4 L-01394-4-05

2.1 Use at low temperatures

The safety of the light fitting is warranted between -30°C up to +40°C/+55°C.

At temperatures below 0 °C, it must be taken into account that the emergency battery will take longer

to charge and the operational life of the emergency lighting mode will be reduced. Testing the duration

of the battery life in lower ambient temperatures can therefore lead to a misleading result.

The battery life test should be repeated manually at a more appropriate time (please refer to the

section about operational life testing in Chapter 2.2).

2.2 Automatic test of the emergency light unit

The functionality of the light fitting and the operational life in emergency lighting mode is tested

automatically by the emergency light unit at specified intervals. A blinking green light is emitted by the

signal LED while the test is being carried out.

Functionality test

Functionality tests are carried out at 7 day intervals and last one minute.

The first test of functionality is carried out one hour after the light fitting has been setup. Before this can

happen, it is necessary to separate the emergency light unit built into the light fitting from the mains

power supply before switching on the power, and the emergency battery must have been charged

continuously for one hour.

Operational life test

During the operational life test, the emergency light unit checks whether the capacity of the emergency

battery is sufficient for the indicated nominal operating time should the emergency light being required.

For the operational life test to be carried out, the emergency battery must be fully charged and

connected. For special versions with the option to deactivate the emergency light function, the remote

cutoff switch must also be closed.

Automatic operational life tests:

The first operational life test carried out automatically by the emergency light unit takes place at

random within a period of 5 to 28 days after the light fitting has been setup. All further automatic

operational life tests are then carried out at 52 week intervals, so long as the energy supply to the

emergency light unit was not interrupted during this period.

A complete interruption of the energy supply to the emergency light unit occurs when the outage of the

power supply exceeds the specified nominal operating time for the emergency light.

Reconnecting the power supply to the emergency light unit after a complete interruption will lead to a

new setup procedure of the emergency light with a subsequent operational life test between 5 and 28

days later.

Should a fault in the battery capacity be indicated before a complete interruption of the power supply to

the emergency light unit, a operational life test will be carried out within 24 hours of reconnection to the

power supply.

If the prerequisites stated above for carrying out an automatic operational life test are not satisfied, the

test will be deferred until these requirements are fulfilled.

Automatic operational life tests that could not be completed successfully will be repeated once after 60

hours, subject to the same prerequisites stated above.

Manual operational life tests:

Operational life tests can be triggered manually in 2 ways. Models with battery box can be triggered

manually in 3 ways:

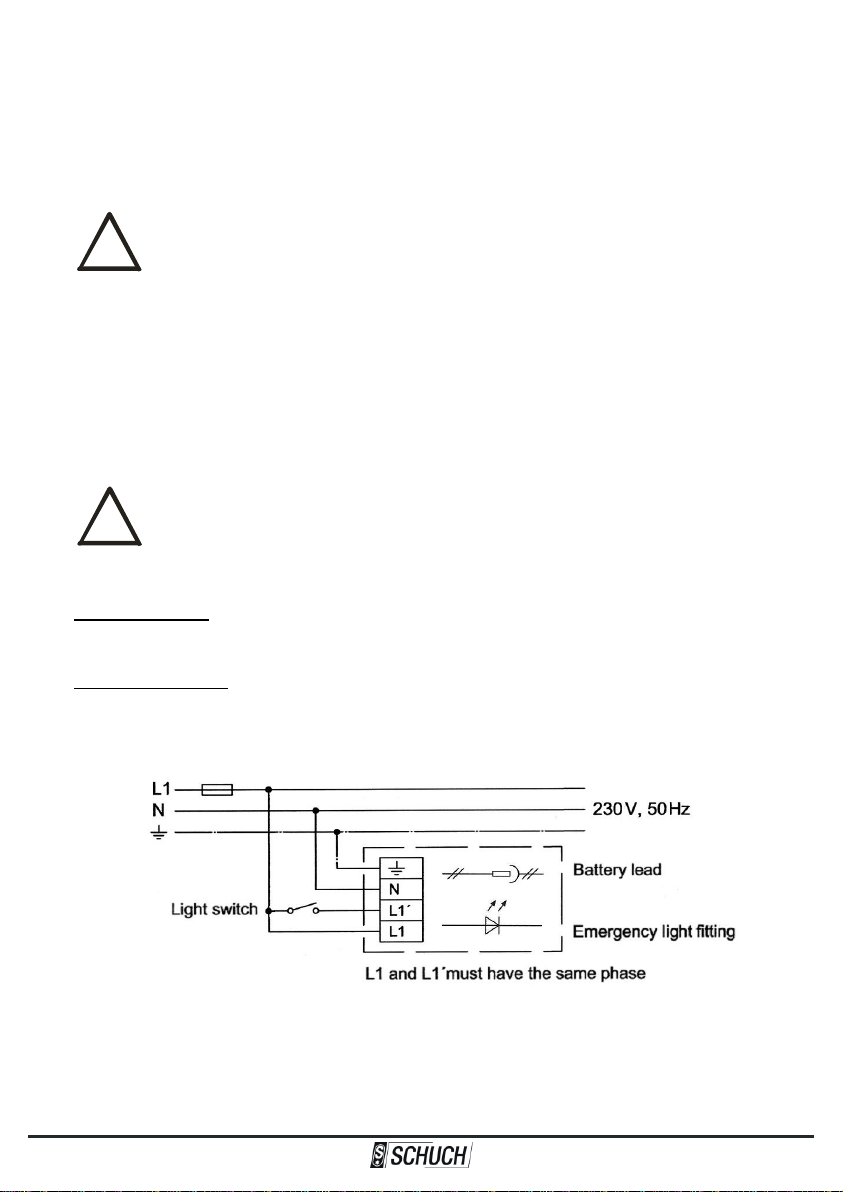

1. By switching the power supply off and on at the L1 terminal.

2. By switching the supply on and off at the L1`terminal.

Switch the power supply at the L1 terminal resp. the supply at L1' terminal off and on again 5 times.

Leave at least 2 seconds between each switch.

In both cases, the sequence of switches must be completed within 60 seconds.

Under the above mentioned preconditions, after a correctly performed switching sequence at L1'

terminal, an operational life test is immediately initiated.

If the switching sequence is correctly carried out on L1 terminal, an operational life test is initiated after