Arostop AS 30 / 60 - Manual

2

Version 2022-01

Inhoud

1. Introduction..................................................................................................................................... 4

1.1 CE-Marking .............................................................................................................................. 4

1.2 Warranty.................................................................................................................................. 4

1.3 Disclaimers .............................................................................................................................. 4

1.4 Standard machine and accessories ......................................................................................... 4

1.5 Not belonging to the machine................................................................................................. 4

1.6 Using the manual..................................................................................................................... 4

2. Safety............................................................................................................................................... 5

2.1 Rules for general safety........................................................................................................... 5

2.2 Prohibited use ......................................................................................................................... 6

2.3 Personal protective equipment............................................................................................... 6

2.4 Preventive safety..................................................................................................................... 6

2.5 Emergency............................................................................................................................... 6

2.6 Warnings on the machine ....................................................................................................... 7

2.7 Protection of the environment................................................................................................ 7

3. General ............................................................................................................................................ 8

3.1 About the machine.................................................................................................................. 8

3.2 Installation..................................................................................................................................... 9

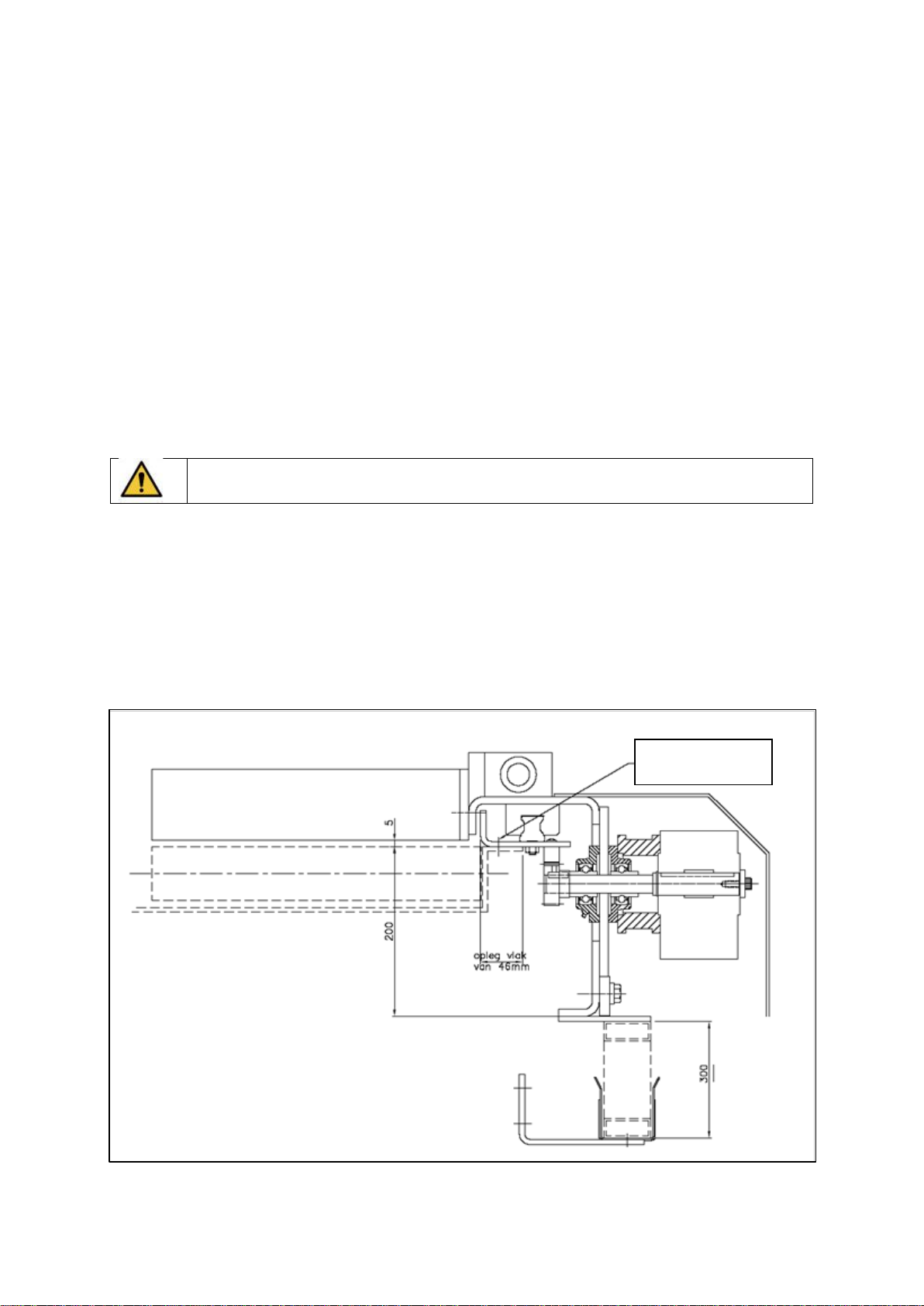

3.2.1 Mechanical ............................................................................................................................. 9

3.2.2 Electric .................................................................................................................................. 10

3.3 First use ....................................................................................................................................... 10

4. Operation .......................................................................................................................................... 11

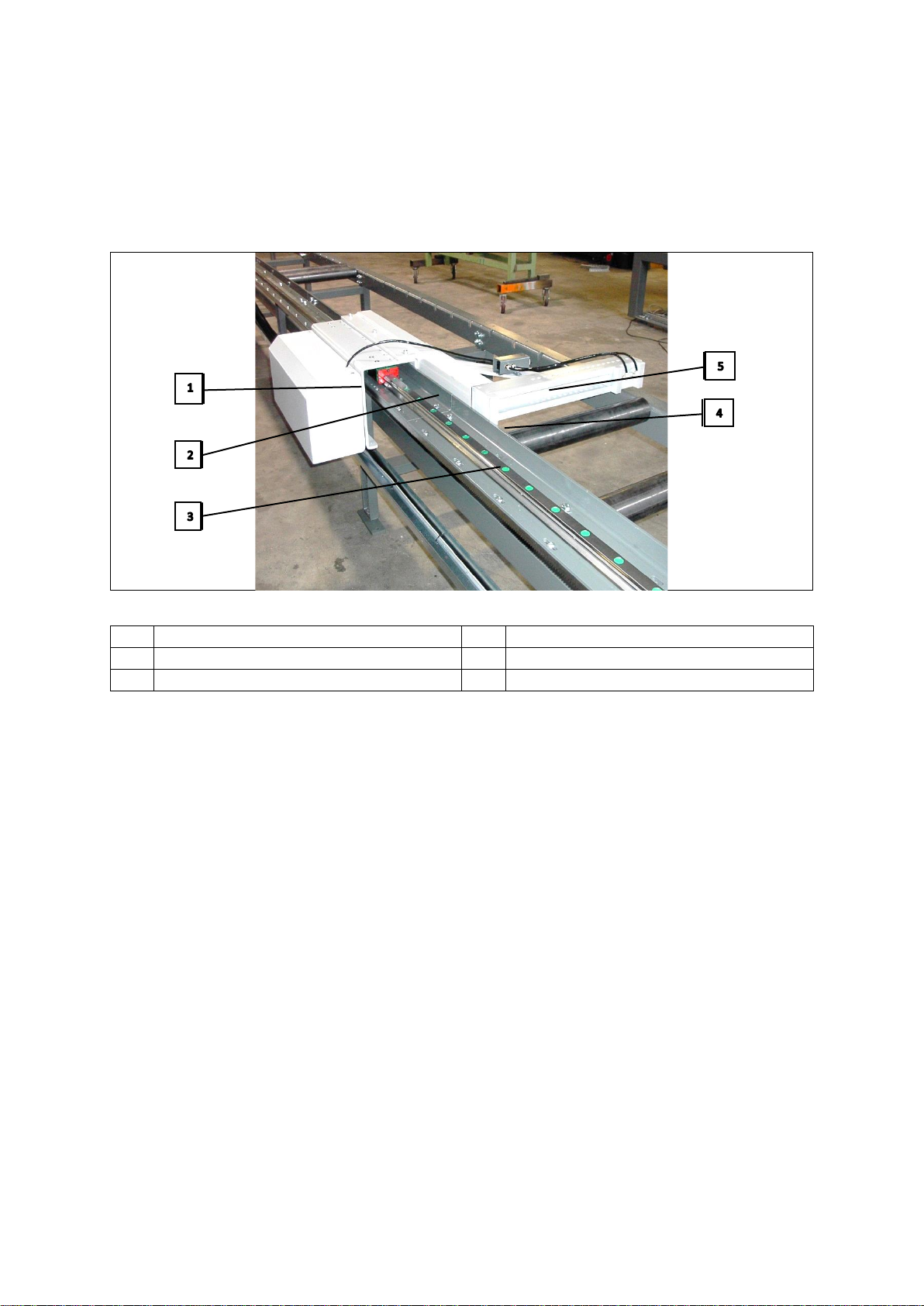

4.1 System construction.................................................................................................................... 11

4.2 Workplace ............................................................................................................................. 11

4.3 Controls ................................................................................................................................. 11

4.4 Working with the system ...................................................................................................... 12

4.5 Operators............................................................................................................................... 12

4.6 Operating instructions................................................................................................................. 12

4.6.1 Control panel........................................................................................................................ 13

4.6.2 Initialization.............................................................................................................................. 15

4.6.3 Manual cycle............................................................................................................................. 16

4.6.4 Automatic cycle .................................................................................................................... 17

4.6.5 Setting................................................................................................................................... 20

4.7 Adjustment of work..................................................................................................................... 23

5. Risks................................................................................................................................................... 24