1

SAFETY INSTRUCTIONS

1. ALWAYS WEAR EYE PROTECTION. A full-face visor is preferred. Any Belt/Disc Grinder can throw

foreign objects into the eyes.

2. AVOID CONTACT WITH BELT OR DISC. The abrasive belt when running is an aggressive cung tool.

Extra care should be exercised when using coarse grit belts because of their rapid cung acon.

3. KEEP CHILDREN AWAY. All visitors should be kept a safe distance from the work area.

4. BOLT THE BENCH GRINDER securely to the bench or supporng surface to stop it from pping over

or moving when in use.

5. DO NOT MOUNT the aachment protruding into walkways.

6. KEEP WORK AREA CLEAN. Cluered areas and benches invite accidents.

7. ALWAYS WEAR A DUST MASK to prevent dust inhalaon when adequate venlaon or extracon is

not available.

8. DO NOT WEAR LOOSE CLOTHING which may become entangled in the machine. Wear protecve

hair covering to contain long hair.

9. ALWAYS HOLD the work piece rmly when grinding and apply a light and steady pressure against

abrasive disc or belt.

10. ALWAYS GRIND ON THE DOWNWARD SIDE of the grinding disc. Grinding on the upward side of

the disc could cause the work piece to y out of posion, resulng in injury.

11. DO NOT USE BELTS THAT ARE DAMAGED, TORN, OR SHOW SIGNS OF WEAR.

12. ALWAYS INSTALL BELTS with arrows in the back of the belts poinng the correct direcon. Belts

with lap joints must be ed facing the correct direcon.

WARNING:

To avoid mistakes that could cause injury, do not use the Multool unl you have

read and understood the following:

The words “us”, “we” or “our” refers to Multool Grinders or

their authorized agent.

A.) The warranty will only apply if the ng and operang

instrucons are followed.

B.) The warranty will only apply for a period of 1 year from the

date of original purchase against any defect in our product,

which can be proved, to our sasfacon to have been caused

by faulty materials or workmanship. Our liability is limited

to the cost of repairing or at our opon, replacement of the

defecve goods or parts of the goods. We will not be liable for

any defect caused by unauthorized repair.

1. If warranty claim is made, we must be noed as soon as

possible aer assumed defect has become apparent.

2. Goods may only be returned with the approval and RGA # from

Multool Grinders. Contact Multool Grinders at 641-628-4253

or email us at sales@multoolgrinders.com to obtain RGA# and

return approval.

3. The customer must prepay all freight charges for returned goods.

4. We will contact the customer with a suggeson aer inspecng

the goods to determine with the customer what acon should be

taken in the circumstances.

INSTRUCTIONS TO FOLLOW FOR WARRANTY CLAIMS:

WARRANTY AND CONDITIONS OF SALE

For parts, tech support, belts, or discs contact Multool Grinders at 641-628-4253 or sales@multoolgrinders.com

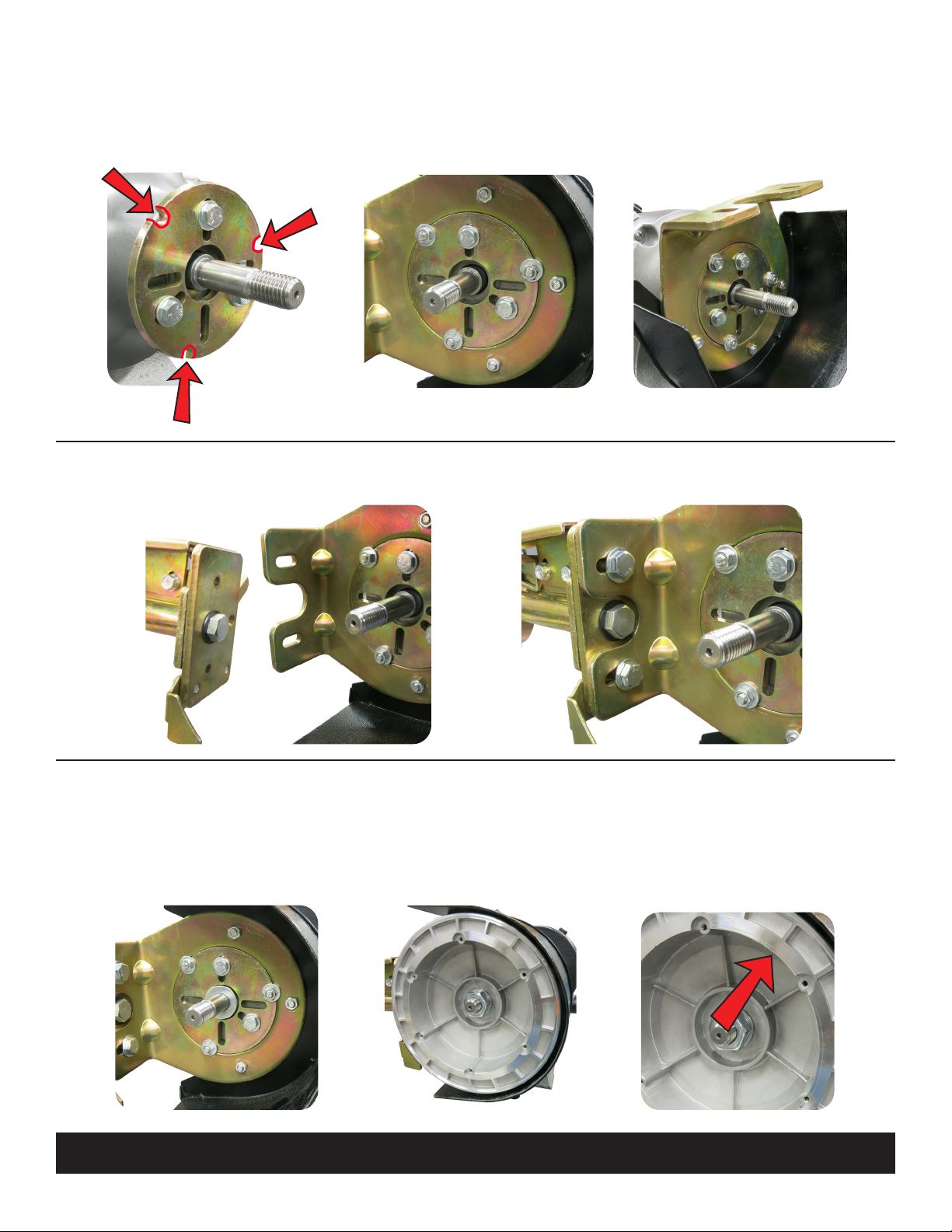

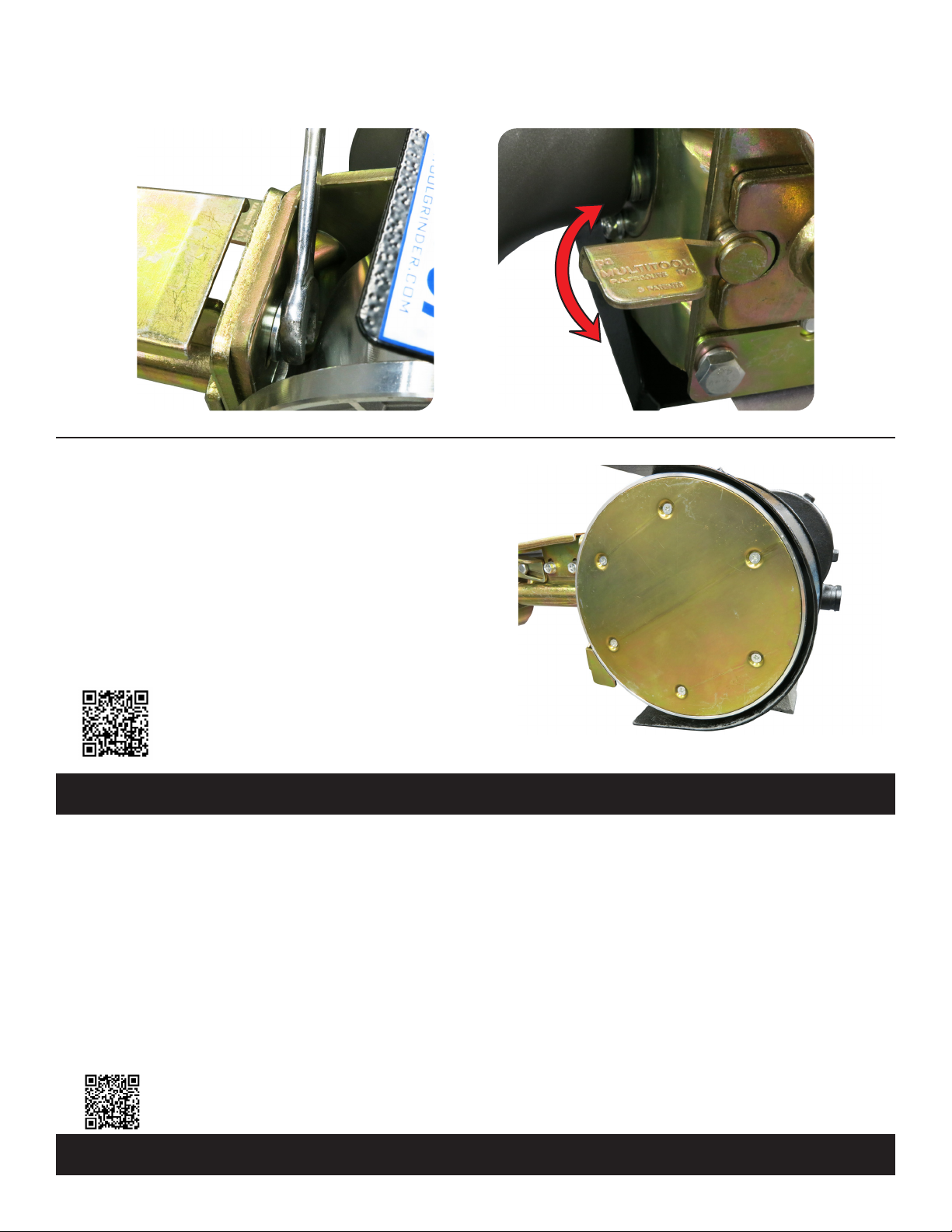

Installaon Instrucons for Belt Grinder Aachment

Models MT362, MT364, MT482 and MT484

USER IS RESPONSIBLE TO HAVE WORKING KNOWLEDGE OF BELT GRINDER

USAGE. MULTITOOL GRINDERS IS NOT RESPONSIBLE FOR ANY DAMAGES OR

INJURIES INCURRED WHILE USING THE MULTITOOL PRODUCT LINE.

!