Flashforge USA Creator User guide

Creator

Quick Start Guide

Version 2.0 (January 2014)

2

Contents

4

Section 1: What’s Included in the Box?

5

Section 2: Unboxing

8

Section 3: Initial Hardware Installation

11

Section 4: Software Installation

17

Section 5: USB Connection & Temperature Setting

22

Section 6: Filament

22

Installing the Filament

23

Feeding the Filament Using LCM Screen

24

Withdrawing the Filament Using LCM Screen

25

Setting the Parameter

26

Initial Print

28

Dual Extruder Print

3

WARNING:

Prior to powering on the Creator, make sure the power supply switch is set

to 115v if you are located in the United States. For other countries, please

refer to your country standards. Failure to do so will damage the

motherboard. For instructions on how to do this, please refer to page 8.

Precautions:

Please make sure to read this page carefully prior to setting up and operating the Creator.

The Creator is very sensitive to static electricity, so please make sure you contact a grounded

object before operating the machine.

-Before repairing or making any alterations to the Creator, it is essential that the machine is

turned off, and the power cord is unplugged.

-The Creator operates at a very high temperature; allow the nozzle, extruded plastic and heating

plate to cool before touching.

-Some plastic filaments may give off a slight odor when heated. Because of this, the machine

should always operate in a well-ventilated area.

-Do not wear gloves when operating or repairing, as entanglement may occur and cause injury.

-Do not leave the machine unattended when in operation.

4

1What’s Included in the Box?

Along with your Creator 3D printer, the box also contains the following.

An accessory box on top of the Creator:

Single or dual extruder heads,

1 or 2 filament holders,

SD Card,

Bolt tool plate, hex wrench toolbox.

Under the Creator’s build platform, there are 2 filaments:

2.2 pounds (1 kg) ABS filament,

2.2 pounds (1 kg) PLA filament.

Under the Creator unit, you’ll find:

Power supply,

USB A to B cable,

2 filament guide tubes

5

2Unboxing

The Creator is carefully packaged at the FlashForge manufacturing facility. Please follow the unboxing

steps laid out below.

CAUTION

Handle the package and its contents with extra care; do not use any unnecessary force.

Do not remove the thin yellow film from the heating plate. It is heat resistant tape that

improves the adhesion of the extruded plastic to the plate.

Do not remove the wrapping around the nozzle. It consists of a ceramic fiber fabric and heat

resistant tape that helps to keep the nozzle at a constant temperature.

First, place the box on the floor in a clean and flat surface. Remove the top carton and pull out the

cardboard packing that encloses the Creator.

You can see the top of the printer along with more boxes inside. The large box with the black wire is the

accessory box. This contains the extruder(s), SD card, and other important components.Do not

remove the accessory box and its contents yet. Note: Do not lift the box by the black cable. Doing so

could cause damage.

Next, take the Creator out of the box by grasping the outer frame. Be sure to grasp only the frame.

Gently lift and transfer the printer to your work surface, as shown on the next page.

6

With the Creator removed, you will find the power supply and cable, USB A to B cable, and a filament

guide tube. Remove them from the box and set them aside. Now, open the accessory box and remove

the accessory sleeve.

You will find the extruder in the protective packaging along the black cable. Carefully remove it and

place it on your work surface. Remove the cardboard packing material and take the accessory box from

the printer; set it aside for later.

The build platform should now be visible. It is an aluminum plate covered in a thin polyamide film. This

is the surface that your objects will be printed on. Note:Remember not to remove this film.

The next step is to raise the build platform. There are two ways to do this:

1. Turn the screw that is behind the rotating platform.

2. Grasp the printing platform with one hand on each side, raising it slowly and keeping it level.

Stop once the platform is just shy of the bronze nozzle.

7

Next, you should be able to see underneath the build platform. Here, you'll find the filament (either one

or two rolls depending on whether your Creator has single or dual extruders). It’s easiest to remove the

filament by setting aside the remaining packaging material.

To do this, remove the long box in the front, then the small box on the right, and finally the two wire

trays. You have now finished unboxing! The next task is to setup the hardware.

8

3Initial Hardware Installation

WARNING:

Prior to powering on the Creator, make sure the power supply switch is set

to 115v if you are located in the United States. For other countries, please

refer to your country standards. Failure to do so will damage the

motherboard.

Prior to installation, please make sure that the red power supply switch at the bottom of the Creator is

set to 115V (for United States).

To do this, begin by carefully placing the Creator on one of its sides so that the bottom is exposed. You

will see the Creator’s power supply. Using a flathead screwdriver, switch the red power supply switch so

that it displays 115V, as shown below. Now you are ready to install the extruder.

You'll need two silver screws from the bolt tool plate found in the accessory box and the appropriate

hex wrench.

First, lower the build platform using one of the methods described in the previous section. Holding the

extruder by both sides, take it out of the accessory sleeve and position it on the extruder seat with the

fan facing forward. Align the screw holes and fasten with the shortest silver screws.

9

Next is the installation of the filament bracket. If you have two brackets, install one on each side; If you

only have one, install it on the right hand side (when viewing the creator from the front).

The installation of the filament bracket is very simple –just insert it into the circular opening and tighten

the nut behind. Then, install the filament guide tube to the empty spot on the extruder. Place one end

of the guide tube into the hole.

The hardware installation is almost complete.

Next, with the power switch in the 'OFF' position, confirm that the power cord is plugged into the power

outlet next to the power switch.

10

Now plug the USB A to B cable into the USB B-type port, do not plug the other end in yet.

Finally, take the filament out of the box, install it onto the bracket and screw in the nut. Do not over

tighten.

Congratulations! You have completed the initial hardware installation! If you're ready to start printing,

proceed to the next step: Software Installation.

11

4Software Installation

ReplicatorG0040 is the ideal software to use with the single or dual extruder Creator. The latest version

can be downloaded from our official website by following the link below and clicking on “Download

Replicator G 0400 Installer”.

http://www.flashforge-usa.com/printer-support/downloads/

Download the files suitable for your system and decompress/extract them. For this guide, we will be

installing on a Windows PC. For Mac users, please e-mail FlashForge USA at

supports@flashforge-usa.com if you encounter any problems or setbacks throughout this guide.

Run the Python installation file and the Python acceleration components. Click Replicator-0040-Installer

to install the Replicator G software. To run the Replicator G software, double click on the ReplicatorG

icon highlighted below.

12

After opening Replicator G software, click on Machine to select your Machine Type. Choose The

Replicator Dual for Creator dual extruder machines, and choose The Replicator Single for Creator II

single extruder machines. In this guide, we will select The Replicator Dual.

After selecting the appropriate machine, click on GCode on the top navigation bar, and under GCode

Generator, select Skeinforge (50).

13

The following gives an introduction on how to import files (.STL) into the Replicator G software and

generate Gcode in order to print.

Click File > Open, then browse and select the file (.STL) that you would like to print. Import the file by

double-clicking on it. The drawing design will appear on the Replicator G interface.

When the object is imported, you may find that it is not on the virtual build platform or even on the

screen. Using the function keys indicated by the blue boxes in the illustration above, you can change the

camera angle and reposition the object onto the center of the build platform. Once you've done this, the

next step is to generate the Gcode. This is achieved by clicking on the Generate GCode at the bottom of

the panel.

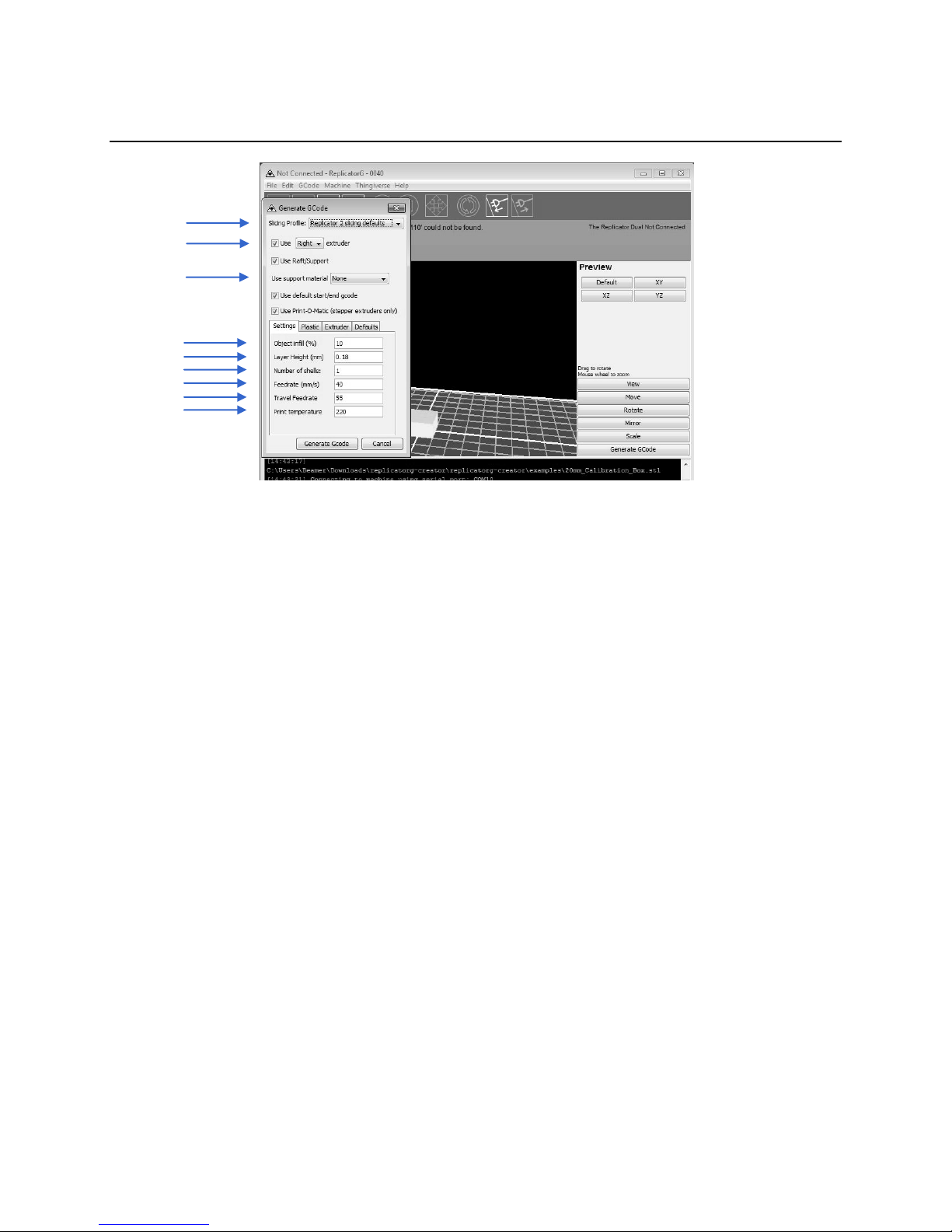

A new window will open up, giving you several options on how the Gcode will be generated:

14

A. Slicing Profile: select Replicator slicing defaults for ABS printing, then select Replicator 2 slicing

defaults for PLA printing.

B. This tells the printer which extruder to use for a dual extruder-headed printer —either the left

head or the right head can be selected.

C. If your sample will have any hanging surfaces, it is recommended to have support. Selecting

‘None’indicates that there is no support; “Exterior” means surface support; and

‘Full Support’means all support.

D. Object infill: where 100% is a solid print, 0% is a hollow object. The recommended setting is

10%; this will save time and filament.

E. Layer Height: this controls the vertical resolution of the print. The recommended thickness is

0.27mm.

F. Number of Shells: this is the wall thickness; it’s usually set at 1.

G. Feedrate: this is the speed at which the filament is fed into the extruder. This is usually set

between 30 and 70 mm/s. For ABS printing, 60 mm/s is recommended; for PLA printing, 100

mm/s is recommended.

H. Travel Feedrate: this is the speed at which the printer head moves over the base, it’s usually set

between 30 and 100. For ABS printing, 80 is recommended, for PLA printing, 120 is

recommended.

I. Print Temperature: this is the temperature at which the nozzle is heated. This varies between

filament types. Set it to 220 for the default filament.

After you are finished inputting in the settings, click Generate Gcode, and the progress bar will appear.

A

B

C

E

F

G

H

I

D

15

For users who did not choose the default installation path in the installation of Python, clicking the

Generate Gcode button in Replicator G will result in dialogue box popping up alerting that the

executable Python file cannot be found.

In order to resolve this, click the ‘No’ button to dismiss the dialogue box. Next, we need to configure the

corresponding menu.

16

Click File > Preferences on the top navigation bar, then click Select Python Interpreter under the

Advanced tab. A new window will pop up. Navigate to the Python installation directory and select

python.exe and click ‘Open’.

Last, click ‘Close’ on the Preferences menu and you are done!

The machine will now work as normal when generating Gcode, and the Python error message will not

pop up again. In the next section, we will start a preliminary test on the machine’s connections and heat

the platform so that the extruder is ready for its first print!

17

5USB Connection & Temperature Setting

First, connect the machine and the computer using the provided USB A to B cable. The USB port on the

machine is bound by the box in the below image. After connecting the cable, open the Replicator G

software as we are going to link the computer and printer.

Inside the Replicator G software, click Machine > Connection (serial port) > Rescan serial ports, if no

new ports appear, then the software driver has not been installed. To install the driver manually, go to

'My Computer' and right click on ‘Properties’. The basic system parameters appear. Next, select ‘Device

Manager’.

18

Locate the software driver shown in the blue box above. Right click and select ‘Update Driver Software’.

Click ‘Browse my computer for driver software’ to find the location of ReplicatorG0040 on your system.

19

Click ‘FTDI USB Drivers’in the driver folder and click ‘OK’. The drivers will then be installed.

The next step is to link the printer. Rescan the serial ports and select the one that appears on your

machine (on our test machine the port was COM10).

Now we can link the machine to the computer. Click on the printer connect icon highlighted in blue.

20

If the printer connect icon turns dim, as shown in the illustration below, the printer has successfully

connected to the computer. Next, we need to preheat the extruder and build platform.

In the same set of menu, click on the cross-shaped icon and a new interface will appear.

Input the following target values: 220°C for the extruder and 115°C for the heating platform. After

entering the values, the platform will start to warm up. When the extruder temperature reaches 50°C,

the cooling fan will activate and the current temperature value will display to the right as shown on the

following page.

Table of contents