Flintec FT-30M User manual

Onboard Weighing | FT-30M | www.flintec.com

FT-30M

On-board Weighing Indicator

Installation +Operation Manual

11

E10R-059362

v1_000001_FT-30M 21/06/2016

Onboard Weighing | FT-30M | www.flintec.com

Table of Contents

About this Manual �������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������1

Introduction, Applications and Main Features��������������������������������������������������������������������������������������������������������������������������������������������������������2

Dimensions and Mounting Options����������������������������������������������������������������������������������������������������������������������������������������������������������������������������3

Installation���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 4-5

Technical Specification����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������6

Electrical Connections ������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 7-8

Accessories��������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������9

Accuracy and Performance�����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������10

Load Cells and Sensors���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������11

First Installation Set-up������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 12-13

Truck Modes���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������14

Graphic User Interface �������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 15

User Functions �����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������16

Set-up Functions������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 17

Calibration - Single Channel����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������18-19

Calibration - Dual Channel����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 20-23

Calibration - Twin Channel������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������24-27

Alarm and PPCO Settings ������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 28-29

Graphical User Interface -Load Mode��������������������������������������������������������������������������������������������������������������������������������������������������������������������� 30

Pickup Mode: Single Pickup per Customer Site ��������������������������������������������������������������������������������������������������������������������������������������������� 31-32

Pickup Mode: Multiple Pickups per Customer Site �������������������������������������������������������������������������������������������������������������������������������������� 33-34

Printed Ticket Templates �������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 35-36

Customer Lists �����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������37

USB Transfers������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 38

Essential Terms ��������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 39

Appendices

Quick Start Guide - Tippers & Bulk Haulage �������������������������������������������������������������������������������������������������������������������������������������������������� 40-41

Quick Start Guide - Waste Collection ��������������������������������������������������������������������������������������������������������������������������������������������������������������� 42-43

v1_000002_FT-30M 21/06/2016

1Onboard Weighing | FT-30M | www.flintec.com

About this Manual

Copyright

All rights reserved. No part of this document may be copied, reproduced, republished, uploaded, posted, transmitted,

distributed, stored or introduced onto a retrieval system in any form, or by any means (electronic, mechanical, photocopying,

recording or otherwise) whatsoever without prior written permission of Flintec AB or any of its subsidiaries.

Disclaimer

In order to improve design, performance and reliability, we reserve the right to make changes to the products contained in

this manual. The information in this manual is believed to be accurate in all respects at the time of publication, but is subject

to change without notice. Flintec AB, its subsidiaries or its distributors assume no responsibility for any consequences resulting

from the use of the information provided herein.

Software Versions

All Flintec instrumentation is subject to continuous improvement and updates. This manual covers FT-30M on-board

weighing indicator software versions from April 2016. If your instrument is a previous version and you require an upgrade to

the most current software, please visit the Flintec web site where the latest software update can be downloaded. Uploading

software updates is explained in this manual. Please note, some options may require additional hardware to function

properly.

Safety

This manual is intended for use by service technicians and operators responsible for installing and setting-up the Flintec FT-

30M on board weighing indicator. Failure to follow these instructions could result in damage to the indicator or injury.

Safety Precautions

Do not operate or work on this equipment unless you have read and understand the

instructions and warnings in this manual. Health and safety is your responsibility. Do

not use weighing indicator whilst driving.

Symbol Definitions

Indicates a potentially hazardous situation that, if not avoided could result in minor

or moderate injury, and includes hazards that are exposed when guards are removed.

Indicates information about procedures that, if not observed, could result in damage

to equipment.

Indicates an important procedure that must be followed to ensure correct set-up and

use.

warning

important

v1_000003_FT-30M 21/06/2016

2Onboard Weighing | FT-30M | www.flintec.com

Introduction

Product description

FT-30M is an on-board digital indicator with a clear and easy to read LED touch

screen display. It is designed for industrial road vehicles, trailers and agricultural

machines. It is modular plug & play, easy to install and use. It provides users with

precise weight information where and when it’s needed. It has two input channels for

separate groups of load cells. The RS485 and RS232 communications ports allows it

to integrate with PLC systems and devices such as printers.

Applications

The FT-30M is designed to work with a range of Flintec products and other makes of

load cells and sensors.

Fits neatly into spare radio slots, panel-mount or on the dash.

FT-30M is a simple to use on-board vehicle weighing indicator. Its easy-to-read full

colour LCD touch screen gives operators the power to control payloads, maximise

prots and avoid dangerous overloads. Simple on-screen menus mean drivers can

choose between Net, Gross, Percent, Collected or Delivered weights.

It’s packed with standard features such as on-screen customer identication, printing

and storing weighing transactions as well as high security anti-tamper pin code

protection and on-screen diagnostics. It’ s compatible with a range of accessory

devices for maximum vehicle utilisation and payload eciency. On screen calibration

makes set-up simple.

Key Features

Two overload alarm set-points

On-screen customer identication

Record collected or delivered loads

Print bin weights with time & date

Two channel mV input

High resolution RGB touch screen

Six languages. Kg or Lbs

Anti-tamper pin code protection

On-screen troubleshoot diagnostics

Versatile mounting options

Applications

Mines & Quarries

Cranes & Skip truck

Articulated

Semi-trailer

Dump truck

Sweepers & Spreaders

Tippers & Bulk

Waste & Recycling

Forestry & Logging

Hook loader

Agricultural

Light commercial

v1_000004_FT-30M 21/06/2016

3Onboard Weighing | FT-30M | www.flintec.com

Dimensions and Mounting Options

Versatile Mounting Options

The indicator is sized to t neatly into the spare radio DIN slot in vehicle cabs and be unobtrusive to the driver’s eld of vision. A RAM

swivel-mount option allows the indicator to be positioned and adjusted to suit in-cab conditions and the position of the driver. A

range of bracket accessories is available to adapt to any kind of installation. An IP68 enclosure option allows it to be tted outside of

the cab; e.g. on the side of the trailer.

Mounting Options

NOT TO SCALE

160

100

156 85 .5

11.5

120

RAM-Swivel Mount

59

RAM Swivel Dash

IP68 Waterproof Enclosure

Radio DIN Slot

Panel Mounted

v1_000005_FT-30M 21/06/2016

4Onboard Weighing | FT-30M | www.flintec.com

Installation

Radio DIN Mount Assembly

Industrial vehicles have spare radio slots for after market hardware

devices. The FT-30M is sized to t the DIN specication of radio slot.

A DIN radio kit comprises two ears, a zinc plated DIN cage, extraction

keys and screws.

In the truck cab, locate a suitable spare DIN radio slot. Remove the

existing cover plate. The DIN cage ts snugly into the opening right

up to the lip of the DIN cage. Before you push it in, pull the wiring

cables through the cage.

Once in place, use a small screwdriver or similar tool to pry down on

the securing tabs around the perimeter of the cage so they grip the

inside the opening. This will prevent the cage from slipping out or

tilting from the weight of the FT-30M.

The DIN cage is symmetrical, either way, top and bottom, left and

right. Some vehicles may already have an ‘ISO Mounting’, this means

the DIN cage is not required, the FT-30M will t snugly into the

opening without the cage.

Connect the power and signal connectors to the back of the FT-30M.

Screw the DIN mounting ears to the FT-30M using the Torx screws

provided.

Push the indicator in to the DIN cage until it snaps into position.

Remove the FT-30M using the two extraction tools, place the keys

into the slots located in either ear and press downwards so they grip

inside the ears, gently pull on the keys and the indicator pulls out.

RAM-Swivel Mount

Locate the most convenient place for mounting the indicator. When

attaching the RAM mount ensure sucient headroom, bear in mind

there will be cables wired into the back of the indicator, make sure to

allocate enough space for them. Device support manufacturers such

as RAM, Tallon and others supply an extensive range of RAM-Mount

and Tallon accessories.

Roof/ under dash mount RAM Mount for dashboard�

1/4 - 20 UNC Camera thread

v1_000006_FT-30M 21/06/2016

5Onboard Weighing | FT-30M | www.flintec.com

IP68 Waterproof Enclosure Mount

For externally mounted applications such as trailer-mounted or close to the loading

area on the rear of the truck. The IP68 mount allows access to the functions of the

indicator. The waterproof mount comprises an IP68 lockable enclosure with hinged

clear lid and rear anged mounts, a panel mount face plate and screws. Installers

are required to t cabling and drill cable entries to suit the application. Right angled

connectors are required at the rear.

Panel Mount

Where installers require tting into a panel, four M3 x 8 mm screws are required. The

template below shows the panel mount prole.

MSB Revision 19 April 2016

IP68 Waterproof enclosure mount

For externally mounted applications such as trailer-mounted or close to

the loading area on the rear of truck. The IP68 mount allows access to

the funtions of the indicator. The waterproof mount comprises an IP68

lockable enclosure with hinged clear lid and rear anged mounts, a panel

mount face plate and screws. Installers are required to t cabling and

drill cable entries to suit the application.

Stainless Steel Latch

132

244.5

216

170

177

FRONT VIEW BACK VIEW

Clear Polycarbonate Lid

225.5

222

101.6

8.5

Installation

5

Panel mount

Where installers require tting into a panel, four M3 x 8 mm long screws

are required. The template below shows the panel mount prole.

Panel mount cut-out

R 4.3

R 76.0

R 500

D 3.2 for M3

R1.0

R 22.5

130.4

41.0

MSB Revision 19 April 2016

IP68 Waterproof enclosure mount

For externally mounted applications such as trailer-mounted or close to

the loading area on the rear of truck. The IP68 mount allows access to

the funtions of the indicator. The waterproof mount comprises an IP68

lockable enclosure with hinged clear lid and rear anged mounts, a panel

mount face plate and screws. Installers are required to t cabling and

drill cable entries to suit the application.

Stainless Steel Latch

132

244.5

216

170

177

FRONT VIEW BACK VIEW

Clear Polycarbonate Lid

225.5

222

101.6

8.5

Installation

5

Panel mount

Where installers require tting into a panel, four M3 x 8 mm long screws

are required. The template below shows the panel mount prole.

Panel mount cut-out

R 4.3

R 76.0

R 500D 3.2 for M3

R1.0

R 22.5

130.4

41.0

Installation

v1_000007_FT-30M 21/06/2016

6Onboard Weighing | FT-30M | www.flintec.com

Technical Specification

The FT-30M on-board indicator for industrial vehicles and agricultural machines is designed to be easy to t and simple to operate,

giving the driver precise weight information where and when it is needed. It incorporates a clear and easy to read colour touch

screen display. It has two analogue input channels, an RS485 and RS232 input and output and two alarm set- points providing power

to external audio-visual alarm devices. It is housed in an ABS injection moulded housing.

Approvals & Regulations

The FT-30M is fully tested and certied for EMC compliance under the UN ECE R10 certication scheme. It is a United Nations

regulation and recognized by 51 countries. This standard covers eects of electro-magnetic interference on electrical equipment. It is

fully compliant with WLVTA (Whole Life Vehicle Type Approvals) by the UK VCA , this is a European Community regulation. The VCA is

the UK Government’s executive agency charged with responsibility to enforce EC compliance.

FT-30M has been extensively environmentally tested for shock loads and vibration under severe conditions at a registered testing

laboratory.

Power

Voltage input 9V to 32V DC

Consumption 100mA at 24V DC + external

loads

Max input current 4 Amps

Display

RGB touch screen. Format 480x169 dots

Operating temperature -20° C to +50° C

Brightness adjustable, high, medium or low

Analogue Inputs

2 independent channels

24 bit sigma-delta ADCs

Excitation 5V DC

Input 8 load cells per channel

8x 350 Ohms. 115 mA per channel

Max input signal: +/-19.0625mV

Input resistance: 120-1000Ohms

Sample Rate 10SPS

Resolution (ENB) 18 bits (19.5 bits)

Alarm Outputs

Alarm 1 supply voltage, high side switch

only

Alarm 2 supply voltage, high side switch

only

RS485 Serial

Baud Rate xed at 9600, n, 8,1 Connector

M12 - 4 pin (to be added)

RS232 Serial

Baud Rate xed at 9600, n, 8,1 Options:

Printer or Format protocol

Connector 9 way D connector

USB2

Enclosure

Housing material ABS

Total weight: 400 gr

Temperature Rating

-20° to +50° C

EMC classification

UN ECE R10.05

Internal Data Storage

65 Mb

Languages

En, De, Fr, Es, It, Pt

11

E10 R 05 9362

ww w. flintec.com

Model No: FT-30M

Serial No : 12345678

Connect to 9-32V supply. Refer to the installation manual before connecting.

WEEE mark

Quick reference (QR) code

This allows the Flintec FT-30M

service app to track software

changes�

CE Mark - laboratory tested

and complies with EMC

and environmental relevant

regulations�

United Nations Economic Commission for Europe (UNESCE) Regulation 10

Electro Magnetic Compliance (EMC) mark and Flintec approval number�

v1_000008_FT-30M 21/06/2016

7Onboard Weighing | FT-30M | www.flintec.com

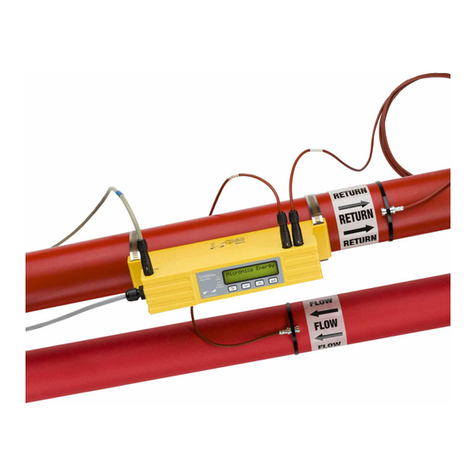

Electrical Connections

Reverse polarity and over-voltage protected. Input load cell and sensors should be

in the 0-3.5mV/V range with typical impedance values of 120Ω-1000Ω. A variety of

sensors comprising multiple pairs of load cells, extensometers, deection sensors,

air pressure sensors, encoders and fth wheel load cells can be connected. The two

channel input allows for applications comprising two separate bodied trucks or

sensors with dierent inputs to be calibrated separately and independently (twin) or

together (dual). The FT-30M MENU provides weighing data and user denable settings

and SET-UP MODE, a password protected menu for service engineers and supervisors

which includes alarm set points, calibrations and diagnostics.

M12 Electrical Connector

The modular M12 connector makes the

electrical installation quick and easy. A

range of versatile M12 accessories means

that combinations of load cells and

sensors to suit thousands of applications

are easily connected. Power and signal

connectors are key-wayed, gendered

and thumb tightened. Junction boxes

are internally wired in parallel for all

analogue systems.

Connections & Junction Boxes

Extender Cables

Flintec DSB7 on-board weighing load cells have a 5 meter MALE M12 cable as standard. Extender cables for longer reach applications

are available in 1, 3, 5, 7.5 and 10 metre lengths.

1. Input Channel ONE, Max +/-19.0625 millivolts

2. Input Channel TWO, Max +/-19.0625 millivolts

3. COM port 1 RS232 port for printers

4. Power Input 9-32 Volts DC & 2 Alarm power outputs

5. COM port 2 RS485 port for LDUs. (To be added in 2017)

6. Panel mount and radio DIN xing screws M3

7. 1/4” - 20 UNC camera mount to attach RAM-Mount 1”ball

8. DIN radio mount ear brackets - two required

Male - Female Extension Cable Junction Boxes

v1_000009_FT-30M 21/06/2016

8Onboard Weighing | FT-30M | www.flintec.com

Wiring Connections - Rear of FT-30M

MSB Revision 19 April 2016

Pin 1 BROWN + Excitation 5 Volts DC

Pin 2 WHITE + Signal milli-Volts from junction box &loadcells

Pin 3 BLUE - Excitation 0 Volts

Pin 4 BLACK - Signal milli-Volts from junction box &loadcells

SIGNAL channel 1 & 2, M12 Female

Pin 1 BROWN Vehicle volts12V (LCV) or24V (MCV & HGV)

Pin 2 WHITE Output 1 12Vor24V

Pin 3 BLUE Ground Ground 0 Volts (common)

Pin 4 BLACK Output 2 12Vor24V

POWER & ALARM, M12 Male

RS232 input and output, Male 9 pin Sub D

Pin 2 - Tx Transmit

Pin 3 - Rx Receive

Pin 5 - GND 0 Volts Ground

Pin 9 - Volts 12 Volts

Wiring connections - Rear of FT-30M

Connection examples

Electrical connections

8

SIGNAL channel 1 & 2, M12 Female Mini-DW

Pin 1 BROWN + Excitation 5 Volts DC

Pin 2 WHITE + Signal millivolts from junction box & load cells

Pin 3 BLUE - Excitation 0 Volts

Pin 4 BLACK - Signal millivolts from junction box & load cells

POWER & ALARM, M12 Male Mini-DW

Pin 1 BROWN Vehicle volts 12V (LCV) or 24V (MCV & HGV)

Pin 2 WHITE Output 1 12V or 24V

Pin 3 BLUE Ground Ground 0 Volts (common)

Pin 4 BLACK Output 2 12V or 24V

RS232 input and output, Male 9 pin Sub D

Pin 2 - Tx Transmit

Pin 3 - Rx Receive

Pin 5 - GND 0 Volts Ground

Pin 9 - Volts 12 Volts

Electrical Connections

Power to FUSED ignition live

Power to FUSED ignition live

6 way split junction box

Load cell wiring configuration� 2, 3, 4, 6 and 8 load cell or sensor combinations�

Air pressure transducer configuration with printer� XT50 + DSB7 with audible alarm

v1_000010_FT-30M 21/06/2016

9Onboard Weighing | FT-30M | www.flintec.com

Accessories

Accessories and Options

To enhance weighing system utility for any application, FT-30M is compatible with a range of recommend accessories and M12

cable-connector components.

THERMAL PRINTER

SIX POINT

JUNCTION BOX

FLASHING BEACON

FOUR POINT

JUNCTION BOX

ALARM SOUNDER

TWO WAY

JUNCTION BOX

FEMALE REWIRABLE

CONNECTOR

REVERSING

SOUNDER

EXTENDER CABLE

R/ANGLE FEMALE

CONNECTOR/CABLE

USB KEYBOARD

MALE REWIRABLE

CONNECTOR

R/ANGLE MALE

CONNECTOR/CABLE

• No ink cartridges

• Custom print

headers

• Plug and play

• Includes swivel

mount

• Compact

• Easy to use

• Plug and play

• 6 Watts - Low power

LEDs

• Bright and easily

seen

• Choice of colours

• 10-30V

• Easy to use

• Plug and play

• High volume

• Choose tone/ pitch • 8-35V terminal

connections

• Easy to use

• Plug and play

• For site use

• Fits any load cell

• High volume

• Fixed tone

• IP68

• 12-80V

• Waterproof

• Easy to use

• Plug and play

• For enclosures

• Where space is tight

• Easy to use

• Plug and play

• For site use

• Fits any load cell

• For enclosures

• Where space is tight

Print weight tickets straight from the cab. A 9

pin D cable connector plugs into the FT-30M. No

additional power lead is required.

Six point ‘splitter’ junction box connects six

load cell into one input port. It has the eect of

averaging the load cell signals.

Amber visual overload alarm. Red, Blue and white

are also available.

Four point‘splitter’ junction box connects four

load cell into one input port. It has the eect of

averaging the load cell signals.

Audible overload alarm. Tone and pitch

adjustable.

Two point ‘splitter’ junction box connects two

load cell into one input port. It has the eect of

averaging the load cell signals.

Also known as eld adaptors, the rewirable plugs

allow on-site eld repairs to be carried out.

Audible overload alarm.

Also known as home run cables, forms the

connection between the junction box and

indicator - also used for extending load cell

cables. Available in dierent lengths.

Extender cable with a right angled female

connector for tight spaces such as enclosures.

Enter customer names for printed weight tickets

and stored transactions.

Amber visual overload alarm. Red, Blue and white

are also available.

Extender cable with a right angled male

connector for tight spaces such as enclosures.

v1_000011_FT-30M 21/06/2016

10Onboard Weighing | FT-30M | www.flintec.com

Accuracy and Performance

Accuracy and Performance

This manual is primarily concerned with the installation and use of the Flintec FT-30M on board weighing indicator. Accuracy and

performance is dependent on the quality, type and installation quality of the load supporting load cells or sensors. The Flintec DSB7

range of vehicle weighing load cells are ideally suited. Please refer to the appropriate load cell installation manual for the load cells

installed. Optimum on-board weighing performance is obtained when the load cells are installed between the load-carrying body

(compactor body, tipper body, box, tank, at-bed, etc.) and the vehicle chassis and carrying the entire weight of the superstructure

and payload. No weight-supporting structure other than the load cells, such as braces or gussets should attach the superstructure to

the chassis; this will result in an alternate load-path that will degrade weighing system accuracy. Typical applications include: waste

trucks, tippers, tankers, at-beds and van type structures mounted on either truck chassis or trailer frame.

Truck bodies and payloads are supported above the chassis with load cells mounted directly to the truck frame (see example

illustrations below). This is usually accomplished by separating the suspension subframe from the body frame and installing load

cells between these structures. Air and uid pressure sensors, extensometers and other forms of secondary sensor are routinely tted

to vehicles. The FT-30M is compatible with any sensor with an output range up to 3.5 mV/V.

Applications

Installations are typically accomplished by separating the body frame from the chassis or trailer frame and installing load cells

between these typical vehicle structures;

MSB Revision 19 April 2016

Accuracy and Performance

This manual is primarily concerned with the installation

and use of the Flintec FT-30M on board weighing

indicator. Accuracy and performance is dependant

on the quality, type and installation quality of the load

supporting load cells or sensors. The Flintec DSB7 range

of vehicle weighing load cells are ideally suited. Please

refer to the appropriate load cell installation manual

for the load cells installed. Optimum onboard weighing

performance is obtained when the load cells are installed

between the load-carrying body (compactor body, tipper

and carrying the entire weight of the superstructure

and payload. No weight-supporting structure other

than the load cells, such as braces or gussets should

attach the superstructure to the chassis; this will result

in an alternate load-path that will degrade weighing

system accuracy. Typical applications include: waste

mounted on either truck chassis or trailers. frame and

installing load cells between these structures.

load cells between these typical vehicle structures;

Tipping Trailer

Under-body tipping arrangement

Tipping Trailer

Front end tipping arrangement

Load cell

Load cell

Load cell

Load cell

Load cell Load cell Load cell

Chassis

4 Axle Rigid Tipping Body

Load cell Load cell

Chassis

2/3 Axle Rigid Fixed Body

2/3 Axle Rigid Tipping Body

Waste/Garbage truck, boxed truck

Waste/Garbage truck, boxed truck

Load cell

Chassis

Load cell

Load cell

Chassis

Load cell

Load cell

Load cellLoad cell

Agricultural Machines

Accuracy & performance

Truck bodies and payloads are supported above the

chassis with load cells mounted directly to the truck

frame (see example illustrations below) are usually

accomplished by separating the suspension subframe

from the trailer frame and installing load cells between

these structures.

extensometers and (another secondry sensor).

Applications

Installations are typically accomplished by separating the

body frame from the chassis or trailer frame and installing

load cells between these typical vehicle structures;

Load cell

Agricultural Machines

Load pin

10

v1_000012_FT-30M 21/06/2016

11Onboard Weighing | FT-30M | www.flintec.com

Load Cells and Sensors

Load Cells and Sensors

FT-30M is compatible with any load cell or sensor with a strain gauge output including the new DSB7 range of high accuracy, high

capacity truck load cells 7.5t, 15t & 25t. Each IP68 load cell is tted with a 5 meter fully sealed M12 cable connector.

See www.intec.com for more details.

MSB Revision 19 April 2016

Load cell & Sensor inputs

Load cell - sensor type Why

DSB7 7.5t

16,000 Lbs

• Low profile, IP68

• High accuracy

• Stainless steel

• M12 connector 5M cable

• 300% overload capacity

Load supporting load cell for lighter commercial vehciles.

DSB7 15t

33,000 Lbs

• Low pro ile, IP68

• High accuracy

• Stainless steel

• M12 connector 5M cable

• 300% overload capacity

Load supporting load cell for moderate to heavy

industrial vehilces.

DSB7 25t

55,000 Lbs

• Low pro ile, IP68

• High accuracy

• Stainless steel

• M12 connector 5M cable

• 300% overload capacity

Load supporting load cell for heavy industrial vehicles

and fth wheels.

SBT 10t

• Alloy steel

• Nickel plated

• Moderate accuracy

• Flying leads - 10M cable

• 300% overload capacity

Load supporting load cell for moderate to heavy

industrial trucks.

XT50

• High gain extensometer

• IP68

• 500 micro strain capacity

Where load cells can’t be fitted or are not practical,

extensometers are used to measure stress on load

carrying beams to provide state of load on truck

axles, suspension systems and structural beams.

Custom load

pins - any size

• High capacity, IP69

• High accuracy

• Stainless steel

• M12 connector 5M cable

• 300% overload capacity

Load pins are used to measure loads at the point of a

linkage between two separate structural assemblies,

e.g. draw pins. Flintec load pins can be any size or

capacity.

PC5H

• High capacity, IP69

• High accuracy OIML C3

• Stainless steel

• 2,000 Kg Capacity

• 300% overload capacity

Wheel bin weighing load cell fitted to container

lifting hoists on waste refuse collection vehicles.

PC6H

• High capacity, IP69

• High accuracy OIML C3

• Stainless steel

• 2,000 Kg Capacity

• 300% overload capacity

Wheel bin weighing load cell fitted to container

lifting hoists on waste refuse collection vehicles.

PC2H

• High capacity, IP69

• High accuracy OIML C3

• Stainless steel

• 2,000 Kg Capacity

• 300% overload capacity

Wheel bin weighing load cell fitted to container

lifting hoists on waste refuse collection vehicles.

Pressure

sensors

• Air pressure sensors

• Fluid pressure sensors

For applications where pressure sensors are preferred

such as vehicle air pressure suspension systems -

typically 20 bar with a mV output. Hydraulic pressure

sensors on vehicles tend to be 150 bar, mV output.

Load cells and load sensors

FT-30M is compatible with any load cell or sensor with a strain gauge output and the new DSB7 range of high accuracy, high

capacity truck load cells 7.5t, 15t & 25t. Each IP68 load cell is tted with a 5 meter fully sealed M12 cable connector.

See www.intec.com for more details.

11

v1_000013_FT-30M 21/06/2016

12Onboard Weighing | FT-30M | www.flintec.com

First Installation Set-up

Power-on and First Set-up

Settings are entered on rst set-up or any time later. All settings can be changed. Turn ignition on, you will be asked to follow this setup

procedure. Access to a weighbridge is required. Calibration is performed by entering tare (unladen) weights whist stationary and on at

ground. Calibration is completed by loading the vehicle to its legal maximum and weighing the vehicle to obtain the Net Payload.

1� Language

Swipe up or down to select a language.

Press:

2� Time Zone

Swipe up or down to select a time zone.

Press:

3� Date Format

Swipe up or down to select a date format.

Press:

4� Date

Swipe up or down to select the date.

Press:

5� Time

Swipe up or down to select the time.

Press:

6� Weight Units

Swipe up or down to select a weight unit.

Press:

7� Single Channel Calibration

Begin Channel 1 calibration.

Press:

8� Tare

Weigh the unladen vehicle. (Tare weight)

Press to enter the Tare weight.

empty

Weighbridge: 12,580kg

v1_000014_FT-30M 21/06/2016

13Onboard Weighing | FT-30M | www.flintec.com

10� Tare mV/V

Conrm the Tare mV/V.

Press:

9� Tare Weight

Input the Tare weight. (12, 580kg)

Press:

12� Net Weight

Input the Net weight. (13, 420kg)

Press:

13� Net mV/V

Conrm the Net mV/V.

Press:

14� Calibration Done

The green tick conrms calibration.

Press:

15� Set Up Complete

Single Channel calibration is now complete.

Press:

16� Home

Home screen displays Gross weight by default.

Press: to toggle the Net Payload to be displayed.

11� Net

Weigh the fully laden vehicle. (Net weight)

Press: to enter the Net weight.

First Installation Set-up

Max Payload

Weighbridge: 13,420kg NET

*mV/V is the signal level from the load cells and must be stable.

Flickering indicates a problem with a load cell, connection or the load

is moving.

*mV/V is the signal level from the load cells and must be stable.

Flickering indicates a problem with a load cell, connection or the load is

moving. Values are different from the Tare mV/V.

*Tare + Net = Gross. (12,580 + 13,420kg = 26,000kg).

The gross weight is what’s displayed on the home screen by default.

v1_000015_FT-30M 21/06/2016

14Onboard Weighing | FT-30M | www.flintec.com

Truck Modes

Changing Modes

The truck mode can be changed in the menu by following the steps below. A choice between Single Channel, Dual Channel, Twin

Channel, Pick-Up or Delivery is available. Choose the mode best suited for your application. More detailed calibration and set-up guides

for each mode appear later in this manual.

6� Truck Modes

Enter the Truck Modes menu.

Press:

7� Select Mode

Swipe up or down to select the desired

Truck Mode.

Press

1� Home

Navigate to the menu.

Press:

2� Menu

Navigate through the User Functions.

Press:

3� Settings

Enter the Settings menu. (Pin code protected)

Press:

4� Pin code

Swipe up or down to enter pin code.

Press:

5� Calibration Settings

Enter the Calibration Menu.

Press:

or or

or or

v1_000016_FT-30M 21/06/2016

15Onboard Weighing | FT-30M | www.flintec.com

Graphic User Interface - Menu Map

Intuitive Touch screen Operation Software

For quick and easy navigation, a nger press or swipe gesture guides users through the graphic functions. Driver MENU settings allow

frequently used adjustments to be made. Critical MENU settings are pin code protected.

30860KG

User Functions Weight Display

User Menu

Home

Enter pin code

On

Off

Not activated/available (greyed out)

Set-up Menu

Home Screen

Alarm Bar

Net (N)

Gross (G)

Percent (%)

Load (L) kg or lb

Pin coded

Settings

Zero or Print

(or Alarm Mute)

Touch Screen

USB

v1_000017_FT-30M 21/06/2016

16Onboard Weighing | FT-30M | www.flintec.com

User Functions

User Functions and Settings

The FT-30M is congured & calibrated for the application. Not all functions are available, some require additional devices.

Faded button = function not available or out of range. Strike-through = not activated.

MENU

ALARM MUTED

PRINT

MOTION DETECT

BLEEP VOLUME

WARNING BAR

NET

ALARM SET-OFF

OFF-SITE DELIVER

HOME

BRIGHTNESS

ENTER

SETTINGS

PERCENTAGE

TIME

ALARM MUTED

ON-SITE PICK-UP

GROSS

iWHEEL

EXPLORE

ON-SITE DELIVER

ZERO

INFORMATION

LOAD COLLECT

ALARM SET-OFF

OFF-SITE PICK-UP

To access user functions. Will revert to HOME after 45 seconds of no activity.

RED ALARM has been triggered AND muted.

Print displayed weight. Press to PRINT.

Display shows‘----’ after 30 seconds of motion. Touch screen to display HOME.

Toggle between o, Low, Medium and High.

Amber means WARNING, the vehicle is close to its maximum legal load.

Red means OVERLOAD, maximum legal payload is reached. Unload the vehicle.

When gross weight reaches 80% of the amber weight, the warning bar shows

and increments by 2% to 100%.

NET is the weight of materials loaded on the vehicle. Press for Gross.

AMBER ALARM has been triggered. Press to mute.

Press when leaving site.

To go back to HOME screen.

Toggle between Low, Medium and High.

To accept a value.

To access passcoded settings menu.

Is the PERCENTAGE of GROSS weight. Press to view another weighing mode.

Press to adjust the time with the adjustment iWHEEL.

AMBER ALARM has been triggered AND muted.

Print & record collected loads. Arrive on site, press & select or enter a

customer name.

Total vehicle weight. Press to view another weighing mode.

To adjust the time or select a customer

Finger swipe to select setting. To accept press:

For next page or back a step. Quick scroll up and down using the iWHEEL.

Print & record delivered loads. Arrive on site, press & select or enter a

customer name.

Press to display ZERO. Max +/-300kg An empty truck may drift.

Press to view: Date & time. Serial no. Software version. Calibration time & date.

Tare and Gross. Alarm status & settings.

Press to record individual container or part loads from or to customer

sites. LOAD and SITE weights are added to NET.

RED ALARM has been triggered. Press to mute.

Press when leaving site.

v1_000018_FT-30M 21/06/2016

17Onboard Weighing | FT-30M | www.flintec.com

Set-up Functions

WEIGH SETTINGS

CALIBRATE CH2

WEIGHT MODES

LANGUAGE

PASSCODE RESET

OPTIONS

ALARM TEST

NET WEIGHT

SET DATE

UPDATE PRINT TICKETS

CALIBRATION

ZERO

COUNT-BY

TIME

USB SETTINGS

TRUCK MODES

RED ALARM

PERCENTAGE

DATE FORMAT

UPDATE CUSTOMER LIST

ALARM & PRINT

AMBER ALARM

GROSS WEIGHT

TIME ZONE

UPDATE SOFTWARE

KILOS OR LBS

PRINT SETTINGS

RESET SETTINGS

CALIBRATE CH1

DIAGNOSTICS

DOWNLOAD WEIGHTS

Access Modes, Kg, Lbs, Gross, Net, %, Count-by.

Press to enter Channel 2 calibration settings.

Weighing modes are Gross, Net, Percent.

Press to access language settings.

To change passcode.

Press for: Language, adjust time, diagnostics, reset, change password, update

software, change print ticket, get data les.

Amber alarm test. OP1 will be set (on power and alarm).

NET is the weight of materials loaded on the vehicle. Press activate/deactivate.

Set the current day, month and year.

Upload print ticket styles.

Calibration settings.

Press to remove zero oset.

Count-by: 1, 10, 20, 50, 100, 200.

Press to access Time Zone, Date, Time and Date Format.

To access USB functions.

Press for truck modes. E.g. Single, Dual or Twin channel or Pick up or Delivery.

RED ALARM is ON, Press to access setting. RED ALARM is OFF.

Is the PERCENTAGE of GROSS weight. Press activate/deactivate.

Choose from: DD-MM-YYY, MM-DD-YYY or YYYY-MM-DD.

Upload customer lists to the FT-30M.

Press for Alarm and Print settings.

AMBER ALARM is ON, Press to access setting. ALARM is OFF.

Total vehicle weight. Press activate/deactivate.

Press to to access Time Zone.

Update FT-30M software from a memory stick.

Toggle for Kilograms or Pounds.

Press to turn printer On or O.

Resets to factory or to new install settings - exercise caution - should be done

by competent person.

Press to enter Channel 1 calibration settings.

Displays analogue to digital counts.

Download weighing transactions to the USB memory stick.

v1_000019_FT-30M 21/06/2016

18Onboard Weighing | FT-30M | www.flintec.com

Calibration - Single Channel

Calibration

If calibration was not completed in the rst set-up, or needs subsequent adjustment follow these steps. Access to a weighbridge is

required. Calibration is performed whilst stationary and on at ground by entering tare (unladen) weights. Calibration is completed by

loading the vehicle to its legal maximum and weighing the vehicle to obtain the Net Payload.

1� Home

Navigate to the menu.

Press:

2� Menu

Navigate through the User Functions.

Press:

3� Settings

Enter the Settings menu. (Pin code protected)

Press:

4� Pin code

Swipe up or down to enter pin code.

Press:

5� Calibration Settings

Enter the Calibration Menu.

Press:

6� Calibration - Channel 1

Begin Channel 1 calibration.

Press:

7� Tare

Weigh unladen vehicle. (Tare weight)

Press to enter the Tare weight.

8� Tare Weight

Input the unladen (Tare) weight. (13, 450kg)

Press:

Weighbridge: 13,450kg

*previous

calibration figured

are displayed.

v1_000020_FT-30M 21/06/2016

Table of contents

Other Flintec Measuring Instrument manuals