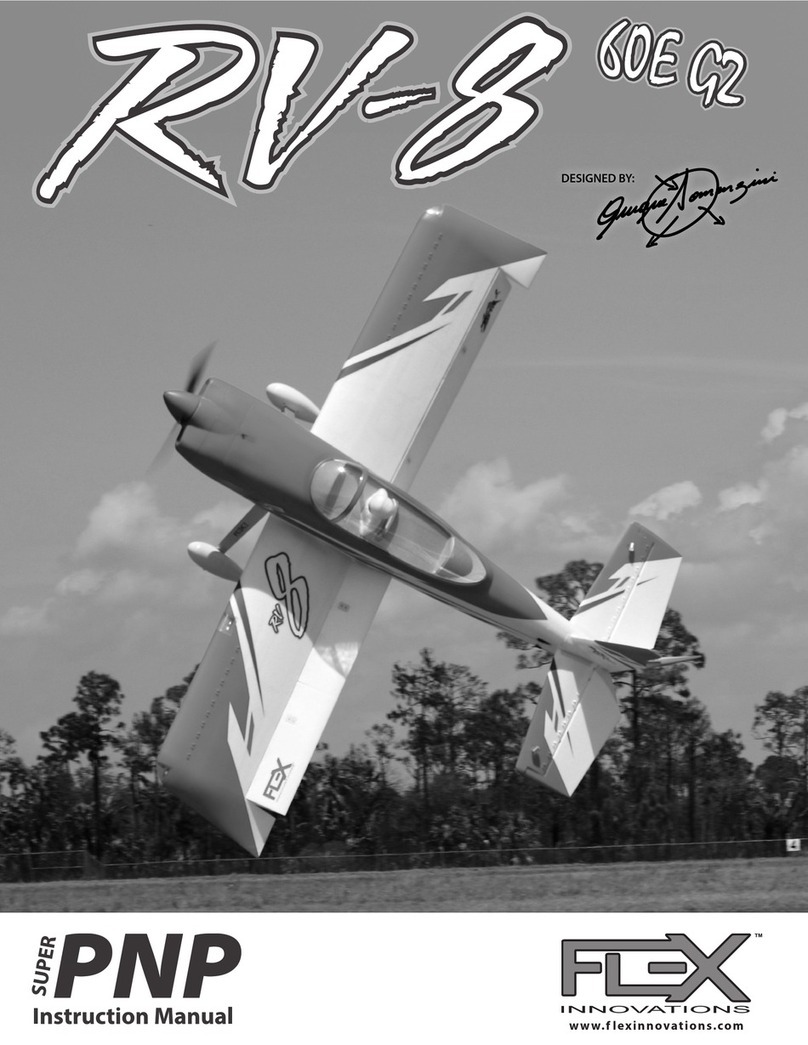

Flex innovations RV-8 60E G2 User manual

Other manuals for RV-8 60E G2

1

Table of contents

Other Flex innovations Toy manuals

Flex innovations

Flex innovations RV-8 10 Super PNP User manual

Flex innovations

Flex innovations MAMBA 120 User manual

Flex innovations

Flex innovations QQ Cap 232EX User manual

Flex innovations

Flex innovations FeatherLite RV-8 70cc FLS User manual

Flex innovations

Flex innovations FV-31 Cypher User manual

Flex innovations

Flex innovations SUPER PNP User manual

Flex innovations

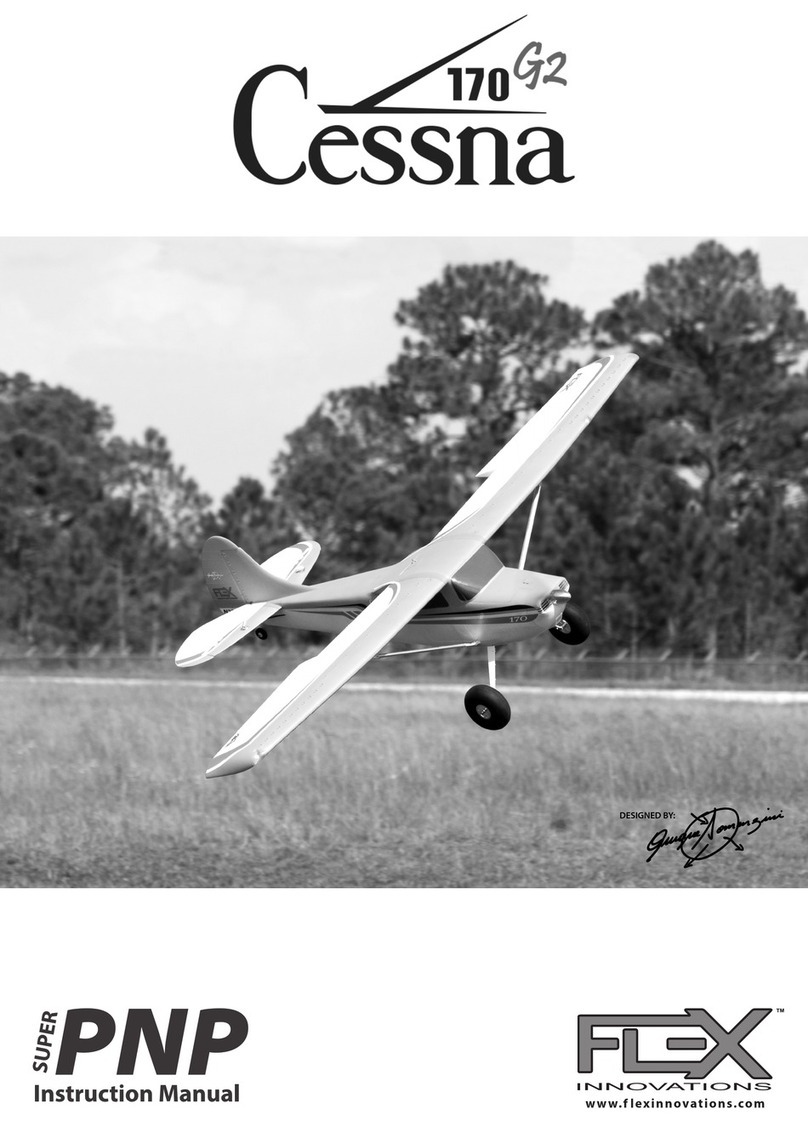

Flex innovations Cessna 170 60E G2 User manual

Flex innovations

Flex innovations MAMBA 10 User manual

Flex innovations

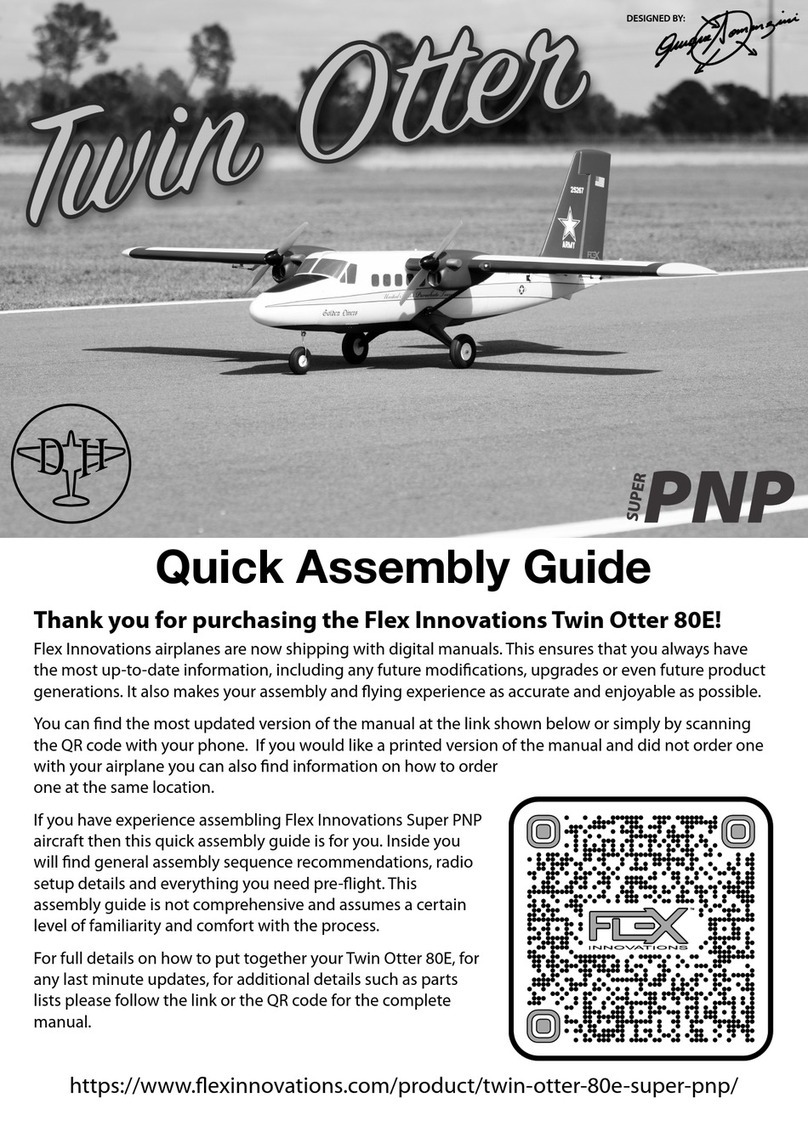

Flex innovations Twin Otter 80E User manual

Flex innovations

Flex innovations FV-31 Cypher Installation and operating instructions

Flex innovations

Flex innovations Super PNP F-100D Super Sabre User manual

Flex innovations

Flex innovations Pirana User manual

Flex innovations

Flex innovations Mamba 60E+ Super PNP User manual

Flex innovations

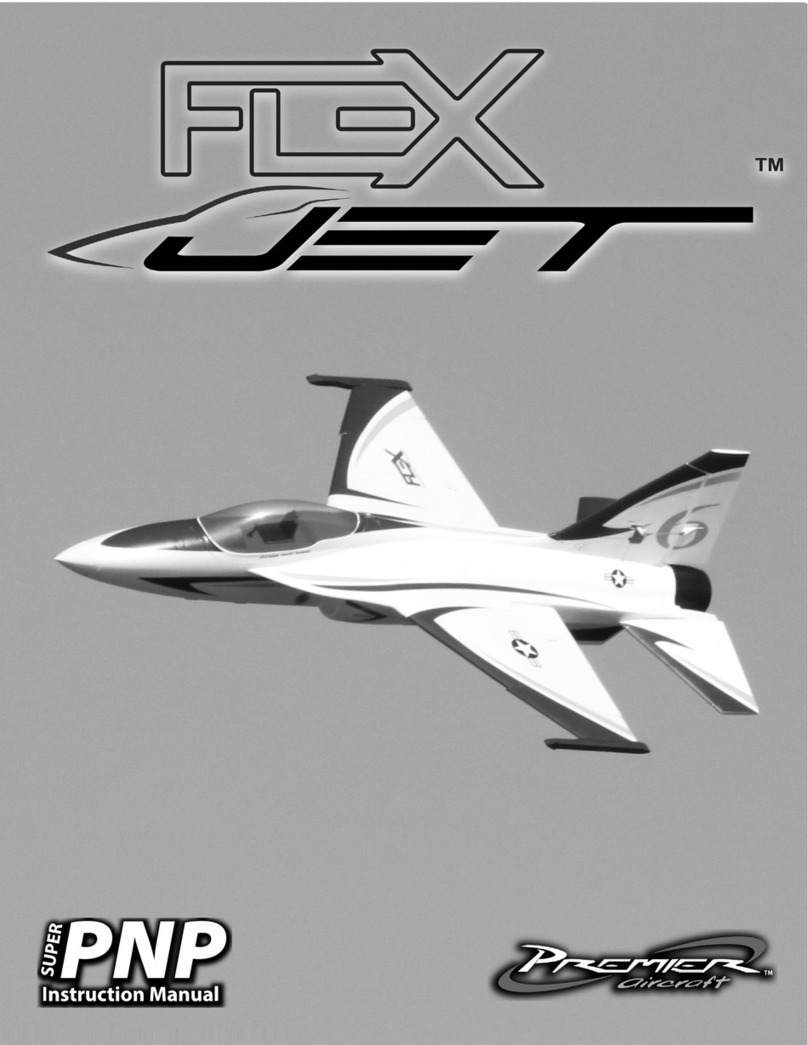

Flex innovations FlexJet Pro 90 mm User manual

Flex innovations

Flex innovations RV-8 60E G2 User manual

Flex innovations

Flex innovations 6S RawPower MAMBA 10 G2 User manual

Popular Toy manuals by other brands

Beyblade

Beyblade Spiral Blitz 2-Pack instructions

Chicco

Chicco Super Rocking Rings 63259 instructions

REVELL

REVELL Albatross D III Assembly manual

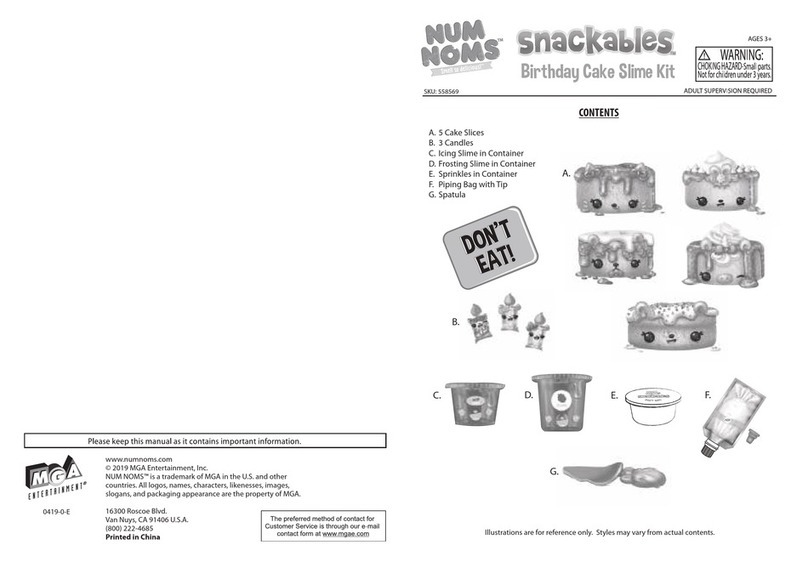

MGA

MGA NUM NOMS Snackables Birthday Cake Slime Kit quick guide

American Flyer

American Flyer GP 7/9 owner's manual

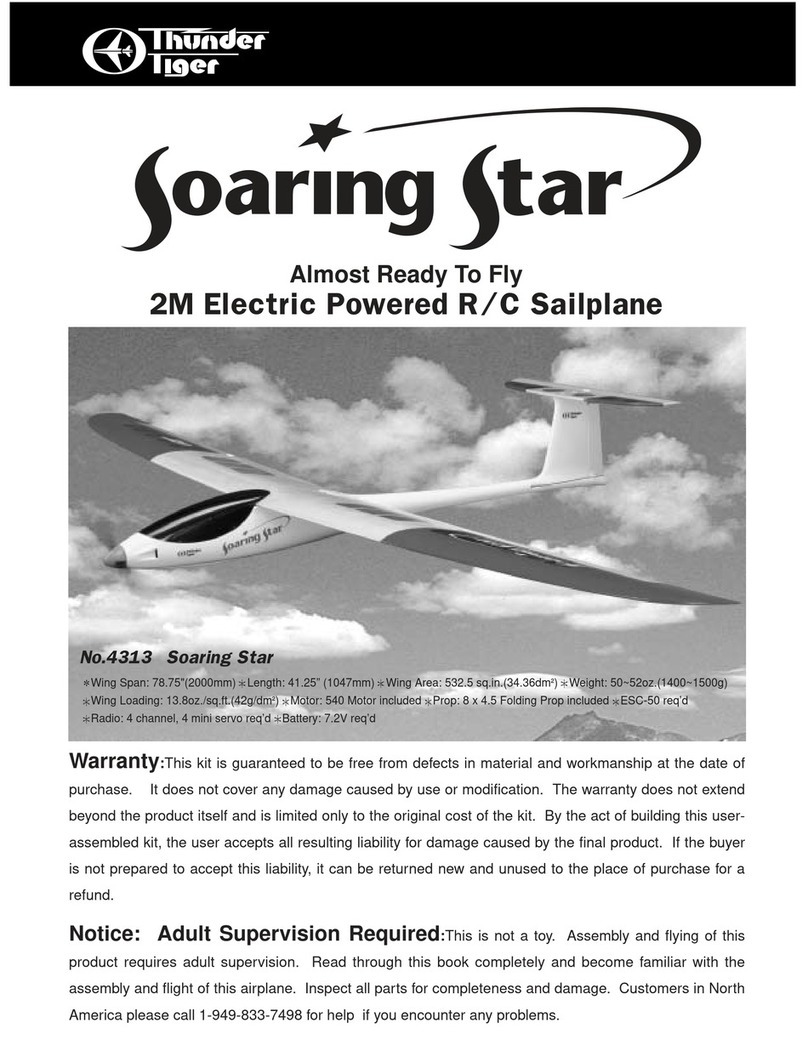

THUNDER TIGER

THUNDER TIGER Soaring Star Assembly instruction