Flexco RBP1 Technical Document

RBP1 Belt Positioner

Installation, Operation

and Maintenance Manual

www.flexco.com

www.flexco.com

2RBP1 Belt Positioner

RBP1 Belt Positioner

Serial Number: _____________________________________________________________

Purchase Date:______________________________________________________________

Purchased From: ____________________________________________________________

Installation Date: ____________________________________________________________

Serial number information can be found on the Serial Number Label

included in the Information Packet found in the cleaner carton.

is information will be helpful for any future inquiries or questions

about belt cleaner replacement parts, specications or troubleshooting.

1

Section 1 - Important Information ...................................................................................................2

1.1 General Introduction...........................................................................................................................2

1.2 User Benets .........................................................................................................................................2

1.3 Proper Belt Trainer Selection..............................................................................................................3

Section 2 - Safety Considerations and Precautions ..........................................................................4

2.1 Stationary Conveyors...........................................................................................................................4

2.2 Operating Conveyors...........................................................................................................................4

Section 3 - Pre-Installation Checks and Options..............................................................................5

3.1 Checklist................................................................................................................................................5

3.2 Optional Installation Accessories.......................................................................................................5

Section 4 - Installation Instructions..................................................................................................6

Section 5 - Pre-Operation Checklist and Testing..............................................................................8

5.1 Pre-Op Checklist..................................................................................................................................8

5.2 Test Run the Conveyor ........................................................................................................................8

Section 6 - Maintenance.....................................................................................................................9

6.1 New Installation Inspection................................................................................................................9

6.2 Routine Visual Inspection...................................................................................................................9

6.3 Routine Physical Inspection ...............................................................................................................9

6.4 Roller Replacement Instructions......................................................................................................10

6.5 Maintenance Log................................................................................................................................11

6.6 Maintenance Checklist ......................................................................................................................12

Section 7 - Troubleshooting ............................................................................................................13

Section 8 - Specs and CAD Drawings..............................................................................................14

8.1 Specs and Guidelines .........................................................................................................................14

8.2 CAD Drawing, RBP1 Small ..............................................................................................................15

8.3 CAD Drawing, RBP1 Medium.........................................................................................................16

8.4 CAD Drawing, RBP1 Large ..............................................................................................................17

8.5 CAD Drawing, RBP1 Extra Large....................................................................................................18

Section 9 - Replacement Parts .........................................................................................................19

9.1 Replacement Parts List ......................................................................................................................19

Section 10 - Other Flexco Conveyor Products ................................................................................21

Table of Contents

2RBP1 Belt Positioner

Section 1 - Important Information

1.1 General Introduction

We at Flexco are very pleased that you have selected a RBP1 Belt Positioner™ for your conveyor system.

is manual will help you to understand the installation, operation and maintenance of this product and

assist you in making it work up to its maximum eciency over its lifetime of service.

It is essential for safe and ecient operation that the information and guidelines presented be properly

understood and implemented. is manual will provide safety precautions, installation instructions,

maintenance procedures and troubleshooting tips. In addition, please follow all standard, approved safety

guidelines when working on your conveyor.

If, however, you have any questions or problems that are not covered, please visit our web site or contact our

Customer Service Department:

Customer Service: 1-800-541-8028

Visit www.exco.com for other Flexco locations and products.

Please read this manual thoroughly and pass it on to any others who will be directly responsible for

installation, operation and maintenance of this impact bed. While we have tried to make the installation and

service tasks as easy and simple as possible, this product does however require correct installation and

regular inspection and maintenance to maintain top working condition.

1.2 User Benets

Belt mistracking is a common problem that produces various problems, ranging from belt and structure

damage to product spillage and safety issues. By utilizing the RBP1 Belt Positioner, it is possible to correct a

belt that is mistracking and causing these problems. Multiple units may be required depending on the length

of the mistracking belt.

3

Section 1 - Important Information

1.3 Proper Belt Trainer Selection

Belt Positioner™

PT Max™

Top Side

PT Max™

Return Side

PT Pro™

PTEZ™

PT Smart™

Standard

MODEL APPLICATION RANGE

Belt Positioner™

Return side only, 800 PIW max tension on Small,

Medium and Large; 1200 PIW max tension on

Extra Large. Also works on reversing belts.

PTEZ™Medium-duty belts up to 1600 PIW max tension.

Also works on reversing belts.

PT Smart™

Medium-duty belts up to 1600 PIW max tension.

Belt width + 3" (75mm) idler. Belt thickness 1"

(25mm) maximum.

PT Smart™Underground

Medium-duty belts up to 1600 PIW max tension.

Belt width + 9" (225mm) idler. Belt thickness 1"

(25mm) maximum. Fits underground structure.

PT Pro™

Medium-duty belts 150 PIW min to 1600 PIW max

tension. Belt width 18” - 72” (450 - 1800mm). Also

works on reversing belts.

HD PT Pro™

Heavy-duty belts 300 PIW min to 2400 PIW max

tension. Belt width 48" - 96" (1200 - 2400mm). Also

works on reversing belts.

PT Max™

Heavy-duty belts up to 3000 PIW max

Generally 3/4" to 1" thick (19mm to 25mm)

Belt width 24" - 60" (600 - 1500mm)

HD PT Max™Heavy-duty belts up to 6000 PIW max tension.

Belt width 54" - 84" (1350 - 2100mm)

PT Smart™

Underground

Structure

Conveyor Criteria Belt

Positioner™PTEZ™PT Smart™PT Pro™

Heavy

Duty PT

Pro™

PT Max™

Heavy

Duty PT

Max™

Super

Duty PT

Max™

Top side mistracking No No No No No Yes Yes Yes

Return side mistracking Yes Yes Yes Yes Yes Yes Yes Yes

Reversing Yes Yes No Yes Yes No No No

Belt mistracking to one side Better Better Better Better Better Better Better Better

Belt mistracking to both sides Acceptable Better Best Better Better Best Best Best

Inconsistent tracking problem Good Better Best Better Better Best Best Best

Belt is cupped (heavy) Best ‡ Better ‡ Better Better Better Better Better Better

Belt has edge damage Best Best Good Best Best Good Good Good

Ease of Installation Best Better Good Good Good Good Good Good

Belt has low running tension (150-300 PIW) Good Good Good Good N/A Good N/A N/A

Belt has medium running tension (300-1600 PIW) Better Better Better Better Better Best Best Best

Belt has high running tension (1600+ PIW) N/A N/A N/A N/A Best Better Best Best

Approx. "upstream" effect *∆ 50’ (15 M) 20' (6 M) 20’ (6 M) 20’ (6 M) 20’ (6 M) 50’ (15 M) 50’ (15 M) 50’ (15 M)

Approx. "downstream" effect *∆ 50’ (15 M) 100' – 120'

(30 – 36 M)

120’ – 150’

(36 – 45 M)

100’ – 120’

(30 – 36 M)

100’ – 120’

(30 – 36 M)

150’ – 200’

(45 – 61 M)

150’ – 200’

(45 – 61 M)

150’ – 200’

(45 – 61 M)

‡ Installed on the clean side of the return belt

* Typical results; actual results may vary

∆ Disc idlers have the potential to reduce these numbers

4RBP1 Belt Positioner

Section 2 - Safety Considerations and Precautions

Before installing and operating the RBP1 Belt Positioner it is important to review and understand the following safety

information.

ere are setup, maintenance and operational activities involving both stationary and operating conveyors. Each case

has a safety protocol.

2.1 Stationary Conveyors

e following activities are performed on stationary conveyors:

• Installation • Impact bar replacement • Repairs

• Skirt rubber adjustments • Cleaning

DANGER

DANGER

WARNING

WARNING

WARNING

!

!

!

!

!

It is imperative that OSHA/MSHA Lockout/Tagout

(LOTO) regulations, 29 CFR 1910.147, be followed before

undertaking the preceding activities. Failure to use LOTO

exposes workers to uncontrolled behavior of the impact

bed caused by movement of the conveyor belt. Severe

injury or death can result.

Before working:

• Lockout/Tagout the conveyor power source

• Disengage any takeups

• Clear the conveyor belt or clamp securely

in place

Use Personal Protective Equipment (PPE):

• Safety eyewear

• Hardhats

• Safety footwear

Close quarters and heavy components create a

worksite that compromises a worker’s eyes, feet

and skull.

PPE must be worn to control the foreseeable

hazards associated with conveyor belt

components. Serious injuries can be avoided.

2.2 Operating Conveyors

ere are two routine tasks that must be performed while the conveyor is running:

• Inspection of the sealing performance

• Dynamic troubleshooting

Every belt conveyor is an in-running nip hazard.

Never touch or prod an operating impact bed.

Conveyor hazards cause instantaneous amputation

and entrapment.

Never adjust anything on an operating impact

bed. Unforseeable materials falling into the chute

can cause violent movements of the impact bed

structure. Flailing hardware can cause serious

injury or death.

Conveyor chutes contain projectile hazards. Stay as far

from the trainer as practical and use safety eyewear and

headgear. Missiles can inict serious injury.

5

3.1 Checklist

•Check the model and size of the belt trainer. Is it the right one for your beltline?

• Check the RBP1 Belt Positioner to be sure all the parts are included in the shipment.

• Find the Information Packet in the shipment.

• Review the “Tools Needed” section on the front of the installation instructions.

• Prepare the conveyor site:

- Identify the point(s) of mistracking, expecting 50' (15M) of downstream and upstream inuence.

- Position the unit in the center of the mistracking.

- Optimal location: No closer than 3' (.9M) and no further than 6' (1.8M) from a return roller.

- Remove old tracking devices.

Section 3 - Pre-installation Checks and Options

3.2 Optional Installation Accessories

Flex-Lier™ Conveyor Belt Lier

e Flexco Flex-Lier makes the job of liing the

conveyor belt easy and safe. Using two Flex-Liers,

the belt can be quickly lied out of the way to install

the PT Smart™. e Flex-Lier has the highest safe li

rating available at 4000 lbs. (1810 kg) for Medium and

Large, 6000 lbs. (2750 kg) for XL. And it’s versatile.

It can also be used to li topside or return side belt

for splicing, roller replacement or other maintenance

jobs. Available in three sizes: Medium for belt widths

36" - 60" (900 - 1500mm), Large for belt widths 48" -

72" (1200 - 1800mm), and XL for belt widths 72" - 96"

(1800 - 2400mm).

Flex-Lifter™ Conveyor Belt Lifter

Description

Ordering

Number

Item

Code

Medium Flex-Lifter 36" - 60" (900 - 1500 mm) FL-M 76469

Large Flex-Lifter 48" - 72" (1200 - 1800 mm) FL-L 76470

XL Flex-Lifter 72" - 96" (1800 - 2400 mm) FL-XL 76983

Optional tools can make the installation of the RBP1 Belt Positioner easier and faster.

6RBP1 Belt Positioner

Section 4 - Installation Instructions

Physically lock out and tag the conveyor at the power source

before you begin cleaner installation.

Locating the Positioner

ABC

• Look at the belt on the return side and identify where the belt is mistracking.

• Locate the Positioner in the center of the problem area.

• Generally, if the belt is correctly positioned at the tail pulley (A) so the belt is

center loaded, it will run straight on the top side.

• Another problem area may be at the counter-weight pulley (B and C).

Tail

Pulley

RBP1 Parts List

Rollers

(Rubber-Lagged or Steel)

Set Screws

& Jam Nuts

Mounting Bolts,

Lock Washers

& Nuts

Mounting

Bracket

Inner

Tubes

Frame Adjustment Bolts,

(2) Nuts & Lock Washers

Roller

Retainer

Frame

1. Reposition mounting brackets (Fig. 1). Remove the

mounting brackets from the inner shipping position,

move them down toward the rollers, and remount them

on the outside of the frames. Remove the mounting

bolts, lock washers and nuts from the brackets and set

them aside for Step 4.

Move down

Remove for

later use

Shipping position

Fig. 1

Fig. 2 2. Determine Positioner location on the belt (in the

selected location). Measure an equal distance from a

common point on both sides of the structure and mark

both sides at the measured points (Fig. 2). e unit must

be square to the conveyor.

NOTE: e Positioner should be centered between

two standard return rollers. For general applications--

standard belts up to 72" (1800mm): position the unit no

closer than 3' (.9M) to a return roller and no farther than

6' (1.8M).

4.1 RBP1 Belt Positioner

Tools Needed:

- Tape measure

- (2) 5/8" (16 mm) wrench or crescent wrench

- (2) 1/2" (13 mm) wrench or crescent wrench

7

Section 4 - Installation Instructions

3. Adjust unit for conveyor width.

a. Measure the structure’s inside width from side to side.

b. Loosen the four jam nuts and set screws on the frames

and slide the unit apart to the same dimension as the inside

structure width measurement minus 1/2" (13mm) to ensure

an easy t. Retighten set screws and jam nuts (Fig. 3).

NOTE: e inner tubes between the two frames should be

kept centered to ensure both sides have maximum support.

Center marks on the inner tubes make it easy to see that

the tubes are centered.

4. Mount unit on the conveyor.

Align the unit with the location marks on the structure.

NOTE: Check the slot adjustment range of the frame and

the mounting bracket (Fig. 4). If there is not 4" to 6" of slot

visible, turn the mounting brackets upside down for more slot

adjustment. Clamp or hold the unit in place, drill mounting

bolt holes on each side and secure with mounting bolts, lock

washers and nuts, or weld in place.

5. Adjust Positioner to the belt.

Loosen the two frame adjustment bolts on the side the belt is

running o and apply pressures as follows (Fig. 5):

a. Push down on unit until roller contacts 6" to 8" (150 to

200mm) of the belt. e roller on the other side should be set

to contact the belt 4" (100mm) or less. Tighten all nuts.

b. Allow the conveyor to run a minimum of ve revolutions

and evaluate the results.

IMPORTANT: If more correction is needed, increase the

roller-to-belt contact pressure on the side running o; if

necessary, decrease contact pressure on the opposite side.

Fig. 3

Fig. 5 FRAME ADJUSTMENT

BOLTS

(on inside of bracket)

Loosen for Adjustment

MAINTENANCE

e rollers on the Positioner are sealed for life.

Center Mark

SET SCREWS

(2 on opposite side)

Fig. 4

Not enough adjustment

range in slot

Increased range of

slot adjustment

MOUNTING

BRACKET

(upside-down)

MOUNTING

BRACKET

(standard)

FRAME

FRAME

Structure

4.1 RBP1 Belt Positioner

8RBP1 Belt Positioner

Section 5 - Pre-Operation Checklist and Testing

• Run the conveyor for at least 15 minutes and conrm the belt is tracking properly.

• If belt is still mistracking too far to one side, increase the roller-to-belt contact pressure on the side

running o; if necessary, decrease contact pressure on the opposite side.

• Recheck that all fasteners are tight

• Apply all supplied labels

• Be sure that all installation materials and tools have been removed from the belt and conveyor area

5.1 Pre-Op Checklist

5.2 Test Run the Conveyor

9

Section 6 - Maintenance

Flexco belt trainers are designed to operate with minimum maintenance. However, to maintain superior performance

some service is required. When the trainer is installed a regular maintenance program should be set up. is program

will ensure that the trainer operates at optimal eciency, and problems can be identied and xed before any damage

is done to the belt, the trainer, other conveyor components, or structure.

All safety procedures for inspection of equipment (stationary or operating) must be observed. e RBP1 Belt

Positioner is in direct contact with the moving belt. Only visual observations can be made while the belt is running.

Service tasks can be done only with the conveyor stopped and by observing the correct lockout/tagout procedures.

6.1 New Installation Inspection

Aer the RBP1 Belt Positioner has run for 15 minutes a visual inspection should be made to ensure the trainer

is performing properly. Make adjustments as needed.

6.2 Routine Visual Inspection (every 2-4 weeks)

A visual inspection of the RBP1 Belt Positioner can determine:

• If the belt is tracking as required

• If the main frame is free of material and rolling properly

• If there is damage to the main frame or other components

• If the rollers are turning freely and without damage

If any of the above conditions exist, a determination should be made on when the conveyor can be

stopped for trainer maintenance.

6.3 Routine Physical Inspection (every 6-8 weeks)

When the conveyor is not in operation and properly locked and tagged out, a physical inspection of the trainer

to perform the following tasks:

• Clean material buildup o the trainer and components.

• Closely inspect main roller for free movement and wear. Replace if needed.

• Closely inspect complete unit for damage.

• Inspect all fasteners for tightness and wear. Tighten or replace if needed.

• When maintenance tasks are completed, test run the conveyor to ensure the trainer is

performing properly.

10 RBP1 Belt Positioner

6.4 Roller Replacement Instructions

Section 6 - Maintenance

2. Remove roller by unbolting (4) Roller Retainers (Fig. 1).

1. Remove tension from belt. Use a Flex-Lier or other appropriate liing equipment to li the belt

approx. 3" (75mm) o the trainer.

3. Install new roller and re-bolt Roller Retainers (Fig. 1). Conrm roller turns smoothly.

4. Lower the belt. Ensure belt completely contacts rollers. Lower brackets if there is not good contact.

Tighten all bolts.

5. Refer to pre-op checklist (page 8) before running the conveyor. If belt is still mistracking, refer to

Section 5.2 on page 8.

CAUTION: Components may be heavy. Use safety-approved liing procedures.

Physically lock out and tag the conveyor at the power source

before you begin cleaner installation.

Tools Needed:

- Tape measure

- 5/16" (8 mm) wrench or crescent wrench

Fig. 1

Roller Retainer

Roller Retainers

Roller Retainer

(hidden)

11

Section 6 - Maintenance

6.5 Maintenance Log

Conveyor Name/No.

Date: Work done by: Service Quote #

Activity:

Date: Work done by: Service Quote #

Activity:

Date: Work done by: Service Quote #

Activity:

Date: Work done by: Service Quote #

Activity:

Date: Work done by: Service Quote #

Activity:

Date: Work done by: Service Quote #

Activity:

Date: Work done by: Service Quote #

Activity:

12 RBP1 Belt Positioner

Section 6 - Maintenance

6.6 Belt Trainer Maintenance Checklist

RBP1 Belt Positioner:

Beltline Information:

Idler Roller Life (Right Side):

Idler Roller Life (Le Side):

RBP1 Frame Condition:

Overall RBP1 Performance:

Other Comments:

Belt Speed Belt ickness

Appearance: Comments:

Location: Comments:

Maintenance: Comments:

Performance: Comments:

(Rate the following 1 - 5; 1=very poor, 5=very good)

Date rollers installed: Date rollers inspected: Estimated roller life:

Date rollers installed: Date rollers inspected: Estimated roller life:

Good Bent Rusted

Roller condition:

Roller condition:

Beltline Number:

Belt Width: 18" 24" 30" 36" 42" 48" 54" 60" 72" 84" 96"

Belt Condition:

Serial Number:

(450mm) (600mm) (750mm) (900mm) (1050mm) (1200mm) (1350mm) (1500mm) (1800mm) (2100mm) (2400mm)

13

Section 7 - Troubleshooting

Problem Possible Cause Possible Solutions

Little to no eect on trouble

area of belt

Unit installed in wrong location Relocate in the center of problem area of belt

Incorrect tension on unit Lower height of unit to provide 1/2" - 1" (13-25mm)

pressure on belt

Unit mis-adjusted Go to step 5 of Installation Instructions

Buildup on main roller Clean unit

Belt not correcting enough Unit mis-adjusted Go to step 5 of Installation Instructions

Belt moving over too much Unit mis-adjusted Go to step 5 of Installation Instructions

Roller not turning

Buildup on main roller Clean unit

Roller bearing bad Replace roller

14 RBP1 Belt Positioner

Section 8 - Specs and CAD Drawings

8.1 Specs and Guidelines

Application Guidelines

• Belt Splice........................................... Mechanically Fastened/Vulcanized

• Belt Speed........................................... 1000 FPM (5M/sec)

• Belt Direction...................................... Reversing

Use next larger size for belt widths between ranges.

• Optimal location: no closer than 3' (.9M) and no

further than 6' (1.8M) from a return roller.

• All rollers are “sealed for life”. No regreasing

maintenance is required.

• MSHA approved.

13 1/2" (343mm) Max

Adjustment Range

Belt Width Specifications

Size

Belt Width

(Min-Max)

Positioner Width

(Min-Max)

in. mm in. mm

Small 18-24 450-600 24-34 600-850

Medium 30-48 750-1200 34-56 850-1400

Large 54-72 1350-1800 56-83 1400-2075

Extra Large 72-96 1800-2400 72-120 1800-3000

Roller Dimensions

Size

Length Diameter

in. mm in. mm

Small 9 225 5 125

Medium 13 325 5 125

Large 19 475 5 125

Extra Large 21 525 6 150

Roller Specifications

Specification Rubber-Lagged Steel

Material STEEL and 3/8"

RUBBER STEEL

Durometer 60 N/A

Rating CEMA D

(XL is CEMA E)

CEMA D

(XL is CEMA E)

Bearings 6305 Sealed Ball

Bearing

6305 Sealed Ball

Bearing

Shaft Diameter 1" (25mm) 1" (25mm)

Wall Thickness 9 Gauge (.148)

(XL - 1/4")

9 Gauge (.148)

(XL - 1/4")

Specific Gravity Over 1 Over 1

Working Temperature -4° to 220° F -4° to 220° F

-20° to 104° C -20° to 104° C

Grease & Chemical

Resistance Good Good

Sticky Material

Performance Excellent Good

15

Section 8 - Specs and CAD Drawings

8.2 CAD Drawing - RBP1 Belt Positioner- Small

16 RBP1 Belt Positioner

Section 8 - Specs and CAD Drawings

8.3 CAD Drawing - RBP1 Belt Positioner- Medium

17

Section 8 - Specs and CAD Drawings

8.4 CAD Drawing - RBP1 Belt Positioner- Large

18 RBP1 Belt Positioner

Section 8 - Specs and CAD Drawings

8.5 CAD Drawing - RBP1 Belt Positioner- Extra Large

Table of contents

Popular Valve Positioner manuals by other brands

OMC

OMC R99P Installation, operation and maintenance instructions

Burkert

Burkert 8791 REV.2 operating instructions

W.E. Anderson

W.E. Anderson 185 Series Installation and operating instructions

Acoustical Systems

Acoustical Systems SMARTractor owner's manual

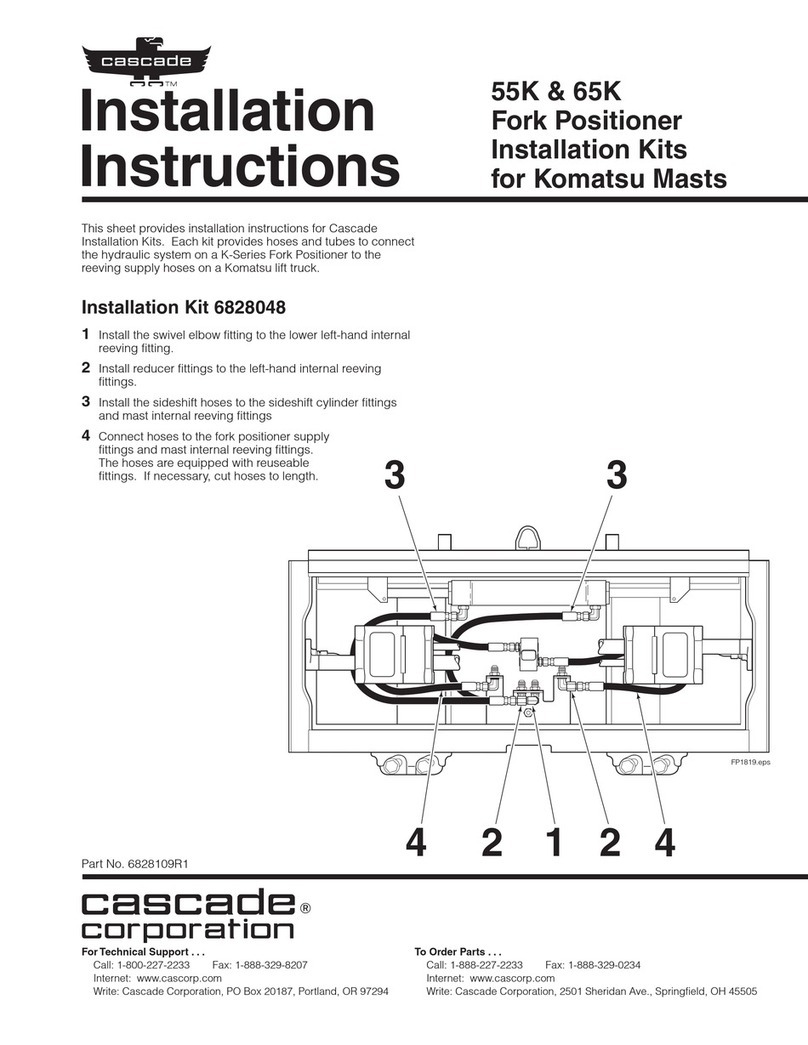

cascade corporation

cascade corporation 55K installation instructions

Siemens

Siemens 6DR50 Series operating instructions

Renishaw

Renishaw ACR2 installation guide

Vahle

Vahle Apos KBH Series Installation and operation instruction manual

AROSTOP

AROSTOP 30 S/A User manual and parts list

Fisher

Fisher 4070 instruction manual

Siemens

Siemens SIPART PS2 Compact operating instructions

Pepperl+Fuchs

Pepperl+Fuchs PGV100-F200A-B25-V1D manual