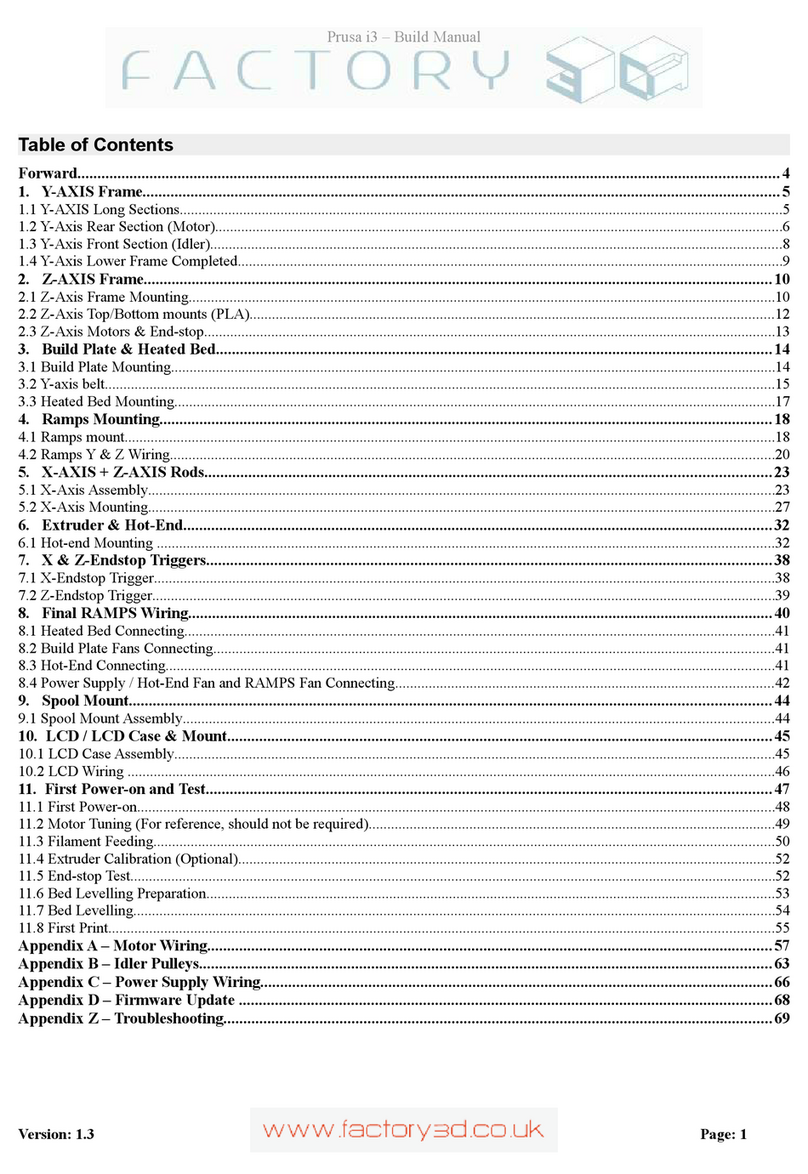

Table of Content

1. General Information

1.1 Specications ...............................................................................................................................04

1.2 System requirements................................................................................................................05

1.3 Additional options..................................................................................................................... 05

2. Operating mode of the X 500

2.1 Operating mode..........................................................................................................................07

2.5 Maintenance mode...................................................................................................................07

3. Network and printer set up

3.1 Connection via router ..............................................................................................................07

3.3 Setup routine...............................................................................................................................08

3.4 How to activate the printer and establish a connection ............................................. 13

4. 4 Workow and operation

4.1 Simplify 3D

4.2 Features......................................................................................................................................... 15

4.3 Quick Start Guide....................................................................................................................... 16

4.4 The Interface Layout ................................................................................................................. 18

5. Repetier Server

5.1 Web interface .............................................................................................................................. 23

5.2 Dashboard....................................................................................................................................24

5.3 Device panel................................................................................................................................25

5.4 Device panel - control..............................................................................................................25

5.5 EEPROM......................................................................................................................................... 28

5.6 LOG-Files .......................................................................................................................................29

5.7 Firmwareupdate ............................................................................................ 30

6. Tool heads and cosumables

6.1 Tool head wiring.........................................................................................................................31

6.2 DD4 Extruder............................................................................................................................... 31

6.3 Material Storage......................................................................................................................... 33

6.4 Filament Surveillance (fs) Set-Up ..........................................................................................33

6.4 FS activates while printing .....................................................................................................34

6.5 FS Workaround ........................................................................................................................... 35

7.1 Cooling System............................................................................................................................ 36

7.2 Heated Chamber ............................................................................................ 37

7.3 Z-Home Position.........................................................................................................................37

8. Tipps & Tricks

8.1 How to determine the X500s MAC address.......................................................................38

8.2 How to update Repetier-Server ........................................................................................... 38

8.3 PVA solution for enhanced adhesion ................................................................................. 39

8.5 PET-foil for printing bed coating..........................................................................................39

02/45