FlexArm B-19 User manual

1

I N S T A L L A T I O N & O P E R A T I ON S

MA N U A L

F l e x A r m

B - 1 9

Distributed by Ergonomic Partners

www.ErgonomicPartners.com

Tel: (314) 884-8884

Book Part No 360740

12/2014

REV.000

2

Table of Contents:

TOPIC: Page:

3

Safe Operation: READ THIS FIRST

Warranty

4

Specifications

4

Installation

5-7

Operating Instructions

8

Parts Diagram

9-10

Plumbing Diagram and Air System Parts

11

Range of Motion

12

REV.000

3

SAFE OPERATION: READ THIS FIRST

READ THE ENTIRE UNIT MANUAL BEFORE OPERATING

WEAR EYE PROTECTION WHEN OPERATING THIS EQUIPMENT

DO NOT WEAR JEWELRY OR LOOSE CLOTHING WHEN OPERATING

TIE HAIR BACK BEFORE USING MACHINE

DO NOT WEAR GLOVES WHEN OPERATING THIS EQUIPMENT

DO NOT USE DAMAGED, FRAYED OR DETERIORATED AIR HOSES

OR FITTINGS

KEEP HANDS CLEAR OF PINCH POINTS ON THE UNIT WHEN

OPERATING

PERIODICALLY INSPECT FOR DAMAGE, LOOSE HARDWARE OR

ANYTHING IRREGULAR

READ THE FLEXARM WARRANTY PAGE BEFORE PERFORMING

ANY MAINTENANCE OR REPAIRS

DISCONNECT THE AIR SUPPLY AND REMOVE ANY WEIGHT

FROM THE ARM BEFORE MAKING ANY ADJUSTMENTS TO THE

ARM OR PERFORMING ANY MAINTENANCE

DO NOT ALTER OR MODIFY THE FLEXARM

IT IS IMPERATIVE THAT THE TABLE OR MOUNTING SURFACE

BE LAGGED TO THE FLOOR AND SECURE BEFORE

INSTALLING THE FLEXARM B-19.

Failure to secure the table or mount surface could result in serious

injury to the operator as well as the FlexArm.

FlexArm is not responsible for accident or injury resulting from the

misuse of this unit or for use other than originally designed and

intended.

The B-19 arm has torque and tool restrictions. See page 4 of

this manual for these restrictions.

Please contact FlexArm with any questions or concerns about

the installation of the FlexArm B-19 assembly arm at

800-837-2503.

REV.000

4

FlexArm

Limited Warranty

A new FlexArm has a 3-year limited warranty on parts and labor. This warranty

does not apply to a FlexArm determined to have been misused or abused,

improperly maintained, or having defects attributed to the use of non-genuine

repair parts.

Air cylinders have a one-year limited warranty from the date of purchase. When

replacing a cylinder, make sure not to scratch, mar, or nick the shaft or tube on

either the old cylinder being replaced or the new cylinder being installed. All

warranty cylinders must be returned to FlexArm for evaluation. The warranty is

void if the cylinder to be evaluated shows signs of scratches or nicks on the

cylinder shaft or tube. Damaged cylinders cannot be returned to the manufacturer

for warranty claims.

This warranty is void if it has been determined that the FlexArm was misused,

abused or improperly maintained.

FlexArm is not responsible for a customer’s air quality. The unit is supplied with

an auto-drain air filter but the responsibility for clean, dry air falls upon the

individual shop.

Once the original warranty expires, Arms carry a limited 60-day warranty

from the date of the repair.

For technical assistance or questions concerning the proper care and maintenance

of the FlexArm unit, please contact FlexArm at 800-837-2503.

Rev. 7/01/14

TORQUE AND WEIGHT LIMITATIONS

Model

Number

Max Motor Torque

Working Range

Max Tool Weight

Ft Lbs

Nm

Inches

Cm

Lbs

Kg

B-19

100

137

1-42

3-107

35

15.9

***Exceeding the weight and torque limitations will void the factory warranty***

REV.000

5

0.406

4 PLACES

EQUALLY

SPACED

4.50

BOLT CIRCLE

5.50

BASE MOUNT

3/8" DIAMETER

MOUNTING BOLTS

(4 REQUIRED)

FLAT MOUNTING SURFACE

ANGLE MOUNT BOLT

WASHER

ANGLE MOUNT

INSTALLATION

1)Drill and tap (4) 3/8" bolt holes on a flat, smooth table or work bench.

(see Base Mount diagram below)

Base Mount pattern

2 ) Secure the Base Mount to the worktable. Slide the Angle Mount onto the shaf t of

the Base Mount and secure the angle wi th the washer & cap screw

before inserting

the FlexArm!

The angle mount may not slide easily through both bearing sets , so

make sure the angle is straight up and down and tap lightly with a rubber mallet if

necessary.

(se e A ngle M ount as semb ly dia gr am bel ow )

REV.000

6

INSTALLATION

3)Insert the rear pin into the upper bore and bearing of the an gle mount. The rear

pin may not slide easily through both be aring sets . Use the cap sc rew to help pull

the unit completely through the bottom be aring.

It may require two people to support t he arm and gui de the rear pin into the

bearing sets.

4) Ins tall the levers at either end or the angle. These are for adjusting the

amount of force needed to move the angle and rear pin.

Tighteni ng the lever wi ll increase the force needed to move the joint and

loos ening the lever will decr ease the amount of for ce needed.

5) Check all airline connections to ensure that no hoses have come loose from the

press-to-release fittings. Hoses m ust be complete ly pushed into the fitti ngs to

lock unde r pressure. Check the connec tion by gently pulling on the hose.

6) Ins tall a ¼”NPT fi tting into the left (input) port of the filter assembly. It is

recomme nded that a 3/8"ID incoming air line be used to get maximum air flow. The

pneumati c system on the FlexArm will require a minimum of 90 -120 psi input to

perform the maximum balancing operations.

7) The air filter is equipped with an auto drain and will autom atically remove

moisture from the bowl.

REV.000

7

INSTALLATION WITH PEDESTAL MOUNT

1) Secure the pedestal to the floor with (8) 1/2" dia meter wedge anchor bolts drilled

a minimum of 3-3/4" into the concrete.

2) Secure the base of the unit to the pedestal with (4) 3/8" bolts .

REV.000

8

OPERATING INSTRUCTIONS

1) Mount tool in the V -block assembly on the e nd of the B -19 assembly arm.

2) Chec k the air regul ator on the rear pin of the B -19. Make sure the knob is

turned comple tely counter -clockwise. Do not remove the knob. Ensure it is

tu rned a s f ar c ou nter -cl oc kwi se as p ossi ble wi thout r emov ing i t. F AILU RE TO

DO SO COULD RESULT IN INJURY IF AIR IS CONNECTED PRIOR TO THIS STEP!

3) Connect air supply to the air filter on the rear pin of the B -19 arm.

(A ir su pply sh ould be at 90 - 12 0 ps i.)

4) Adjust air regulator clockw ise until arm counterbalances the weight of the tool .

5) Always wear safety glasses and use proper safety precautions when

operating this unit.

IT IS IMPERATIVE THAT THE TABLE OR MOUNTING SURFACE BE LAGGED TO THE

FLOOR AND SECURE BEFORE USING THE FLEXARM B-19.

FlexArm is not responsible for accident or injury resulting from the misuse of

this machine or for use other than originally designed and intended.

REV.000

9

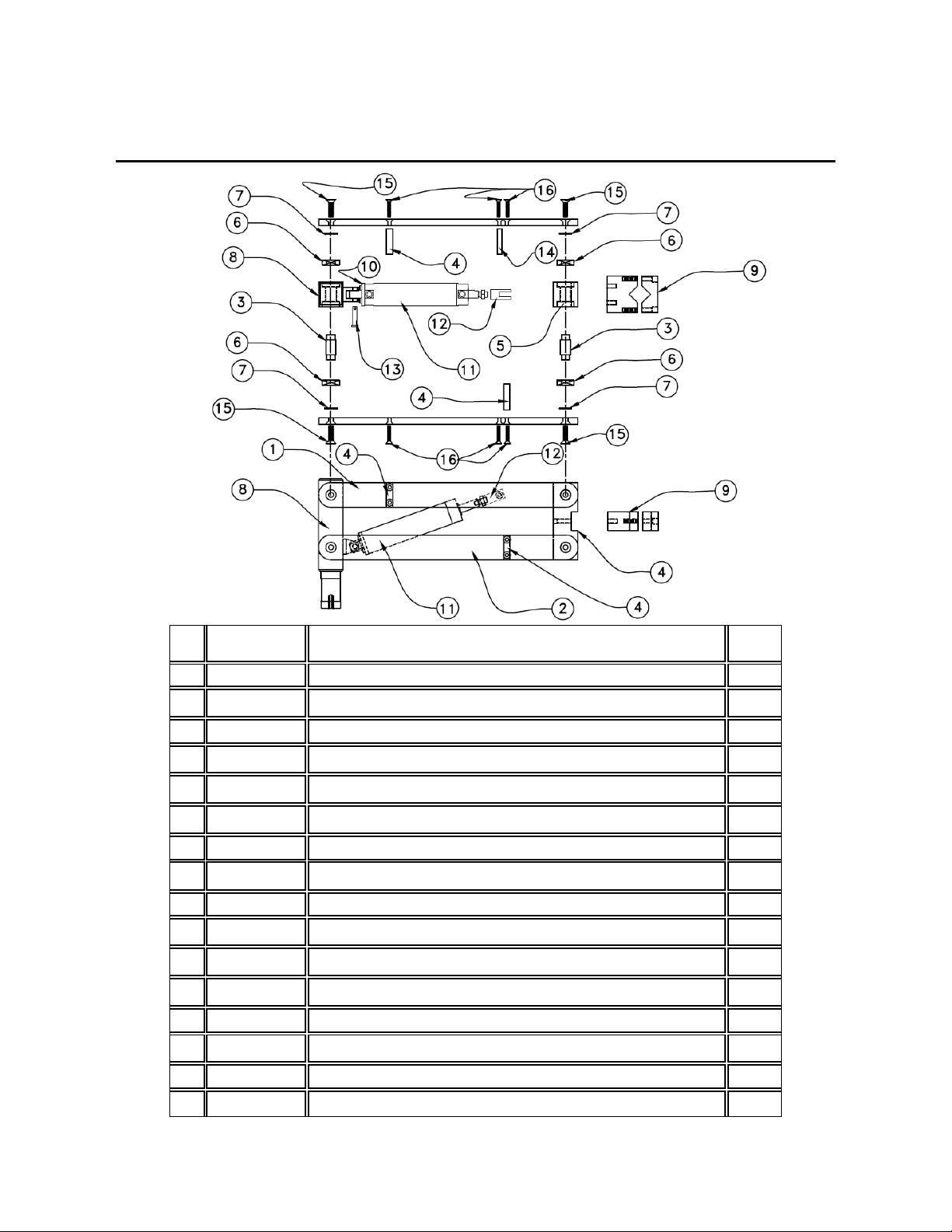

B-19 PARTS DIAGRAM: LOWER ASSEMBLY

Item

No

:

Part No:

Description:

QTY

Used

1

360701

BASE

1

2

360703

LOWER ANGLE ASSEMBLY

1

3

360706

UPPER ANGLE ASSEMBLY

1

4

360716

BEARING

4

5

360717

SPACER

2

6

360702

ANGLE WASHER

2

7

360315

LEVER

2

8

360707

REAR PIN ASSEMBLY

1

9

0375M

SOCKET HEAD CAP SCREW 3/8-16x1

2

10

360737

HEX HEAD BOLT 1/2-13x1-1/4 GRADE 5

2

11

360738

HEX NUT 1/2-13

2

REV.000

10

B-19 PARTS DIAGRAM: UPPER ASSEMBLY

Item

No

:

Part No:

Description:

QTY

Used

1

360710

ARM UPPER

2

2

360711

ARM LOWER

2

3

360712

ARM PIN

4

4

360713

ARM SPACER BLOCK

2

5

360714

FRONT BLOCK

1

6

360715

ARM BEARING

8

7

360719

ARM SHIM

8

8

360707

REAR PIN ASSEMBLY

1

9

360739

V—BLOCK ASSEMBLY

1

10

360722

AIR CYLINDER SINGLE MOUNTING CLEVIS

1

11

360723

AIR CYLINDER

1

12

360724

DOUBLE ROD CLEVIS

1

13

360728

PIN CYLINDER BASE

1

14

360729

PIN CYLINDER ROD

1

15

360720

SOCKET DRIVE FLAT HEAD SCREW 3/8-16x1-1/4

8

16

360721

SOCKET DRIVE FLAT HEAD SCREW 1/4-20x1-1/4

10

REV.000

11

360727 PRESSURE GAUGE

360062 FILTER

PLUMBING DIAGRAM AND

AIR SYSTEM PARTS

MUFFLER

REV.000

REV.000

Distributed by Ergonomic Partners

www.ErgonomicPartners.com

Tel: (314) 884-8884

12

FLEXARM B-19: RANGE OF MOTION

Table of contents

Popular Power Tools Accessories manuals by other brands

Clarke

Clarke CAT150 FITTING & MAINTENANCE

Dremel

Dremel 1453 Original instructions

Multitool

Multitool MT482 installation instructions

Hilti

Hilti TE DRS-4-A operating instructions

Scheppach

Scheppach 55 Translation from the original instruction manual

Wolfcraft

Wolfcraft 3001000 Translation of the original operating instructions

Cembre

Cembre CS-SD Operation and maintenance manual

DeWalt

DeWalt D512382 Assembly instructions

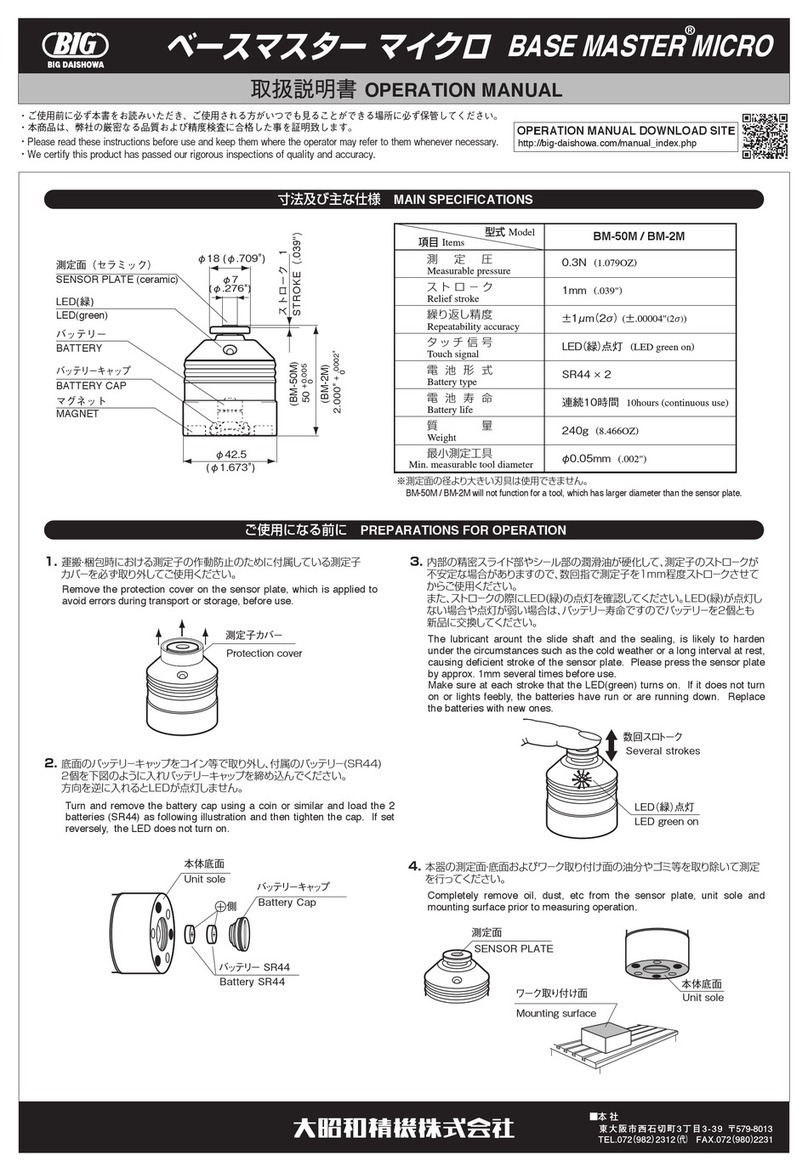

Big Daishowa

Big Daishowa BASE MASTER MICRO Operation manual

Stihl

Stihl DuroCut 20-2 manual

Sherline Products

Sherline Products 1074 quick start guide

Baileigh Industrial

Baileigh Industrial DDT-3519 Operator's manual