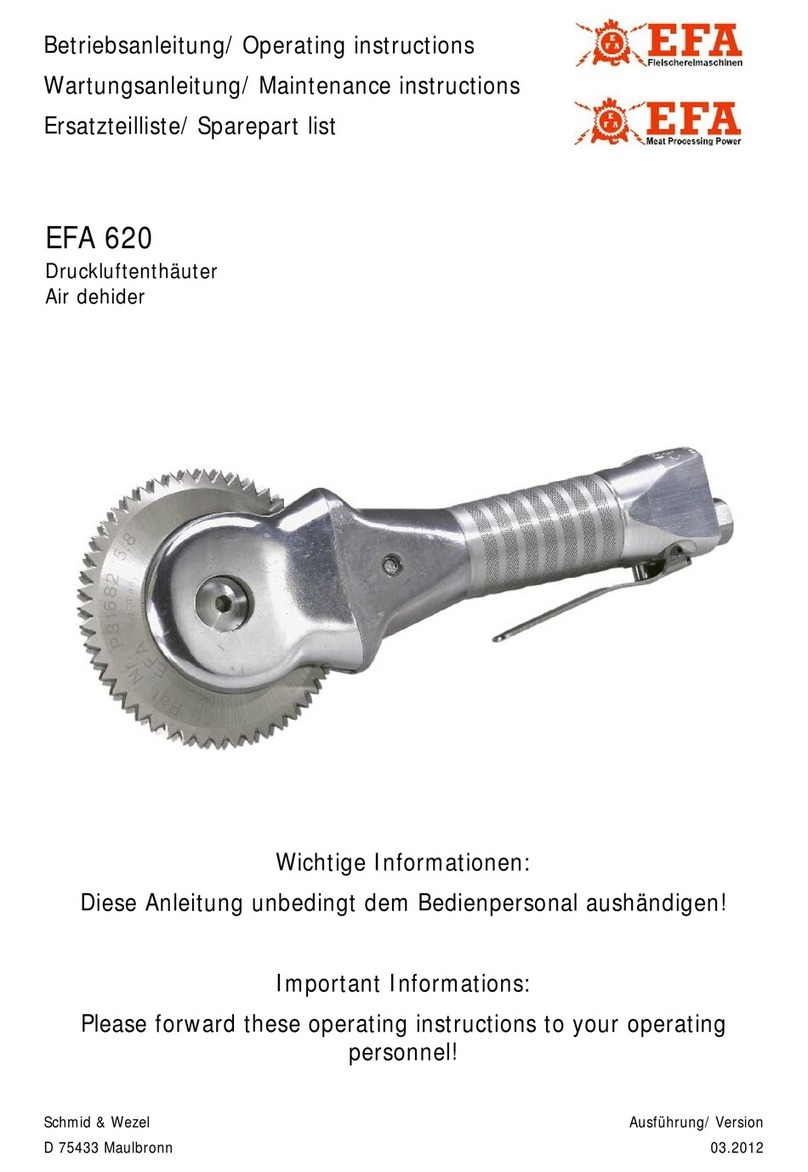

FITOK HPT-DF User manual

Hydraulic Presetting Tools

(Medium & High Pressure)

Instruction Manual

info@fitokgroup.com

www.fitokgroup.com

info@fitokgroup.com

www.fitokgroup.com

FITOK Group

FITOK GmbH

Sprendlinger Landstr. 115, 63069 Offenbach am Main, Germany

Tel.: +49 69 8900 4498 Fax: +49 69 8900 4495

FITOK, Inc.

13843 North Promenade Blvd., Suite 750, Stafford, Texas 77477,

USA

Tel.: +1 281 888 0077 Fax: +1 281 582 4051

FITOK (Wuhan) Incorporated

Zhongbai Yangluo Industrial Park, Hanshi Road, Xinzhou District,

Wuhan, Hubei Province, 430415, China

Tel.: +86 27 8983 8988 Fax: +86 27 8983 8980

FITOK (Shenzhen) Incorporated

No.164 Xinqu Village, Tiantou Community, Shijing Street,

Pingshan District, Shenzhen 518118, China

Tel.: +86 755 2803 2500 Fax: +86 755 2803 2619

FITOK (Suzhou) Metal Products Co., Ltd.

No. 29 Changsheng Road, Yangyuan Industrial Park, Xinzhuang

Town, Changshu, Jiangsu 215562, China

Tel.: +86 512 5247 9001 Fax: +86 512 5247 9002

FITOK Corporation

1F, B1, 119, Gyeonggi-daero 632beon-gil, Osan-si, Gyeonggi-do,

Republic of Korea

Tel: +82 31 831 9811 Fax: +82 31 831 9812

FITOK Middle East Oil Equipment Trading LLC

Makateb Building, P.O. Box 185412, Airport Road, Deira,

Dubai, UAE

Tel.: +971 4 2959 853 Fax: +971 4 2959 854

1

Introduction

This instruction manual specifies FITOK Hydraulic

Presetting Tool that is used to preset 20D Series double

ferrules onto the tubing.

Please read and understand this instruction manual before

using FITOK Hydraulic Presetting Tool.

Model Specification

HPT-N

HPT-DF

Model

Hydraulic Presetting Tools

Description

Without die heads

The die heads can be ordered

individually

With full set of die heads

CAUTION - It states the correct operation, maintenance

procedure and how to avoid damaging the equipment

or other property.

WARNING - Proper personal protection equipment must

be used when operating the Hydraulic Presetting Tool.

CAUTION - Do not tamper with or alter any components.

CAUTION - Please contact FITOK Group or authorized

distributors if any signs of hydraulic fluid leakage or

malfunction occur.

CAUTION - Keep away from flame or heat source. Do

not expose the tool to the temperature of 65 °C or

higher, and protect the cylinder from welding sparks.

WARNING - It states a potential danger existed to

require correct procedure and convention to avoid

personal injury.

Definitions

Safety Precautions

Symbols are used in this document to identify safety

concerns. Read the definitions below before installing

and operating the Hydraulic Presetting Tool.

HPT-DFF9

HPT-DFF12

HPT-DFF8

Model

Die Heads

Tube O.D., in.

1/2

9/16

3/4

HPT-DFF16 1

Caution

32

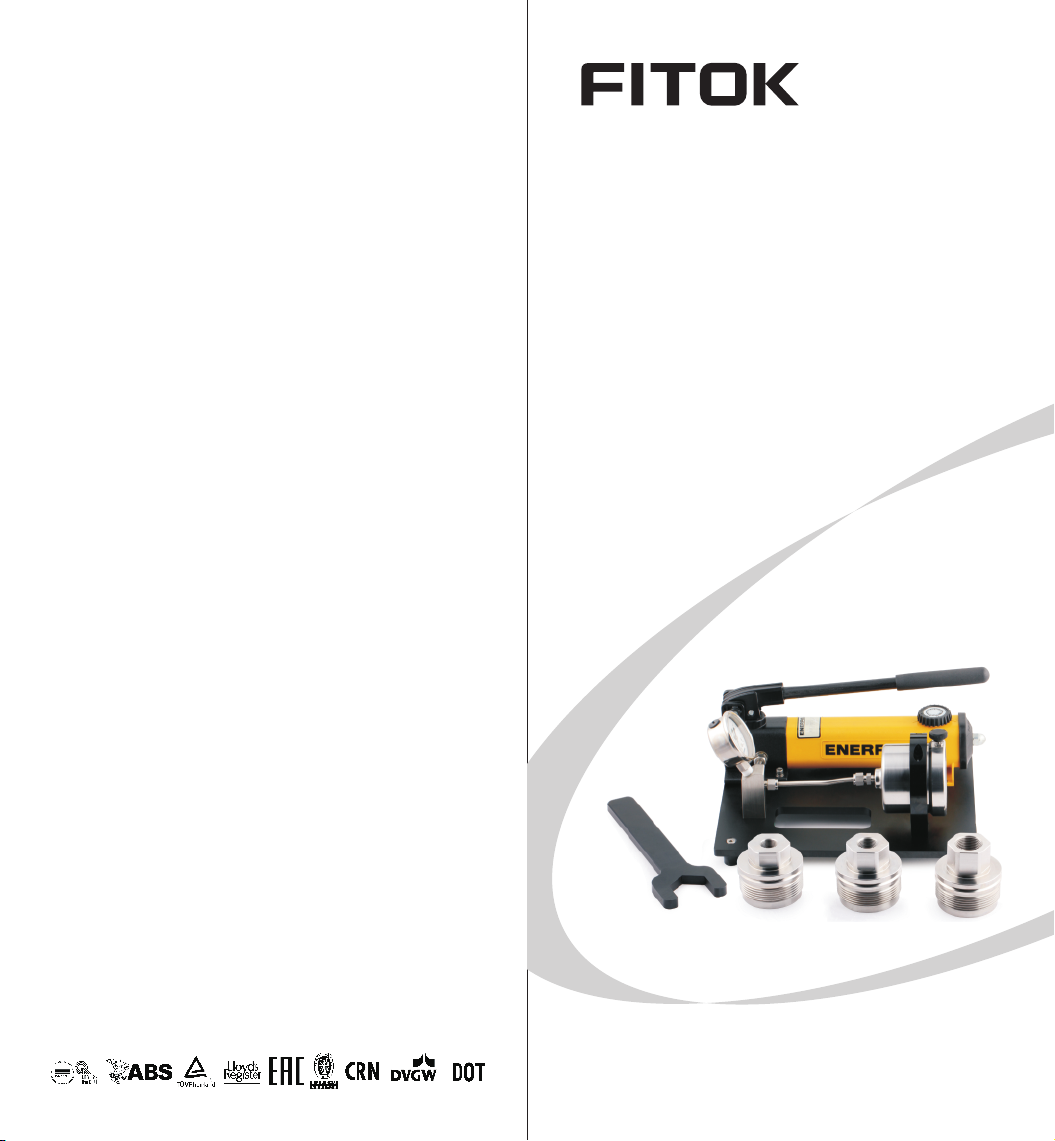

Components

(Unit with Die Heads and Base)

Installation

Operation

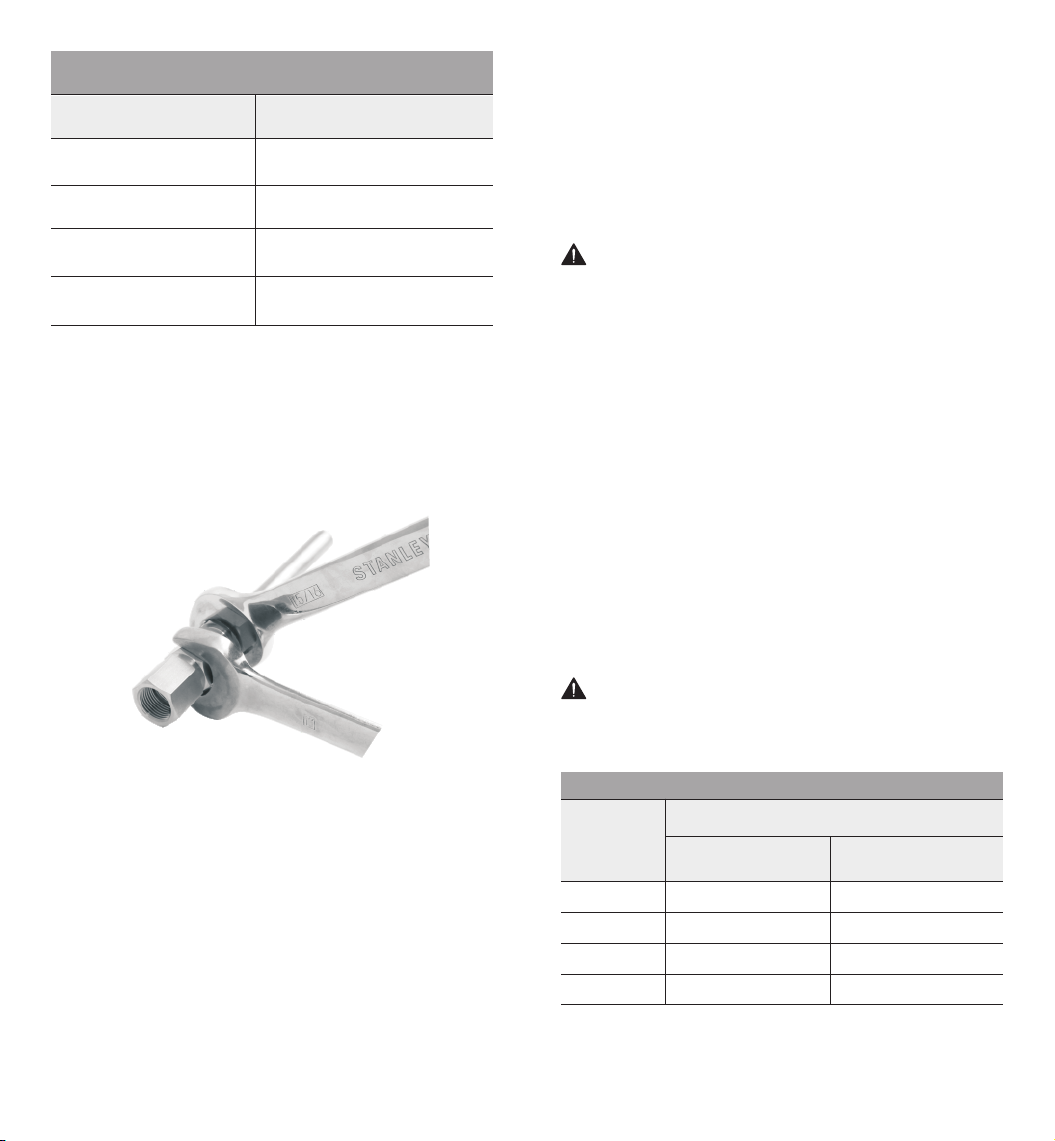

When disassembling the die head, loosen the locking

handle first, and disassemble the die head.

1. Select an appropriate die head.

2. Install the selected die head into the hydraulic housing

clockwise until the end face of the die head is aligned

with that of the hydraulic housing. Then use a wrench to

tighten it. See Fig. 1.

1. Prepare tube ends by deburring.

Note: Remove any burrs. Use of FITOK Tube Deburring

Tool is recommended.

2. Put a nut, a rear ferrule and a front ferrule onto the

tubing in proper sequence and orientation. See Fig. 2.

3. Insert the tubing into the die head until it rests firmly

against the piston shoulder. Tighten the nut until finger-

tight. See Fig. 3.

4. Make sure that the bleed valve is in the closed position.

While holding the tubing against the piston shoulder,

press the pump handle gently till the gauge shows the

corresponding pressure value. Hold for more than 30s.

See Fig.3 and Table 1.

3. Turn the locking handle clockwise to the finger-tight

position to ensure the die head is firmed. See Fig.1.

Fig. 1 Die Head Installation

Fig. 2. Nut and Ferrules Orientation

Wrench

Hydraulic hand pump

Bleed valve

Pressure gauge

Hydraulic housing

Base

Die heads

Locking handle

step 3

step 2

Fig.3 Tubing Presetting

4

1. If it is difficult to remove the tubing from the hydraulic

presetting tool after presetting, rock the tubing back

and forth.

Refer to the Recommended Minimum Wall Thickness

table - presetting tubing below the recommended

minimum wall thickness may result in tube sticking.

Troubleshooting

5. Open the bleed valve. Loosen the nut and remove the

tubing from the hydraulic presetting tool.

6. Install the preset assembly into the fitting body and turn

the nut onto the fitting body until it is -tight.

While holding the fitting body steady, tighten the nut

1/4 turn with a wrench for tube O.D. 1/2", 9/16", 3/4",

and 1/2 turn for tube O.D. 1". See Fig. 4.

finger

Do not rotate the tubing.

Use of tubing below the recommended minimum wall

thickness may result in the tube sticking in the die head.

2. If the die head piston is binding, contact FITOK Group or

authorized distributors.

3. If the pump fails to build pressure, check the oil level in

the pump by removing the dipstick and checking for a

proper amount of oil. Too much or too little oil will

prevent the pump from operating properly.

4. The pump manufacturer specifies using 10W, AW-46

grade hydraulic oil or equivalent with an antifoaming

additive.

CAUTION

WARNING

Table 1

Fig. 4 Tighten Nut with Wrench

Presetting Pressure, Mpa

Tube O.D., in.

Recommended Minimum Wall

Thickness of Tubing for Use with

the Hydraulic Presetting Tool

Tubing Wall Thickness, in.

Tube O.D.,

in. Annealed Stainless

Steel tubing

9/16

9/16 20 22~

3/4

3/4 33 36~

1/2

1/2 13 15~

0.134

0.188

0.188

1/8-hard Stainless

Steel tubing

0.109

0.125

0.165

5

1 45 47~

10.22 0.17

Reinstallation Instructions

1. Insert the tubing into the fitting body or the valve,

finger tight the nut.

2. While holding the fitting body or the valve steady, for

tubing O.D. 1'', tighten the nut to the previous assembly

position and further tighten it with a wrench; for other

dimension tubing, tighten the nut 1/4 turn with a

wrench for the initial reinstallation, and for reinstallations

thereafter, tighten the nut to the previous assembly

position and further tighten it with a wrench.

This manual suits for next models

5

Popular Tools manuals by other brands

Cleco

Cleco LiveWire 47BC Series manual

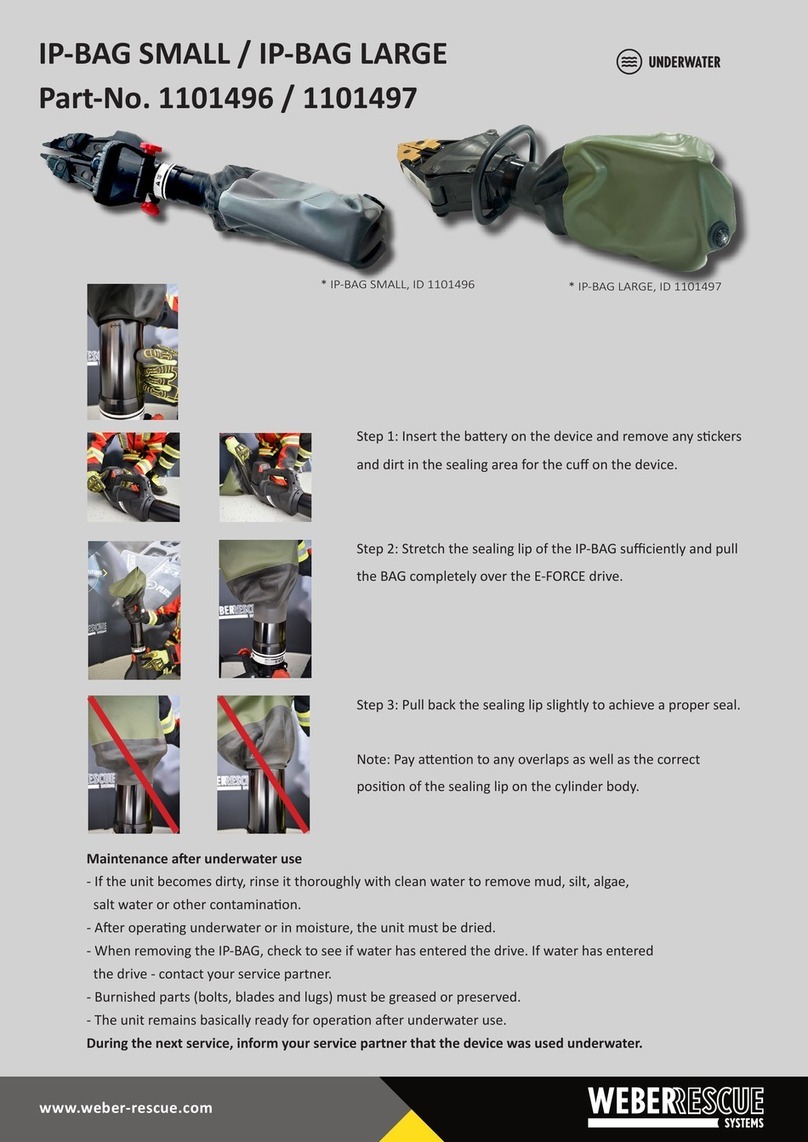

Weber Rescue Systems

Weber Rescue Systems IP-BAG SMALL quick start guide

Schneider Airsystems

Schneider Airsystems SLA 8-9 Original operating manual

Piper Aircraft Corporation

Piper Aircraft Corporation Cherokee PA-28-180 Airplane Flight Manual

Kreg

Kreg KHI-CDIJ owner's manual

Glomar

Glomar EPG-ULTRA-ID instruction manual

Atlas Copco

Atlas Copco LTV39-2 R48-10-ATEX Product instructions

Hilti

Hilti TE 6-CL Original operating instructions

Summit

Summit SME-906006 instructions

MSW Motor Technics

MSW Motor Technics MSW-SG-125 user manual

Matco Tools

Matco Tools MWD2 Operating instructions and warnings

Sealey

Sealey GH80.V2 instructions