FlexiModal BicyLift User manual

1/13

BicyLift maintenance manual

This document is intended for BicyLift users. As the bike trailer is a purely mechanical system,

its maintenance and repairs remain accessible to anyone equipped with the standard tools.

In order to ensure quality, safety and durability of the entire product, we supply spare parts on

request.

Due to the continuous improvement of the BicyLift, some parts may have evolved from the

model you own. These improvements are possible thanks to your feedbacks!

Please don’t hesitate to contact us for any feedback or product advice,

FlexiModal technical team

Table of Contents

Trailer frame.......................................................................................................................................2

Mudguards .........................................................................................................................................2

Lighting...............................................................................................................................................3

Wheels ...............................................................................................................................................3

Lifting/Unloading................................................................................................................................6

Rear hooks......................................................................................................................................6

Striker.............................................................................................................................................6

Braking system ...................................................................................................................................9

Checkpoints ....................................................................................................................................9

Settings & repairs..........................................................................................................................10

Hitch trailer/bike...............................................................................................................................11

Drawbar............................................................................................................................................12

2/13

Trailer frame

•Check the tightness of the frame/wheel blocks with a 5mm Allen key and a 13mm

wrench.

•Check that the ducts are securely fastened to the frame with the 9 plastic hose

clamps.

Mudguards

•Check the general condition of the mudguards, that the wheel does not rub.

Check with a 4mm Allen key that the 4 M5x14 screws of each mudguard are tightened

properly to avoid unwanted vibrations.

If a mudguard is warped, it can be removed by hand after removal from the trailer. Otherwise

spare mudguards are available.

3/13

Lighting

•Check that the lights are screwed onto their support and that the support itself is

tightened onto the wheel block (4mm Allen key).

•Check that the front and rear lights on both wheels are working when each wheel turns.

If necessary, move the magnet so that it passes in front of the lights.

The lights are ReeLight SL150 (fixed lights) or SL100 (flash lights), contact us for spare

parts.

Wheels

Checkpoints

•Tires pressure: 4bar / 55psi

Check the tyre pressure regularly to maintain good driving quality. Riding under-inflated means

that the range of the electric bicycle is reduced and the risk of pinch punctures is increased.

•Wheel curvature

Turn the wheel and check the wheel camber. If the wheel rubs against the wheel block, remove

the wheel as explained in the next section and then unveil the wheel as for a conventional

bicycle wheel.

•Tire condition

Regularly check the condition of the tires, sidewalls and tread. This could prevent a puncture

during a tour.

Tires are 20x2.15inch, contact us for spare parts.

Repairs

•Dismounting the wheel: puncture / tire change / wheel unveiling

The wheels are mounted with 20inch Schrader valve tubes and 20x2.15inch tires.

For more efficiency, we recommend having a spare wheel in the workshop to be able to

quickly change the wheel if a puncture occurs during a tour.

Necessary material (to take with you on the bike if you need to repair it on the spot): Allen key

6mm.

4/13

1. If the trailer is carrying a load, set the load down as usual

2. Turn the trailer over

3. Loosen and remove the screw on the axle of the punctured wheel (Allen 6mm)

4. Remove the black axle from the wheel.

5. To remove the wheel without removing the brake calliper, the wheel must be

completely deflated.

6. If wheel repair, inner tube 20inch Schrader valve. Repair as on the wheel of a classic

bicycle. Check the condition of the inner and outer tire as well as the inside of the rim.

Remove any body that can puncture the inner tube.

5/13

7. Reinstall the repaired wheel or spare wheel. It must be completely deflated to pass

without removing the brake caliper. The black axle is inserted from the outside of the

trailer. Make sure that the square end of the black axle matches the square of the

wheel block plate.

8. Tighten the M10 screw + washer with a 6mm Allen key. If possible, use a threadlocker

to prevent any loosening.

9. Inflate the wheel to 4bar.

6/13

Lifting/Unloading

Rear hooks

•Check the condition of the rubber roller which limits vibrations. It is a wearing part,

available as a spare part, which is fixed with TBHC M4x16 screws.

•Check that the rear hooks don’t vibrate in the wheel blocks. If necessary, tighten the

two M8 screws again with a 5mm Allen key and a 13mm flat spanner. To do so, turn

the trailer over and tighten by turning the spanner instead of the Allen key to avoid

damaging the screw head.

Latch system

Checkpoints

•Check the general condition of the latch control cables and their

casings

•Check the condition of the rubber stop. If it is in too bad

condition, contact us for spare parts.

•Check the position of the latch hooks:

Both latch hooks must reposition themselves vertically after fully

depressing the white lever that actuates them. If it’s not the case, see the

adjustments in the following section.

7/13

Settings & repairs

If you are having problems picking up or dropping off, identify the problem as appropriate:

•Problem depositing the charge

Reminder: To drop the load, the load must rest firmly on the ground at the front (lower the

front of the trailer) before pulling the white trigger to release the latch hooks.

The latch hook goes too far:

Tighten the relevant latch cable by unscrewing the cylinder until the hook returns to the

correct position. If the cylinder adjustment is not sufficient, re-tension the strike cable as

explain in the section “replace the latch cables and casings”.

•Problem lifting the front of the load: the strike does not pull out enough.

Check that nothing is blocking the rotation of the hook in the wheel block by turning the hook

by hand.

If the hook is blocked, this may be due to the following reasons:

- Objects jammed (packaging, plastic film, etc...) between the

strike plate and the metal sheet.

- of the screw around which the hook plate turns if it is too

tight.

- Cables or sheaths that are blocked or not securely fastened

•Problem lifting the front of the load: the strike does not pull out enough.

•If the white lever is difficult to operate

Check that the screw which serves as the rotation axis of the lever is not too tight (Allen

5mm).

8/13

•If the cables and their casings are damaged or if the problem stays unresolved

If the sheaths and cables are damaged or if the strike system does not work despite the

previous adjustments, proceed to disassembly and reassembly with spare parts.

References: Left latch cable 1.25m and right latch cable 1.75m. MTB head brake cables

sheath length +10cm.

1. Turn the trailer over

2. Unscrew the M5 nut with an 8mm open-end wrench.

3. Remove the wheel block cylinder

4. Remove the cable head from the striker plate

5. Remove the clamps securing the latch sheaths on the trailer frame

6. Remove the rubber cover

7. Unscrew the M8 screw that serves as the rotation axis for the white trigger with a

5mm Allen key

8. Unscrew the M4 screw with a 2.5mm Allen key

9. Remove the trigger and its cables+sheaths from the drawbar

10. Unscrew the two trigger screws with a 2.5mm wrench

11. Change the sheaths and cables then reassemble the system

9/13

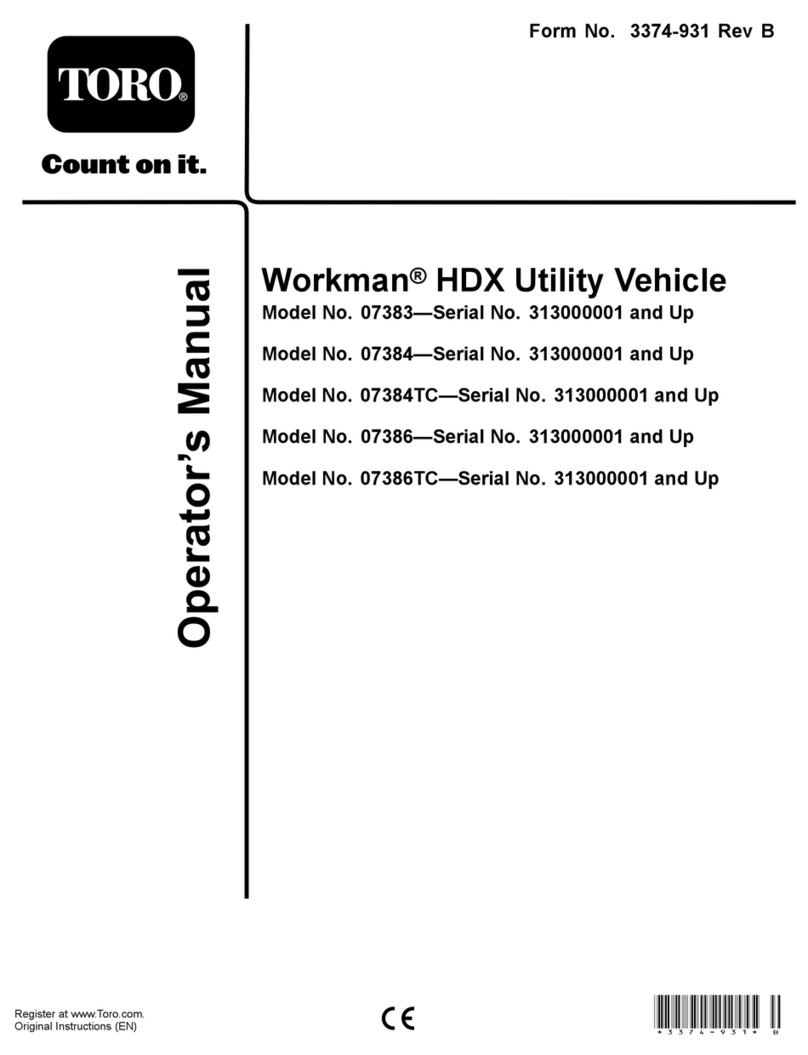

Braking system

Checkpoints

•Check the brake pads and disc for wear.

The padding of the brake pads must be sufficient. Noise may occur during braking if the

pads are too worn. The brake pads are Shimano M515 type, to change them you can follow

the TRP manual supplied with the trailer documentation.

•Check that the brake pads are parallel to the brake disc.

•Check the braking capacity of the trailer

The brake lever must be able to completely brake the trailer with the minimum possible lever

travel. When the brake lever is fully applied, the hitch brake control screw must be able to

come into contact with the brake lever.

If the lever goes further than the hitch brake control screw, the brakes must be re-tightened.

See the next section on how to adjust the brakes.

•Check the brake parallelism

Both wheels must brake as much as the other because there is only one brake control.

Test for parallelism by gradually applying the brake lever while pushing the trailer forward. If

the trailer deviates to the right, the left wheel does not brake sufficiently and vice versa. In

this case, unscrew the black ring on the caliper of the wheel with the least braking power.

•Check the general condition of the sheaths and cables, their attachment to the trailer

frame.

10/13

Settings & repairs

•Setting the braking system

For easy adjustment, use the black knurls

on the brake calipers to adjust cable

tension.

Place the brake caliper upright against a

wall and let the wheel turning while

adjusting with the knurl so that the pads

are as close to the disc as possible without

touching it.

If the adjustment with the knurl is not

sufficient because it reaches the end of its

travel, you can screw it back a few turns

and adjust the position of each brake pad

in its caliper. To do this, use a 3mm Allen

key (pictures below). Let the wheel turning

and screw to move the pad as close as

possible to the disc without it touching the

disc.

•If the pads are no longer parallel to the brake disc

It is possible to realign the bracket by unscrewing the two M6 support screws with a 5mm

Allen key.

11/13

•If the brake lever does not return properly.

Check sheaths and cables. Check that the brake cables are securely attached to the brake

calipers at the wheels.

•Change the sheaths and cables or if problem not solved

1. Remove the brake cable ferrule

2. Unscrew the grey screw that locks the brake cable to the caliper.

3. Remove the brake cable from the caliper.

4. Remove the plastic clamps that secure the sheaths to the trailer frame.

5. At the brake handle of the drawbar, unscrew the M5 screw with a 4mm Allen key and

a 10mm open-end wrench.

6. Remove the entire brake system and replace the brake lines or cables if necessary.

Sheath left: 165cm, right: 245cm. Caution, use only low compression tubing such as

Kevlar tubing.

Hitch trailer/bike

Checkpoints

•Bike hitch

Check that the bike hitch ball is vertical and free of any abnormalities.

Check the attachment of the BicyLift attachment to the bicycle (tightening of screws,

condition of the clamps, etc.).

•Trailer hitching system

Make sure that the bushing that slides on the trailer hitch does not

have the corners bent so that the hitch ball can escape. A deformation

is observed when the bike/trailer angulation is too large.

Maximum angles

•Check that all screws are properly tightened.

12/13

Settings & repairs

•Disassembly of the hitch

1. Unscrew the grey screw with a large flat screwdriver OR the

black screw if previous model with a 4mm Allen key (screw

with threadlocker).

2. Unscrew the black brake control screw with a 3mm Allen

key.

3. Unscrew the hollow screw with a 13mm wrench (screw

with threadlocker).

4. Pull out the coupling system

5. To remove the ring from the coupling, unscrew the wing

knob by hand or the CHC screw with a 3mm wrench.

6. Pull out the bushing

Drawbar

Checkpoints

•Check that the lever is firm in the 3 fixed positions of the drawbar, that it has no

rotational play.

Settings & repairs

•If the rotation becomes complicated, or a position has difficulty passing

Check the indexing ring on the drawbar.

1. Remove the 8 screws from the trailer frame with a 4mm Allen key.

2. Pull out the drawbar

3. Press the tiller position lever and pull the indexer out of the drawbar

1

2

3

5

13/13

4. Check that the indexing ring is in good condition and does not protrude from its

housing. If this is the case, contact us.

5. Reassemble the indexer, taking care to ensure that it is correctly oriented. For

example, refer to the standing position of the drawbar, which must be at right angles

to the frame tube.

Need advice or spare parts: contact us!

contact@fleximodal.fr

+33 222 930 940

Other manuals for BicyLift

1

Table of contents

Popular Utility Vehicle manuals by other brands

Westward

Westward GO-4 EV INTERCEPTOR IV Operator's manual

DK2

DK2 MMT4X6OG user manual

Federal Signal Corporation

Federal Signal Corporation LEACH 2R-III Service manual

Great Dane

Great Dane 42101203 Operator's manual

Arctic Cat

Arctic Cat PROWLER XT Operator's manual

Snapper

Snapper GROUNDS CRUISER GC9520KW parts manual

Razor

Razor Ground Force owner's manual

Kendon

Kendon Stand-Up TRIKE/SPYDER/SIDECAR Ride-Up SRL owner's manual

Toro

Toro Workman GTX Series installation instructions

ShoreLand'r

ShoreLand'r 69175 Series Service manual

Sodikart

Sodikart Sigma User maintenance guide

CBS Products

CBS Products C-823-13 Operating and maintenance manual