1.

Connect air hose from compressed air 70-100 psi (5-7 bar) to the “Main Air In” port on the

back of the machine.

2.

Connect the foot pedal switch to the port on the back of the machine.

Or connect the cable from the dispenser port of the Fisnar robot here. Alternatively, the

machine can be connected to be actuated by an external device using the I/O connector

on the back of the machine.

3.

Attach appropriate country type plug adapter onto the power supply and then connect

Electrical Power Cord (3) to the power input connector on the back of the machine.

4.

Connect a length of ¼” OD pneumatic tubing between the operating air inlet / open fitting

of the dispense valve and the “Valve Open Air Out” port on the back of the machine.

1

2

4

3

5

6

7

VC300 Pneumatic Valve Controller Operating Manual

© 2021 Fisnar - 16 - VC300 Rev 01

If a third-party dispense valve is being connected to the machine, then depending on the

air fitting size used on the dispense valve, either ¼” OD tubing (5801060-10FT), or

5/32”/4mm OD tubing (5601966-10FT) in conjunction with air fitting reducer (5779K712)

installed into the “Valve Open Air Out” can be used.

5.

Connect a length of ¼” OD pneumatic tubing between the 2

nd

operating air inlet /close

fitting of the dispense valve and the “Valve Close Air Out” port on the back of the machine.

If a third-party dispense valve is being connected to the machine, then depending on the

air fitting size used on the dispense valve, either ¼” OD tubing (5801060-10FT), or

5/32”/4mm OD tubing (5601966-10FT) in conjunction with air fitting reducer (5779K712)

installed into the “Valve Close Air Out” can be used.

If the dispense valve being connected to the machine does not utilize this function, then

instead insert a blanking plug into the “Valve Close Air Out” port on the back of the

machine.

6.

Connect ¼” OD pneumatic tubing between the “Fluid Air Out” port on the back of the

machine and the air inlet port of the connected fluid feed system to be pressurized.

If a Fisnar QuantX syringe barrel is being used as the fluid feed system to the dispense

valve, then a standard Fisnar syringe barrel adapter can be used as the compressed air

connection between the syringe barrel and “Fluid Air Out” port on the back of the machine.

(If the syringe barrel adapter to be used with the machine has a bayonet fitting attached to

the end of it, make sure to cut the bayonet fitting off from the hose and install the included

push to connect air fitting (1/4” stem x 5/32” tube O.D.) (5779K712) onto the end of the

tubing.)

If the “Fluid Air Out” port is not required for use (e.g. a fluid reservoir tank is being used as

the fluid feed system with its own individual pressure supply and regulator), it is

recommended that the pressure regulator on the machine be set to 0psi and a blanking plug

be inserted into this port.

7.

Connect ¼” OD fluid tubing between the fluid outlet of the fluid feed system and the fluid

inlet fitting on the dispense valve, using the appropriate required fittings. Note, in some

cases e.g., when dispensing high viscosity fluid materials, it may be necessary to use 3/8”

OD fluid tubing.

If a Fisnar QuantX syringe barrel is being used as the fluid feed system to the dispense

valve, then an 1/8” luer lock elbow fitting (5601821) can be used to connect the syringe

barrel directly to the dispense valve. Note, dispense valves fitted with a ¼” NPT female

fluid inlet thread will also require reducer fitting (561861).

VC300 Pneumatic Valve Controller Operating Manual

© 2021 Fisnar - 17 - VC300 Rev 01

DISPENSE SETUP

FIG. 6: Dispense Setup

1.

Ensure fluid fittings used to connect the fluid feed system to the dispense valve are tight

and secure.

2. Switch on the machine using the power switch located on the back panel.

3. Gradually apply air pressure (80 psi) to the “Main Air In” port on the back of the machine.

4.

Slowly increase the fluid pressure by rotating the pressure regulator clockwise on the front

of the machine.

Stop rotating the pressure regulator when fluid can be seen travelling through the fluid

tubing from the fluid feed system to the dispense valve.

5. Check the operation mode of the machine is set to “Manual” mode.

6.

Locate the stroke control knob on the top of the dispense valve. Rotate the stroke control

knob clockwise until it can no longer be rotated any further. Then rotate the stroke control

knob counterclockwise by 1 full turn (360°).

This step can be ignored when using Fisnar 790HP spool valve.

Dispense Valve and Stand

sold separately

VC300 Pneumatic Valve Controller Operating Manual

© 2021 Fisnar - 18 - VC300 Rev 01

7.

Press the shot button on the front of the machine until fluid begins to dispense out of the

fluid outlet orifice of the connected dispense valve. When fluid is consistently flowing from

the fluid outlet of the dispense valve and no bubbles/air-pockets are observed, release the

shot button on the front of the machine.

If no fluid is dispensed from the dispense valve after approx. 1 minute stop the actuation of

the machine. The below steps can then be carried out, and the machine actuated again.

a) Rotate the stroke control knob counterclockwise by 1 full turn (360°).

b) Increase fluid pressure.

If fluid is still not dispensed, please contact your local sales representative.

8.

Attach a suitable dispense tip to the dispense valve.

Note:- A low gauge number / larger I.D. dispense tip will dispense a larger diameter dot or

bead width. A high gauge number / smaller I.D. dispense tip will dispense a smaller

diameter dot or bead width.

9.

Use the below parameters to achieve the necessary settings for the dispensing application.

1.) Adjust the fluid pressure of the fluid feed system, and stroke control knob on the

dispense valve to achieve the required flow rate.

2.) Adjust the dispense time to set the required volume / time.

3.) Adjust the dispense tip size to assist in fine tuning the dispense dot or bead size.

VC300 Pneumatic Valve Controller Operating Manual

© 2021 Fisnar - 19 - VC300 Rev 01

DISPENSE MODES

FIG. 7: Dispense Mode - Manual

MANUAL

MODE

1.

Use the button to switch to MANUAL mode. The green light on the front of

the machine next to the text “MANUAL” will alight.

MANUAL mode allows the operator to actuate the machine on demand

whenever the foot pedal switch or shot button is pressed.

MANUAL mode can also be used to allow an externally connected device to

control the dispense actuation and time signal duration of the machine.

2.

Press the foot pedal switch or button or supply an external machine

actuation input signal to start the machine and begin dispensing.

VC300 Pneumatic Valve Controller Operating Manual

© 2021 Fisnar - 20 - VC300 Rev 01

Release the foot pedal or button or remove an external machine actuation

input signal to stop dispensing.

The machine will count the amount of time you are dispensing whilst the foot

pedal or button is pressed, or an external machine actuation input signal

is held on for.

This may be helpful in determining a dispense time to be used when actuating

the machine in TIMED mode.

The TIME shown on the digital display after the foot pedal or button, or

external machine actuation input signal has been released, will automatically

reset to zero (0) seconds every time the machine is actuated.

Table of contents

Other FISNAR Controllers manuals

Popular Controllers manuals by other brands

Missile Works

Missile Works RRC2X User manual and instructions

LG

LG PACP4B000 Installation & user manual

Delta Electronics

Delta Electronics Programmable Logic Controller DVP04AD-H2 instruction sheet

Condec

Condec UVC1000 Operation and maintenance manual

IOTA

IOTA IQ-TURBO owner's manual

Siemens

Siemens LOGO! 8 manual