FLETCHER Alfamacchine T-300 User manual

EN INSTRUCTIONS MANUAL

PLEASE RETAIN FOR FUTURE REFERENCE

Name DOUBLE MITRE SAW FOR “V” CUTTING

Function 45° CUTTING OF MOULDINGS MADE FROM WOOD, ENGINEERED WOOD AND SIMILAR, HARD

PLASTIC AND LIGHTWEIGHT ALLOYS

Model / Type T300/T350/T400

Serial number

Year of construction

Manual Revision 01

2TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

T300 - T350 - T400 ISTRUZIONI 01 14/07/2016 14/07/2016

EN

Alfamacchine S.r.l.

Via Curie M. e P., 3

47122 Forlì - Italy

EC DECLARATION OF CONFORMITY

The Manufacturer Alfamacchine S.r.l.

&XULH0DULHH3LHUUH

47122 Forlì - Italy

Tel. +39. 0543.783301

that the machine:

HEREBY DECLARES,

Model: T300-T350-T400

Type: PNEUMATIC

Serial number:

- Machinery Directive 2006/42/EC

- Electromagnetic Compatibility (EMC) Directive 2014/30/EU

REFERENCE TO HARMONIZED STANDARDS APPLIED:

EN ISO 12100:2010; EN 60204-1:2006; UNI EN 1870-16:2012

NOTIFIED BODY no. 0476

KIWA CERMET ITALIA S.p.a.

40057 - GRANAROLO DELL’EMILIA (BO)

And authorizes

Alfamacchine S.r.l.

&XULH0DULHH3LHUUH

47122 Forlì (FC)

TO COMPILE THE TECHNICAL FILE ON ITS BEHALF

___________________________________ _______________________________

Date The Manufacturer

1

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

T300 - T350 - T400 ISTRUZIONI 01 14/07/2016 14/07/2016 EN

TRANSLATION OF THE ORIGINAL INSTRUCTIONS

INDEX

EN

1. INTRODUCTION TO USE......................................................................................................................................................... 2

1.1. HOW TO CONSULT THIS MANUAL AND THE SYMBOLS ADOPTED ....................................................................... 2

1.3. TYPE OF USE AND CONTRAINDICATIONS............................................................................................................... 5

1.4. TECHNICAL CHARACTERISTICS............................................................................................................................... 7

1.5. PRODUCTS PROCESSED - HANDLED OR GENERATED ........................................................................................ 7

1.6. EMISSION OF AIRBORNE NOISE............................................................................................................................... 8

1.7. SAFETY INSTRUCTIONS ............................................................................................................................................ 8

1.7.1. RESIDUAL RISKS ........................................................................................................................................................ 8

1.7.2. DANGERS .................................................................................................................................................................... 9

1.8. DESCRIPTION OF SAFETY FUNCTIONS................................................................................................................. 10

1.9. MACHINE DESCRIPTION.......................................................................................................................................... 12

1.10. MAIN MACHINE COMPONENTS................................................................................................................................ 12

2. INSTALLATION ....................................................................................................................................................................... 16

2.1. STORING.................................................................................................................................................................... 16

2.2. CHECKS ON RECEPTION......................................................................................................................................... 16

................................................................................................................... 17

2.4 LIFTING AND HANDLING .......................................................................................................................................... 17

.................................................................................................................................. 19

3. PRELIMINARY PREPARATION AND ADJUSTMENT PROCEDURES ................................................................................. 20

3.1. POSITIONING............................................................................................................................................................. 20

3.2. SECURING THE MACHINE TO THE FLOOR ............................................................................................................ 20

4. INITIAL START-UP AND USE OF THE MACHINE................................................................................................................. 24

4.1. WORKSTATIONS AND OPERATORS' TASKS........................................................................................................... 24

.............................................................................................................. 24

4.3. START-UP................................................................................................................................................................... 25

5. MAINTENANCE, TROUBLESHOOTING AND CLEANING ................................................................................................... 32

5.1. MAINTENANCE TECHNICIAN REQUIREMENTS ..................................................................................................... 32

5.2. WORK STATIONS AND MAINTENANCE TECHNICIAN DUTIES.............................................................................. 32

5.3. MAINTENANCE PRESCRIPTIONS............................................................................................................................ 32

5.4. GENERAL WARNINGS .............................................................................................................................................. 32

5.6. ROUTINE MAINTENANCE......................................................................................................................................... 33

5.6.1. TASKS THAT CAN BE PERFORMED BY THE OPERATOR ..................................................................................... 34

5.6.2. TASKS THAT CAN BE PERFORMED ONLY BY MAINTENANCE TECHNICIANS ................................................... 35

Blade replacement ...................................................................................................................................................... 36

Cutting angle adjustment ............................................................................................................................................ 37

Blade positioning......................................................................................................................................................... 37

Checking the vertical angle of the blades ................................................................................................................... 37

............................................................................................... 38

Condensate drainage from tanks ............................................................................................................................... 40

Check the vertical stoppers for wear........................................................................................................................... 41

Checking the horizontal stopper (optional) for wear.................................................................................................... 41

Checking the internal stopper (optional) for wear ....................................................................................................... 41

........................................................................................................................... 42

Check the oil level in the pneumatic unit..................................................................................................................... 42

Lubricator adjustment.................................................................................................................................................. 42

5.6.3 CLEANING.................................................................................................................................................................. 43

Stem lubrication (by the maintenance technican) ....................................................................................................... 46

Grease nipple lubrication (by the maintenance technician) ........................................................................................ 46

6. TROUBLESHOOTING AND RELEASE OF MOVING PARTS ............................................................................................... 47

7. REINSTALLATION AND REUSE ............................................................................................................................................ 48

8. INSTRUCTIONS FOR EMERGENCIES.................................................................................................................................. 49

9. SCRAPPING AND DISPOSAL................................................................................................................................................ 49

9.1. SCRAPPING............................................................................................................................................................... 49

9.2. DISPOSAL .................................................................................................................................................................. 50

PNEUMATIC DIAGRAM ................................................................................................................................................................... 51

ELECTRICAL DIAGRAM.................................................................................................................................................................. 52

ELECTRICAL SYSTEM ON BOARD THE MITRE SAW MACHINE................................................................................................ 53

2TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

T300 - T350 - T400 ISTRUZIONI 01 14/07/2016 14/07/2016

EN

DANGER - WARNING

BEFORE USING THE MACHINE PLEASE READ THIS MANUAL CAREFULLY SO THAT YOU BECOME FAMILIAR

WITH THE MACHINE, ITS ENVISAGED USE AND ANY RISKS ASSOCIATED WITH IT.

to get best machine performance in maximum safety while performing the operations described therein.

DANGER - WARNING

USE THE MACHINE SOLELY AND EXCLUSIVELY FOR THE USES INDICATED AND IN ACCORDANCE WITH THE

RECOMMENDATIONS PROVIDED IN THIS MANUAL. NEVER TAMPER WITH IT, FORCE IT OR USE IT IN ANY

INAPPROPRIATE MANNER.

1. INTRODUCTION TO USE

1.1. HOW TO CONSULT THIS MANUAL AND THE SYMBOLS ADOPTED

accompanied by symbols and notes to highlight the presence of any hazards and indicate the safe use of the equipment. These

DANGER – WARNING: IMPORTANT INFORMATION CONCERNING GENERAL SAFETY.

DANGER-CAUTION: highlights situations where careful and sensible actions are essential.

NOTES: information of a technical nature.

3

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

T300 - T350 - T400 ISTRUZIONI 01 14/07/2016 14/07/2016 EN

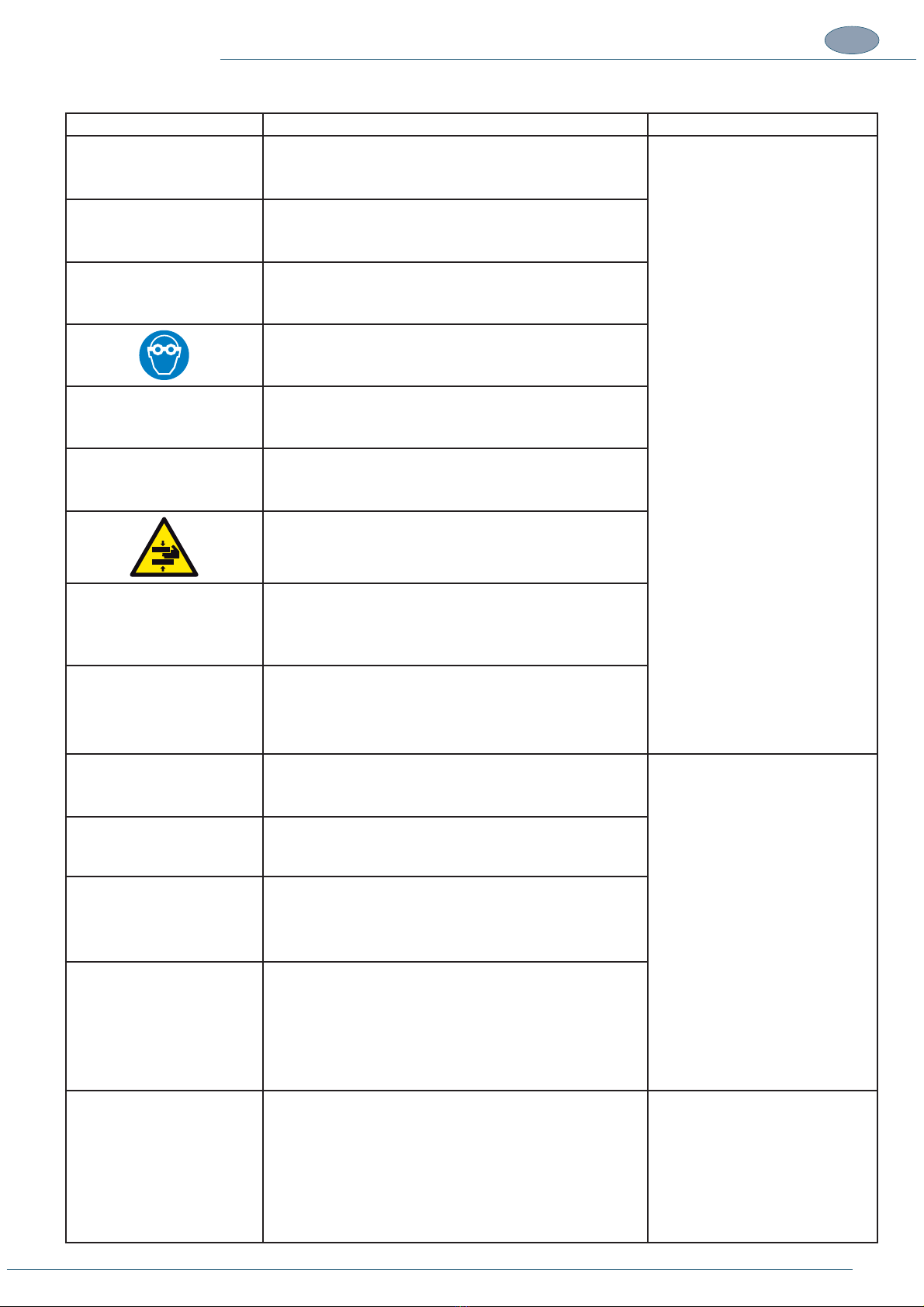

DECAL DESCRIPTION LOCATION

Wear protective goggles.

Wear protective gloves.

Wear safety footwear

Wear protective safety glasses

Wear a mask to protect the respiratory tract

Consult the instruction manual

Hand crushing hazard.

Cutting hazard

Blades dataplate

Isolate the energy source

Working pressure

Horizontal clamp command pressure adjustment

It is prohibited to perform maintenance operations on moving

parts.

This manual suits for next models

2

Table of contents