Type 4060 & 4070

5

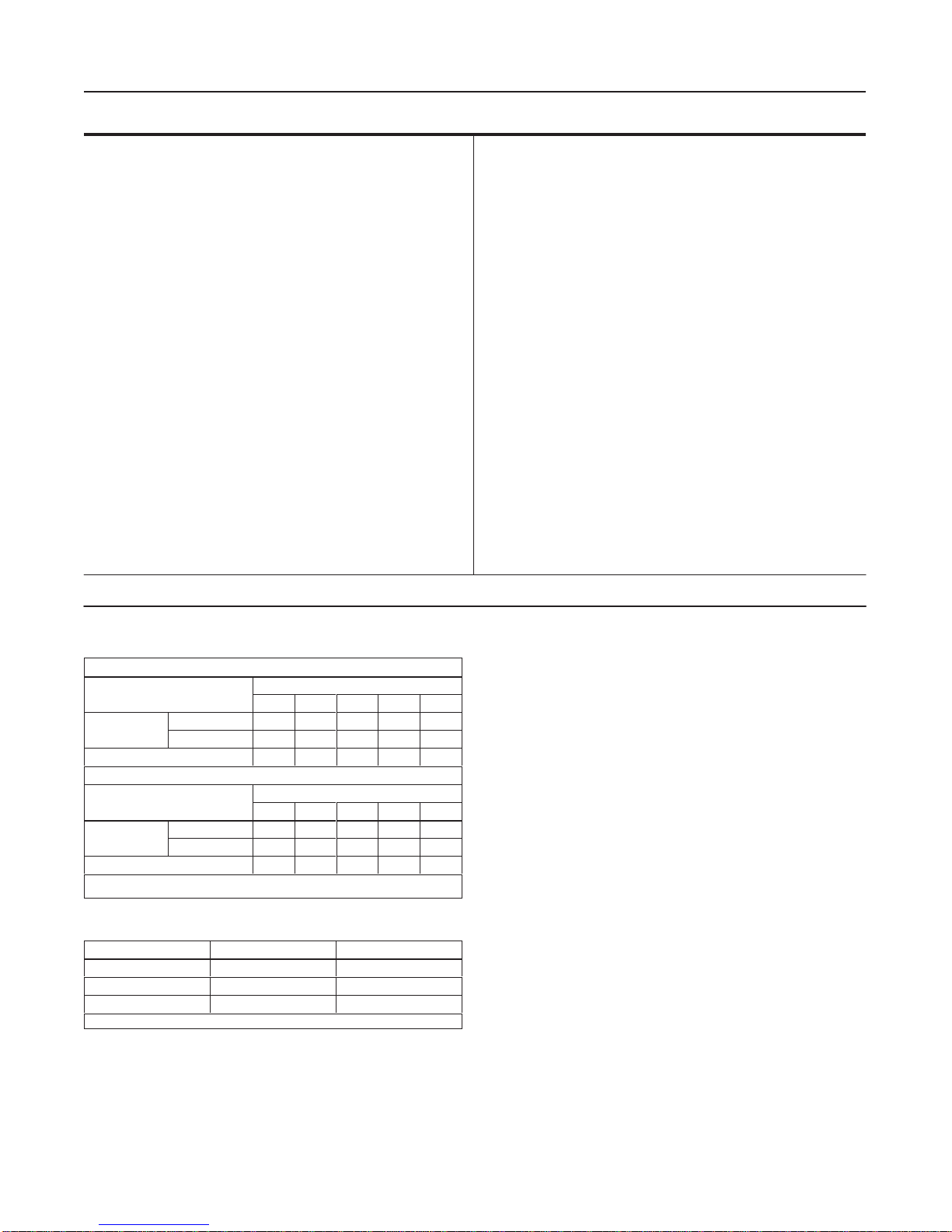

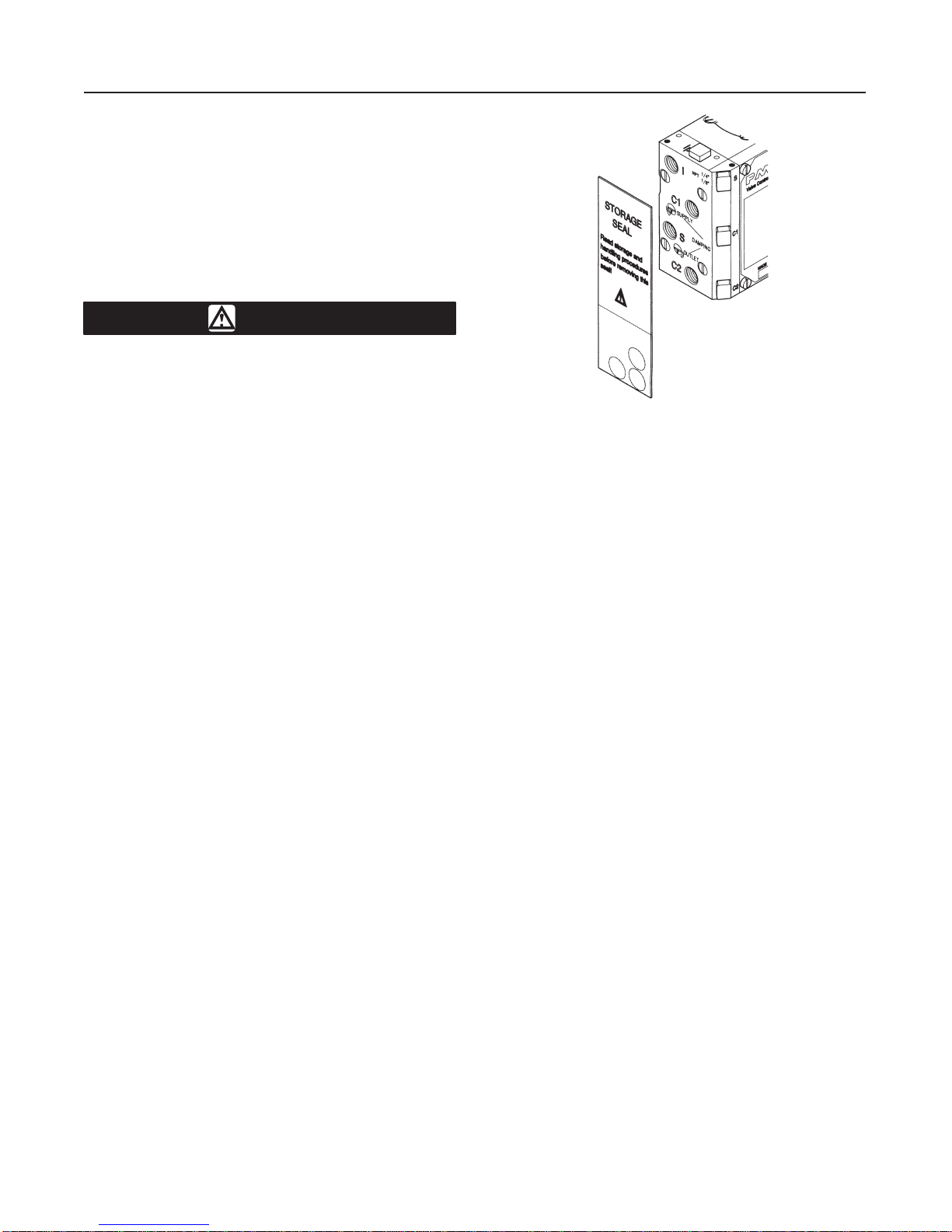

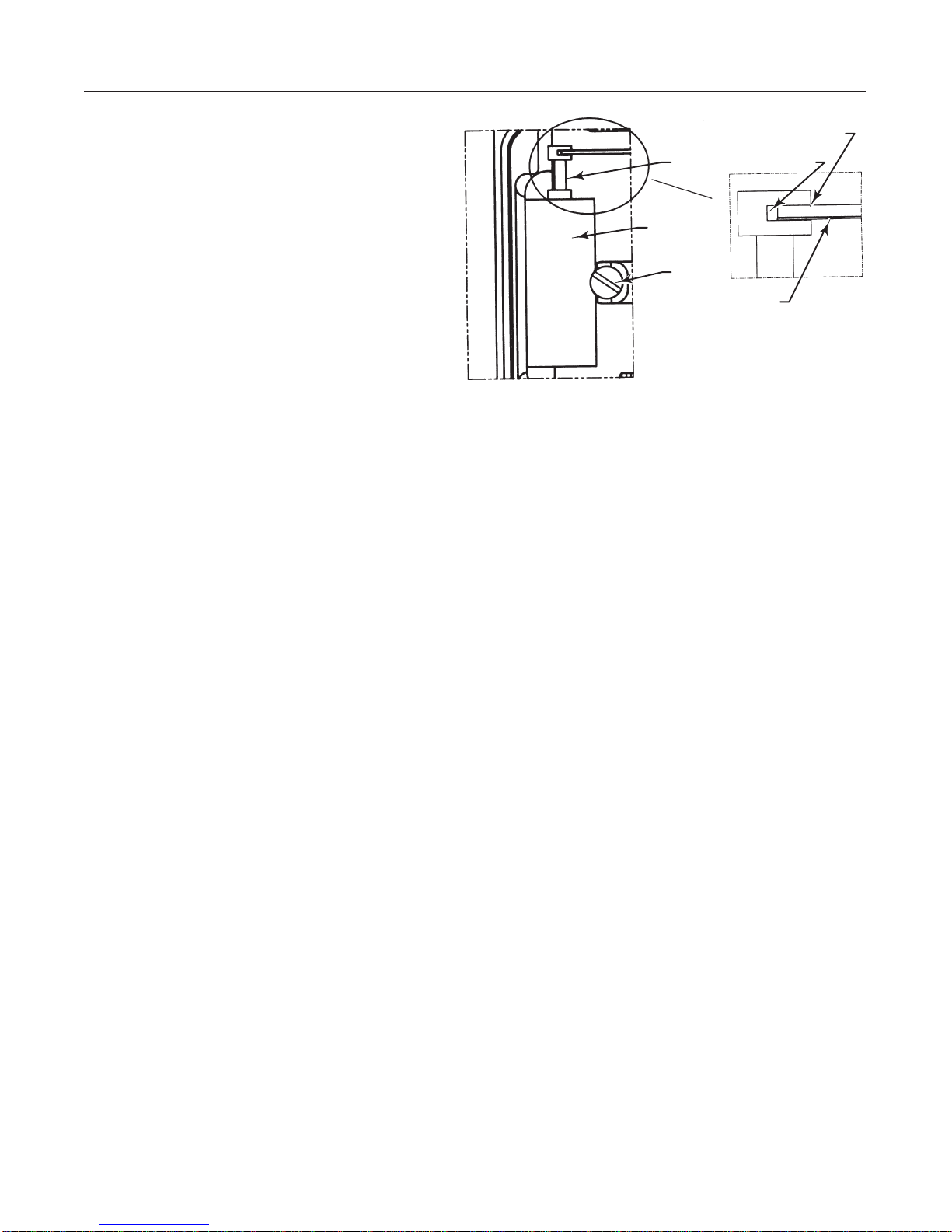

Figure 5. Positioner Pressure and Gauge Connections

INSTRUMENT

CONNECTION

SUPPLY

CONNECTION

OUTPUT

CONNECTION

GAUGE

PORTS

I/P UNIT,

TYPE 4070

OUTPUT

CONNECTION

INPUT SIGNAL GAUGE

PORT FOR TYPE 4060

A7227/ IL

instrument air quality standards de-

scribe acceptable dirt, oil, and moisture

content. Due to the variability in nature

of the problems these influences can

have on pneumatic equipment, Fisher

Controls has no technical basis to rec-

ommend the level of filtration equipment

required to prevent performance degra-

dation of pneumatic equipment. A filter

or filter regulator capable of removing

particles 40 microns in diameter should

suffice for most applications. Use of

suitable filtration equipment and the es-

tablishment of a maintenance cycle to

monitor its operation is recommended.

The supply medium must be clean, dry air or noncor-

rosive gas that meets the requirements of ISA Stan-

dard S7.3-1975. The supply pressure should not ex-

ceed the following limits:

DFor the actuator and positioner, do not exceed

the maximum pressure rating of 125 psig (8.6 bar).

DFor the valve, do not exceed the maximum allow-

able thrust of the specific valve.

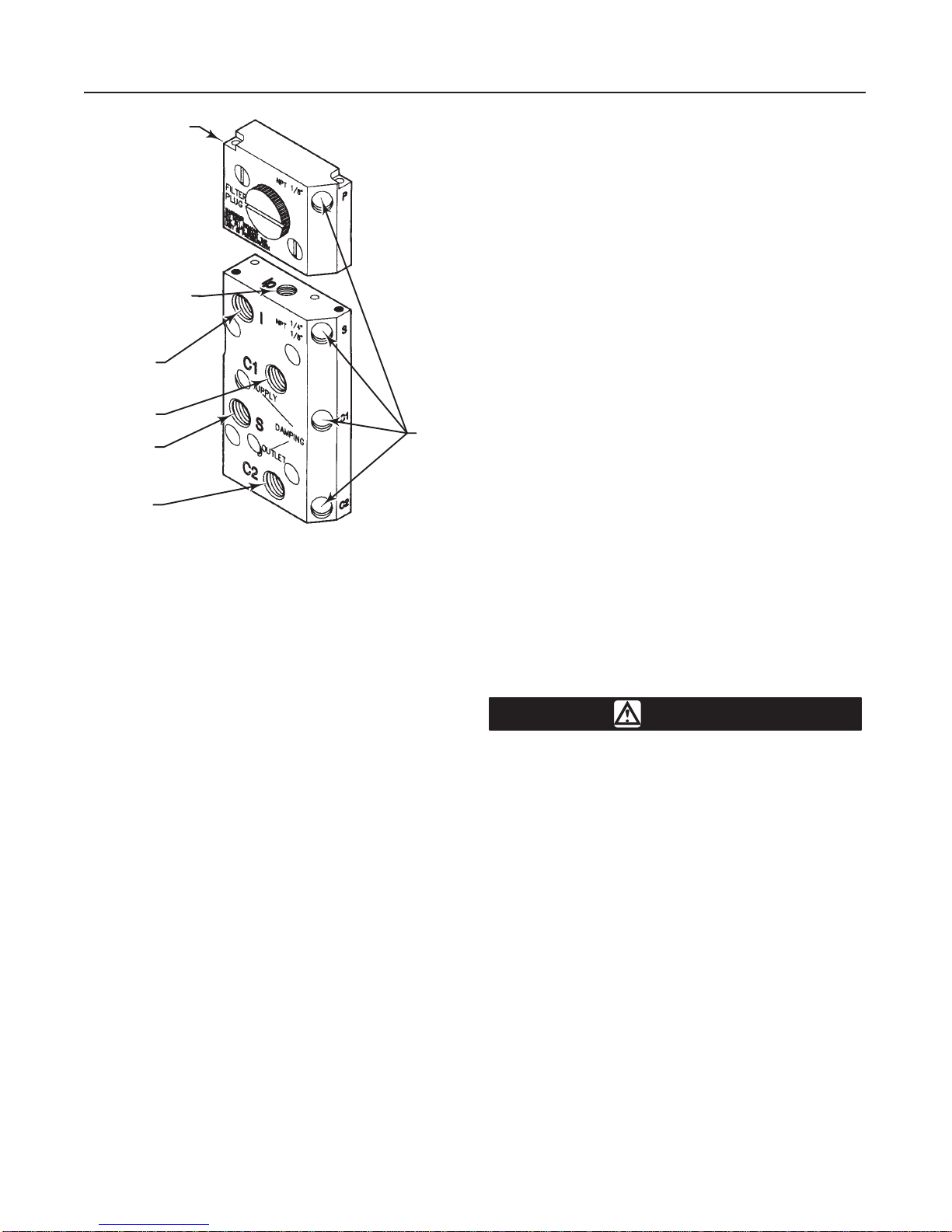

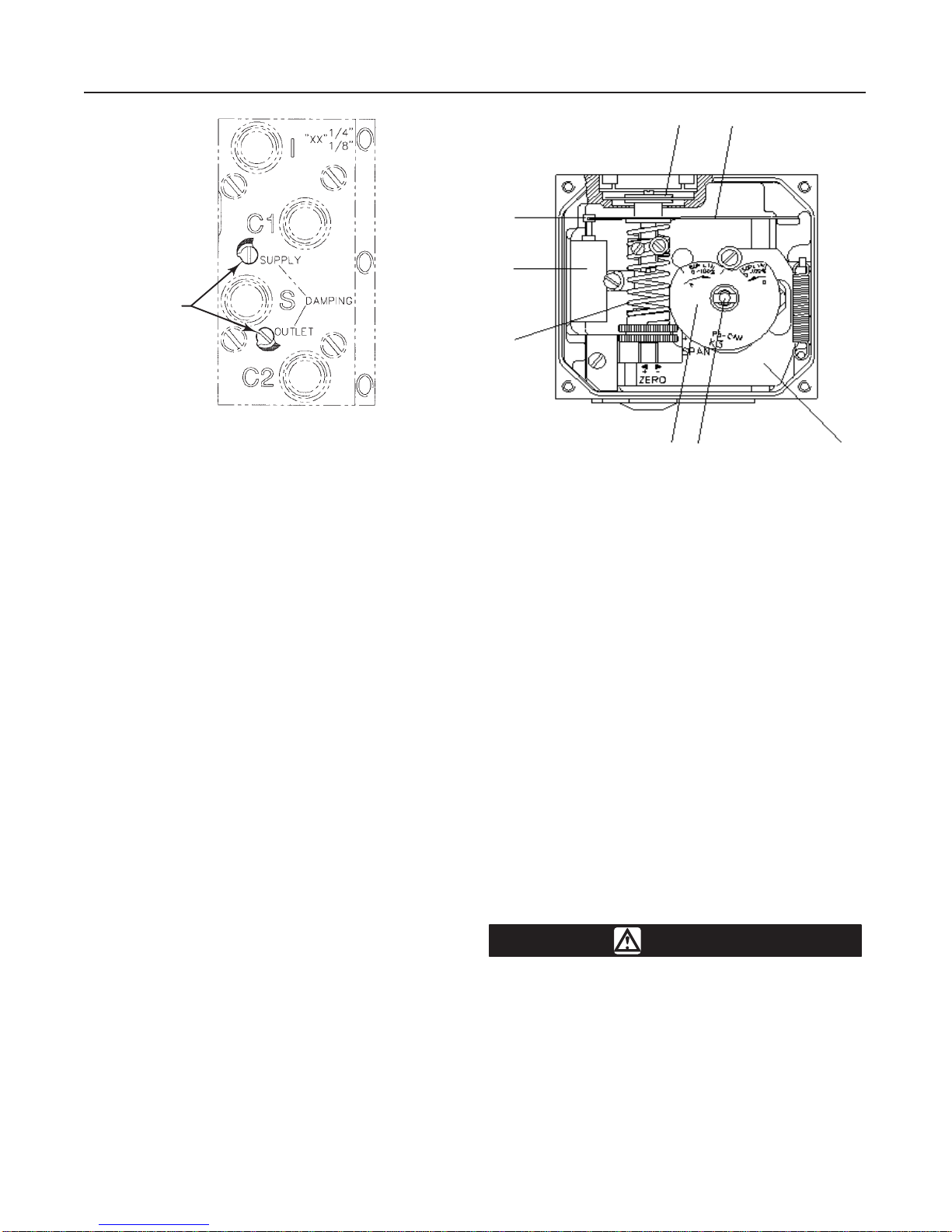

Connect supply pressure to the positioner supply port

S. Gauge port S is sealed with a plug. To install a sup-

ply gauge, unscrew the plug and install an appropriate

gauge.

Output Connections

For Type 585C actuators, connect the positioner out-

put port C1 to the actuator lower cylinder (yoke) con-

nection. Connect output port C2 to the actuator upper

cylinder connection.

For Type 585CR actuators, connect the positioner

output port C1 to the actuator upper cylinder connec-

tion. Connect output port C2 to the actuator lower cyl-

inder (yoke) connection.

For single-acting operation plug port C1 for increasing

signal to open or close. Plug C2 for decreasing (re-

verse) signal to close.

Gauge ports C1 and C2 are sealed with plugs. To

install gauges, unscrew the plugs and install gauges.

Instrument Connection

Connect the control device 3 to 15 psig (0.2 to 1.0 bar)

output to the positioner input port I. If a gauge is de-

sired, remove the plug from port Ipand install an ap-

propriate pressure gauge.

The Type 4070 electro-pneumatic positioner requires

a 4 to 20 milliampere dc current input signal from the

control device. For connections to the Type 4070, re-

fer to the electrical connections section.

Vent

WARNING

If a flammable, toxic, or reactive gas is

to be used as the supply pressure me-

dium, personal injury or property dam-

age could result from fire or explosion

of accumulated gas or from contact with

toxic, or reactive gas. The positioner/ac-

tuator assembly does not form a gas-

tight seal, and when the assembly is en-

closed, a remote vent line, adequate

ventilation, and necessary safety mea-

sures should be used. A remote vent

pipe alone cannot be relied upon to re-

move all hazardous gas. Vent line pip-

ing should comply with local and re-

gional codes and should be as short as

possible with adequate inside diameter

and few bends to reduce case pressure

buildup.

The port (OUT) is for venting the unit. All air from the

positioner, actuator, and I/P unit is vented to atmo-

sphere through this port. This port should be left open