flakt woods CURO Touch Owner's manual

AIR TREATMENT

CONTROL EQUIPMENT

AIR COMFORT LCD CONTROL PANEL

CURO®TOUCH FOR ECOSTAR

» Technical insTrucTion for version 2.02

APRIL 2015

Curo

®

Touch - Technical Instruction Version 2.02

Fläkt Woods 9401 GB 2015.04.07 Specifications are subject to alteration without notice

3

NOTE: THE INSTALLATION, ADJUSTMENT AND COMMISSIONING DESCRIBED WITHIN

THIS MANUAL MUST BE CARRIED OUT BY THE INSTALLER, OR SERVICE PERSONNEL.

CONTENTS

WARNING: This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have

been given supervision or instruction concerning use of the appliance by a person responsible for

their safety. Children should be supervised to ensure that they do not play with the appliance.

INSTALLATION INSTRUCTIONS

Installation & Connection................................................................................................................................... 4

USER INSTRUCTIONS

Introduction, Conventions & Using the unit................................................................................................5

Home Screen overview......................................................................................................................................6

Basic Operation, overview................................................................................................................................. 7

Operating modes, Alarms & User settings................................................................................................8

COMMISSIONING INSTRUCTIONS

Settings of date/time, language.....................................................................................................................9

Advanced settings.............................................................................................................................................. 10

Commissioning Wizard.....................................................................................................................................11

Schedules .............................................................................................................................................................. 12

Timer function....................................................................................................................................................... 14

Curo

®

Touch - Technical Instruction Version 2.02

Fläkt Woods 9401 GB 2015.04.07 Specifications are subject to alteration without notice

4

INSTALLATION & CONNECTION OF LCD CONTROL PANEL CURO®TOUCH

1. Open the control panel using a screwdriver

2. Lift the display out of the enclosure.

4. Push the connection cable through a suitable hole and if

needed make an outlet for the cable on side of the cover.

Mount the enclosure directly on the wall.

5. Push back the display in the enclosure.

3. Connect the cable to the back of the display as shown above.

Note. Please do not touch the electronics.

Curo

®

Touch - Technical Instruction Version 2.02

Fläkt Woods 9401 GB 2015.04.07 Specifications are subject to alteration without notice

5

INTRODUCTION, CONVENTIONS & USING THE UNIT

INTRODUCTION

HMI

This section provides an introduction to the touchscreen LCD

control panel, also known as the ‘Human Machine Interface’, or

simply, HMI.

The HMI serves two main purposes: To provide information about

the current operational state of the unit. To allow the unit to be

setup and configured.

TOUCH SCREEN TIPS

To select an item, touch the center of the icon or option. Do not

press too hard, the touch screen is sensitive enough to pick up

light, firm touches. Use the tip of your finger or the back of a pen-

cil to touch the required option. Be careful not to touch any other

options.

CLEANING THE SCREEN

Disconnect the power cord. Gently wipe the screen with a soft,

dry non-abrasive cloth. If the marks remain, moisten the cloth

slightly with a detergent that is designed for LCD or mobile

screens and wipe the screen gently from top to bottom. Never

use detergents, as these may contain ammonia or other additives.

IMPORTANT:

• Never spray, or pour liquids directly on to the screen.

• Do not clean the screen while the system is on.

CONVENTIONS USED WITHIN THIS MANUAL

The following buttons and symbols are universal and available on

many menu pages.

Home key, to return to the Home Screen.

Back button, to cancel and return to the previous

page.

Confirm button to confirm and proceed.

Changing a value:

Option 1: Press the arrow keys to increase or

decrease the value.

Option 2: Press the displayed number to

numerically adjust the value.

USING THE UNIT

POWERING ON

Each time power is applied, the unit will run through a series of

internal system tests which take approximately 20 seconds to

complete.

Once the internal system tests have been completed, the HMI will

always display the Home screen. The unit will be in Manual Mode

the first time that power is applied.

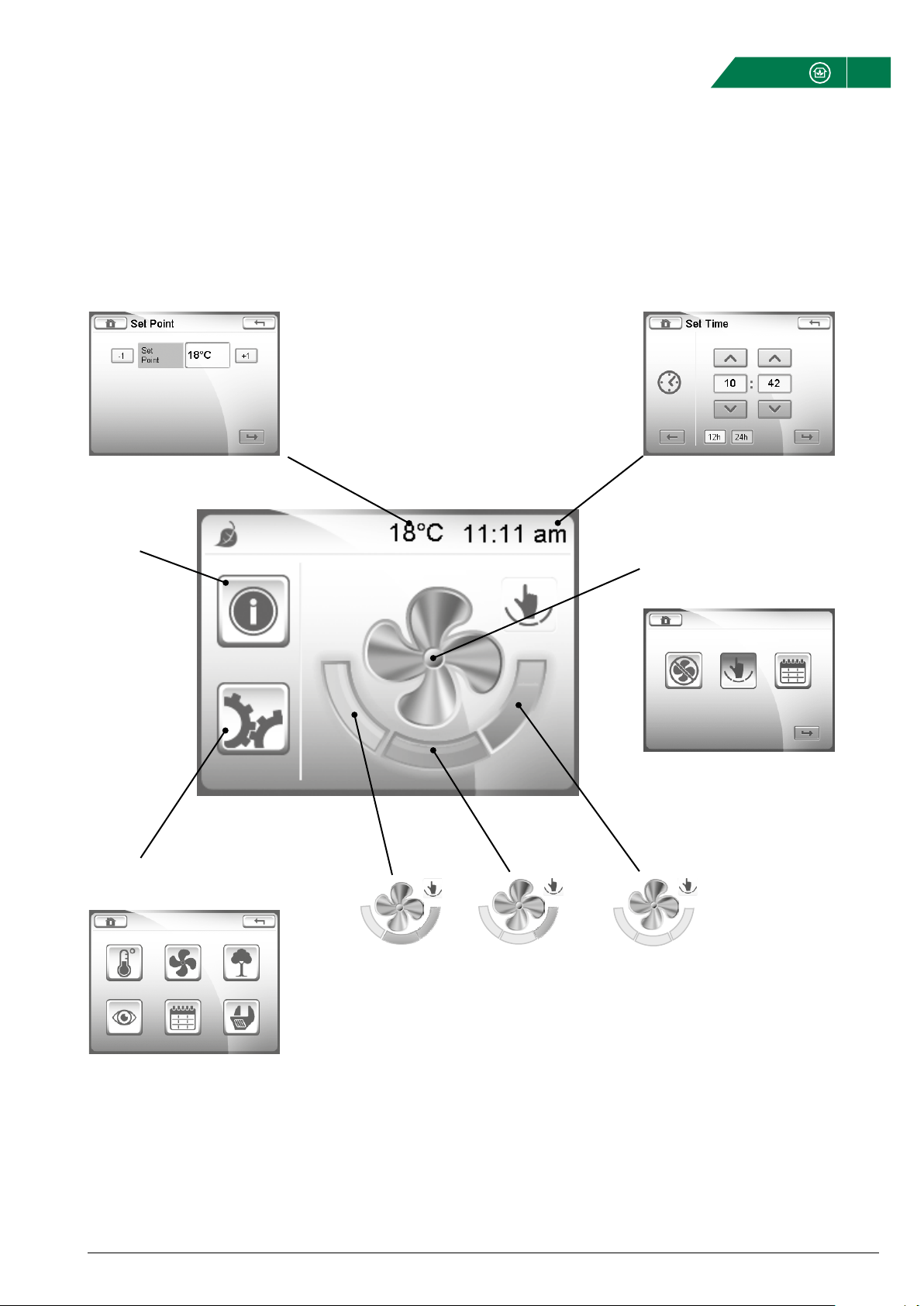

HOME SCREEN

The unit always powers up in the Home screen. From the Home

screen it is possible to determine how the unit is operating as

well as navigating to further screens to configure the unit to suit

the demands of the end system.

From the Home Screen, it is possible to:

Navigate to further configuration screens to setup system param-

eters.

• Manually adjust the fan speed.

• Determine the operating status of the product.

• Interrogate and acknowledge system alarms.

Use the number buttons to enter

a value.

Confirm with or cancel with .

Values that can only be read, but not written,

are displayed without a surrounding window.

Values that can be both read and written,

are displayed with a surrounding window.

Some submenus has several

pages. Touch the upper or the

lower part of the scroll list to

navigate between pages.

Curo

®

Touch - Technical Instruction Version 2.02

Fläkt Woods 9401 GB 2015.04.07 Specifications are subject to alteration without notice

6

HOME SCREEN OVERVIEW

ALARM

No alarm

Alarm B

Alarm A

Heat recovery active

Post-heater active

Pre-heater active

Cooling active

Defrosting in progress

Manual mode

CO

2

regulation

Automatic mode

Constant pressure

Timer 1

Timer 2

Timer 1/Timer 2

Trickle or low speed

Normal or medium speed

Boost or high speed

STATUS LINE

OPERATING STATUS

OPERATING MODES

CLOCK

CURRENT SET POINT

TEMPERATURE

COP

Curo

®

Touch - Technical Instruction Version 2.02

Fläkt Woods 9401 GB 2015.04.07 Specifications are subject to alteration without notice

7

ALARM

See page 8.

BASIC OPERATION OVERVIEW

SHORTCUT TO SET THE

TEMPERATURE SET POINT

USER SETTINGS

See page 8.

SHORTCUT TO SET THE TIME

AND DATE

SELECT OPERATING MODE

See page 8.

TRICKLE OR

LOW SPEED

NORMAL OR

MEDIUM SPEED

BOOST OR

HIGH SPEED

Press each field to select the operating mode.

Only active in Manual Mode.

Curo

®

Touch - Technical Instruction Version 2.02

Fläkt Woods 9401 GB 2015.04.07 Specifications are subject to alteration without notice

8

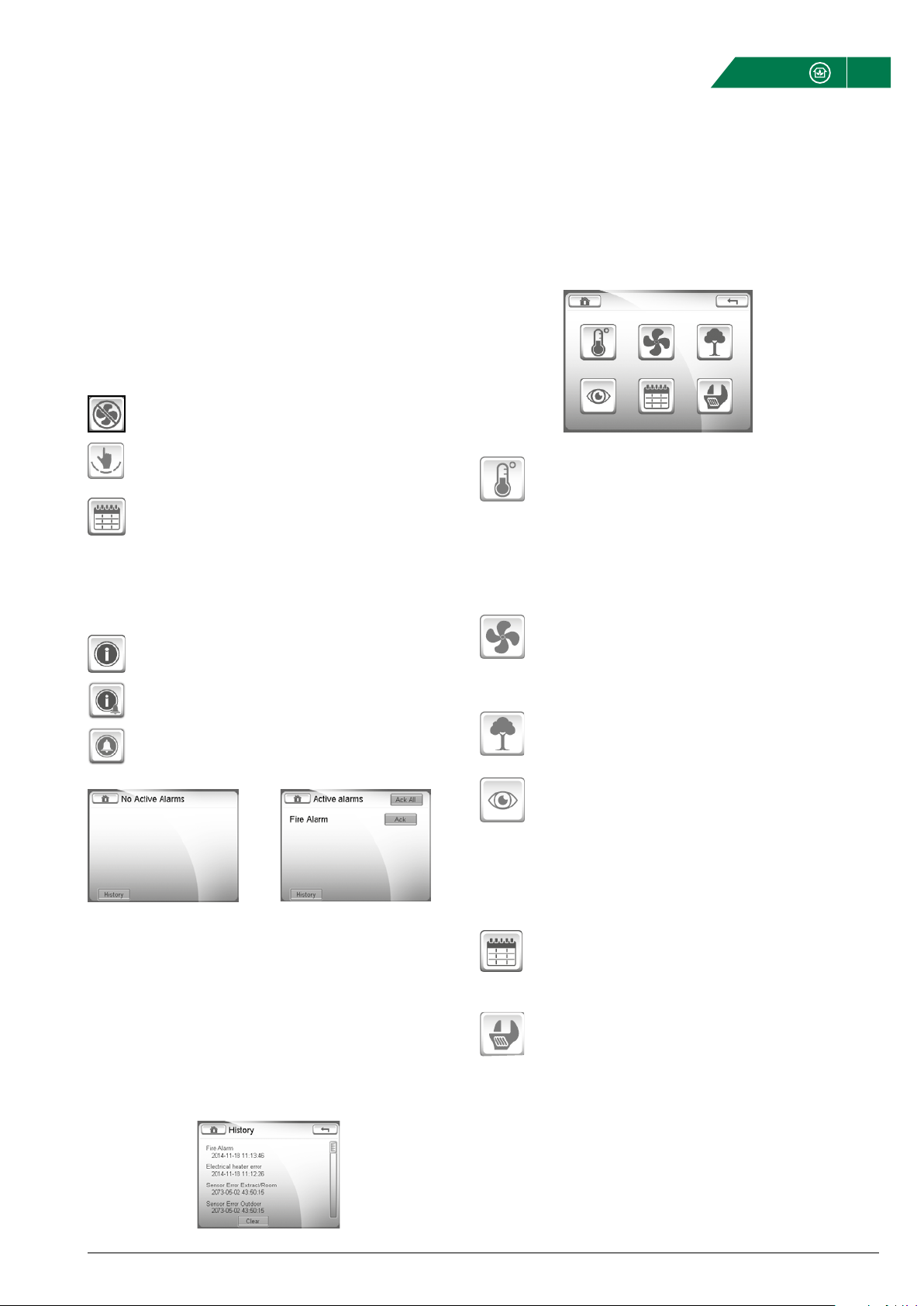

OPERATING MODES

The operating status icon present on the Home Screen dis-

plays the current operating mode. To change the operating

mode, press the large fan icon located on the Home Screen.

The unit has three operating modes selectable through the

Operating Modes screen:

Stop Mode: In this mode, the unit will stop both the

supply and the extract fans.

Manual Mode: In this mode, the unit can be manually

adjusted on the Home Screen to run at three different

speeds.

Automatic Mode: In this mode, the unit will be automa-

tically controlled using internal schedules and timers,

CO

2

demand control, PIR sensors, etc.

ALARM SCREEN

The alarm icon on the Home Screen indicates the status of any

system alarms:

No alarm

Alarm type B are deemed non-critical

and do not stop the unit ventilation.

Alarm type A are deemed critical and will

cause the unit to stop ventilating.

Press the icon to enter the Alarm Screen.

USER SETTINGS

OPERATING MODES, ALARMS & USER SETTINGS

TEMPERATURE STATUS

The temperature set point is used to determine when

the post-heater (if fitted) starts to warm the supply air

entering the property. The temperature set point can be

adjusted to any temperature between 15° C and 35° C,

factory setting is 18° C.

Temperatures and output signals are read only values.

FAN STATUS

From the Fan Control Status screen it will be possible

to view parameters such as supply and extract fan

speeds, %, off and pressures.

AIR QUALITY

CO

2

value and CO

2

set point (if activated).

SYSTEM OVERVIEW

Version Control Panel IP Octet 1

Bootloader Control Panel IP Octet 2

Version Control Card IP Octet 3

Bootloader Control Card IP Octet 4

Unit type

SCHEDULES

Read only. For more information see section ”Schedules”

on page 21.

ADVANCED SETTINGS

See section ”Advanced settings” on page 10.

Example 1: No alarm Example 2: Active alarms

CLEARING ALARMS

To clear an individual alarm, press the Ack button. To clear all the

Alarms press the Ack All button on top of the screen.

It may not always be possible to clear the status of an alarm as the

source of the alarm may immediately trigger the status to return.

For example, it will not be possible to clear a faulty temperature

sensor alarm until the sensor itself has been repaired or replaced.

Alarm B

Alarm A

ALARM HISTORY

Curo

®

Touch - Technical Instruction Version 2.02

Fläkt Woods 9401 GB 2015.04.07 Specifications are subject to alteration without notice

9

CONFIGURING LANGUAGE, DATE & TIME

SETTINGS

To enter the settings menu:

1. Push on the gear cog button.

2. Push the spanner button.

3. In this menu you set the date, time and language. It is also

possible for installers and service personnel to log in and

access additional parameters.

DATE/TIME

2 Set the time and press the Confirm button

1. Set the date and press the Confirm button.

CHOOSE LANGUAGE

1. Choose the appropriate language flag and press

the Confirm button.

Note, further language flags are available after

pressing the right arrow icon.

Curo

®

Touch - Technical Instruction Version 2.02

Fläkt Woods 9401 GB 2015.04.07 Specifications are subject to alteration without notice

10

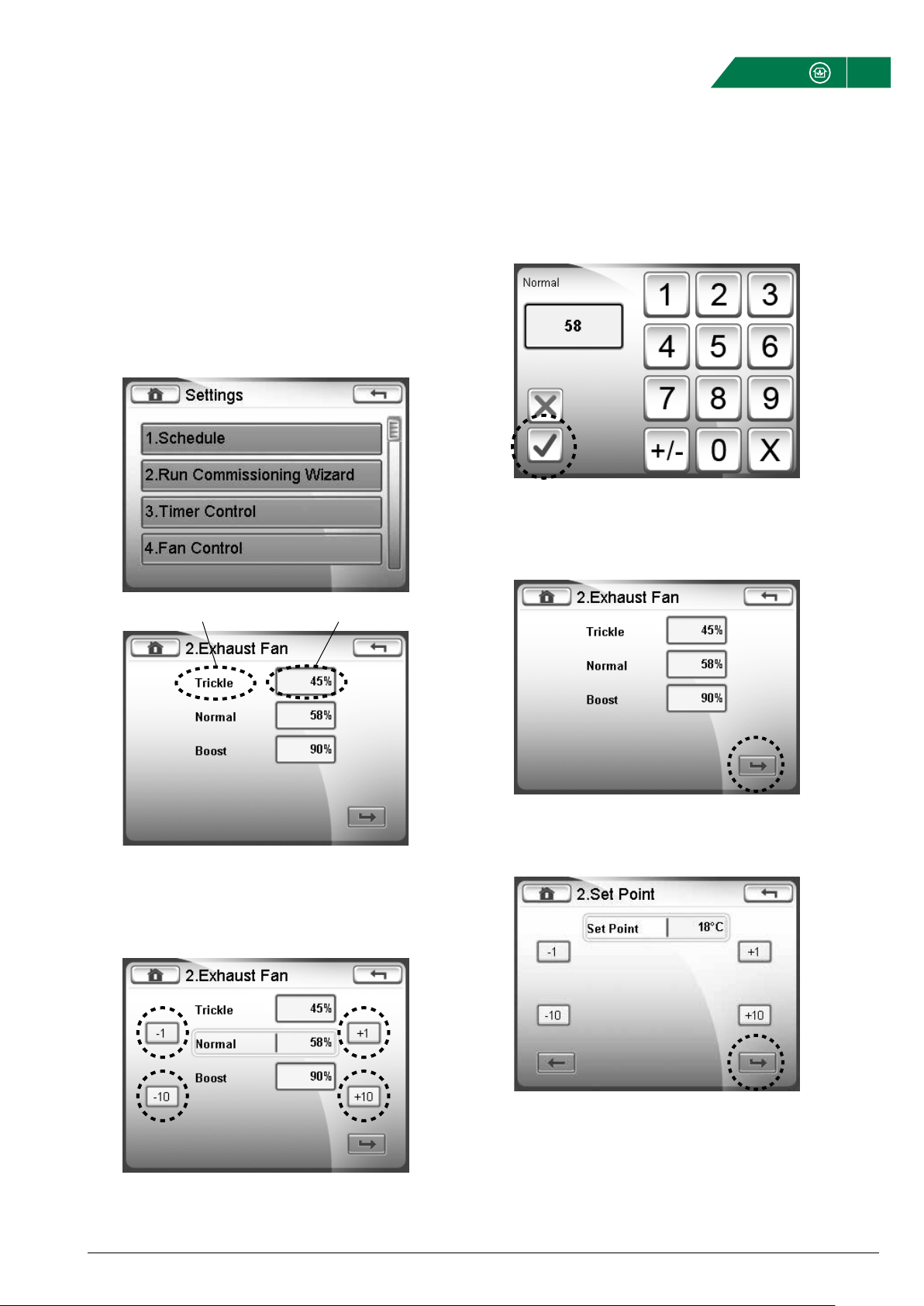

ADVANCED SETTINGS

LOGIN

Advanced settings requires the Login passcode, 0000, to be

entered.

1. Enter the correct passcode and press the Confirm button.

SETTINGS FOR INSTALLER AND SERVICE PERSONNEL

This section provides an overview to the more advanced opera-

tions that are available from the Home Screen via the passcode

protected Advanced Settings option.

Numerous system parameters can be adjusted through the

Settings Screen; however, only those that are relevant and appro-

priate to the scope of the HMI User Manual will be described. It

is strongly recommended to avoid the adjustment of any system

parameters not outline within this section.

Access to the Settings Screen is passcode protected to prevent

system critical parameters from being accidentally adjusted to

values that could compromise the correct operation of the unit.

Therefore, extreme caution should be observed when adjusting

Advanced Settings parameters.

Curo

®

Touch - Technical Instruction Version 2.02

Fläkt Woods 9401 GB 2015.04.07 Specifications are subject to alteration without notice

11

COMMISSIONING WIZARD

OPTION 1 - Press Trickle, Normal, Boost, then use the

±1 or ±10 buttons.

OPTION 2 - Press the values within the boxes adjacent to Trickle,

Normal, or Boost, then use the numerical keypad.

OPTION 1

OPTION 2

When completed, press the Confirm button to proceed to the

supply fan.

Make the appropriate settings for the supply fan and press the

Confirm button.

OPTION 1 OPTION 2

Adjust the supply air temperature set point in ° C and press the

Confirm button to complete the Commissioning Wizard.

Note, whilst in the Commissiong Wizard, the Back button can be

pressed at any time to access the previous page of settings.

The Commissioning Wizard allows the basic unit settings to be

configured in a simple and intuitive manner.

The Commissioning Wizard is accessed by selection the ”Run

Commissioning Wizard” option from the advanced settings screen.

The speeds for each operation mode can be changed in two ways:

Curo

®

Touch - Technical Instruction Version 2.02

Fläkt Woods 9401 GB 2015.04.07 Specifications are subject to alteration without notice

12

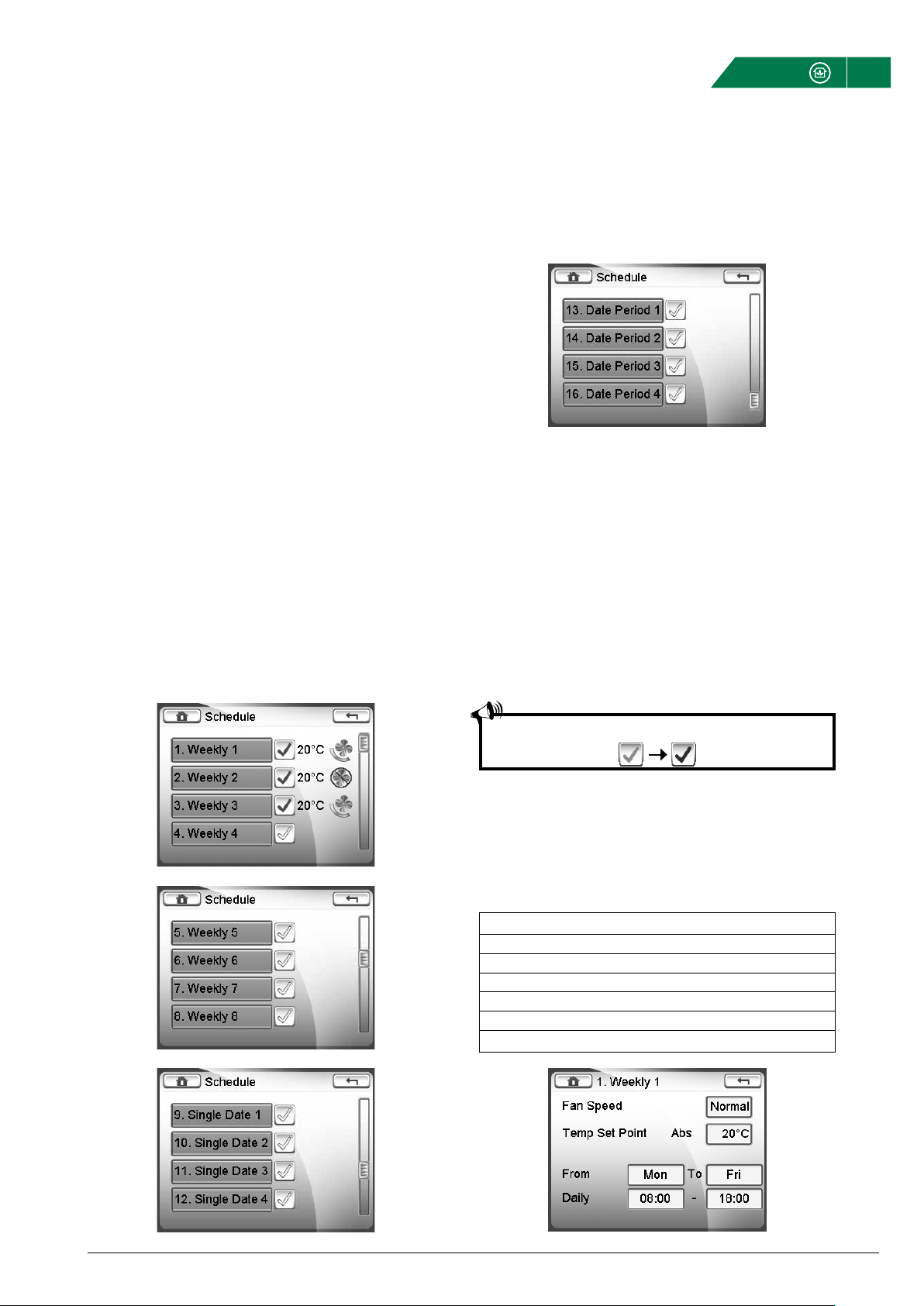

SCHEDULES

EXAMPLE 1 - WEEKLY SCHEDULE

Below is an example of a weekly schedule configured to run the

fans at normal speed from 08:00 to 18:00 Monday to Friday. At

all other times, the fans are turned off.

If a post heater has been fitted, this will maintain the supply air

temperature at 20°C.

Day Time Fan Speed Temp Setpoint

Monday 8-18 Normal 20 °C

Tuesday 8-18 Normal 20 °C

Wednesday 8-18 Normal 20 °C

Thursday 8-18 Normal 20 °C

Friday 8-18 Normal 20 °C

Other time Stop

SCHEDULES

Using schedules, it is possible to fully automate the unit to pro-

vide specific levels of ventilation at specific times of the day,

week or year and to activate the post-heater at a given tempera-

ture set point.

To activate schedules, the unit has to be in Automatic mode.

Each schedule also needs to be activated by pressing the grey

tick button.

WEEKLY (1-8)

Pressing this option selects the Weekly Schedule adjustment

screen to create a timed schedule to run daily in a week.

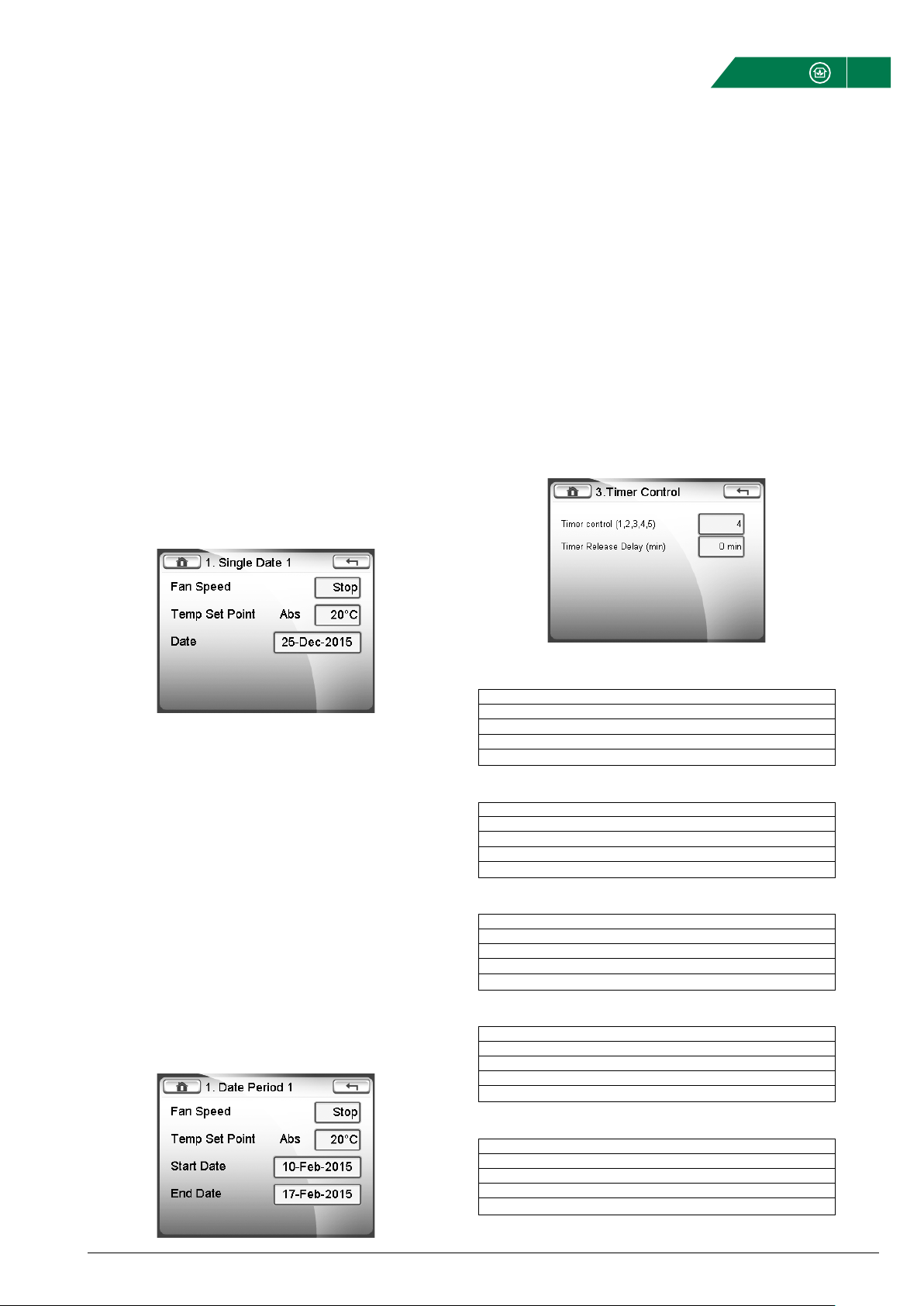

SINGLE DATE (1-4)

Pressing this option selects the Single Date Schedule adjustment

screen to create a timed schedule to run for 24 hours on any

single date.

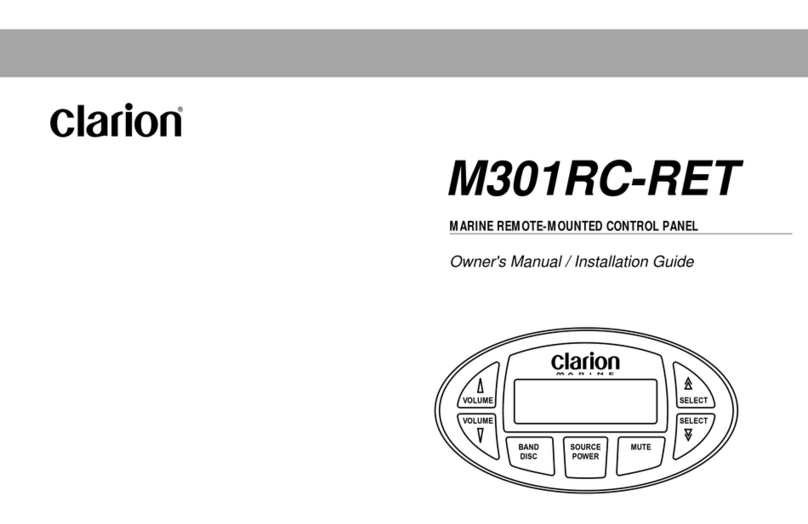

DATE PERIOD (1-4)

Pressing this option selects the Date Period Schedule adjustment

screen to create a timed schedule to run from any date to any

other date.

WEEKLY SCHEDULE

A weekly schedule is defined as a schedule that automatically

runs from a given time to a given time on specified days.

During a weekly schedule, the fans can be set to run at any of the

available speeds: Stop, trickle, normal or Boost.

The eight individual weekly schedules are prioritized to remove

the potential for time periods to clash with each other. Weekly

8 Schedule has the highest priority and Weekly 1 Schedule the

lowest priority. If two or more weekly schedules have start and

end times that clash with each other, only the schedule with the

highest priority will be used, the other(s) will be ignored.

The supply and extract fans will run at the same speed when set-

up through a weekly schedule.

Remember to activate the desired schedules by pressing

Curo

®

Touch - Technical Instruction Version 2.02

Fläkt Woods 9401 GB 2015.04.07 Specifications are subject to alteration without notice

13

EXAMPLE 2 - WEEKLY SCHEDULE

Below is an example of a weekly schedule configured to run the

fans at normal speed from 08:00 to 18:00 Monday to Thursday,

from 08:00 to 17:00 on Friday and 10:00 to 14:00 on Saturday. At

all other times, the fans are turned off.

If a post heater has been fitted, this will maintain the supply air

temperature at 20°C.

Day Time Fan Speed Temp Setpoint

Monday 8-18 Normal 20 °C

Tuesday 8-18 Normal 20 °C

Wednesday 8-18 Normal 20 °C

Thursday 8-18 Normal 20 °C

Friday 8-17 Normal 20 °C

Saturday 10-14 Normal 20 °C

Other time Stop

SCHEDULES (CONT)

EXAMPLE 3 - WEEKLY SCHEDULE

Below is an example of a weekly schedule configured to run the

fans at normal speed from 08:00 to 18:00 Monday to Friday. At all

other times, the fans are configured to run at trickle speed. Note,

this schedule uses the higher priority of Weekly 2 schedule to

over-ride Weekly 1 schedule during the Monday to Friday normal

speed periods.

If a post heater has been fitted, this will maintain the supply air

temperature at 20°C from 08:00 to 18:00 Monday to Friday and at

18°C at all other times.

Day Time Fan Speed Temp Setpoint

Monday 8-18 Normal 20 °C

Tuesday 8-18 Normal 20 °C

Wednesday 8-18 Normal 20 °C

Thursday 8-18 Normal 20 °C

Friday 8-18 Normal 20 °C

Other time Trickle (Low) 18 °C

Curo

®

Touch - Technical Instruction Version 2.02

Fläkt Woods 9401 GB 2015.04.07 Specifications are subject to alteration without notice

14

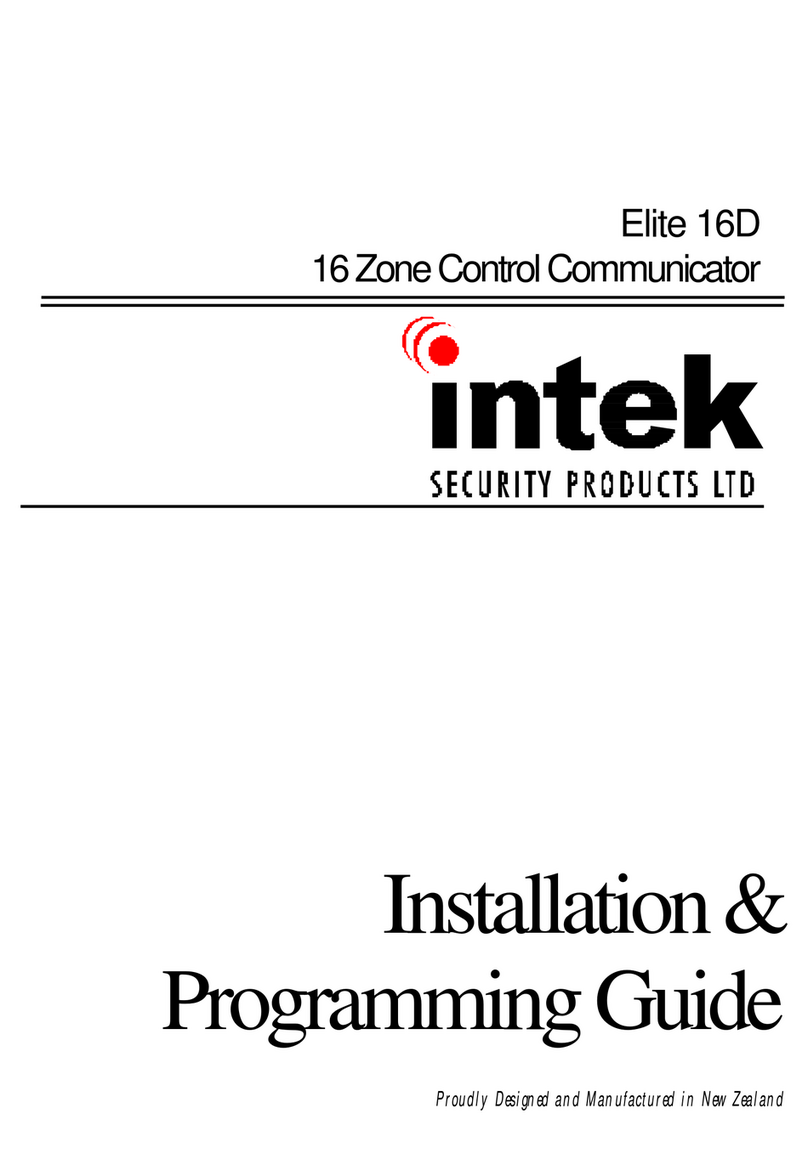

TIMER FUNCTION 1

Timer 1 Timer 2

Manual/Automatic Mode 0 0

Trickle 1 0

Normal 0 1

Boost 1 1

TIMER FUNCTION 2

Timer 1 Timer 2

Manual/Automatic Mode 0 0

Trickle 1 0

Boost 0 1

Stop 1 1

TIMER FUNCTION 3

Timer 1 Timer 2

Manual/Automatic Mode 0 0

Normal 1 0

Boost 0 1

Stop 1 1

TIMER FUNCTION 4 (DEFAULT)

Timer 1 Timer 2

Stop 0 0

Manual/Automatic Mode 1 0

Stop 0 1

Boost 1 1

TIMER FUNCTION 5

Timer 1 Timer 2

Stop 0 0

Manual/Automatic Mode 1 0

Stop 0 1

Normal 1 1

SCHEDULES (CONT) & TIMER FUNCTION

A single date schedule can be cancelled by setting the schedule

date to any date earlier than the current date.

A single date period schedule can be cancelled by setting both

the From and To schedule dates to any date earlier than the cur-

rent date.

DATE PERIOD SCHEDULE

A date period schedule is defined as a one-off schedule that is

configured to run between any to dates, staring at 00:00:00 on

the first date and finishing at 23:59:59 on a second date.

During a weekly schedule, the fans can be set to run at any of the

available speeds: Stop, trickle, normal or Boost.

The four individual date period schedules are prioritized to

remove the potential for time periods to clash with each other.

Date Period 4 Schedule has the highest priority and Date Period 1

Schedule the lowest priority. If two or more date period schedules

have start and end times that clash with each other, only the

schedule with the highest priority will be used, the other(s) will be

ignored.

The supply and extract fans will run at the same speed when

setup through a date period schedule.

SINGLE DATE SCHEDULE

A single date schedule is defined as a one-off schedule that

automatically starts and finishes on the same date and runs for

the whole day, i e, from 00:00:00 to 23:59:59.

During a single date schedule, the fans can be set to run at any

of the available speeds: Stop, trickle, normal or Boost.

The four individual single date schedules are prioritized to remove

the potential for time periods to clash with each other. Single

Date 4 Schedule has the highest priority and Single Date 1 Sched-

ule the lowest priority. If two or more single date schedules have

start and end times that clash with each other, only the schedule

with the highest priority will be used, the other(s) will be ignored.

The supply and extract fans will run at the same speed when set-

up through a single date schedule.

TIMER CONTROL

The Timer Control setting determines what speed the fans will

run at when up to two external, volt-free switches are applied to

the TM1 and PIR terminals - refer to page 12 for customer wiring

options.

A ’0’ in the tables below indicates a volt-free open-circuit input

and ’1’ indicates a volt-free short-circuit input.

FWG-Curo® Touch Technical instruction-GB-2015.04.07 9401GB © Copyright 2015 Fläkt Woods Group

WWW.FLAKTWOODS.COM CURO® TOUCH v 2.02 | 9401GB | 20150407

We bring

BETTER AIR™

to life

» To learn more about our offering and get in contact with your

nearest sales representative please visit www.flaktwoods.com

With over a century of innovation and expertise to share with our

customers, Fläkt Woods is a global leader in Air Technology products

and solutions. We specialize in the design and manufacturing of a

wide range of products and solutions for Air Movement, Air Treatment,

Air Distribution, Air Management and Air Diffusion with focus on two

major benefits – Air Comfort and Fire Safety. With market presence

in 65 countries we are in a unique position to be a local supplier

and an international partner in our customer’s projects.

Our product brands such as SEMCO

®

, eQ

®

, eQ Prime

®

, JM Aerofoil

®

,

Econet

®

, Veloduct

®

, Optivent

®

, Optimix

®

, Econovent

®

and Clean-

vent

®

are well-known and trusted by customers all over the world

to deliver high quality and energy efficient solutions.

Table of contents

Popular Control Panel manuals by other brands

ROEL

ROEL CERBER C52 Installation and programming manual

Clarion

Clarion M301RC-RET Owner's manual and installation guide

NKE

NKE Multigraphic USER MANUAL & INSTALLATION SHEET

Toa

Toa MW-41BT user manual

aguilera electronica

aguilera electronica AE/SA-C1 installation guide

Sony

Sony ICP-X7000 installation manual

Intek

Intek Elite 16D Installation & programming guide

GST

GST GST301 Installation and operation manual

Zeta Alarm Systems

Zeta Alarm Systems SMARTCONNECT SMART6 installation manual

Graco

Graco Therm-O-Flow 243698 instructions

Ampac

Ampac LoopSense EN54.2 user manual

Siemens

Siemens SED2 Series operating instructions