Flintec FT-111 Series User manual

FT-111 User Manual

FT-111

Weighing Indicator

User Manual

Flintec

www.flintec .com

FT-111, User Manual Rev. 2.0.0, June 2022 Page 2of 137

Table of Contents

1Safety Instructions.........................................................................................................5

2Introduction.....................................................................................................................6

2.1 Overview.................................................................................................................................................................................6

2.2 Specifications.........................................................................................................................................................................6

2.3 Housing..................................................................................................................................................................................10

2.4 Mounting kits.......................................................................................................................................................................10

3The Front View and Key Functions........................................................................12

3.1 Display...................................................................................................................................................................................12

3.2 Keypad...................................................................................................................................................................................14

4Installation......................................................................................................................15

4.1 Recommendations ............................................................................................................................................................15

4.1.1 Environment........................................................................................................................................................................15

4.1.2 Mechanical Installation Recommendations..............................................................................................................15

4.1.3 Cabling Recommendations.............................................................................................................................................15

4.1.4 Electrical Connection Recommendations ..................................................................................................................16

4.2 Installation Steps................................................................................................................................................................17

Step 1: Preliminary Preparations ................................................................................................................................ 17

Step 2: Mechanical Installation ................................................................................................................................... 17

Step 3: Open the Housing / Close the housing.......................................................................................................19

Step 4a: Analogue Load Cell Connection.................................................................................................................19

Step 4b: Digital Load Cell Connection (Only FT-111 D) ..........................................................................................20

Step 5: RS 232C Serial Ports......................................................................................................................................... 21

Step 6: RS 485 Serial Port.............................................................................................................................................22

Step 7: Ethernet TCP/IP.................................................................................................................................................22

Step 8: USB Port...............................................................................................................................................................23

Step 9: Alibi Memory (option......................................................................................................................................24

Step 10: Optional Board Installation...........................................................................................................................24

Step 11: Power Source Connection and Grounding................................................................................................24

Step 12: Scale Setup and Calibration ...........................................................................................................................25

Step 13: Use..........................................................................................................................................................................25

4.3 Installation of Optional Boards.....................................................................................................................................26

4.4 Cleaning................................................................................................................................................................................ 27

4.5 Disposal................................................................................................................................................................................ 27

5FT-111 Functions..........................................................................................................28

5.1 Basic Functions..................................................................................................................................................................28

5.2 Advanced Functions.........................................................................................................................................................29

5.3 Backup and Restore (with SD card)..............................................................................................................................31

5.4 Setup, Backup and Restore via Indface2x Software..............................................................................................32

5.5 Firmware Upgrade............................................................................................................................................................32

5.6 Copying the weighing-related data from SD card to a PC..................................................................................32

6Digital Inputs and Outputs.......................................................................................33

6.1 Digital inputs.......................................................................................................................................................................34

6.2 Digital outputs....................................................................................................................................................................34

7RS232 and RS485 Data Outputs...........................................................................39

7.1 Continuous Data Output.................................................................................................................................................39

7.2 Fast Continuous Data Output.......................................................................................................................................40

7.3 Print Mode...........................................................................................................................................................................40

FT-111, User Manual Rev. 2.0.0, June 2022 Page 3of 137

7.4 EPL Format..........................................................................................................................................................................42

7.5 BSI Data Structure for Dialog with PC........................................................................................................................42

7.6 Fieldbus Interface..............................................................................................................................................................42

8Programming and Calibration...............................................................................43

8.1 Alphanumeric Entry for Headers and Footers.........................................................................................................43

8.2 Entering to the Programming and Calibration........................................................................................................44

8.3 Quick Access Parameter Blocks used frequently....................................................................................................44

8.4 Exit from Programming..................................................................................................................................................44

8.5 Programming and Parameters....................................................................................................................................45

[1-- INTERFACE] Interface Block ...........................................................................................................................46

[2-- CONFIGURATIO] Configuration Block..............................................................................................................56

[3-- APPLICATION] Application Block..................................................................................................................58

[5-- SCALE] Scale Block............................................................................................................................................61

[6-- CALB / ADJUST] Calibration and Adjustment Block...................................................................................64

[8-- METROLOGY] Metrology Block ...................................................................................................................65

[9-- DIAGNOSTIC] Diagnostic Block.....................................................................................................................66

8.6 Calibration ...........................................................................................................................................................................68

8.6.1 Linearity Correction..........................................................................................................................................................68

8.6.2 Zero and Span Adjustments..........................................................................................................................................69

8.6.3 eCal Electronic Calibration.............................................................................................................................................70

8.6.4 Gravity adjustment............................................................................................................................................................71

8.6.5 Calibration coefficients.....................................................................................................................................................71

9Digital Load Cells (DLC).............................................................................................72

9.1 Addressing of Digital Load cells.................................................................................................................................... 72

10 Sealing of Approved Scale.......................................................................................75

11 Optional Boards...........................................................................................................76

11.1 Digital Inputs and Outputs.............................................................................................................................................76

11.2 Alibi Memory .......................................................................................................................................................................77

11.2.1 Installation of Alibi SD card.............................................................................................................................................77

11.2.2 Activating Alibi Memory..................................................................................................................................................78

11.2.3 How is the Data Recorded into the Alibi Memory?................................................................................................78

11.2.4 Recall Data from Alibi Memory....................................................................................................................................78

11.3 Installation of SD Card.....................................................................................................................................................80

11.4 BSI Protocol to Interface with PC and PLC.................................................................................................................81

11.4.1 BSI-Base Commands.......................................................................................................................................................82

11.5 Continuous Data Formats..............................................................................................................................................88

11.6 Analogue Output................................................................................................................................................................91

11.6.1 Analogue Output Connection.........................................................................................................................................91

11.7 Modbus RTU .......................................................................................................................................................................93

11.7.1 Modbus RTU Data Structure .........................................................................................................................................93

11.8 Ethernet TCP/IP.................................................................................................................................................................99

11.8.1 Ethernet Parameters .......................................................................................................................................................99

11.8.2 Modbus TCP Data Structure........................................................................................................................................100

11.9 Profibus DP ........................................................................................................................................................................101

11.9.1 Electrical Connection.......................................................................................................................................................101

11.9.2 Data Format.....................................................................................................................................................................102

11.9.3 GSD Configuration..........................................................................................................................................................102

11.9.4 Profibus DP Data Structure .........................................................................................................................................102

11.10 Profinet...............................................................................................................................................................................103

11.10.1Electrical Connection......................................................................................................................................................104

11.10.2 Data Format...............................................................................................................................................................104

11.10.3 Profinet Parameters ................................................................................................................................................105

11.10.4 GSDML Configuration..............................................................................................................................................105

FT-111, User Manual Rev. 2.0.0, June 2022 Page 4of 137

11.10.5 Profinet Data Structure...........................................................................................................................................106

11.11 EtherNet/IP .......................................................................................................................................................................107

11.11.1 Electrical Connection......................................................................................................................................................108

11.11.2 Data Format .....................................................................................................................................................................109

11.11.3 EtherNet/IP Parameters...............................................................................................................................................109

11.11.4EDS Configuration...........................................................................................................................................................109

11.11.5 EtherNet/IP Data Structure..........................................................................................................................................110

11.12 EtherCAT..............................................................................................................................................................................111

11.12.1 Electrical Connection.......................................................................................................................................................112

11.12.2Data Format ......................................................................................................................................................................112

11.12.3ESI Configuration..............................................................................................................................................................113

11.12.4EtherCAT Data Structure...............................................................................................................................................113

11.13 CC-Link.................................................................................................................................................................................114

11.13.1 Electrical Connection.......................................................................................................................................................114

11.13.2Data Format......................................................................................................................................................................115

11.13.3CC-Link Configuration.....................................................................................................................................................115

11.13.4CC-Link Data Structure...................................................................................................................................................115

11.14 Powerlink............................................................................................................................................................................116

11.14.1Electrical Connection.......................................................................................................................................................117

11.14.2Data Format......................................................................................................................................................................117

11.14.3XDD Configuration...........................................................................................................................................................118

11.14.4 Powerlink Data Structure........................................................................................................................................118

12 Appendix 1 Data Structure Profibus, Profinet, EtherNET/IP, EtherCAT,

CC-Link, Powerlink..............................................................................................................119

13 Appendix 2: Data Structure CANopen............................................................126

14 Error Codes..................................................................................................................135

FT-111, User Manual Rev. 2.0.0, June 2022 Page 5of 137

Disclaimer

All rights reserved.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by

any means, mechanical, photocopying, recording, or otherwise, without the prior written permission of

Flintec.

No patent liability is assumed with respect to the use of the information contained herein. While every

precaution has been taken in the preparation of this book,Flintec assumes no responsibility for errors or

omissions. Neither is any liability assumed for damages resulting from the use of the information contained

herein.

The information herein is believed to be both accurate and reliable. Flintec, however, would be obliged to be

informed if any errors occur. Flintec cannot accept any liability for direct or indirect damages resulting from

the use of this manual.

Flintec reserves the right to revise this manual and alter its content without notification at any time.

Neither Flintec nor its affiliates shall be liable to the purchaser of this product or third parties for damages,

losses, costs, or expenses incurred by purchaser or third parties because of: accident, misuse, or abuse of this

product or unauthorized modifications, repairs,or alterations to this product, or failure to strictly comply with

Flintec operating and maintenance instructions.

Flintec shall not be liable against any damages or problemsarising from the use of any options or any

consumable products other than those designated as Original Flintec Products.

NOTICE: The contents of this manual are subject to change without notice.

1SAFETY INSTRUCTIONS

CAUTION: READ this manual BEFORE operating or servicing this equipment. FOLLOW

these instructions carefully. SAVE this manual for future reference. DO NOT allow

untrained personnel to operate, clean, inspect, maintain, service, or tamper with this

equipment. ALWAYS DISCONNECT this equipment from the power source before

cleaning or performing maintenance.

CALL Flintec for parts, information, and service.

WARNING: Only permit qualified personnel to service this equipment. Exercise care

when making checks, tests and adjustments that must be made with power on. Failing

to observe these precautions can result in bodily harm.

WARNING: For continued protection against shock hazard connect to properly

grounded outlet only. Do not remove the ground prong.

WARNING: Disconnect all power to this unit before removing the fuse or servicing.

WARNING: Before connecting/disconnecting any internal electronic components or

interconnecting wiring between electronic equipment always remove power and wait at

least thirty (30) seconds before any connections or disconnections are made. Failure to

observe these precautions could result in damage to or destruction of the equipment or

bodily harm.

CAUTION: Observe precautions for handling electrostatic sensitive devices.

FT-111, User Manual Rev. 2.0.0, June 2022 Page 6of 137

2INTRODUCTION

2.1 OVERVIEW

FT-111 Weighing Terminal is an economical and powerful state-of-the-art measuring instrument. It is ideal for

industrial weighing applications like basic weighing, labelling, system control with digital outputs, fieldbus

interfacing, etc. Its set values memory with 500 items record size which each item has 5 pieces limit values

gives big advantage in operation.

Digital inputs and outputs of the instrument can be programmed as a Remote IO on the fieldbus. This feature

The scales equipped with FT-111 weighing terminal can be used in all kinds of industrial areas up to harsh,

wet, and hygienic environments with its fast and efficient cleaning that was designed and built according to

the international guidelines.

2.2 SPECIFICATIONS

Analogue Load cell

A/D converter type

24 bit Delta-Sigma ratio metric with integral analogue and digital filters

Conversion rate

Up to 800 measurement values per second

Input sensitivity

0,4 μV/e approved, 0.05 μV/e non approved.

Analogue input range

-5 mV to +19 mV

Internal resolution

up to 16 000 000

Excitation

5 VDC max. 125 mA

Number of load cells

Up to 8 load cells 350 Ωor 25 load cells 1100 Ω.

Connection

4- or 6-wire technique.

Home cable length: maximum 1000 m/mm² for 6-wire connection between

FT-111 and junction box.

Scale

Range

Single range, up to 3 x multi-intervals, up to 3 x multi ranges.

Display resolution

Approval, up to 10 000 division at usage in trade, according to EN45501 and

OIML R76. Up to 999 999 division at industrial usage.

Platform

Every kind of platform which is equipped with strain gage-based load cells.

Calibration and Functions

Calibration

Calibration with test weights,

eCal electronic calibration without test weights,

Temporary zero calibration,

Zero adjustment, Gain adjustment,

Coefficient entry.

Digital filter

5 steps programmable adaptive filter

Average filter

Programmable dynamic filter

Weighing functions

Taring, zeroing, auto zero tracking, motion detection, auto zero at power up,

tare status saves at power off, increased resolution, automatic tare and clear,

temporary gross indication, unit change.

FT-111, User Manual Rev. 2.0.0, June 2022 Page 7of 137

Standard applications

Labelling with barcode, free set points, functional digital outputs, livestock

weighing, Remote IO of PLC or HMI, fieldbus interface.

Memory

Application memories

Set Memory to save limit values at your industrial weighing.

Memory size is 500 item records.

Alibi memory (optional)

99 999 records

Communication

Connectable with

PC, PLC, Printer, Remote display, EPL printer etc.

RS 232

Port

2 pieces opto-isolated, 3 wire.

Baud rate

1200 to 57600 programmable

Data

Length 7 or 8 bits; parity even, odd or none

RS 485

Baud rate

1200 to 57600 programmable

Data

Length 7 or 8 bits; parity even, odd or none

Stations

Up to 31 stations

Ethernet TCP/IP

Transmission

rate

10 / 100 Mbit/s, Full duplex

TCP/IP settings

Manual IP assign over EtherX PC Software or by keys in programming mode.

Connection

method

Server or Client

Installation

Switched Ethernet transmission with shielded twisted pair cables and RJ-45.

Isolation

Galvanically isolated bus electronics

Response speed

Max. 4 ms response delay after read/write commands

USB

Connection

Standard USB Mini-B cable

Response speed

Max. 4 ms response delay after read/write commands

Digital Inputs and Outputs (optional)

Digital Inputs

Opto-isolated 4 digital input, 12 to 28 VDC, 10mA

Digital Outputs

5 free relay contact, 250 VAC or 30 VDC, 0.2A

Analogue Output (optional)

Voltage output

0-5 VDC, 0-10 VDC

Current output

4-20mA, 0-20mA

Resolution

60 000 steps between minimum and maximum output.

Max. cable length

300 meters

Max. load resistance

(current output)

500 Ω

Min load resistance

(voltage output)

10 kΩ

Profibus DPV1 (optional)

Data rate

Up to 12000 kbit/s with automatic baud rate detection

GSD file

Generic GSD-file provided

FT-111, User Manual Rev. 2.0.0, June 2022 Page 8of 137

Topology

Depending on physical media

RS-485:segmented line topology without stubs

Installations

Shielded twisted pair cable

Line length depending on physical media and transmission speed

Max. Stations

up to 126 stations per network

Isolation

Galvanically isolated bus electronics

Response speed

Min. 4 ms response delay after read/write commands

Profinet (optional)

Data rate

100 Mbit/s, full duplex

GSDML file

Generic GSDML-file provided

TCP/IP settings

DHCP or manual IP are assigned over EtherX PC Software or by keys in

programming mode. Device identity customization

Topology

Line, Bus, Star or Tree topology depending on physical media

Installation

Switched Ethernet transmission with shielded twisted pair cables and RJ-45

connectors.

Web client

Available

Isolation

Galvanically isolated bus electronics

Response speed

Min. 4 ms response delay after read/write commands

EtherNet/IP (optional)

Data rate

10 Mbit/s or 100 Mbit/s, full duplex

EDS file

Generic EDS-file provided

DLR (Device Level Ring)

Available

TCP/IP settings

DHCP or manual IP assign over EtherX PC Software or by keys in programming

mode.

Device identity customization

Topology

Line, Bus, Star or Tree topology depending on physical media

Installation

Switched Ethernet transmission with shielded twisted pair cables and RJ-45

connectors.

Web client

Available

Isolation

Galvanically isolated bus electronics

Response speed

Up to 4 ms. response delay after read/write commands.

EtherCAT (optional)

Data rate

100 Mbit/s, full duplex

ESI file

Generic ESI-file provided

Topology

Line, Tree, Star or Daisy-chain topology depending on physical media

Installation

Switched Ethernet transmission with shielded twisted pair cables and RJ-45

connectors.

Isolation

Galvanically isolated bus electronics

Response speed

Up to 4 ms. response delay after read/write commands.

FT-111, User Manual Rev. 2.0.0, June 2022 Page 9of 137

CC-Link (optional)

Data rate

156 kbit/s 10 Mbit/s (selectable)

Topology

Line with Trunkline, Branch structure and Termination at both Ends.

Installation

3 wires shielded twisted pair cable.

Max. Stations

Up to 64 stations per network

Isolation

Galvanically isolated bus electronics

Response speed

Up to 4 ms. response delay after read/write commands

Powerlink (optional)

Compatibility

Supports Ethernet POWERLINK V2.0 Communication Profile Specification

version 1.2.0

Data rate

100 Mbit/s, half duplex

XDD file

XDD-file provided

Ring redundancy

Available

Topology

100% free choice of star, tree, ring or daisy chain

Installation

Switched Ethernet transmission with shielded twisted pair cables and RJ-45

connectors.

Isolation

Galvanically isolated bus electronics

Response speed

Min. 4 ms response delay after read/write commands

Power Consumption

100 240 VAC, 50 60 Hz max. 25 mA + max. 50 mA for fieldbus interfacing

OR 12 28 VDC 250 mA + max. 500 mA for fieldbus interfacing

Environment and Enclosure:

Operation temp. range

Approved scales -10 °C to +40 °C

Industrial usage -15 °C to +55 °C

Humidity

Approved scales 80% RH max, non-condensing

Industrial usage 90% RH max, non-condensing

Enclosure

Stainless steel

Protection

IP67

Sizes ( W x H x D )

Wall type

: 260 x 200 x 64 mm (

Weight

2,3 kg ( 5,07 lb )

Packing sizes

Weight packed

3,2 kg ( 7,05 lb )

FT-111, User Manual Rev. 2.0.0, June 2022 Page 10 of 137

2.3 HOUSING

2.4 MOUNTING KITS

Wall mounting kit

This kit can be used to install the weighing terminal on to the desk or to the wall. Its mounting dimensions

and adjustment angles are shown below.

Mounting part

Side view

Rear part of indicator

FT-111, User Manual Rev. 2.0.0, June 2022 Page 11 of 137

2D Wall mounting kit

This kit can be used to install the weighing terminal on to the wall. 2D wall mounting kit provides to adjust the

angles of the terminal at two directions. Its mounting dimensions and adjustment angles are shown below.

Mounting part

Side view

Top view

Column mounting kit

This kit can be used to install the weighing terminal on to the column of the platform. Its mounting

dimensions and adjustment angles are shown below.

Mounting part

Side view

FT-111, User Manual Rev. 2.0.0, June 2022 Page 12 of 137

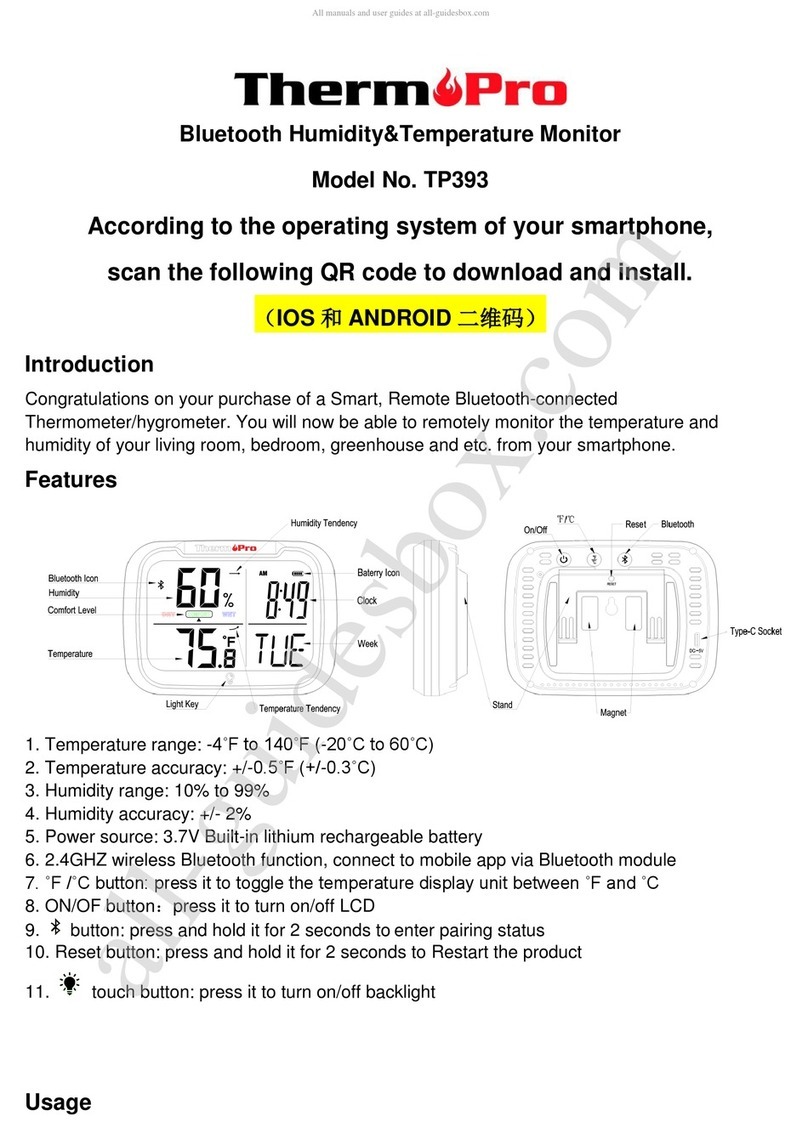

3THE FRONT VIEW AND KEY FUNCTIONS

Figure 3.1 Front view of FT-111

3.1 DISPLAY

The bright and wide-angle LCD display of the FT-111 is shown below.

2

4

5

10

9

1

7

13

12

11

6

8

3

14

FT-111, User Manual Rev. 2.0.0, June 2022 Page 13 of 137

The meanings of the announcement symbols on the display are:

1

6-digit 22 mm height big weighing display with sign

2

16-digit 8 mm height alphanumeric information display

3

High resolution digit separator.

4

Announces the indicated value is the net weight.

5

Announces the indicated value is the gross weight.

6

Bar graph

7

Indicates the range of the scale at multi range and multi-interval

operations.

8

g, oz, kg, t, lb units are located on the right of the display.

9

Announces the activated inputs and outputs.

10

Announces the instrument is at repair status or call service.

11

Announces the weight value is in the centre of zero range.

12

Announces the weighing is not stable. After stabilization of the

weighing, this symbol disappears.

13

Announces the keys are locked.

14

Announces the battery charging level.

FT-111, User Manual Rev. 2.0.0, June 2022 Page 14 of 137

3.2 KEYPAD

The keys and the key functions of FT-111 in usage are:

On: Press the key to switch on the weighing terminal.

Off: Press the key more than 2 seconds to switch off the instrument.

Page 28

Date & Time: This key used to indicate date and time on the alphanumeric

display.

Page 30,

57

Temp. Gross in Net: This key is used to indicate the Gross weight temporarily in

net mode.

SET value entry: Press this key to enter set points.

Page 33,

59

Print: By pressing this key weight data transferred to a printer or to PC.

Page 29,

40

Navigation keys: Date, G/N, SP and Print keyshave navigation functions in the

set point memory and in the programming.

The meanings of the symbols on keys at usage are;

Page 43

Return.

Increase the blanking digit or next step.

Decrease the blanking digit or previous step Change the item or enter

into parameter.

Save the data after entry.

Go to the next parameter.

Unit change key: This key is used to change unit. The unit change is available

between kg and lb, and between g and oz.

Esc: The second function of this key is escape. Pressthe key to escape from any

entry or step in operation.

Page 29,

62

High resolution key: This key is used to indicate 10 times higher resolution of

the weight value.

Memory: The second function of the key is memory transactions. Press for

more than 2 seconds to enter memory. Or press this key to load any item from

memory in Set point entry step.

Page 29,

61, 38

Tare: Press this key for taring the scale.

Key lock: This key is used to lock/unlock the keys.

Page 29,

56, 30,

58

Zeroing: If

key to compensate zero drift.

Page 28,

62

Clear: Clears the tare and indication returns to the gross value.

Plus/Minus: This key is used to set negative set point value.

Page 29,

38

Enter: Save the data and go to the next step.

Print: By pressing this key the weight data is transferred to a printer or to a PC.

Page 43,

40

FT-111, User Manual Rev. 2.0.0, June 2022 Page 15 of 137

4INSTALLATION

PRECAUTION: Read this section carefully before installation of the instrument. Applying the

recommendations in this section will increase your system reliability and its long-term performance.

4.1 RECOMMENDATIONS

4.1.1 Environment

The weighing terminal should be placed in an area which is clean, not getting direct sun light if possible,

having a temperature between -15 ºC and +55 ºC and humidity not exceeding 80% non-condensing. All

external cables should be installed safely to avoid mechanical damages.

This instrument is very low-level signal measuring instrument. To avoid electrical noise, it should be

separated from equipment that produce electrical noise. The instrument body must be connected to the

good ground against the electromagnetic disturbances. Load cell cable must be separated from other cables

especially from power cables if possible. If there are electrical noise-generating equipment such as heavy

load switches, motor control equipment, inductive loads etc., please pay attention against the EMC

interference and take all the prevention. Connect parallel reverse diodes to the DC inductive loads like relays,

solenoids etc. to minimize voltage peaks on the DC power lines.

4.1.2 Mechanical Installation Recommendations

You may install your weighing indicator on a column, on a table or on a wall. Take care of the housing

drawings and dimensions given in this manual to design your weighing scale or weighing station

mechanically.

4.1.3 Cabling Recommendations

All cables coming to the instrument must be of high quality and shielded. Distance from load cell cables,

interface cables and DC power supply cables to power line cables must be minimum 50 cm. The separate

cable tray usage for these low signal level cables is strongly recommended.

For cable connections of different thicknesses, as seen in Figure 4.1 there are 3 interlocking gaskets with

different diameters, indicated as B, C, and D, inside the glands used in the FT-111 weighing terminal.

Depending on the thickness of the cable, remove the gaskets B and C respectively, pass the cable through the

gland and tighten it. In this way, wires ranging in thickness from 4 to 8 mm can be easily connected to the

terminal using the same gland with the appropriate sealing combination.

To maintain the immunity of the device against electromagnetic interference, the cable shields should be

connected to the grounding pins inside the device, shown in Figure 4.2.

Figure 4.1- Seal combination and mounting of gland assembly

Figure 4.2 - Ground pins in FT-111 for cable shield grounding

E

C

D

A

FT-111, User Manual Rev. 2.0.0, June 2022 Page 16 of 137

Warning: Incorrectly closed back cover and poorly tightened glands may be unwanted results with loss of IP

4.1.4 Electrical Connection Recommendations

1. Always remember that FT-111 terminal is very low voltage measuring instrument used in the

industrial environment. Your proper installation increases the reliability and performance of the

instrument.

2. Only a trained person should interface the instrument due of the 230 VAC voltage in the instrument

and against malfunction at installation.

3. If the energy condition of your plant is not good enough, prepare a special power line.

4. The quality of your plant grounding will provide weighing accuracy and the safety of FT-111. If

grounding of your plant is not good enough, prepare a special power line and grounding.

5. Power off the instrument before connecting or disconnecting any peripheral instrument.

6. The shielded cable and ground connection of the shield will increase the immunity of FT-111 against

electrical disturbances. Shields of cables should be connected to the grounding pins in

FT-111.

7. All required electrical connections should be done as described in the installation section, page 17.

If you need to service the terminal, turn the power off and wait at least 30 seconds before opening

housing.

Location of the Peripheral Connections

The electrical terminals of the main board are shown in the 2 pictures below.

Figure 4.3 FT-111 main board

Load Cell

RS232-2 RS485

INT2 INT3

RS232-1

INT1

Power

230 VAC

Mini

USB

Calib.

DIP switch

Connectors of

optional board

Alibi

(Option)

J14, automatic

switch on.

(If short circuit)

Modbus

Ethernet

TCP/IP

FT-111, User Manual Rev. 2.0.0, June 2022 Page 17 of 137

Figure 4.4 FT-111D main board

4.2 INSTALLATION STEPS

Follow the steps below carefully to install the instrument.

Step 1: Preliminary Preparations

Before starting the installation,

1. Select the weighing terminal location. Refer to recommendations in the previous section.

2. Prepare the Protective Earth (PE) cable to grounding the FT-111 housing. The protective earth should

be as good as possible for scale reliability.

3. Prepare the required power source near the weighing terminal.

4. Prepare the cabling tray, pipe etc. from platform to the weighing terminal.

Step 2: Mechanical Installation

Be sure that the mechanical installation of the instrument is done properly for long time operation life and

suitable for the electrical installation as descripted below. Installations of the desk type and wall type

If you use the weighing terminal on a desk without additional mechanical hardware, place the instrument on

the desk. Go to the next step.

Digital

Load Cell

RS232-2 RS485

INT2 INT3

RS232-1

INT1

Power

230 VAC

Mini

USB

Calib.

DIP switch

Connectors of

optional board

Alibi

(Option)

J14, automatic

switch on.

(If short circuit)

Modbus

Ethernet

TCP/IP

FT-111, User Manual Rev. 2.0.0, June 2022 Page 18 of 137

Wall mounting

Dismounting the wall mounting kit before installation and follow the steps below.

Install the wall

mounting part of the

kit to the wall with 3

screws.

Install the holder of the

kit to the rear the

instrument with 4 pcs M5

x 15 mm screws.

Reassemble the wall

mounting kit as seen in

the picture.

Adjust the angle of

weighing terminal.

Wall mounting with 2D kit

Install the mounting kit to the

wall with 4 pcs screws.

Install the mounting kit to the

rear of the instrument with 4 pcs

M5 x 15 mm screws.

direction and angle.

Column mounting

Dismount the column mounting kit before installation and follow the steps below.

Install the small part of the kit

to the column.

Assemble the kit as seen in the

picture.

Install the weighing terminal to

the kit with 4 pcs M5 x 15 mm

screws.

65°

110°

120°

60°

FT-111, User Manual Rev. 2.0.0, June 2022 Page 19 of 137

Step 3: Open the Housing / Close the housing

Be sure that the mechanical installation of the instruments is done properly, and environment is convenient

to open the housing.

Open the housing from its rear. The rear part of the housing will be hanged to two stainless steel wires

connected to body.

Warning:

Incorrectly closed cover and poorly tightened glands may be unwanted result with loss of IP rating

and safety. Close the cover's bolts with minimum 1.5 Nm torque.

Step 4a: Analogue Load Cell Connection

To avoid damages, the load cell wiring should be made carefully before energizing the instrument. Load cell

connection detail is shown in Figure 4.6. In 4-wire installations the sense and excitation pins with the same

polarity should be short circuited at the connector side. If you have junction box in your system, use 6 wire

cable between FT-111 and the junction box, and short circuit these pins at junction box for better

performance.

Figure 4.5- Analogue load cell terminal

Figure 4.6 Analogue load cell and junction box connection

4 wire load cell connection

6 wire load cell connection

Junction box connection

Wiring between instrument and

junction box will be 6 wire.

FT-111, User Manual Rev. 2.0.0, June 2022 Page 20 of 137

Warning:Always connect Sense pins to Excitation pins for 4 wire connection. Non-connected sense pins may

cause the wrong Excitation voltage measurement and create an accuracy and instability problem.

Warning:Connect the load cell cable shield to the housing (recommended to increase the EMC immunity

against disturbances) or shield pin of the load cell connector.

Step 4b: Digital Load Cell Connection (Only FT-111 D)

The digital load cell wiring should be made carefully before energizing to avoid FT-111D and load cells from

damages. The instrument cable between the instrument, LPK24 Lightning protection kit and junction box

must be shielded and convenient for high speed RS485 interface. The wire diameter of the instrument cable

should be selected for maximum 0,5 volt drop between Junction box and LPK24 lightening protection kit.

Pin number (J2)

Definition

Description

1

A

+ RS485 for DLC interfacing

2

B

-RS485 for DLC interfacing

3

Gnd

Ground

4

Pin

Power input (from LPK24)

5

Pout

Power output (to load cells via LPK24)

6

PE

Protective Earth

Table 4.1

Imported Note:

Since the supply voltage of the digital load cell is isolated, its Ground (0 VDC) should NOT be connected to

another ground or PE-Protective Earth!!!

Figure 4.7 FT-111D, LPK24 and DLC connection with junction box

Figure 4.8 FT-111D, LPK24 and DLC connection without junction box

Other manuals for FT-111 Series

1

Table of contents

Other Flintec Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Pintek

Pintek hvp-40 instruction manual

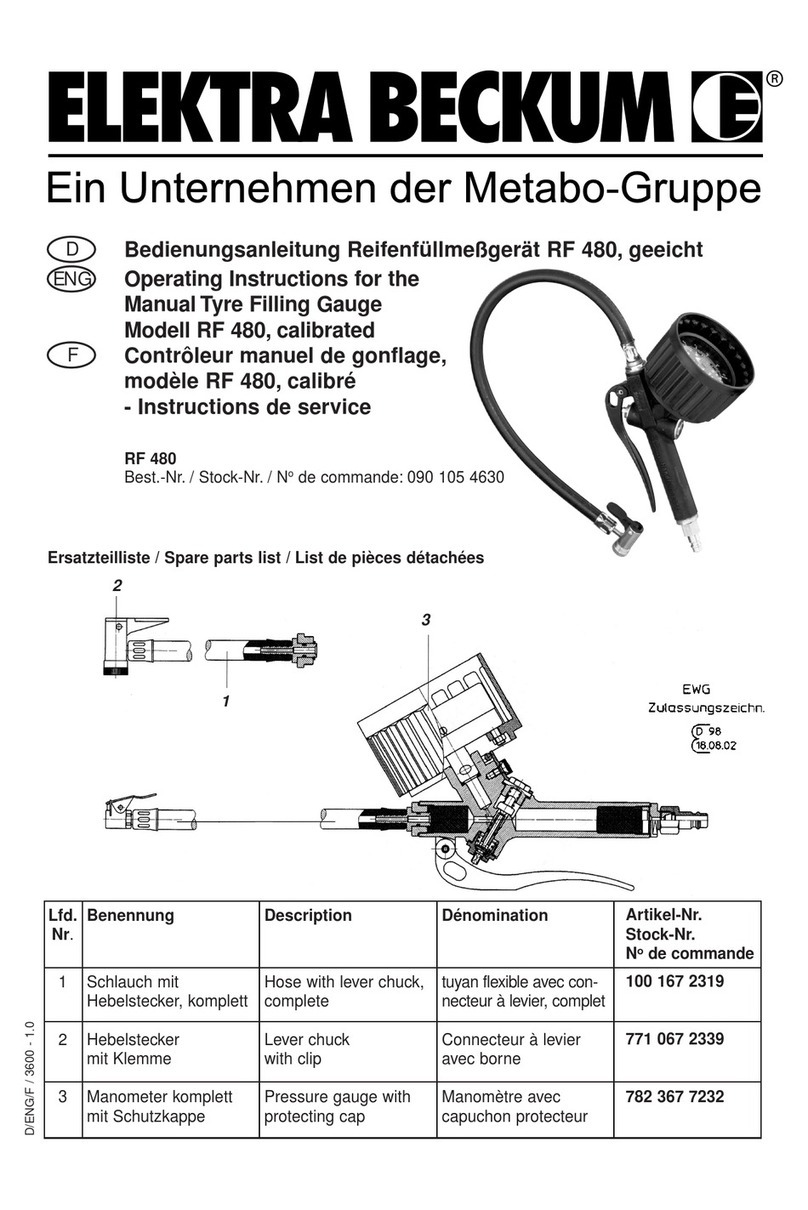

Metabo

Metabo Elektra Beckum RF 480 operating instructions

Morskate

Morskate DH 010 FPM Installation and operating instructions

Onicon

Onicon System-10 BTU Meter installation guide

OWL

OWL WaveSource Series Operation guide

Magnescale

Magnescale DK812S Series instruction manual