Page

1. SAFETY INSTRUCTIONS ................................................................................3

VDI 6022 ............................................................................................................3

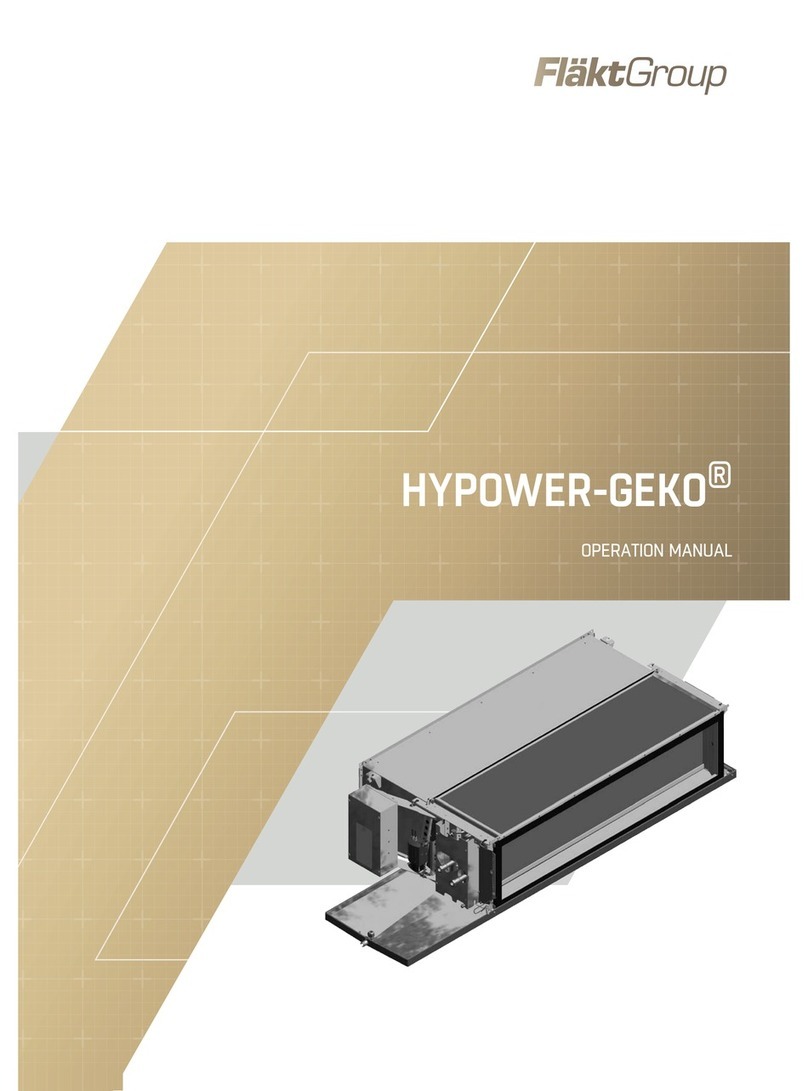

2. DESCRIPTION OG THE UNIT..........................................................................4

3. TRANSPORT AND PLACEMENT ..................................................................5

4. CONNECTIONS

4.1 Duct connections.....................................................................................6

4.2 Post heater, electrical (9 kW).............................................................6

4.3 Post heater, hot water...........................................................................6

4.4 Cooling coil, water...................................................................................7

4.5 Valve and valve actuator......................................................................7

4.6 Damper........................................................................................................7

4.7 Silencer........................................................................................................7

5. ELECTRICAL CONNECTIONS

5.1 Fuse protection ........................................................................................8

5.2 Electrical data...........................................................................................8

5.3 Main supply...............................................................................................8

5.4 Connection of control panel................................................................9

6. CONNECTION OF EXTERNAL COMPONENTS

6.1 Electrical post heater (Size 06, 9 kW) .........................................10

6.2 Post heater, hot water.........................................................................10

6.3 Cooling coil, water................................................................................10

6.4 Cooling coil, DX......................................................................................10

6.5 Damper .....................................................................................................10

6.6 Temperature sensors...........................................................................11

6.7 Extended / Forced ventilation..........................................................11

6.8 Fire protection function .......................................................................11

6.9 Summary alarm .....................................................................................11

7. WIRING DIAGRAMS...............................................................................12

8. TESTING OF FUNCTIONS.......................................................................15

9. CONTROL PANEL, OPEERATIONS, COMMISSIONING

9.1 General.......................................................................................................16

9.2 Home screen overview ...................................................................... 17

9.3 Sub menus ..............................................................................................19

9.4 Date/time, language...........................................................................20

9.5 Advanced settings for installers and sevice personnel..........21

9.6 Commissioning Wizard.....................................................................22

9.7 Schedules................................................................................................26

Page

10. CONTROL FUNCTIONS

10.1 Rotor, heating and cooling .............................................................29

10.2 Temperature controls......................................................................29

10.3 Freeze protection...............................................................................31

10.4 Defrost function...................................................................................31

10.5 Cooling recovery................................................................................31

10.6 Night cooling........................................................................................31

10.7 Pressure or Constant flow control .......................................32

11. COMMUNICATION

11.1 Modbus, RS485...................................................................................33

11.2 Modbus, TCP/IP .................................................................................33

11.3 Webserver............................................................................................33

12. PARAMETER LIST ........................................................................................34

13. MAINTENANCE

13.1 General...................................................................................................40

13.2 Filter........................................................................................................40

13.3 Rotary Heat Exchanger...................................................................41

13.4 Post heater, hot water.....................................................................42

13.5 Post heater, electrical ....................................................................43

13.6 Cooling coil, water............................................................................ 43

13.7 Fans........................................................................................................ 44

13.8 Service schedule ..............................................................................45

14. DECLARATION OF CONFORMITY ............................................................46

15. DISPOSAL ....................................................................................................... 47

CONTENTS