Flintec FT-150 User manual

FT-150

Weighing Terminal

Truck Scale User Manual

FT-150 Truck Scale Rev.1.1.0 User Manual, October 2022 Page 2of 75

Table of Contents

1Introduction...............................................................................................5

1.1 Disclaimer .....................................................................................................................5

1.2 Safety Instructions......................................................................................................6

1.3 Overview .......................................................................................................................7

1.4 Specifications...............................................................................................................8

1.5 Housing........................................................................................................................10

2Main Screen and Softkeys....................................................................11

2.1 Softkeys.......................................................................................................................12

3INSTALLATION ........................................................................................14

3.1 Rekommandation .....................................................................................................14

3.1.1 Environment..........................................................................................................................................................14

3.2 Mechanical Installation Rekommandation .........................................................14

3.2.1 Cabling Rekommandation................................................................................................................................15

3.2.2 Electrical Connection Rekommandation .....................................................................................................15

3.3 Installation Steps.......................................................................................................18

3.4 Cleaning...................................................................................................................... 24

3.5 Disposal......................................................................................................................24

4FT-150 Functions.................................................................................. 25

4.1 Overview .................................................................................................................... 25

4.2 Login, Password ....................................................................................................... 25

4.3 Weighing ....................................................................................................................28

4.3.1 First Weighing......................................................................................................................................................28

4.3.2 Second weighing.................................................................................................................................................30

4.4 Home Screen Softkeys.............................................................................................31

4.4.1 Tables......................................................................................................................................................................31

4.4.2 Ticket Setup..................................................................................................................................................... 32

4.4.3 Vehicle...............................................................................................................................................................38

4.4.4 Records.............................................................................................................................................................39

5Setup Menu............................................................................................42

5.1 Scale Setup ................................................................................................................43

5.1.1 1st. Scale Setup....................................................................................................................................................43

FT-150 Truck Scale Rev.1.1.0 User Manual, October 2022 Page 3of 75

5.2 Calibration..................................................................................................................48

5.2.1 Full Calibration.....................................................................................................................................................49

5.2.2 Linearity Calibration:..........................................................................................................................................49

5.2.3 Adjustment...........................................................................................................................................................50

5.2.4 Electronic Adjustment..................................................................................................................................50

5.3 Metrological Settings .............................................................................................. 52

5.4 Alibi Memory............................................................................................................. 53

5.5 Scale Status...............................................................................................................54

5.6 Application Setup.....................................................................................................54

5.6.1 Select Application...............................................................................................................................................54

5.6.2 Database...............................................................................................................................................................55

5.6.3 Programm Setup................................................................................................................................................ 57

5.6.4 Deleting Records............................................................................................................................................58

5.7 System Setup ............................................................................................................58

5.7.1 Screen Setup........................................................................................................................................................59

5.7.2 Region / Language Setup ................................................................................................................................59

5.7.3 Interface Setup....................................................................................................................................................60

5.7.4 Display Setup.......................................................................................................................................................63

5.7.5 Web Service..........................................................................................................................................................63

6Users Setup ............................................................................................64

7Diagnostic...............................................................................................65

7.1 Signal Test..................................................................................................................65

7.2 Serial Port Test..........................................................................................................65

7.3 Remote Connection.................................................................................................66

7.4 Log Records............................................................................................................... 67

7.5 I/O Test....................................................................................................................... 67

7.6 Versions...................................................................................................................... 67

8Backup / Restore ..................................................................................68

8.1 Logo File.....................................................................................................................68

8.2 Backup........................................................................................................................68

8.3 Restore........................................................................................................................69

8.4 Factory Default.........................................................................................................69

9SEALING OF APPROVED SCALE.........................................................69

FT-150 Truck Scale Rev.1.1.0 User Manual, October 2022 Page 4of 75

10 TROUBLESHOOTING.............................................................................70

11 .................................................71

11.1 Digital I/O Board Funktion......................................................................................71

11.2 Installation of Digital I/O Board.............................................................................72

12 Appendix 2: Data Transfer Programs ..............................................74

12.1 Data Editor Program............................................................................................... 74

12.2 Web Service............................................................................................................... 74

FT-150 Truck Scale Rev.1.1.0 User Manual, October 2022 Page 5of 75

1Introduction

1.1 Disclaimer

All rights reserved.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any

form or by any means, mechanical, photocopying, recording, or otherwise, without the prior written

permission of Flintec.

No patent liability is assumed with respect to the use of the information contained herein. While every

precaution has been taken in the preparation of this book, Flintec assumes no responsibility for errors

or omissions. Neither is any liability assumed for damages resulting from the use of the information

contained herein.

The information herein is believed to be both accurate and reliable. Flintec, however, would be

obliged to be informed if any errors occur. Flintec cannot accept any liability for direct or indirect

damages resulting from the use of this manual.

Flintec reserves the right to revise this manual and alter its content without notification at any time.

Neither Flintec nor its affiliates shall be liable to the purchaser of this product or third parties for

damages, losses, costs, or expenses incurred by purchaser or third parties as a result of: accident,

misuse, or abuse of this product or unauthorized modifications, repairs, or alterations to this product,

or failure to strictly comply with Flintec operating and maintenance instructions.

Flintec shall not be liable against any damages or problems arising from the use of any options or

any consumable products other than those designated as Original Flintec Products.

NOTICE: The contents of this manual are subject to change without notice.

FT-150 Truck Scale Rev.1.1.0 User Manual, October 2022 Page 6of 75

1.2 Safety Instructions

CAUTION: READ this manual BEFORE operating or servicing this equipment.

FOLLOW these instructions carefully. SAVE this manual for future reference. DO

NOT allow untrained personnel to operate, clean, inspect, maintain, service, or

tamper with this equipment. ALWAYS DISCONNECT this equipment from the

power source before cleaning or performing maintenance.

CALL Flintec for parts, information, and service.

WARNING: Only permit qualified personnel to service this equipment. Exercise

care when making checks, tests and adjustments that must be made with

power on. Failing to observe these precautions can result in bodily harm.

WARNING: For continued protection against shock hazard connect to properly

grounded outlet only. Do not remove the ground prong.

WARNING: Disconnect all power to this unit before removing the fuse or

servicing.

WARNING: Before connecting/disconnecting any internal electronic

components or interconnecting wiring between electronic equipment always

remove power and wait at least thirty (30) seconds before any connections or

disconnections are made. Failure to observe these precautions could result in

damage to or destruction of the equipment or bodily harm.

CAUTION: Observe precautions for handling electrostatic sensitive devices.

FT-150 Truck Scale Rev.1.1.0 User Manual, October 2022 Page 7of 75

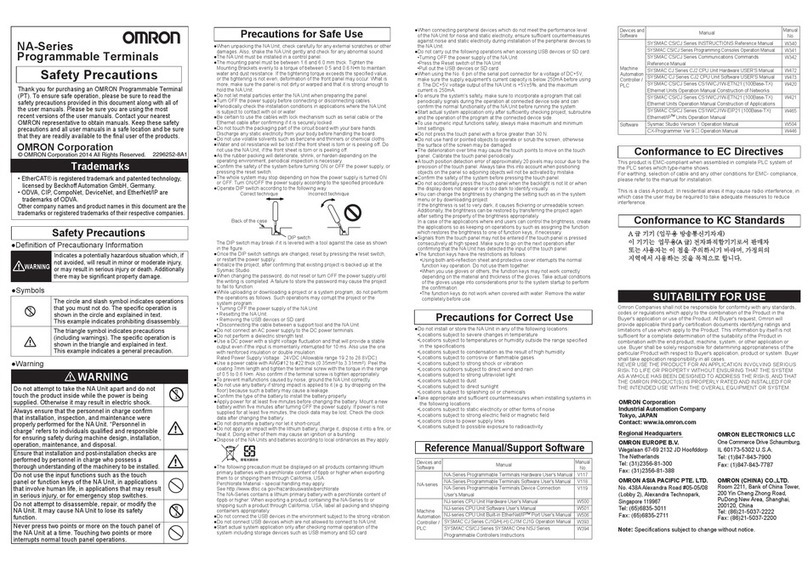

1.3 Overview

FT-150 Truck is a state-of-the-art, OIML type-approved weighing terminal that offers economical

and powerful solutions for all kinds of truck scale applications consisting of analogue load cells,

thanks to its special software and hardware developed for truck scales.

FT-150 Truck, with a digital I/O card offered as an option, provides the feature to control traffic lights

and barriers at the entrances and exits of the truck scale with position sensor inputs. Its wide range of

interfaces and powerful software provides a seamless connection to peripheral devices, such as

external display, RFID / Barcode reader, PC, keyboard, label printer, etc., and data transfer to USB

memory, backup, and restore facilities.

FT-150 H version has IP67 protection class, and it is designed for harsh industrial conditions. Thanks

to this feature, it offers the most suitable usage solutions in all kinds of industrial environments.

A typical truck scale application, using the digital input and output option, is shown in the figure

below.

Figure2.1-Truckscaleapplication

This technical manual details the FT-150 Truck features, installation, and how to use it. While the

common features of FT-150 Truck and FT-150H Truck terminals are explained in the manual, the

names of both terminals will not be written separately, but only as FT-150 Truck.

Those who will install and & or operate the FT-150 Truck should read this document before installation

and operation and know the system. Saving this manual for future reference is highly recommended.

FT-150 Truck Scale Rev.1.1.0 User Manual, October 2022 Page 8of 75

1.4 Specifications

Analogue Load cell

A/D converter type

24-bit Delta-Sigma ratio metric with integral analog and digital filters

Conversion rate

Up to 800 measurement values per second

Input sensitivity

0,4 μV/e approved; 0.05 μV/e non approved.

Analog input range

-5 mV to +19 mV

Internal resolution

up to 16 000 000

Excitation

5 VDC max. 125 mA

Number of load

cells

Up to 8 load cells (350 Ω) or 24 load cells (1150 Ω)(min. 43 Ω)

Connection

4- or 6-wire technique.

Home cable length: maximum 1000 m/mm² for 6-wire connection between

FT-150 Truck and junction box.

Scale

Accuracy class &

EU type approval

OIML class III, single-interval, multi-range, or multi-interval up to 10.000

division

Operating system

WinCE6.0

Display

-glare, 800x400 pixel, colour LCD Touchscreen

Display resolution

Up to 500 000

Platform

A truck scale platform equipped with the strain gage-based analogue load

cells can be connected to FT-150 Truck.

Alibi Memory

(Option)

20900 records

Calibration and Functions

Calibration

Full calibration (zero and gain)

Linearity Correction

Zero adjustment,

Gain adjustment

eCal electronic calibration without test weights,

Digital filter

5 steps programmable adaptive filter

Weighing functions

Taring, zeroing, auto zero tracking, motion detection, auto zero at power up,

tare status saving at power off, increased resolution, automatic tare and clear,

temporary gross indication, unit change.

Standard

Application

Truck scale, basic weighing

FT-150 Truck Scale Rev.1.1.0 User Manual, October 2022 Page 9of 75

Communication

Connectable with

PC, printer, Remote display, EPL printer, RFID / Barcode reader, etc.

Parallel-Port

Centronics Parallel Port, DB-25 Connector for printer connection

RS 232

Port

2 x galvanically isolated, 3 wire

Baud Rate

1200 to 115200 programmable, default 9600

Data

Length 7 or 8 bits; parity even, odd or none

Ethernet

TCP/IP

Transmission

rate

10 / 100 Mbit/s, Full duplex

TCP/IP

settings

Manual IP assign over EtherX PC Software or by keys in programming

mode

Connection

method

Server or Client

Installation

Switched Ethernet transmission with shielded twisted pair cables and RJ-

45.

Isolation

Galvanically isolated bus electronics

Response

speed

Max. 4 ms response delay after read/write commands

USB

Connection

Standard USB 1.1

Response

speed

Max. 4 ms response delay after read/write commands

Digital Inputs and Outputs (option)

Digital Inputs

Opto-isolated 4 digital inputs, 12 to 28 VDC, 10mA

Digital Outputs

4 free relay contact, 250 VAC or 30 VDC, 0.2A

Power Consumption

100 240 VAC 50-60 Hz max. 25 mA or

12 28 VDC max. 250 mA

Environment and Enclosure

Operation temp. range

Approved scales

Industrial usage

-15 °C to +55 °C

-10 °C to +40 °C

Humidity

Approved scales

Industrial usage

80% RH max, non-condensing

90% RH max, non-condensing

Enclosure

Stainless steel

Protection

IP30 for FT-150 Truck,

IP67 for FT-150H Truck

Sizes ( W x H x D )

FT-150 Truck

: 245 x 190 x 75 mm

FT-150H Truck

: 249 x 238 x 75 mm

FT-150 Truck Scale Rev.1.1.0 User Manual, October 2022 Page 10 of 75

1.5 Housing

FT-150

FT-150 Truck and FT-150H Truck weighing terminals technical drawings and dimensions are shown

below. Side view dimensions of FT-150 and FT-150H Truck weighing terminals are the same.

Figure 1-1

Figure 1-2

FT-150 Truck Scale Rev.1.1.0 User Manual, October 2022 Page 11 of 75

2Main Screen and Softkeys

After the FT-150 Truck weighing terminal is energized and logged in, the Main Screen in Figure 3.2

appears, where the truck weighs is performed. The Main Screen consists of 3 different sections, as

seen in the figure.

Weight Display

This section contains the weighing-related info such as weight value, gross or net, etc.

Info display & HMI

This section is used as an information display and HMI for vehicles. In this section, there are text

boxes where the license plate numbers are entered, the vehicle with code and the first weighed

vehicle plates are displayed, the "LIST" softkey that brings the list of these vehicles, and the "OKAY"

softkey to confirm the operation.

Softkeys

The soft keys in this section are to perform a function or to access another menu. Softkey

configuration may change according to the selected menu.

The meanings of the symbols on the weight display are.

Gross

Indicates that the weight on the display is the gross weight.

kg

Indicates that the selected weight unit is kg. Selectable weight

units: g, kg, t, lb, klb.

Indicates that the weight is in the zero range.

Indicates that the scale is not stable. This symbol disappears

after the scale is stable.

Indicates the number of ranges of the FT-150 Truck weighing

terminal.

Figure 2-1

Weight Display

Info Display &

HMI

Softkeys

Figure 2-2

FT-150 Truck Scale Rev.1.1.0 User Manual, October 2022 Page 12 of 75

Indicates that the scale is OIML approved and its accuracy

class.

xx

weighing display indicates the maximum capacity set for the

Refer to 5.6.1

xx

weighing display indicates the minimum capacity set for the

Refer to 5.6.1

x

display section indicates the scale interval set for the scale in

Refer to 5.6.1

The number (1) on the balance icon indicates that one

weighing platform is connected to the FT-150 Truck weighing

terminal. Only one weighing platform consisting of analog

load cells can be connected to the FT-150 Truck weighing

terminal.

An external scale can be connected to the FT-150 Truck

weighing terminal via RS232 serial output. The number 3 on

the balance icon identifies the external balance.

Indicates the software version of the FT-150 Truck weighing

terminal. The version in the example is v01.12.

2.1 Softkeys

The function of the softkey can be understood intuitively. When the softkey is clicked, its background

colour changes to light blue to indicate that its function is executed.

The function of the softkey is not active for the user logged on.

The function of the softkey is active but not executed.

The function of the softkey is being executed.

-purpose softkeys are explained below.

Other softkeys are explained in the releted sections.

FT-150 Truck Scale Rev.1.1.0 User Manual, October 2022 Page 13 of 75

Zero drift is compensated by this softkey.

It is used for two purposes, depending on the current screen:

1- To enter the data into the database,

2- To recall the data from the database.

It is used to save frequently incoming vehicles and their data, and to bring up the

vehicle list.

It is used to access the weighing records.

It is used to get the ticket printout.

It is used to log out of the current session and log in with another code or name.

It is used to increase the resolution 10 times.

It is used to download a labelfile from the USB memory to the FT-150 Truckweighing

terminal or to copy the existing label file to the USB memory.

It is used to access the ticket setup menu. Refer to Chapter 4.3.2

It is used to access the Setup menu. Refer to Chapter 5

It is used to turn the device off and on again.

Turn off key

It is used to weigh without logging in.

It is used to enter alphanumeric information.

It is used to save the data entered or weighing result.

"Edit" key is used to make changes to a record.

FT-150 Truck Scale Rev.1.1.0 User Manual, October 2022 Page 14 of 75

It is used to add a record.

"Delete" key is used to delete a record.

These keys are used to move to the next, previous screen,

navigate through records or pages.

3INSTALLATION

IMPORTANT: Read this section carefully before the installation of the instrument. Applying the

recommendations in this section will increase your system reliability and its long-term performance.

3.1 Rekommandation

3.1.1 Environment

Ensure that the environment where the FT-150 Truck weighing terminal will operate is clean and that

the device is mounted in a way not exposing to direct sunlight if possible.

The ambient air temperature should be -10°C to +40°C for approved scales ( -15°C to +55°C for

unapproved scales), and the non-condensing humidity should be 80 %.

All external cables should be installed to avoid mechanical, chemical, or thermal damage.

The electronic systems used in open areas such as truck scales or in industrial environments are

highly susceptible to electrical noise-generating and damaging effects such as lightning strikes,

electrostatic discharge, high-power power lines and switches, motor control equipment, inductive

loads, etc.

Making a quality grounding in accordance with the current industry standards is very important to

prevent the truck scales from being damaged due to the above-mentioned effects and to ensure

stable and reliable operation.

Protection measures should also be taken against overvoltage surges coming from the mains and

lightning strike. For this purpose, Flintec´s LPK24 lightning protection unit can be used. LPK24

protects the weighing system from high voltage by connecting it in parallel to the mains input.

3.2 Mechanical Installation Rekommandation

FT-150 Truck weighing terminal can be installed on to a column, a desk, or a wall. Take care the

housing drawings and dimensions given in this manual to design your weighing scale or weighing

station mechanically.

FT-150 Truck Scale Rev.1.1.0 User Manual, October 2022 Page 15 of 75

3.2.1 Cabling Rekommandation

FT-150 Truck weighing terminal is very low-level signal measuring instrument. For this reason,

necessary precautions should be taken to prevent the disruptive effects of electrical noises and

electromagnetic interferences on the weighing system. In this context, the FT-150 Truck should be

separated from equipment producing electrical noise, and all cables coming to the instrument should

be high quality and shielded.

The instrument body must be connected to the good ground against the electromagnetic

disturbances. Load cell cable should be separated from other cables especially from power cables if

possible. If there are electrical noise-generating equipment such as heavy load switches, motor

control equipment, inductive loads etc., please pay attention against the EMC interference and take

all the prevention. Connect parallel reverse diodes to the DC inductive loads like relays, solenoids etc.

to minimize voltage peaks on the DC power lines.

Distance from load cell cables, interface cables and DC power supply cables to power line cables

should be minimum 50 cm. The separate cable tray usage for these low signal level cables is strongly

recommended.

All cables coming to the control cabinet should be grounded. The cables shield should be grounded to

their glands or connected to the grounding pins of the related connectors.

3.2.2 Electrical Connection Rekommandation

Make the cable connections of the mains, load cells, and peripheral devices with the FT-150 Truck

according to the following instructions.

1. Since the device works with 230 VAC supply, only trained persons should make the electrical

connections of the device. Intervention by untrained persons may cause some undesired

damage or injury.

2. Power off the instrument before connecting or disconnecting any peripheral instrument.

3. If you need to service the terminal, turn the power off and wait at least 30 seconds before

opening housing.

4. Remember, the FT-150 Truck weighing terminal is a very low voltage measuring device.

Correct installation will ensure reliable and stable operation of the device.

Cables and Junction Box

5. Using a shielded cable and grounding the shield will increase the device immunity against

electrical disturbances (interference). Connect the cable shield to the gland, or the grounding

pin of the related terminal.

6. The cable between the junction box and the FT-150 Truck must be shielded, and the shield of

the cable must be connected to the grounding screw of the box on the junction box side and

to the relevant grounding connection on the FT-150 Truck side.

7. The shields of the serial interface cables must be connected to the ground connection at the

FT-150 Truck side and must be left open at the other side.

8. If a communication connection is made to the weighing system electronic equipment (such

as FT-150 Truck or a computer) from a device that is not powered from the weighing system

group socket, the connection must be signal isolated.

9. Do not use low-quality cables. Ensure that the cables have sufficient thickness, high quality,

and high-quality shield. It is recommended to use load cell and communication cables

specially produced by Flintec.

10. Use junction box with lightning protection and special grounding screw.

FT-150 Truck Scale Rev.1.1.0 User Manual, October 2022 Page 16 of 75

11. Power line connection and grounding

12. Protection measures should also be taken against overvoltage surges coming from the

mains and lightning strike. For this purpose, Flintec´s LPK24 lightning protection unit can be

used. LPK24 protects the weighing system from high voltage by connecting it in parallel to

the mains input.

13. If the mains voltage and grounding at the facility are not suitable for the device, lay a

dedicated line with appropriate mains voltage to power the device and make a proper

grounding.

14. The facility grounding quality is very important for the accuracy of the weighing and the

safety of the device. Do not use the facility grounding unless it is specially made considering

the scale located outside the building or if the company or country does not have a specific

restriction for grounding.

15. Within whole power system, it is a MUST to apply only one protecting method, either

methods is not allowed.

16. If the neutralized protection method is applied to the weighing system, a sole neutral line

should be considered. No other electrical device is allowed to use this line.

17. For devices other than the weighing system devices in the weighing room, such as the air

conditioner, another residual current protective device should be installed in the cabinet.

18. ONLY connect weighing instruments to the group socket of the scales

Figure 3-1

19. If a safe power supply such as UPS is utilized, the voltage protector must be connected

between the safe power supply and mains.

Figure 3-2

20. Weighing system grounding: If the distance between the weighing room and the weighing

platform is more than 15 meters, lay a metal conduit and pass the cables between the

weighing room and the scale through it. Connect all the grounds of the weighing equipment

to this metal conduit.

21. All weighing system equipment enclosures must be connected to the ground to protect the

22. person from electric shock.

FT-150 Truck Scale Rev.1.1.0 User Manual, October 2022 Page 17 of 75

Figure 3-3

The inputs and outputs of the FT-150 Truck and FT-150H Truck weighing terminals are shown in the

figure below.

FT-150 Truck

FT-150 H Truck

Figure 3-4

FT-150 Truck Scale Rev.1.1.0 User Manual, October 2022 Page 18 of 75

3.3 Installation Steps

Follow the steps below carefully to install the FT-150 Truck weighing terminal.

Step 1 : Preliminary Preparations

1. Make the following preparations, considering the recommendations in section 3.1.1

2. Select the most suitable place to install the weighing terminal.

3. Prepare the Protective Earth (PE) cable for grounding the FT-150 housing. The grounding

quality is very important in terms of the safety of the user and the reliability of the weighing

system.

4. Prepare the electrical power supply connection near the weighing terminal.

5. Prepare the conduit, cabling tray, etc. from the platform to the weighing terminal.

Step 2: Mechanical Installation

FT-150 Truck weighing terminal can be used as a desktop, or wall-mounted or column mounted

thanks to its tilt stand. The FT-150 Truck weighing terminal can be mounted on the wall using the

holes in the four corners of the tilt stand and suitable fasteners. It can also be attached to a column

with the screw holes in the middle of the tilt. The tilt stand allows the device to be used on the desk

without fasteners. If need be, the FT-150 Truck terminal can be fixed to the desk via the holes in the

four corners of the tilt stand.

FT-150 Truck

FT-150H Truck

Figure 3-5

Step 3: Opening the rear cover plate

CAUTION: Only authorized persons should open the rear cover plate of the device.

CAUTION: Before opening the rear cover plate of the device, turn off the device, unplug the power

cord and wait 30 seconds.

To connect the load cells and digital inputs cables, and to access the calibration switch the rear cover

plate of the device must be opened. Open the rear cover plate by removing the 7 screws for FT-150

Truck, 8 screws for FT-150H Truck, shown in Figure 3-4.

FT-150 Truck Scale Rev.1.1.0 User Manual, October 2022 Page 19 of 75

Step 4: Analog Load Cell Connection

The load cell connection must be made carefully before energizing the device to avoid damaging the

load cell and the device. Load cell connection details are shown in Figure 3-6.

Junction box connection

Wiring between the instrument and the

junction box will be 6 wires.

Figure3-6

IMPPORTANT:Usinga6-wirecablebetweentheFT-150TruckandtheJ-Boxandmakingtheexcitation

and sense terminals with the same polarity a short circuit in the junction box will provide better

performance. Non-connected sense pins may cause the wrong Excitation voltage measurement and

create an accuracy and instability problem

IMPPORTANT: It is recommended to connect the load cell cable shield to the housing or shield pin of

the load cell connector to increase the EMC immunity against electromagnetic disturbances.

To connectthe load cell cabletothe FT-150/FT-150HTruckweighingterminal,followthestepsbelow.

FT-150 Truck

1. Open the FT-150 Truck rear plate by removing the 7 screws as shown in Figure 3-7/1.

2. To remove the plate covering the load cell connector, remove the 3 screws marked in Figure

3-7/2.

3. Install the load cell cable through the gland towards the load cell terminal, as shown in Figure

3-7 /3.

4. Connect the load cell cable to the load cell terminal, as shown in Figure 3-7/ 4.

FT-150H Truck

1. Open the FT-150H Truck rear plate by removing the 8 screws as shown in Figure 3-7/5

2. To remove the plate covering the load cell connector, remove the 3 screws marked in Figure

3-7/6.

3. Install the load cell cable through the gland towards the load cell terminal, as shown in Figure

3-7 /3.

4. Connect the load cell cable to the load cell terminal, as shown in Figure 3-7/ 4.

FT-150 Truck Scale Rev.1.1.0 User Manual, October 2022 Page 20 of 75

1

2

3

4

5

6

Figure3-7

Step 5: RS 232C Serial Ports

FT-150 Truck has 2 x RS232C serial ports, which are galvanically isolated from other circuitry to

increase the EMC immunity. RS232C serial ports are defined as COM1 and COM2 in the "Interface

setup" menu. Technical specifications of these serial ports are given in Table 4.1, and their positions

on the devices and pinouts are given in Figure 3-8.

Usage

Interfacing with printer, PC, remote display, card reader

Data formats

Continuous, Printer

Baud rate

1200 / 2400 / 4800 / 9600 (Default) / 19200 / 38400 / 57600 bps

Length

7 or 8 (default) bits

Parity

Even, Odd or No (default)

Start / Stop bits

1 start bit and 1 stop bit

Table4.1-RS232CSerialInterfaceSpecifications

Table of contents

Other Flintec Touch Terminal manuals