Flash Technology VANGUARD FTS 370d User manual

Flash Technology, 332 Nichol Mill Lane, Franklin, TN 37067

www.flashtechnology.com

(615) 261-2000

VANGUARD®

FTS 370d, 370w, 370r

LED Medium Intensity Obstruction Lighting System

Reference Manual

Part Number F7913702

SERIAL NUMBER

FTS 370d/w/r Revision 19 – 05/23/2018 a

FTS 370d/w/r INSTALLATION CHECKLIST

System Controller (SC) 370

The SC 370 is mounted away from radio frequency interference (RFI).

The SC 370 is mounted upright.

Lightning protection is grounded to the site grounding system.

2 AWG (min.) is used from the SC 370 grounding lug to the site lightning grounding system (tested for 1ohm or less).

The bend radius for all ground wires is greater than 8" (avoid bending ground wires if possible).

Important! It is recommended that all exposed ground connections are coated with a corrosion inhibitor (NO-OX or

equivalent).

There are no holes punched or drilled in the top or sides of the enclosure.

Airflow can properly circulate around the enclosure (allow 8” min. of unused space on both sides).

Room allowed for door access (multi-unit installations).

The input power (and frequency for AC systems) matches the voltage specified on the unit’s data label.

Electrical connections, and inside cabinet hardware mounts have been double-checked for tightness before powering up.

All wire connections are installed properly into the terminal blocks (TB1 and TB2).

ALL PCB connectors are securely plugged into the board (Phoenix Connectors).

All PCB connector wires are properly inserted and screws are tightened.

RS 485 Data cables are installed on PCB1 J4 and routed between System Controllers (multi-unit installations).

Circuit Breakers are securely fastened to din rail.

The “Binding Procedure” has been performed on each SC 370 installed in the system.

(See Section 3 “Local Tower Config” for special instructions regarding the binding procedure.)

PCB1 Intensity select switch is in the “Auto” position on the System Controller (s).

The SC 370 designated as System 1 is connected to the top flashhead and programmed as AOL.

The flashhead cable is connected to TB2, and corresponds to the internal wiring diagram and color guides on the

terminal block.

Flashhead CABLE

Flashhead cable is NOT spliced except at the marker interface enclosure, if installed.

Flashhead individual conductor insulation has not been nicked.

A service loop for the flashhead cable is placed at the base of the tower near the System Controller (5 feet).

Service loop is attached to the H-Frame or Wall vertically.

The flashhead cable is properly secured to the tower so the insulation won’t become cut or damaged with wind and time.

Using the Flash Technology’s two supplied tapes and the 2-3-4 layer method, secure the cable to the tower (Not

exceeding 5’ in-between)

A service loop is placed just below the beacon.

Service loop is secured at (2) points to the tower structure using the 2-3-4 tape method.

The flashhead cable is not pulled tight against sharp edges.

1-3” of space should be between the cable and tower leg flanges or obstructions.

b Revision 19 – 05/23/2018 FTS 370d/w/r

Flashhead

The LED beacon is wired correctly.

The wires are positioned so no arcing can occur and wire colors match the terminal designations, and flashhead cable

is secured in the terminal block.

The dome nut of the beacon’s cable strain relief is tightened for cable support and to prevent moisture intrusion.

Drip loop is present for the LED beacon.

The LED beacon is securely closed with both latches in place.

The LED beacon at the top of the tower has a lightning rod(s) provided at least 36” above the top of the beacon, and a

minimum of 18” away from the beacon.

The LED beacon is level (Use separate leveling tool).

8 AWG (min.) insulated ground wire is used from the LED beacon grounding lug to the tower structure.

The LED beacon is mounted in an FAA approved location (No obstructions; allowing a 360° view of the beacon).

Marker Interface Junction Box (SC 370d or SC370r)

The Marker Interface Enclosure is mounted at the marker tier level.

Flash Technology provided hardware used for mounting the Marker Interface Enclosure (4 points of contact to Universal

Mounting brackets).

Both latches are secured to prevent water intrusion.

Marker Interface Enclosure is grounded to the tower.

8 AWG (min.) insulated ground wire is used from the Marker Interface Enclosure grounding lug to the tower structure.

Side marker cable connections match all PCB labels (Connections are polarity sensitive, correct wiring is critical).

Service loop for the flashhead cable to the ground is present near the base of the Marker Interface Enclosure.

Service loop for the flashhead cable to the flashhead is present near the base of the Marker Interface Enclosure.

MARKERS (Red LED sidelights, side-markers, or obstruction lights L-810)

Only Flash Technology provided 24 Volt DC Marker Fixtures are installed.

The dome nuts of the cable strain reliefs are tightened for cable support and to prevent moisture intrusion.

PHOTODIODE (PHD 516)

The PHD 516 is connected to PCB2 (Surge Board) P-6 (White, Black, and Drain wires correspond to the label on board).

The PHD 516 is mounted vertically to prevent water entry.

The PHD 516 cable is protected through conduit so it will not be stepped on or damaged.

The PHD 516 is facing north and no artificial lights (security lights, street lights, lighted signs, or direct sunlight) will affect

its operation.

ALARMS and ALARM WIRING

NO alarm LEDs are lit on PCB1 of the SC 370.

The display located on PCB1 of the SC 370 is showing “Status OK” along with the correct configuration of the system type

installed (Dual or White with the correct number of beacons, and markers if applicable).

A Lighting Inspection has been performed via the User Interface Panel.

Call 1-800-821-5825 if additional TECHNICAL or INSTALLATION assistance is needed.

FTS 370d/w/r Revision 19 – 05/23/2018 i

Front Matter

Abstract

This manual contains information and instructions for installing, operating and maintaining the

FTS 370d, 370w and 370r LED Medium Intensity Obstruction Lighting Systems with the

following input voltages: 120-240V AC, 24V DC and 48V DC. All model variants support

IR (infrared) output.

Copyright

Copyright © 2018, Flash Technology, Franklin, TN, 37067, U.S.A.

All rights reserved. Reproduction or use of any portion of this manual is prohibited without

express written permission from Flash Technology and/or its licenser.

Trademark Acknowledgements

Flash Technology and Vanguard are registered trademarks of SPX Corporation.

All other trademarks and product names mentioned are properties of their respective

companies, and are recognized and acknowledged as such by Flash Technology.

Applicable Specifications

This equipment meets or exceeds requirements for the following FAA Types: L-864/865, L-

865, L-866/885, L-866 and L-885.

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Patent Information

FH 370, described within this document, is covered by the following patent: Patent No.

8,926,148

MKR 371, described within this document is, covered by the following patent: Patent No.

8.998.443

Additional patents pending.

Disclaimer

While every effort has been made to ensure that the information in this manual is complete,

accurate and up-to-date, Flash Technology assumes no liability for damages resulting from any

errors or omissions in this manual, or from the use of the information contained herein. Flash

Technology reserves the right to revise this manual without obligation to notify any person or

organization of the revision.

In no event will Flash Technology be liable for direct, indirect, special, incidental, or

consequential damages arising out of the use of or the inability to use this manual.

Warranty

With proper installation and with normal operating conditions, Flash Technology warrants all

lighting components of the LED lighting system for 5 years from the date of shipment from

Flash Technology. Monitoring components such as modem or battery, if present, are only

covered by 1–2 years warranty from the date of shipment.

ii Revision 19 – 05/23/2018 FTS 370d/w/r

Parts Replacement

The use of parts or components, in this equipment, not manufactured or supplied by Flash

Technology voids the warranty and invalidates the third party testing laboratory certification

which ensures compliance with FAA Advisory Circulars 150/5345-43H, 150/5345-53D, and

Engineering Brief No. 67D. The certification is valid as long as the system is maintained in

accordance with FAA guidelines (FR doc. 04-13718 filed 6-16-04).

Personnel Hazard Warning

Dangerous Voltages

Dangerous line voltages reside in certain locations in this equipment. Also, this equipment

may generate dangerous voltages. Although Flash Technology has incorporated every

practical safety precaution, exercise extreme caution at all times when you expose circuits and

components, and when you operate, maintain, or service this equipment.

Avoid Touching Live Circuits

Avoid touching any component or any part of the circuitry while the equipment is operating.

Do not change components or make adjustments inside the equipment with power on.

Dangerous Voltages Can Persist with Power Disconnected

Under certain conditions, dangerous voltages can be present because capacitors can retain

charges even after the power has been disconnected.

Protect yourself — always turn off the input (primary) power and wait for storage capacitors

to drain their charge. Then check the system controller’s TB2 output terminals with a voltmeter

for any residual charge before touching any circuit element or component.

Do Not Depend on Interlocks

Never depend on interlocks alone to remove unsafe voltages. Always check circuits with a

voltmeter. Under no circumstances remove or alter any safety interlock switch.

FTS 370d/w/r Revision 19 – 05/23/2018 iii

Table of Contents

Front Matter............................................................................................................................... i

Personnel Hazard Warning....................................................................................................... ii

Table of Contents.....................................................................................................................iii

List of Figures............................................................................................................................v

List of Tables ........................................................................................................................... vi

Section 1 – Introduction and Operation.....................................................................................1

Introduction............................................................................................................................1

System Overview...............................................................................................................1

Specifications.....................................................................................................................2

SC 370....................................................................................................................................4

Operation Overview...........................................................................................................4

PCB1 Controller Board......................................................................................................5

PCB2 Surge Board...........................................................................................................12

FH 370d/w/r.........................................................................................................................13

Marker Interface Enclosure..................................................................................................14

MKR 371 .............................................................................................................................15

Section 2 – Mounting and Installation.....................................................................................16

Controller Installation..........................................................................................................16

Verify the Installation......................................................................................................16

SC 370 Access .................................................................................................................16

Mounting..........................................................................................................................16

Mounting Adapter Panel (Optional) ................................................................................16

Wiring..............................................................................................................................17

Input Power......................................................................................................................17

Photodiode Wiring...........................................................................................................17

Photodiode Mounting.......................................................................................................17

Cellular Antenna..............................................................................................................18

GPS Antenna....................................................................................................................19

Communication Cable Kit ...............................................................................................21

Wi-Fi Option Antenna Installation ..................................................................................21

USB Wi-Fi (Optional)......................................................................................................23

Dry Contact Alarm Outputs.............................................................................................24

Flashhead Cable...................................................................................................................24

Marker Interface Enclosure..................................................................................................26

Wiring Procedure.............................................................................................................26

Flashhead Installation ..........................................................................................................28

System Wiring Diagram Notes (D1 & D2)..........................................................................43

System Wiring Diagram Notes (E1 & E2) ..........................................................................45

System Wiring Diagram Notes (Catenary)..........................................................................47

Section 3 – Information Display..............................................................................................57

Navigating the Information Display ....................................................................................57

Ctrl Type..............................................................................................................................58

Site Tower Config................................................................................................................58

Local Tower Config.............................................................................................................62

Monitoring Config...............................................................................................................64

Monitoring Status.................................................................................................................66

Local Diagnostics.................................................................................................................66

iv Revision 19 – 05/23/2018 FTS 370d/w/r

Lighting Inspection (LI).......................................................................................................68

Mode Override.....................................................................................................................69

System Settings....................................................................................................................69

Factory Diagnostics .............................................................................................................69

System X Firmware .............................................................................................................70

USB Firmware Update.........................................................................................................70

Information Display Alarms ................................................................................................71

Section 4– Web Interface.........................................................................................................73

Web Interface (Optional).....................................................................................................73

Lighting Inspection (LI).......................................................................................................74

Mode Override.....................................................................................................................75

Auxiliary Input.....................................................................................................................76

Event Log.............................................................................................................................76

Diagnostics...........................................................................................................................77

Download Log File ..............................................................................................................77

Configuration.......................................................................................................................77

Tower Lighting ................................................................................................................78

System “X” ......................................................................................................................79

Monitoring .......................................................................................................................80

Network............................................................................................................................80

SNMP Labels...................................................................................................................80

SNMP Settings.................................................................................................................81

Login Settings..................................................................................................................83

System Settings................................................................................................................83

Cellular Modem...............................................................................................................83

Section 5 – Maintenance and Troubleshooting........................................................................84

Safety ...................................................................................................................................84

Preventive Maintenance.......................................................................................................84

Storage .................................................................................................................................84

RFI Problems.......................................................................................................................84

Diagnostic Test ....................................................................................................................84

Component Testing..............................................................................................................84

Troubleshooting...................................................................................................................85

Component Removal and Replacement...............................................................................88

Section 6 – Recommended Spare & Replaceable Parts...........................................................89

Ordering Parts......................................................................................................................89

RMA Policy.........................................................................................................................89

FTS 370d/w/r Revision 19 – 05/23/2018 v

List of Figures

Figure 1-1 – SC 370 (AC)......................................................................................................... 4

Figure 1-2 – PCB1 Controller Board........................................................................................ 5

Figure 1-3 – Information Display and User Interface............................................................... 6

Figure 1-4 – Alarm Interface & Mode Indicator Connections ................................................. 9

Figure 1-5 – PCB 3 with GPS................................................................................................. 11

Figure 1-6 – PCB2 Surge Board (PN 2420600 or 2420601).................................................. 12

Figure 1-7 – FH 370d/w/r....................................................................................................... 13

Figure 1-8 – Marker Interface PCB........................................................................................ 14

Figure 1-9 – MKR 371............................................................................................................ 15

Figure 2-1 – Antenna Mounting Bracket with PHD 516, Cellular and GPS Antennas.......... 20

Figure 2-2 – Antenna Mounting Options................................................................................ 20

Figure 2-3 – Wi-Fi Antenna Installation................................................................................. 22

Figure 2-4 – USB Wi-Fi Installation ...................................................................................... 23

Figure 2-5 – SC 370 Flashhead Cable Connection................................................................. 24

Figure 2-6 – Marker Interface Wiring .................................................................................... 27

Figure 2-7 – Flashhead Leveling ............................................................................................ 28

Figure 2-8 – Flashhead Cable Terminal Block....................................................................... 29

Figure 2-9 – SC 370 Mounting and Outline (Painted Aluminum Option)............................. 30

Figure 2-10 – SC 370 Mounting and Outline (Stainless Steel Option) .................................. 31

Figure 2-11 – Adapter Mounting Panel Mounting and Outline (Optional)............................ 32

Figure 2-12 – Photodiode Mounting and Outline................................................................... 33

Figure 2-13 – Flashhead Dimensions and Mounting Outline................................................. 34

Figure 2-14 – MKR 371 Mounting and Outline..................................................................... 35

Figure 2-15 – Marker Interface Mounting and Outline (Painted Aluminum Option)............ 36

Figure 2-16 – Marker Interface Mounting and Outline (Stainless Steel Option)................... 37

Figure 2-17 – Typical E1/D1 Component Locations.............................................................. 38

Figure 2-18 – Typical E2/D2 Component Locations.............................................................. 39

Figure 2-19 – Typical E2/D2 Avian Component Locations (AC 70/7460-1L)...................... 40

Figure 2-20 – Typical Catenary Component Locations.......................................................... 41

Figure 2-21 – Typical D1 & D2 System Wiring Diagram...................................................... 42

Figure 2-22 – Typical E1 & E2 System Wiring Diagram ...................................................... 44

Figure 2-23 – Typical Catenary System Wiring Diagram...................................................... 46

Figure 2-24 – SC 370 (AC) Internal Wiring Standard System............................................... 48

Figure 2-25 – SC 370 (AC) Internal Wiring with Smart Board Option ................................. 49

Figure 2-26 – SC 370 (AC) Internal Wiring with Modem Options........................................ 50

Figure 2-27 – SC 370 (AC) Internal Wiring with Modem & Wi-Fi Options......................... 51

Figure 2-28 – SC 370 (AC) Internal Wiring with Wi-Fi Option............................................ 52

Figure 2-29 – SC 370 (DC) Internal Wiring Standard System............................................... 53

Figure 2-30 – SC 370 (DC) Internal Wiring with Smart Board Option ................................. 54

Figure 2-31 – SC 370 (DC) Internal Wiring with Modem Option......................................... 55

Figure 2-32 – Marker Interface Enclosure Wiring Diagram .................................................. 56

Figure 3-1 – Information Display........................................................................................... 57

Figure 6-1 – SC 370 (AC) Component Locations.................................................................. 90

Figure 6-2 – SC 370 (DC) Component Locations.................................................................. 92

vi Revision 19 – 05/23/2018 FTS 370d/w/r

List of Tables

Table 1-1 – Physical Specifications...........................................................................................2

Table 1-2 – Performance Specifications....................................................................................3

Table 1-3 – Status & Alarm LEDs.............................................................................................7

Table 1-4 – Multitech Modem LEDs.........................................................................................8

Table 1-5 – Alarm Interface & Mode Indicator Connections....................................................9

Table 3-1 – Controller Display Buttons 1................................................................................57

Table 3-2 – Top Level Menu Options 1...................................................................................57

Table 3-3 – Information Display Status and Alarm Definitions..............................................71

Table 3-3 – Information Display Status and Alarm Definitions (continued) ..........................72

Table 5-1 – Troubleshooting – Initial Inspection ....................................................................85

Table 5-2 – Troubleshooting – System Voltage......................................................................85

Table 5-3 – Troubleshooting - Flashhead................................................................................86

Table 5-4 – Troubleshooting – L810 Side Markers (SC 370 Information Display)................86

Table 5-5 – Troubleshooting – Marker Interface Box.............................................................87

Table 5-6 – Troubleshooting – GPS Synchronization.............................................................87

Table 6-1 – SC 370 (AC) Replacement Parts..........................................................................91

Table 6-2 – SC 370 (DC) Replacement Parts..........................................................................93

Table 6-3 – FH 370 Replacement Parts...................................................................................94

Table 6-4 – Marker Interface Replacement Parts....................................................................94

Table 6-5 – System Replacement Parts ...................................................................................95

FTS 370d/w/r Revision 19 – 05/23/2018 1

Section 1 – Introduction and Operation

Introduction

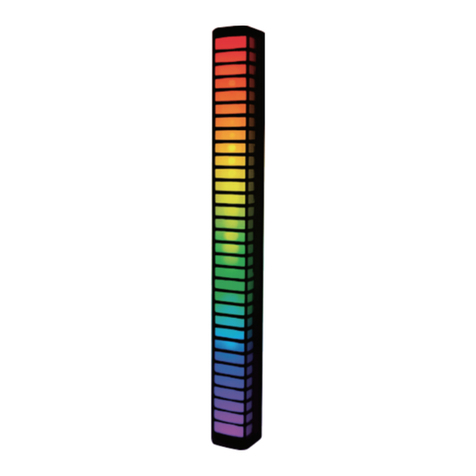

FTS 370d and FTS 370w are LED Medium

Intensity Obstruction Lighting Systems.

FTS 370d series are Dual Lighting Systems

(red/white) for L-864/865 applications.

FTS 370w series are White Lighting

Systems for L-865 applications.

FTS 370 series lighting systems may also

be configured for Catenary operation.

Catenary lighting systems require three

levels (tiers) of lights. One tier is installed

at each of the following three locations: top

of the structure, lowest point of the catenary

and half way between the upper and lower

levels. Each level must be lit to provide

360-degree coverage. The flash rate is 60

flashes per minute in all modes and the

flash sequence is as follows: middle – top

– bottom.

FTS 370d Catenary series are Dual

Lighting Systems for L-866/885

applications. FTS 370w Catenary series are

White Lighting Systems for L-866

applications. FTS 370r series are Red

Lighting Systems for L-885 Catenary

applications only.

System Overview

The FTS 370d, FTS 370w and FTS 370r

LED Lighting Systems have been designed

for long life, reducing the need for service.

Ease of installation and service is enhanced

by simple wiring, setup, and diagnostics.

Increased safety is provided with operating

voltages of less than 60VDC.

Each Lighting System consists of one or

more SC 370d, SC 370w or SC 370r, here

after referred to as SC 370, power and

control unit(s) and its associated flashhead.

Each flashhead requires its own SC 370. A

maximum of six (6) SC 370s and associated

flashheads may be connected to form one

lighting system. Optional GPS

synchronization is available if additional

SC 370s are required.

The light source for the flashhead is

comprised of LEDs (Light Emitting

Diodes). The LED control circuitry and

drivers are located in the flashhead. Power

Line Communication is utilized as the

communication link between the SC 370

and the flashhead; simplifying installation

and minimizing the number of conductors

required. Installation of FTS 370d systems

(L-864/865) requiring L-810 markers is

simplified by requiring only one cable run

for both markers and flashhead. The

flashhead may be located up to 850’ (cable

length) from the controller.

Any SC 370 in the lighting system may be

configured as the control unit which is

referred to as System 1. This unit provides

overall system control including mode

control, synchronization, and alarm

collection and notification. Robust and

highly reliable communication between

multiple SC 370 units is provided by RS-

485.

SC 370 systems may be ordered configured

for operation by AC or DC input power. AC

systems are not sensitive to input power

phase and have an operational voltage

range of 120-240 VAC, 50/60 Hz with no

modification necessary to the input power

module. DC powered systems are available

configured for 24 or 48 VDC. The DC input

voltage must be specified when ordering.

This manual provides guidance and

recommendations for the installation,

operation, and troubleshooting of the

lighting system. Please read this document

in its entirety before installation.

2 Revision 19 – 05/23/2018 FTS 370d/w/r

Specifications

Table 1-1 – Physical Specifications

Equipment Model Physical Specifications

SC 370 System Controller (Standard):

Dimensions H x W x D (millimeters)

Weight (kilograms) 23.82 x 17.25 x 8.51 in (605 x 438.3 x 216.2)

39 lb (18.1)

SC 370 System Controller

(Stainless Option):

Dimensions H x W x D (millimeters)

Weight (kilograms) 23.00 x 17.13 x 6.44 in (584.2 x 435.1 x 163.6)

40 lb (18.1)

Marker Interface (Standard):

Dimensions H x W x D (millimeters)

Weight (kilograms) 16.1 x 10.5 x 4.91 in (408.9 x 266.7 x 124.8)

10.1 lb (4.6)

Marker Interface (Stainless Option):

Dimensions H x W x D (millimeters)

Weight (kilograms) 13.75 x 11.05 x 4.36 in (349.3 x 280.7 x 110.7)

11.7 lb (5.3)

FH 370 Flashhead:

Dimensions H x D (millimeters)

Weight (kilograms)

Aerodynamic Wind Area (cm2)

7.5 x 15.75 in (190.5 x 400)

26.3 lb (11.9)

99.13 in2 (639.5)

MKR 371:

Dimensions H x W x D (millimeters)

Weight (kilograms) 9.0 x 2.75 x 2.13 in (228.6 x 69.9 x 54.1)

1.6 lb (0.7)

PHD 516 Photodiode:

Dimensions H x W x D (millimeters) 4.27 x 2.02 x 1.31 in (108.4 x 51.3 x 33.3)

FTS 370d/w/r Revision 19 – 05/23/2018 3

Table 1-2 – Performance Specifications

Parameter Lighting Type

FAA

CAR 621 ICAO

Type A/B

Type A/C

4K White

Night

L-864/L-865

CL-864/CL-865 L-866/ L-885

CL-866/ CL-885

Flash Intensity (ECD ± 25%):

White Day 20,000 20,000 20,000 min. -

Red Night 2,000 2,000 2,000 -

White Night 2,000 2,000 2,000 4,000 nom.

Flash Rate (flashes per minute):

White Day 40 60 20/30/40 -

Red Night 20/30/40 60 20/30/40/Stdy2-

White Night 40 60 20/30/40 40

Primary Power 120V - 240V AC, 50/60 Hz (3A - 1.5A Peak)

+/- 24 V DC (20–30 V) (16A Peak)

+/- 48 V DC (40-60 V) (8A Peak)

Power Consumption3(Watts ±5%)

White Day 65

55 80

60 80

Red Night 35

35 40

40 35

552

White Night 35

35 40

40 40 45

Environmental

Temperature

Humidity

Complies with FAA specifications in AC 150/5345-43H

for continuous operation which includes the following:

Storage/shipping: -67° to 130° F / -55° to 55° C

Operating: -40° to 130° F / -40° to 55° C

95% relative humidity

Flashhead cable

6-375 ft.

6-600 ft.

6-850 ft.

PN 4210000, 10 AWG

PN 4370000, 8 AWG

PN 4206000, 6 AWG

Notes:

1. For 60 fpm, enable Catenary, Middle

2. ICAO Type C, Steady on.

3. Power measurements are for IR and non-IR Flashheads.

4 Revision 19 – 05/23/2018 FTS 370d/w/r

SC 370

Operation Overview

An internal view of the SC 370 is shown in

Figure 1-1. Component layout diagrams

with part names and numbers are shown in

Figures 6-1 (AC) and 6-2 (DC). Internal

wiring diagrams are shown in Figures 2-24

– 2-28 (AC) and 2-29 – 2-31 (DC).

Input power is connected to terminal block

TB1. Mounted on TB1 is a Metal Oxide

Varistor (VR1) which reduces line surges

and transients. Input power Circuit

Breakers are also mounted on TB1.

Disconnect power from the SC 370 before

servicing Circuit Breakers or MOV.

Flag Indicator on the 2-pole Circuit

Breakers is clearly marked with green OFF

and red ON.

The power supplies located in each SC 370

unit convert input power to the correct DC

operating voltages for the system. (Shown

with single power supply below).

The control PCB (PCB1) supervises system

operation. A User Interface with

alphanumeric display and pushbuttons

provides system configuration and alarm

notification.

Note: Shown with Modem and Wi-Fi options.

Figure 1-1 – SC 370 (AC)

FTS 370d/w/r Revision 19 – 05/23/2018 5

OLED

Display Control

Interface

Manual

Override

Alarm

Interface

& Mode

Indicator

Connections

Auxiliary In-

put

& PCB Input

Power

PCB1 Controller Board

PCB1 controls and monitors operation of

the SC 370 and its associated flashhead.

Each section of PCB1, outlined in the photo

below, is discussed in the following

subheadings.

Figure 1-2 – PCB1 Controller Board

Important! Do not install or remove

wires from terminal blocks or PCB’s until

DC voltage indicator on PCB2 has been

extinguished. This applies especially to

connection at PCB1 P1. If it is necessary

to remove connection or make other

wiring adjustments, power the system

down and wait until the LED on PCB2 is

off.

Status &

Alarm LEDs

PCB 3

(Optional) J4 RS 485

Communication

Cable Connection

P1 Photodiode

& PLC Input

(See Important

Note Below)

PCB1 P1

6 Revision 19 – 05/23/2018 FTS 370d/w/r

PCB1 Information Display and User Interface

A multi-line OLED (Organic Light-

Emitting Diode) display provides system

status, alarm and programming

information. Three pushbuttons located to

the immediate right of the display provide

the user interface for the system. The top

and bottom buttons move the cursor

position (*) up and down on the display.

The center button selects the action at the

cursor position. The information display

defaults to show the current system status

as well as the basic configuration for the

unit. See Section 3 for a detailed

description for all menu functions of the

information display. See Table 3-3 for a

complete list of alarms provided by the

information display.

Figure 1-3 – Information Display and User Interface

Manual Override

The Manual Mode switch

provides temporary

control of the system’s

operating mode. When

the manual mode switch

of the unit is moved to

either MAN DAY or

MAN NIGHT, the display reads “M-DAY”

or “M-NIGHT” respectively and the

corresponding Mode LED blinks. Manual

mode expires 30 minutes after initiating the

mode override. Each change to the manual

mode switch restarts the 30 minute timer.

The Manual Mode switch must be moved

after power up to activate mode override.

The switch has no effect if it is set to Day

or Night before power up.

Status and Alarm LEDs

Twelve Status and Alarm LEDs are

provided for immediate visual reference of

the current status of the unit. Table 1-3

describes the function of each LED.

FTS 370d/w/r Revision 19 – 05/23/2018 7

Table 1-3 – Status & Alarm LEDs

Note: See Table 3-3 for a complete list of alarms provided by the information display.

LED Indication

DAY ALARM

Red to indicate one or more of the following conditions:

1. The connected beacon is experiencing a failure in Day mode.

2. The beacon is not communicating with the SC 370. The Day Alarm will

be accompanied by the Night Alarm and the Comm. Alarm in this instance.

NIGHT ALARM

Red to indicate one or more of the following conditions:

1. The connected beacon is experiencing a failure in Night mode.

2. The beacon is not communicating with the SC 370. The Night Alarm

will be accompanied by the Day Alarm and the Comm. Alarm in this

instance.

3. Beacon IR failure. Activation of Night Alarm due to IR failure requires

that “IR Enable” and “IR Alarm Is Night Alarm” are set to “Yes”. See

Section 3 “Site Tower Config.” for additional information.

MARKER ALARM

Red to indicate one or more of the following conditions:

1. One or more L-810 markers have failed.(FTS 370d L-864/865 only)

2. The marker interface board is not communicating with the SC 370 *.

* The Marker Alarm will be accompanied by the Comm. Alarm in this

instance.

PHOTODIODE Red when more than 19 hours have passed since the system has

changed modes via the photodiode input.

COMM ALARM

Red to indicate a communications failure in one or more of the following

conditions:

1. One or more connected units (Systems 2 – 6) are not communicating

with System 1.

2. The connected beacon is not communicating with the SC 370. The

Comm. Alarm will be accompanied by the Day Alarm and Night Alarm.

3. The connected marker tier is not communicating with the SC 370. The

Comm. Alarm will be accompanied by the Marker Alarm.

GPS SYNC More than one hour has passed since the unit received a GPS Sync.

pulse.

DAY MODE Green continuous when unit is in DAY mode, blinking when the unit is in

manual DAY mode.

RED NIGHT Green continuous when unit is in RED NIGHT mode, blinking when the

unit is in manual RED NIGHT mode.

WHITE NIGHT Green continuous when unit is in WHITE NIGHT mode, blinking when the

unit is in manual WHITE NIGHT mode.

485 TX Red blinking when the unit is sending data to other units in the system.

485 RX Red blinking when the unit is receiving data from other units in the system.

FLASH Active only if GPS is enabled. Blinks approximately once per minute when

SAT lock is achieved.

8 Revision 19 – 05/23/2018 FTS 370d/w/r

Table 1-4 – Multitech Modem LEDs

LED Indication

POWER On Solid: The modem is properly powered

STATUS On Solid: Modem is starting up or saving its configuration.

Blinking: Modem initialization is complete and ready for use

CD On Solid: A data connection has been established. ON during normal

operation

LS ATT Modem:

On Solid: Not registered on the

network

Slow Blinking: Registered and

connected to the network

Verizon Modem:

Fast Blinking: Not registered on the

network or is searching for connection

Slow Blinking: Registered and connected

to the network

On Solid: Modem is transmitting or

receiving

SIGNAL 1 Bar: Very weak signal

2 Bars: Weak Signal

3 Bars: Good Signal

FTS 370d/w/r Revision 19 – 05/23/2018 9

Alarm Interface & Mode Indicator Connections

Dry contact alarm connections, located on

PCB 1, are available regardless of any

additional monitoring method used. The

available dry contact alarm outputs are

listed in Table 1-5 and shown in Figure 1-

4. Each contact may be wired as normally

open or normally closed. The contacts are

labeled to indicate their state with the

system powered on without an alarm

present.

Mode indicator contacts are available on P4

terminals 10 – 12. When powered on, an

open contact between COM and NO

indicates the system is operating in Night

mode and a closed contact indicates the

system is operating in Day mode. An open

contact between COM and NC indicates the

system is operating in Day mode and a

closed contact indicates the system is

operating in Night mode. The mode

indicator contacts do not differentiate

between manual and automatic operation as

determined by the Manual Mode Switch.

Figure 1-4 – Alarm Interface & Mode Indicator Connections

Table 1-5 – Alarm Interface & Mode Indicator Connections

Connector Alarm Terminal Function

P3 Day

Alarm

COM (1)

NO (2)

NC (3)

Common

Closes to indicate an alarm in day mode.

Opens to indicate an alarm in day mode.

P3 Night

Alarm

COM (4)

NO (5)

NC (6)

Common

Closes to indicate an alarm in night mode.

Opens to indicate an alarm in night mode.

P3 Marker

Alarm

COM (7)

NO (8)

NC (9)

Common

Closes to indicate a marker alarm.

Opens to indicate a marker alarm.

P4 Photo-

Diode

Alarm

COM (1)

NO (2)

NC (3)

Common

Closes to indicate a photodiode alarm.

Opens to indicate a photodiode alarm.

P4 GPS

Sync.

Alarm

COM (4)

NO (5)

NC (6)

Common

Closes to indicate a Sync Alarm.

Opens to indicate a Sync Alarm.

P4 Comm.

Alarm

COM (7)

NO (8)

NC (9)

Common

Closes to indicate a Comm. failure.

Opens to indicate a Comm. failure.

P4 Mode COM (10)

NO (11)

NC (12)

Common

Open indicates Night mode. Closed indicates Day mode.

Open indicates Day mode. Closed indicates Night mode.

P3

P4

10 Revision 19 – 05/23/2018 FTS 370d/w/r

P2 Auxiliary Input

The Auxiliary Input (previously labeled

LOW BAT) allows an external device, such

as a radar system, to inhibit the output of

the beacon. Control via the Auxiliary Input

is limited to systems consisting of a single SC

370 power and control unit. Control is

supplied by a dry contact from the external

device connected to “Aux In” (P2 terminal

3) and “DC –” (P2 terminal 1). The fail-safe

design requires a closed contact to inhibit

the output of the beacon.

Any unused dry contact may be reassigned

to provide confirmation that the system is

operating normally while the beacon output

is inhibited. See Figure 1-4 and Table 1-5

for available dry contacts.

Auxiliary Input configuration

programming is located in the “Site Tower

Configuration” menu of the controller

programmed as System 1. See Section 3 for

additional information regarding this

feature.

Note: Firmware 2.9 or above is required for

Auxiliary Input Control. The beacon output

may also be controlled by Modbus. See

Section 3 and Technical Bulletin “SC 370

SMART Modbus interface” (part number

7904502) for additional information.

J4 Communication Cable Connection

FTS 370 systems

consisting of more than

one SC 370 unit require

connection of a

communication cable

between units. J4,

located on the lower

right of PCB1, provides

connection for two RJ 45

connectors. The double RJ 45 connector

allows the communication cables to be

daisy chained from System 1 to each

subordinate unit. Either port may be

utilized as an input to or output from PCB

1. See “Communication Cable Kit” in

Section 2 for additional connection and

cable routing information.

Other manuals for VANGUARD FTS 370d

1

This manual suits for next models

2

Table of contents

Other Flash Technology Lighting Equipment manuals

Flash Technology

Flash Technology FTS 812 L User manual

Flash Technology

Flash Technology Vanguard FTS 370 User manual

Flash Technology

Flash Technology VANGUARD FTS 370d User manual

Flash Technology

Flash Technology FTS 350i-2 User manual

Flash Technology

Flash Technology VANGUARD FTS 370i-2 User manual

Flash Technology

Flash Technology VANGUARD FTS 270 User manual

Flash Technology

Flash Technology FTB 312-3 User manual

Flash Technology

Flash Technology R247-G User manual

Flash Technology

Flash Technology Vanguard Red FTS 371 SMART User manual

Flash Technology

Flash Technology Vanguard Red FTS 371 User manual