Figure 4: System 450 Control Module Output Analog LEDs,

LCD, four-button touchpad UI

Table 2: System 450 Control Module Output Analog

LEDs, LCD, four-button touchpad UI

Callout Feature Description

1 Status or

setup value

Displays the current input status, output

status, or setup parameter value for the

displayed input sensor, output, or setup

parameter. Press Down or Up to select

a different parameter value when the

value is flashing. Here, 100 = 100%.

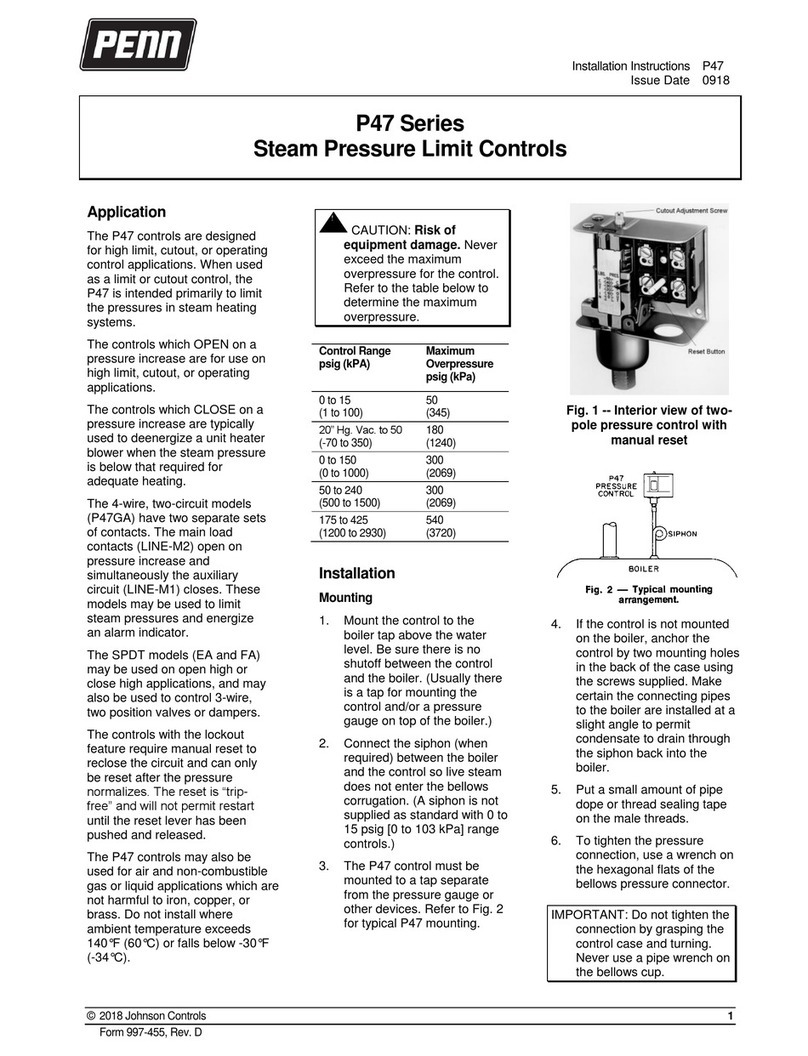

2 LED Green LEDs on Analog Control Module

and Analog Expansion Modules (only)

indicate the analog output’s signal

strength. When the analog output

signal is between 0 and 10 VDC, the LED

blinks. The higher the output signal

strength, the longer the LED is on. The

LED is off when the analog output is not

generating a signal.

3 Output

number

Displays a numerical value that

identifies the output associated with

the status or setup value shown on

the screen. Output numbers are

automatically determined by the

outputs' physical positions (left to

right) in the module assembly. Here,

4 = Output 4.

4 Control

ramp icon

Displays whether an analog output

(only) is set as direct-acting or reverse

acting, and whether the output signal

strength is at minimum or maximum

when the sensed property is at Setpoint.

The control ramp icon displayed is

determined by the output's SP, EP, OSP,

and OEP setup values.

Table 2: System 450 Control Module Output Analog

LEDs, LCD, four-button touchpad UI

Callout Feature Description

5 Next button In the Main screens, press Next to scroll

through the system status screens. In

a setup screen, press Next to save the

flashing setup value and go to the next

setup screen.

6 Up and

Down

buttons

Press Up or Down to select a different

value for any flashing value in the setup

value field. In the Main sensor status

screens, press and hold both Up and

Down for 5 seconds to access the setup

Start screens.

7 Menu

button

Press M to move through the sensor

and output setup start screens. When

moving through the status or setup

screens, press M to return to the status

start screen or setup start screen.

8 Status

or setup

identifier

Displays the unit of measurement,

output, sensor number, or setup

parameter for the displayed status or

setup value. Here, the setup identifier

OSP represents % output signal

strength at setpoint.

9 LCD Backlit LCD screen. The LCD brightness

is adjustable. During normal operation,

the LCD displays the Main screens.

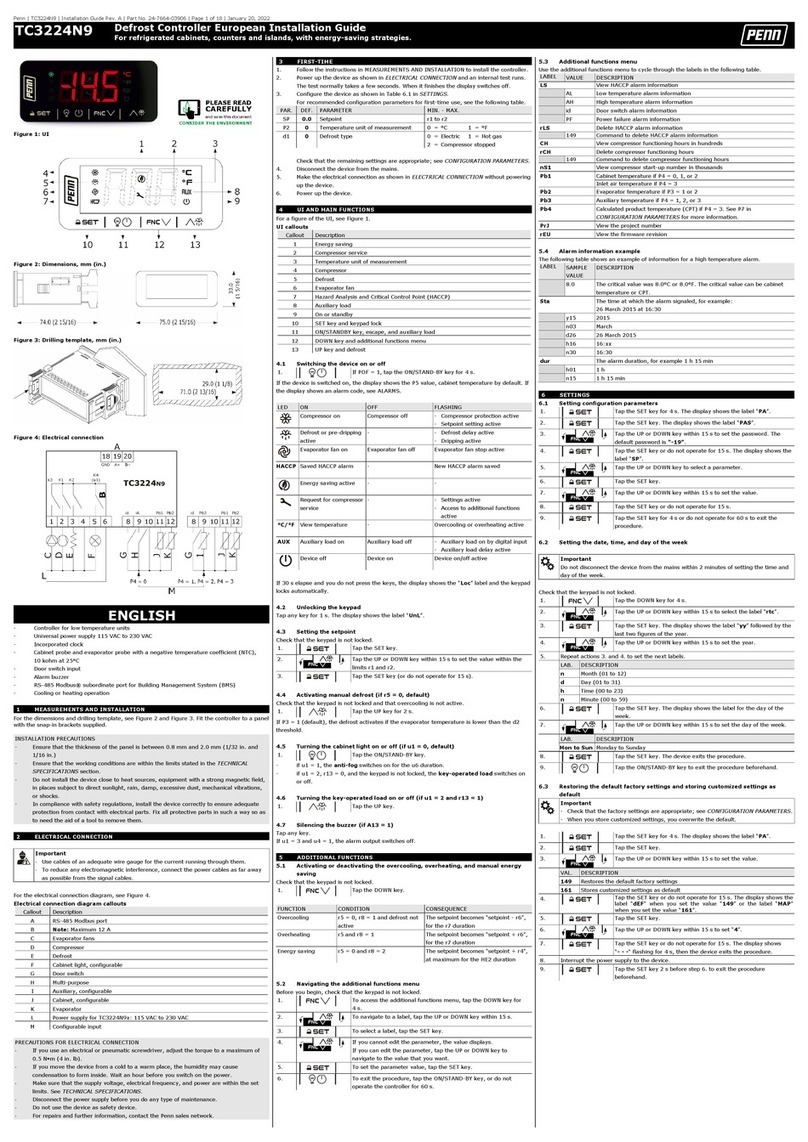

Viewing the Startup, Main, and System

Status screens

Every time you connect power to a System 450 control

module, the Startup screen appears for several seconds

before the Main screens appear. The Startup screen

displays the current firmware version for the module.

After you install, wire, power on, and set up your control

system in the UI, the Main screens appear on the LCD,

immediately after the Startup screen. During normal

operation, the Main screens automatically scroll through

the current status of each sensor in your control system

and the backlight low level setting is applied.

The System Status screens display the current status of

each input and output in your control system. With the

Main screen displayed, press any key to exit idle mode,

then press Next repeatedly to scroll through and view all

of the status screens in your control system.

When you power on a System 450 control module, the

LCD displays the control module’s current firmware

version for approximately five seconds before it displays

the Main (Input Status) screen. The following figure

shows System 450 firmware version number 4.00 on

the top of the screen. The number on the bottom of the

screen (indicated in this example with xxxx) identifies the

Johnson Controls firmware.

Figure 5: Startup screen

System 450 Series Control Modules with Analog Outputs Installation Guide 5