flakt woods CPdb User manual

AIR TREATMENT

HOUSING VENTILATION

AIR COMFORT

» Technical Manual

COOKER HOOD CPD

Cooker hood CPD Technical manual

2

Fläkt Woods 8757 GB 2016.12.05

Specifications are subject to alteration without notice

CONTENT

WARNING! THE DEVICE CAN BE USED BY CHILDREN FROM 8 YEARS UPWARDS AND PEOPLE (INCLUDING

CHILDREN) WITH REDUCED PHYSICAL, SENSORY OR MENTAL CAPABILITIES, OR LACK OF EXPERIENCE AND

KNOWLEDGE UNLESS THEY HAVE RECEIVED GUIDANCE OR INFORMATION ON HOW TO USE THE DEVICE SAFELY

AND UNDERSTAND THE RISKS THAT CAN OCCUR. CHILDREN SHOULD NOT PLAY WITH THE APPLIANCE. CLEANING

AND MAINTENANCE IS NOT CARRIED OUT BY CHILDREN WITHOUT SUPERVISION.

MAINTENANCE (FOR THE USER)

Cleaning .......................................................................................................... 3

Replacing of the low energy lamp....................................................... 3

General ............................................................................................................ 3

Operating of CPDA and CPDJ...................................................................4

Operating of CPDB, CPDC, CPDG, CPDH, CPDK.............................. 5

INSTALLATION (FOR INSTALLERS AND SERVICE PERSONNEL)

Installation height ...................................................................................... 6

Main supply .................................................................................................. 6

General ............................................................................................................ 6

CPDA .................................................................................................................7

CPDB................................................................................................................. 8

CPDC ............................................................................................................... 8

CPDG ............................................................................................................... 9

CPDH ............................................................................................................. 10

CPDK ............................................................................................................. 10

CPDJ ................................................................................................................ 11

ELECTRICAL CONNECTIONS (FOR INSTALLERS AND SERVICE PERSONNEL)

CPDG........................................................................................................................12

ADJUSTMENT, COMMISSIONING (FOR INSTALLERS AND SERVICE PERSONNEL)

CPD(A, B, C, G) - Basic ventilation .....................................................13

CPD(A, B, C, G) - Forced ventilation ..................................................14

CPD(H, K) - Basic ventilation ................................................................15

CPD(H, J, K,) - Forced ventilation ....................................................... 16

GENERAL

Spare parts CPD(A, B, C, G, H, J, K) .............................................................17

Declaration of conformity................................................................................18

Disposal of product and packaging materials...................................... 19

Cooker hoods CPDD and CPDL, see separate instruction.

Technical manual Cooker hood CPD

3

Fläkt Woods 8757 GB 2016.12.05

Specifications are subject to alteration without notice

MAINTENANCE

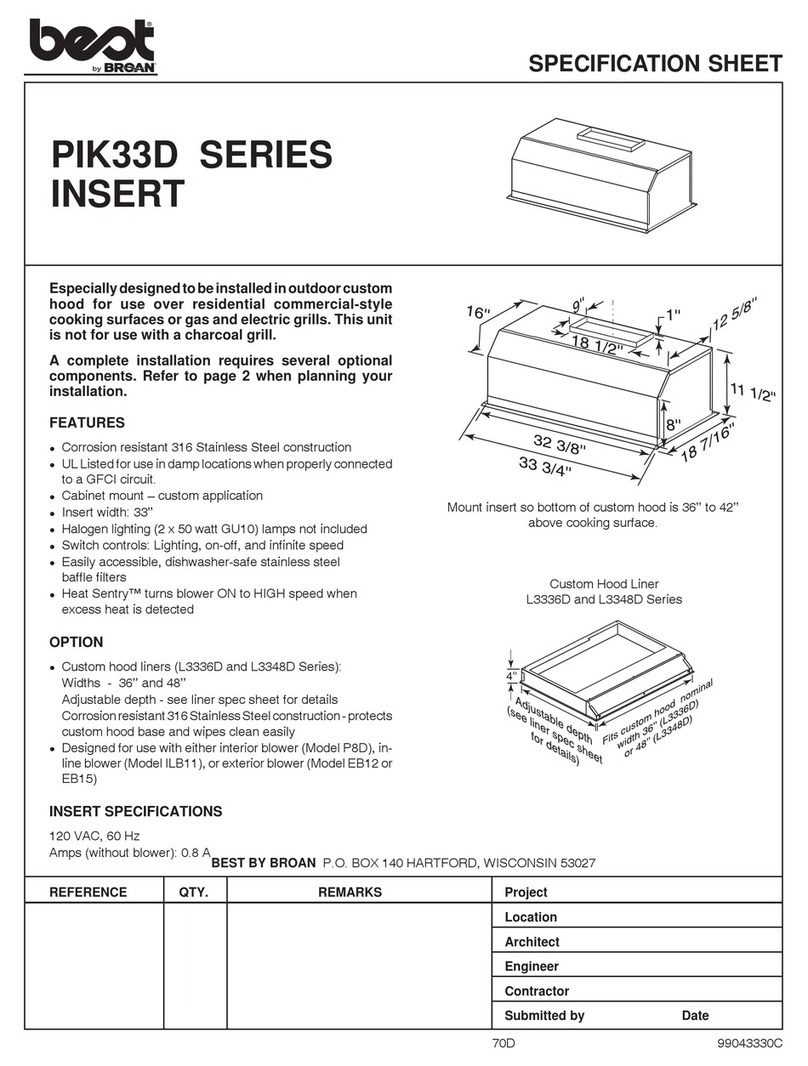

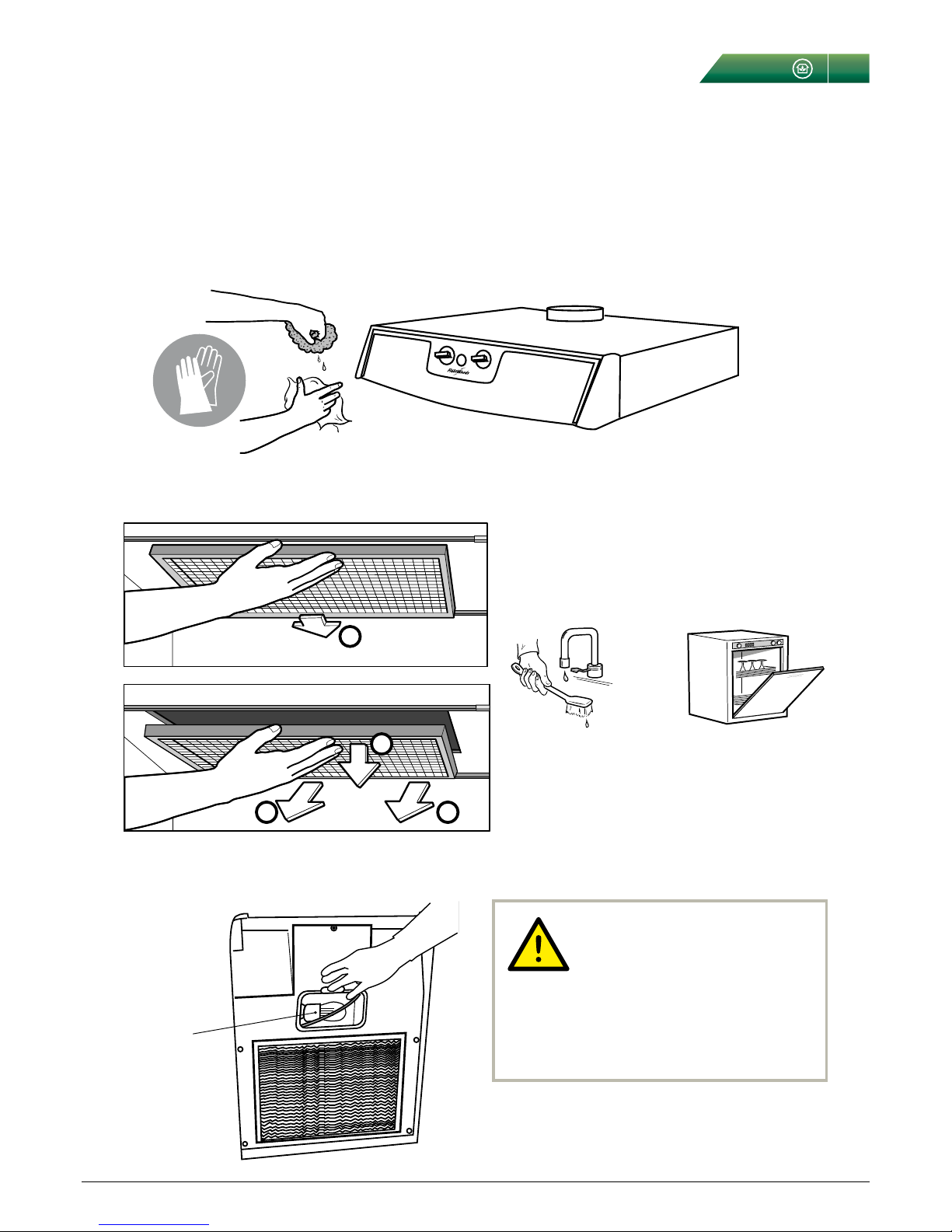

CLEANING OF COOKER HOOD

Do not use abrasive sponge or cloth.

alt.

1

2

33

CLEANING OF GREASE FILTER

REPLACING OF THE LOW ENERGY LAMP

Check the grease filter every week.

Clean if needed.

Note! Do not use the cooker hood

without grease filter fitted.

GENERAL

There is a fire risk if cleaning is not carried

out in accordance with the instructions.

Accessible parts may become hot when

used with cooking appliances.

Do not flambé under the cooker hood.

If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent or similarly qualified per-

sons in order to avoid hazard.

11 W/E14

Cooker hood CPD Technical manual

4

Fläkt Woods 8757 GB 2016.12.05

Specifications are subject to alteration without notice

MAINTENANCE

OPERATING OF CPDA AND CPDJ

Handle for boosting Lighting

Technical manual Cooker hood CPD

5

Fläkt Woods 8757 GB 2016.12.05

Specifications are subject to alteration without notice

NORMAL

MIN

MAX

MIN

1

2

MIN

1

2

MIN

1

2

MAINTENANCE

OPERATING OF CPDB, CPDC, CPDG, CPDH AND CPDK

Handle for boosting Lighting Handle for fan speed

MIN

1

2

Cooker hood CPD Technical manual

6

Fläkt Woods 8757 GB 2016.12.05

Specifications are subject to alteration without notice

INSTALLATION (FOR INSTALLERS AND SERVICE PERSONNEL)

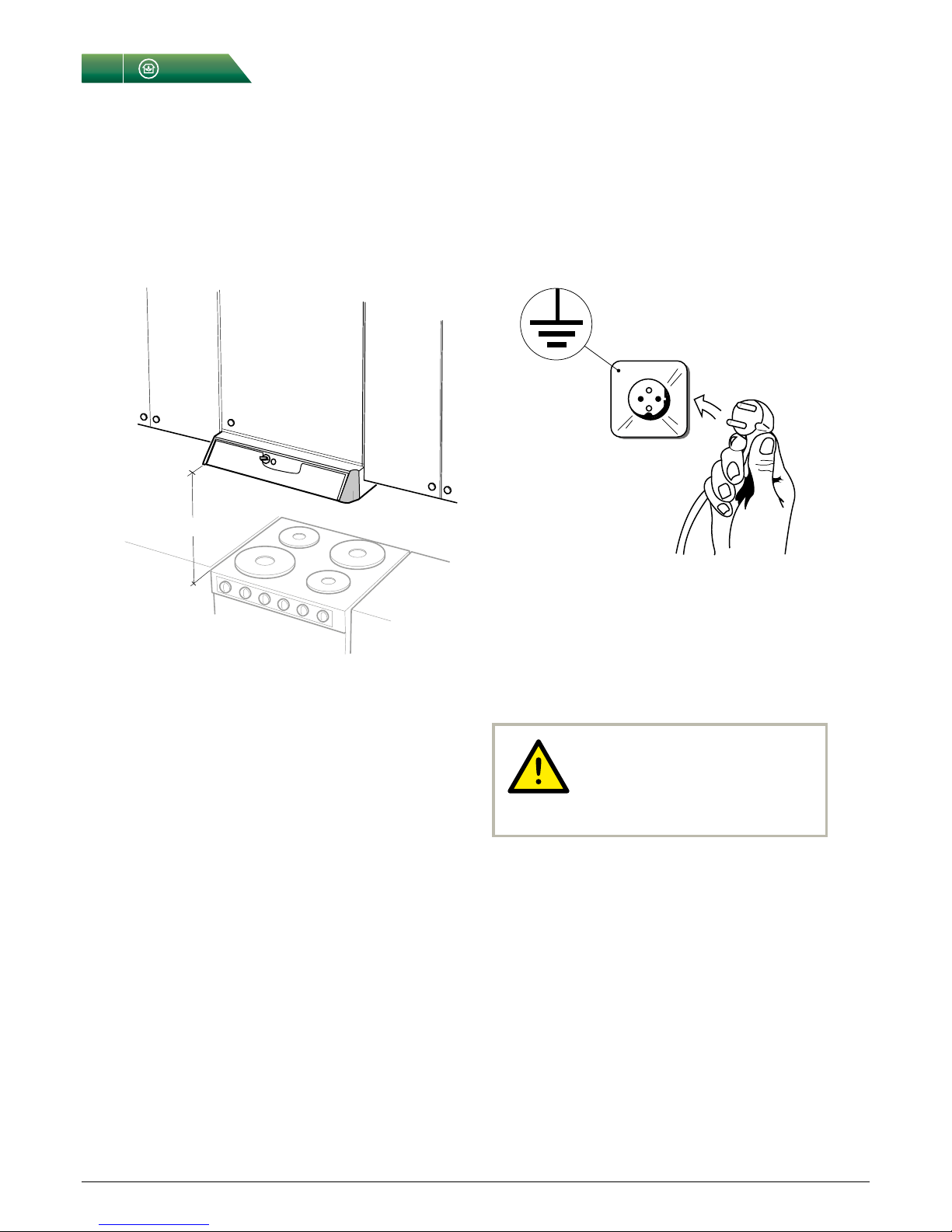

INSTALLATION HEIGHT MAIN SUPPLY

min 400 mm

All cooker hoods has to be connected directly or indirectly via the

heat recovery unit/exhaust fan to earth.

If the supply cord is damaged, it must be replaced by the manu-

facturer, its service agent or similarly qualified persons in order to

avoid hazard.

The distance between the stove and the lower edge of the cooker

hood has to be at least 400 mm, recommended distance 500 mm.

When the cooker hood is located above a gas appliance, this dis-

tance shall be at least 650 mm. If the instructions for installation

of the gas hob specify a greater distance, this has to be taken

into account.

GENERAL

The air must not be discharged into a flue that

is used for exhausting fumes from appliances

burning gas or other fuels.

Regulations concerning the discharge of air

have to be fulfilled.

Technical manual Cooker hood CPD

7

Fläkt Woods 8757 GB 2016.12.05

Specifications are subject to alteration without notice

min 500 mm

2

3

1

max

300 mm

1

2

3

54

max

300 mm

12mm

Ø 50

160 100

a

min 500 mm

a =700

a =600

a =500

200

100

100

415

365

365

255

205

205

INSTALLATION (FOR INSTALLERS AND SERVICE PERSONNEL)

CPDA

Intended for multiple-unit dwellings with a central extract air fan or a heat recovery unit.

Suitable for both new production and replacement of older cooker hoods.

INSTALLATION BENEATH KITCHEN CABINETS

a

a

b

b

INSTALLATION BETWEEN KITCHEN CABINETS

Cooker hood CPD Technical manual

8

Fläkt Woods 8757 GB 2016.12.05

Specifications are subject to alteration without notice

INSTALLATION (FOR INSTALLERS AND SERVICE PERSONNEL)

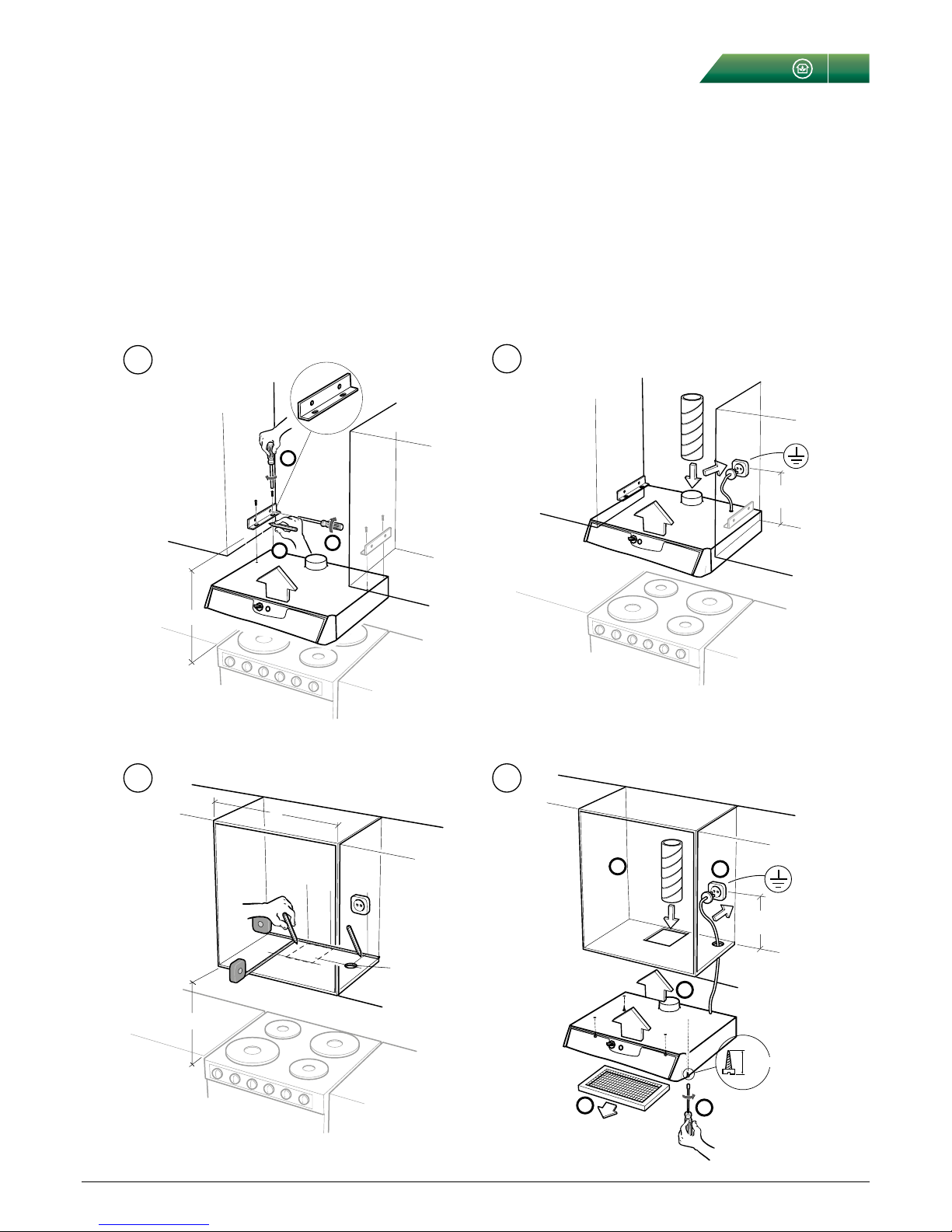

CPDB

Replacement hood for older exhaust air fan JBDD-aa with capacitor box, manufactured before 2007.

JBDD-aa

(earlier version)

CPCB

JBDD-aa

(earlier version)

a

a

b

b

CPDC

Replacement hood for older heat recovery unit RDKG without bypass (fits RDKG-a-1-c-d-1).

1

5

6

2

3

4

3.1 3.2

Remove the old

cooker hood.

It is important to seal the grommet by putting

back the small piece of sealing material.

Remove the old cooker hood.

Technical manual Cooker hood CPD

9

Fläkt Woods 8757 GB 2016.12.05

Specifications are subject to alteration without notice

CPDG

With transformer, fits for example the new JBDD and JBFG. (Fits JBDD-aa-1-2 but also as replacement

cooker hood for controlling older exhaust air fans and units, for example JBDB, JBDC and RDAA.)

INSTALLATION (FOR INSTALLERS AND SERVICE PERSONNEL)

Ø50

176

115

33

96

min 500 mm

160

2

3

1

JBDD

1

2

1 = Orange - Supply

voltage

to fan

2 = Blue - Neutral

3 = Black - Phase

4 = Yellow/Green - Ground

3

2

3

1

min 500 mm

CONNECTION TO EXHAUST FAN JBDD, GENERATION 2

INSTALLATION BETWEEN KITCHEN CABINETS

CONNECTION TO OTHER FANS

For electrical installation, see wiring examples on page 12.

INSTALLATION BENEATH KITCHEN CABINETS

Cooker hood CPD Technical manual

10

Fläkt Woods 8757 GB 2016.12.05

Specifications are subject to alteration without notice

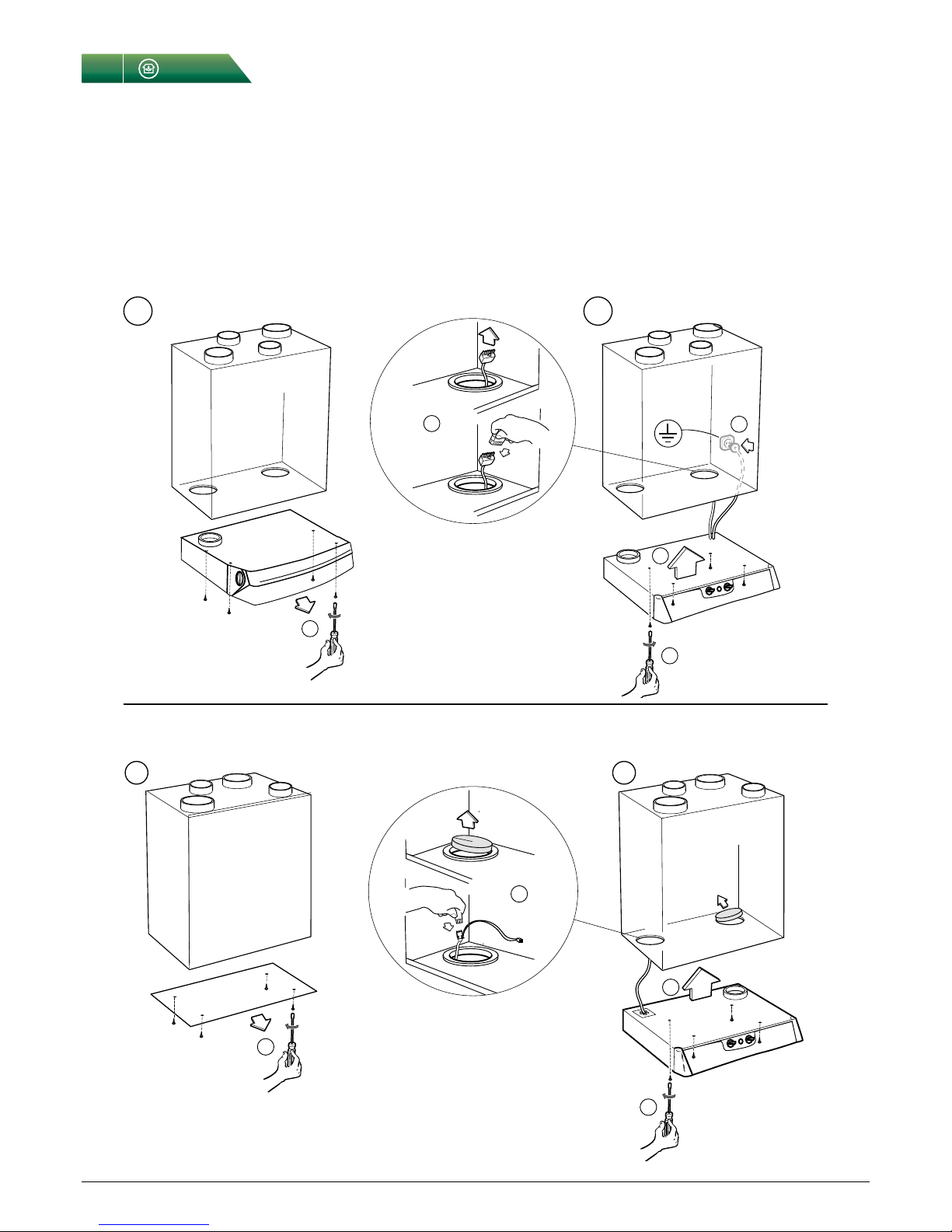

CPDH

Replacement hood for older heat recovery units RDKG with bypass. (Fits RDKG-a-2-c-d-1).

ab

CPDK

For heat recovery unit RDKG. (Fits RDKG-a-b-c-d-2).

ab

INSTALLATION (FOR INSTALLERS AND SERVICE PERSONNEL)

1

4

5

3

2

Remove the old cooker hood.

2

1

3

4

Technical manual Cooker hood CPD

11

Fläkt Woods 8757 GB 2016.12.05

Specifications are subject to alteration without notice

INSTALLATION (FOR INSTALLERS AND SERVICE PERSONNEL)

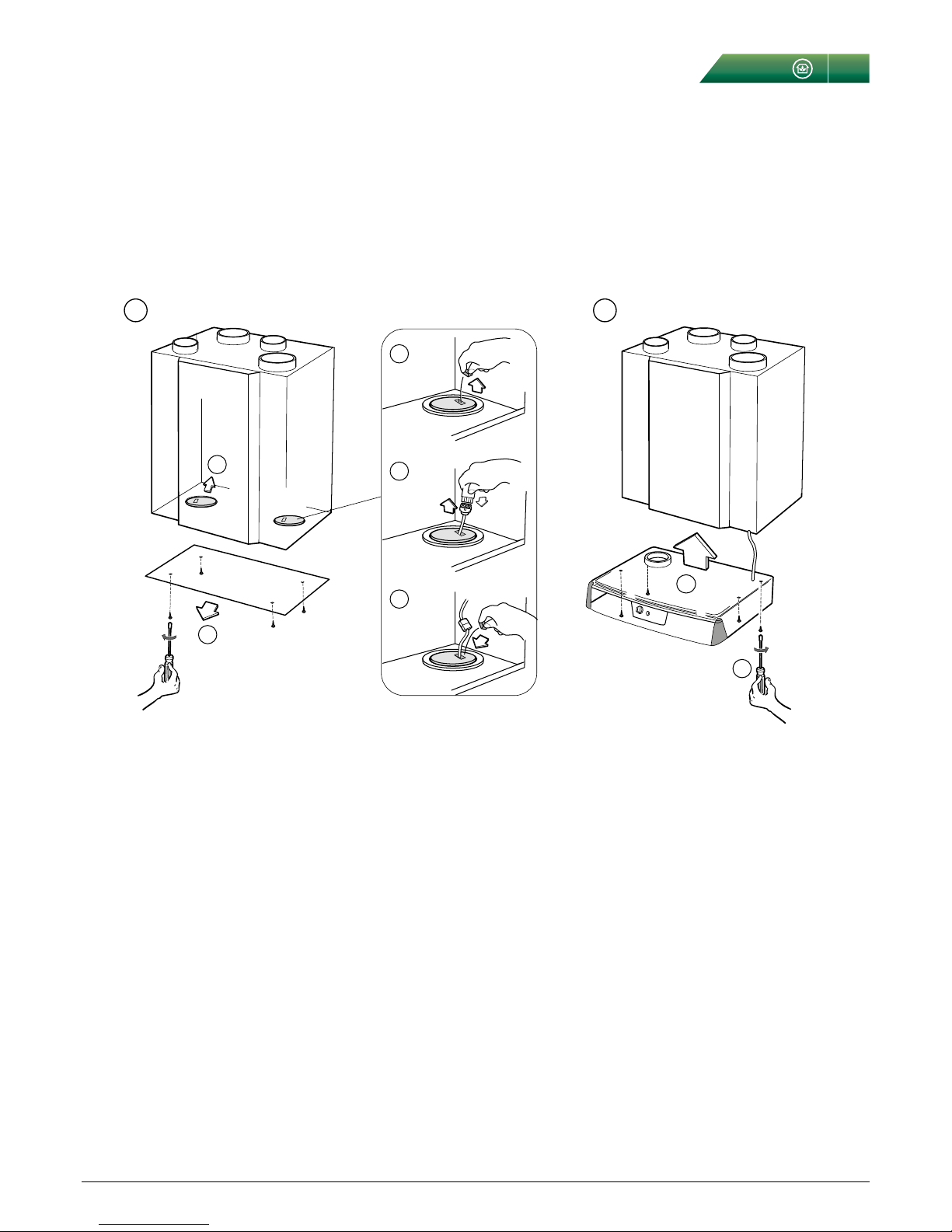

CPDJ

For heat recovery unit RDKR or RDKS.

ab

3

2

1

RDKS

RDKS

4

5

4.1 4.2

7

6

It is important to seal the grommet by putting

back the small piece of sealing material.

The picture illustrates a right hand unit.

Cooker hood CPD Technical manual

12

Fläkt Woods 8757 GB 2016.12.05

Specifications are subject to alteration without notice

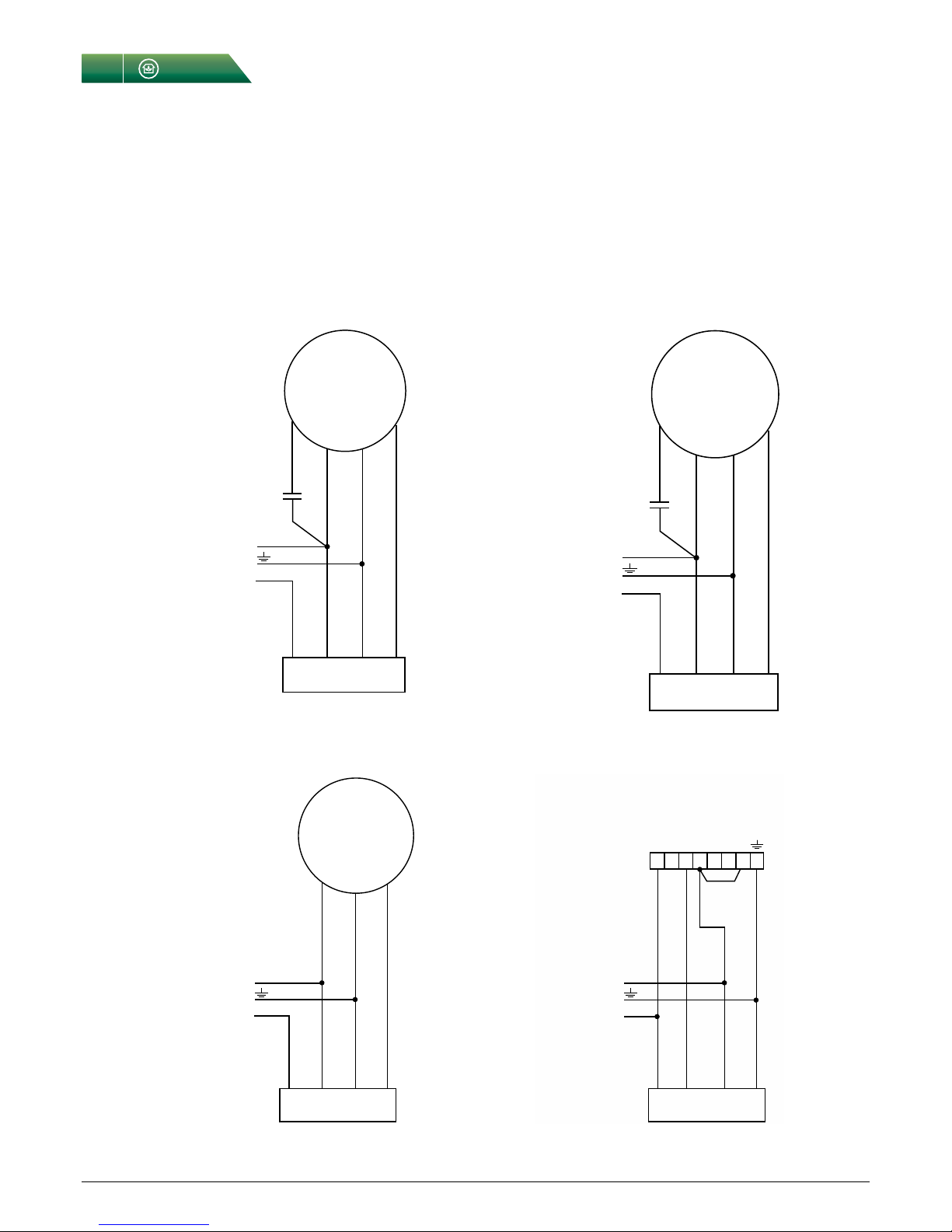

ELECTRICAL CONNECTIONS (FOR INSTALLERS AND SERVICE PERSONNEL)

Note! Electrical connections have to be made by authorized personnel.

EXHAUST FAN JBDB EXHAUST FAN JBDC

ROOF FAN JBFG HEAT RECOVERY UNIT RDAA

1)

Not for

conversion kit

JBDB-99-05-0 JBDB

1)

CPDG/CPTG

Supply 230V

JBDA-99-031

2µF, not included

N

L

Blue

Blue White

Black

Black

Yellow/Green Yellow/Green

Orange

JBFG

CPDG/CPTG

Supply 230V

N

L

Blue Blue

Brown

Black

Yellow/GreenYellow/Green

Orange

JBDC1)

CPDG/CPTG

N

L

1) Also for

conversion kit

JBDB-99-05-0

Supply 230V

JBDA-99-031

2µF, not included

Brown

Blue Black

Blue

Black

Yellow/Green Yellow/Green

Orange

RDAA

CPDG/CPTG

Supply 230V

N

2 4 5 6 731

L

Orange

Black

Blue

Yellow/Green

CPDG

Technical manual Cooker hood CPD

13

Fläkt Woods 8757 GB 2016.12.05

Specifications are subject to alteration without notice

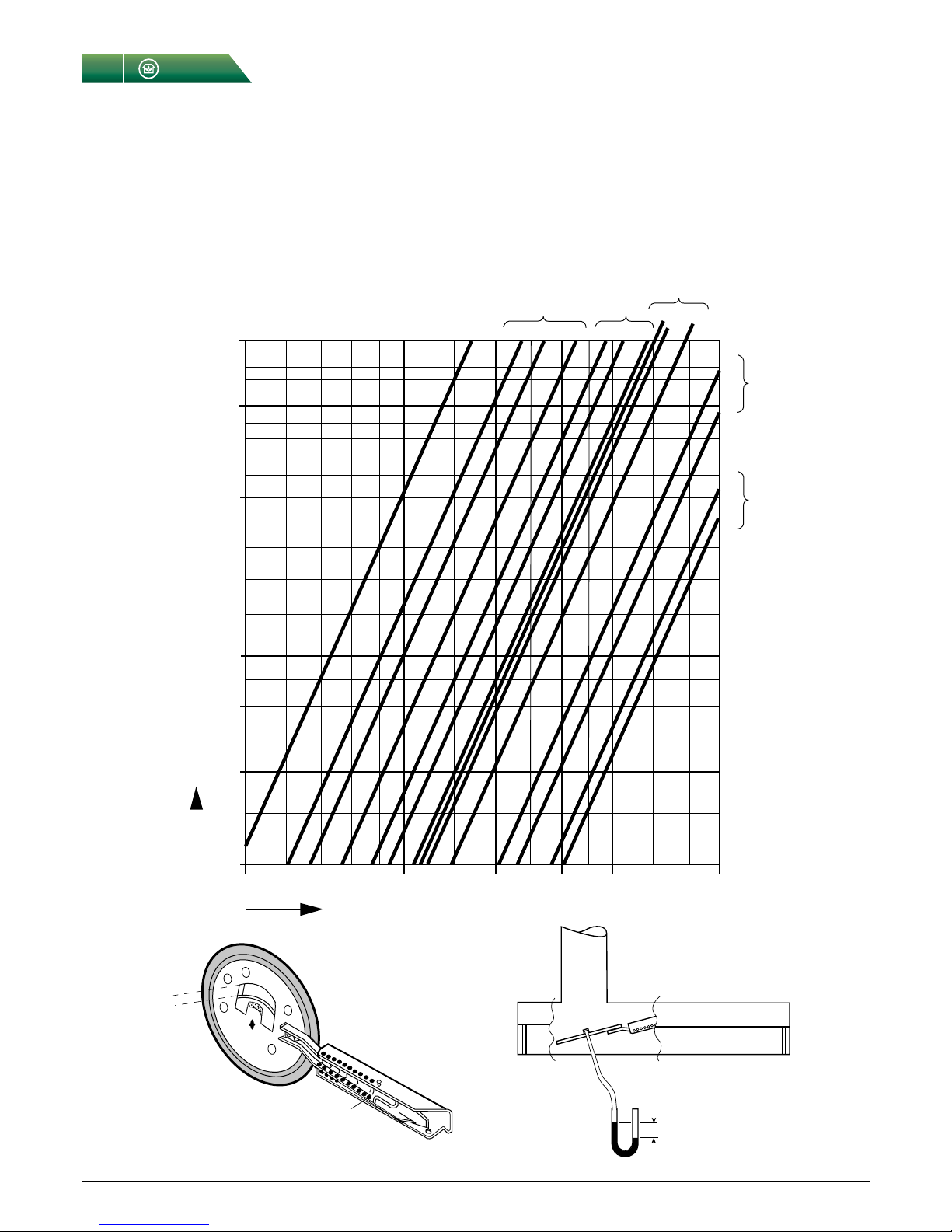

ADJUSTMENT

b

c

a

Pa a = 7,5 10 12,5 15 20 25

250

200

100

50

40

30 5678910 12 15 20 30

Air flow q l/s

Measuring pressure ∆pm, Pa

30

30 + 1xC

30 + 4xC

30 + 2xC

CPDA, CPDB, CPDC AND CPDG – BASICVENTILATION

∆p

Cooker hood CPD Technical manual

14

Fläkt Woods 8757 GB 2016.12.05

Specifications are subject to alteration without notice

CPDA, CPDB, CPDC AND CPDG – FORCED VENTILATION

When adjusting the forced air flow the fan speed must be increased up to the forced flow.

10

20

30

40

50

100

200

150

20 30 40 50 80

Air flow q, l/s

Measuring pressure ∆p

m

, Pa

b = 5

a = 25 10

10

10

13

25

1015 15

15

25 25

25

7 9

11

a b

10

14

25

a

b

a

∆p

ADJUSTMENT

Technical manual Cooker hood CPD

15

Fläkt Woods 8757 GB 2016.12.05

Specifications are subject to alteration without notice

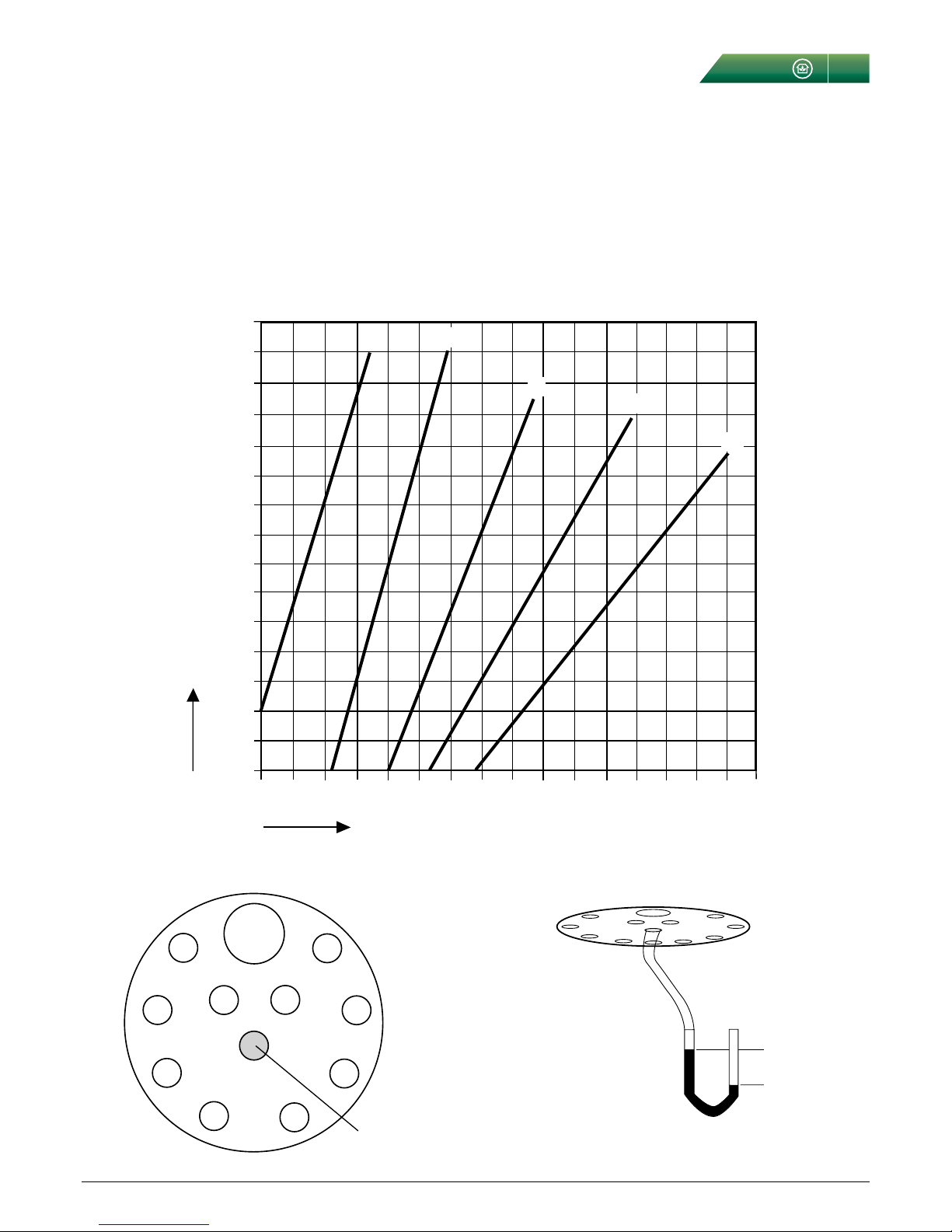

CPDH AND CPDK – BASIC VENTILATION

The basic air flow in the hood is adjusted by removing any number of plugs in the cover plate.

1

2

3

45

6

7

8

9

10

∆p

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

30

10

8

6

4

2

Air flow q, l/s

Measuring pressure ∆p

m

, Pa

2, 4, 6, 8 och 10 = number of open holes in the cover plate.

Connection of the

measuring tube

ADJUSTMENT

When forcing the air stream must be measured at both measure-

ment points (basic flow and forced flow).

Cooker hood CPD Technical manual

16

Fläkt Woods 8757 GB 2016.12.05

Specifications are subject to alteration without notice

CPDH AND CPDK - FORCED VENTILATION

Damper blade without basic flow valve (sealed damper blade)

When adjusting the forced air flow the fan speed must be increased up to the forced flow.

ADJUSTMENT

10

20

30

40

50

100

200

150

20 30 40 50 80

Air flow q, l/s

Measuring pressure ∆pm, Pa

b = 7

13

14

15

8 9 11

∆p

b

Technical manual Cooker hood CPD

17

Fläkt Woods 8757 GB 2016.12.05

Specifications are subject to alteration without notice

CPDA, CPDB, CPDC, CPDG, CPDH, CPDJ AND CPDK

SPARE PARTS

Pos No. Designation Description Intended for CPD...

A B C G H J K M

125 CPDA-99-01 Handle xxxxxxxx

210 CPDA-99-02 Lightning switch xxxxxxxx

3 1 CPDA-99-03 Front board 1-handle, 500 mm x

3 1 CPDA-99-04 Front board 1-handle, 600 mm x x

3 1 CPDA-99-05 Front board 1-handle, 700 mm x x

3 1 CPDC-99-02 Front board 2-handles, 500 mm x x

3 1 CPDC-99-03 Front board 2-handles, 600 mm x x x x x x

3 1 CPDC-99-04 Front board 2-handles, 700 mm xxx

410+10 CPDA-99-07 Black plastic corners, right and left xxxxxxxx

5 1 CPCA-99-15 Timer with shaft: 600 mm (R, L), 700 mm (R) xxxxx xx

5 1 CPDA-99-10 Timer with shaft: 500 mm (M), 600 mm (M), 700

mm (M, L) x x x

5 1 CPDJ-99-01 Timer w. shaft: 600, 700 mm (w. contact function) x

610 CPCA-99-09 Lamp socket xxxxxxx

610 CPDA-99-12 Lamp socket, transverse light xxxxxxxx

7 1 CPCA-99-12 Throttling device, complete xxxx

7 1 CPDH-99-02 Throttling device, complete (without basic flow) x x x x

825 BHGA-99-48 Plastic plugs xxxxx x

910 CPDA-99-06 Lamp protecting glass xxxxxxxx

10 1CPCA-99-13 Grease filter xxxxxxxx

11 5CPDC-99-01 Switch x x x x x x

12 1CPDG-99-01 Transformer x x

13 1CPDH-99-01 Time relay x

14 10 CPDA-99-15 Damper eccentric, 10-pack xxxxxxxx

15 10 CPDA-99-13 Damper gasket, 10-pack xxxxxxxx

1

2

3

6

12

13

9

4

4

814

15

7

10

511

Pos 5. R = Rght, M = Middle, L = Left

Cut the power before start working with the unit. All work has to be carried out by qualified personnel in order to avoid hazard.

Cooker hood CPD Technical manual

18

Fläkt Woods 8757 GB 2016.12.05

Specifications are subject to alteration without notice

DECLARATION OF CONFORMITY

Bilaga II A

Fläkt Woods AB

Postal Address Street Address Telephone Telefax Reg. no:

Fläkt Woods AB Fläktgatan 1 Nat 036 - 19 30 00 Nat 036 - 19 31 40 556239-2463

S-551 84 Jönköping Int +46 36 19 30 00 Int +46 36 19 31 40 Reg. office:

Sweden Jönköping

8364GB_CPD Declaration of conformity(2A)201512

Declaration of Conformity

In accordance with:

EU Directive for Machinery, 2006/42/EC

EU EMC Directive, 2004/108/EC

EU Low voltage Directive, LVD 2006/95/EC

Manufacturer Fläkt Woods AB

Fläktgatan 1

551 84 Jönköping

Herewith declares that:

Product Type: Cooker Hood

Manufacturer: Fläkt Woods AB

Commercial name: CPD/A/B/C/D/G/H/J/K/L ( several versions / variants)

The machine is designed and manufactured in accordance with the following standards, in relevant parts.

EN ISO 12100 Safety of machinery – General principles for design- Risk assessment and risk reduction

EN 60204-1 Safety of machinery; electrical equipment of machines; general requirements

EN 60335-1 Household and similar electrical appliances - Safety - Part 1: General requirements

EN 60335-2-31 Household and similar electrical appliances - Safety - Part 2: Particular requirements

EN 61000-6-1 Electromagnetic compatibility (EMC) - Part 6-1: Generic standards - Immunity for

residential, commercial and light-industrial environments

EN 61000-6-3 Emission standard for residential, commercial and light-industrial environments.

EN 50106:2008 Safety of household and similar electrical appliances - Particular rules for routine tests

referring to appliances under the scope of EN 60335-1

EN 62233:2008 Measurement methods for electromagnetic fields of household appliances andsimilar

apparatus with regard to human exposure

A risk analysis has been made according to requirements of the Directive for Machinery.

Authorized To prepare technical documentation:

Ann-Sofie Andersson

Design- R&D

Fläkt Woods AB, Housing

Gesällgatan 17

745 39 Enköping

The declaration applies only to the installation made according to Fläkt Woods instructions and assuming no

changes made to the unit.

Enköping 2015-12-15

Matthias Junker, Produktionschef Fläkt Woods AB, Enköping

Technical manual Cooker hood CPD

19

Fläkt Woods 8757 GB 2016.12.05

Specifications are subject to alteration without notice

DISPOSAL OF PRODUCT AND PACKAGING MATERIALS

Recycling should be made in accord-

ance with local regulations. When the

product is scrapped the following parts/

components/materials shall be sorted.

Depending on what product it is may not

all parts/components/materials be rep-

resented.

– Printed circuit boards, cables, batteries, motors, sensors etc.

– Filters, except made of pure metal (in cooker hoods).

– Packaging materials, such as cardboard, plastic and

styrofoam.

– The units casing may contain condense- or mineral wool

insulation sandwiched between the inner and outer shell.

– The remaining parts shall be sorted as metallic.

– Lamps and fluorescent lights.

See www.flaktwoods.com/ecodesign for recycling instructions.

FWG-CPD Technical manual-SE-2016.12.05 8757GB © Copyright 2016 Fläkt Woods Group

WWW.FLAKTWOODS.COM CPD | 8757GB | 20161205

We bring

BETTER AIR®

to life

» To learn more about our offering and get in contact with your

nearest sales representative please visit www.flaktwoods.com

With over a century of innovation and expertise to share with our

customers, Fläkt Woods is a global leader in Air Technology products

and solutions. We specialize in the design and manufacturing of a

wide range of products and solutions for Air Movement, Air Treatment,

Air Distribution, Air Management and Air Diffusion with focus on two

major benefits – Air Comfort and Fire Safety. With market presence

in 65 countries we are in a unique position to be a local supplier

and an international partner in our customer’s projects.

Our product brands such as SEMCO

®

, eQ

®

, eQ Prime

®

, JM Aerofoil

®

,

Econet

®

, Veloduct

®

, Optivent

®

, Optimix

®

, Econovent

®

and Clean-

vent

®

are well-known and trusted by customers all over the world

to deliver high quality and energy efficient solutions.

This manual suits for next models

4

Table of contents