floorex Lightning User manual

LIGHTNING

OPERATIONS AND MAINTENANCE MANUAL

Floorex Products © Page 1

Floorex Products © Page 3

TABLE OF CONTENTS

SECTION I GENERAL DESCRIPTION

SECTION II SPECIFICATIONS

SECTION III SAFETY AND PRECAUTIONS

SECTION IV INSTRUMENTS AND CONTROLS

SECTION V START-UP AND BREAK-IN

SECTION VI MACHINE OPERATION

SECTION VII PREVENTIVE MAINTENANCE

SECTION VIII ENGINE

SECTION IX FRAME AND COWLINGS

SECTION X HYRAULIC DRIVE COMPONENTS

SECTION XI VALVE JOYSTICK ASSEMBLY AND CABLES

SECTION XII STEERING JOYSTICK AND CABLES

Floorex Products © Page 4

OPERATIONS

AND

MAINTENANCE MANUAL

CUSTOMER: ______________________________________

SERIAL NUMBER: ___________________________________

DATE SHIPPED: _____________________________________

Floorex Products © Page 5

SECTION I

GENERAL DESCRIPTION

LIGHTNING STRIPPER

The Lightning is operated by a propane (LPG) powered engince,

driving a tendem hydrostatic pump system, creating a (skid-steer)

zero turn radius drive train.

Suface coverings and coatings are removed by lowered a weighted

blade onto the surface and moving forward under a high torque

drive system. The surface coating is removed by a exible sharpened

blade conforming to the oor surface, with the weight of the machine

holding the blade rmly to the oor. The weight does not allow the

blade to lift or ride over well-adhered sruface coating material, this

lifting off the oor coating.

After layers of carpet or laminated are removed the machine can

be connected to a grinde ror slicer attachment to either clean up

adhesive or remove stubborn coatings.

Floorex Products © Page 6

SECTION II

SPECIFICATIONS

LIGHTNING STRIPPER

Weight 2120 lbs

Removable Weight 516 lbs

Height 51 inches

Width 26 inches

Length 51.5 inches

Engine 25HP Kohler Engine LPG

Max Ground Speed 320 ft per min

Floorex Products © Page 7

SAFETY

LIGHTNING STRIPPER

WARNING

CARBON MONOXIDE

can cause sever nausea, fainting or death.

Do not operate engine in closed or conned

are without proper ventilation.

Floorex Products © Page 8

SECTION III

SAFETY and PRECAUTIONS

LIGHTNING STRIPPER

Before operating the Lightning please read the entire operation and safety manual

with complete undersating of the safety section. If you have any questions on safety

and precauction please call 1-866-636-7763.

There are several advantages to an effective safety program which include: lower

operating costs, lower workman compensations, less work time lost, high employee

morale, and less problems. No one can safely without knowing what precautions to

take to insure personal safety. Operators must know what safety equipment to wear,

which job practices are safe and which are not, and must be aware of what hazards

are possible in the work area. A regular schedule of Prevenative Maintenacne on your

equipment is the best protection against unpleasand surprises that slow production

and sometime result in injuries. Here are a few suggested safety tips.

1. The rst step before any maintenance or inspection takes place should be to

stop the engine and disconnect the battery terminals.

2. Wear proper eye and ear protection and heavy duty work gloves at all times.

3. Practice good Preventative Maintenance.

4. Practice good housekeeping

5. Allow the Lightning to come to a complete stop, turn off engine and chock rear

wheels before performing any maintenance procedures

6. Replace worn parts when necessary.

7. Do not reach into blade or control arm areas which machine is in operation.

8. Do not attempt to open and access door until the machine has come to a

complete stop and the engine and propane is turned off.

9. Be sure all electrical inspecations or changes are done by qualied electrician.

10. Loose surface coating can cause dangerous footing. Always be alert and careful.

11. After replacing parts be sure all tools used are removed from the machine. Be

sure all bolts and nuts are tightened. The loose connection of a rotating part

could cause the part to y off with explove force, causing serious damage to

the equipment and possible injury to the operator.

12. Always lower blade to the ground when the machine is unoccupied by the

operator. Serious bodily injury may result if arms are not in the lowered positions

when not occupied.

13. Never allow unauthorised personnel or the general public into the work area.

14. The work area should be barricaded off to adequately keep all untrained

persons out of the work site. If an unauthorised person enters the work are,

stop the machine immediately and do not restart the machinery until they have

left the work area.

Floorex Products © Page 9

15. Always allow a 200-foot buffer saftey zone around all suface preparation

activity.

16. Always run the Lightning in a well-venitlated area, with an OSHA air

monitoring system in place at all times.

17. Read and obey all safety labels placed on the machinery at all times. If

safety labels have been destroyed or removed, call Flooring on 1800 356

673 for free replacement prior to operating the machinery.

18. The Lightning is not a toy. All operators must be over 18 years of age age

and must have read and reviewed the safety and procedures manyual

before operating the machinery.

19. The Lightning is designed for surface preparation ONLY. It is not intended

for towing, pushing or any other procedure not described in this manual.

20. Propane systems should be checked and documented twice yearly by a

certied propane proffessional for leaks and damaged parts. If a propane

leak is detected leave the machine immediately and seek assistance from

propane proffessional. Do not use or restart machinery until it is determined

safe.

21. Horseplay and or high speed cornering is not allowed with this machine and

could cause rollover resulting in injury or death.

22. No smoking or open ame is allowed while machinery is running or within

50 feet of the machine.

23. Operator must be sober and not under the inuence of drugs or medication

and under full control of all bodily senses while operating this or any

machinery.

24. When transporting the Lightning, it is recommended to use a low bed tilt

trailer. This procedure insures the wheels do not leave a stable surface.

25. All Lightning operators must receive safety training before performing any

functions with the machine.

SECTION III

SAFETY and PRECAUTIONS

LIGHTNING STRIPPER

Floorex Products © Page 10

VIEW #1 - Top view of Lightning machine

VIEW #2 - Left side view of Lightning machine

VIEW #3 - Right side view of Lightning machine

VIEW #4 - Front view of Lightning machine

SECTION IV

INSTRUMENTS & CONTROLS

LIGHTNING STRIPPER

VIEW #1 - Top view of Lightning machine

Floorex Products © Page 11

VIEW #2- Left Side view of Lightning machine

Floorex Products © Page 12

VIEW #3 - Right Side view of Lightning machine

Floorex Products © Page 13

VIEW #4- Frontview of Lightning machine

Floorex Products © Page 14

SECTION V

START-UP and BREAK-IN

LIGHTNING STRIPPER

The Lightning has been safety tested and run at our factory prior to shipping. All

uid levels have been topped up; however no propane (LPG) has been added to the

tanks for saftey shipment purposes. Before running the Lightning please check the

following items that may have shifted or changed during shipping.

1. Raise Engine covers and check oil level.

2. Check air cleaner lter for snug t

3. All battery cable connectors are tight.

4. Inspect major hydraulic oil leaks. Tighten hydraulic ttings using two wrenches.

Use Caution not to over tighten.

5. Fill propane (LPG) tank.

6. Mount propane bottle in brackets, be sure bracket alignment pin corresponds

with alignment spot on bottle.

7. Mount propane hose to liquid side of bottle by attaching to the handle valve.

Snug t the female connector attached to hose and slowly turn valve on. You

should hear gas briey enter the propane hose. Immediately check for propane

leaks with soapy water solution. If leak persists after retightening the knurled

female connector; STOP, turn off the bottle at valve and seek assistance from

certied propane professional. Serious damage and or an explosion could occur.

8. Check lug bolts for tightness, torque 85-100 lbs.

9. Return all engine guards to proper position.

10. You are now ready to start the engine.

11. Crank the engine by turning the key in the on position. The engine will crank

for 3 to 5 seconds while the propane enters the carburetor. If the engine does

not start, turn the key off, wait 1 minute and try again. If again unsuccesul

check propane valve to be sure it is open. If still unsuccessful, turn off propane

valve and seek assistance or call 1-866-636-7763.

12. Once the engine is warming and running, and the operator is safely in the seat,

the machine can be driven.

Please return to Section VI for machinery operation.

NEW MACHINE BREAK-IN

Since the Lightning is a very low maintenance and user-friendly machine, the only

break-in is the the Kohler engine. Please refer to the owners manual, included is the

manual and maintenance schedule found inside the air cleaner plastic cover supplied

by Kohler.

Floorex Products © Page 15

SECTION VI

MACHINERY OPERATION

LIGHTNING STRIPPER

Before reading the machinery operation section, new operators should familiarize

themselves with the 3 diagrams depicting the TOP, LEFT and RIGHT views of the

machine. These drawings show the activation of all moving parts of the Lightning.

1. To move the machine: using the right hand, slowly move the shifter lever in the

desired direction. Forward and left moves the machine to the left, backward and

Right reverses the maching to the right. It is just that simple to drive. Speed is

controlled by amount of movement on the joy stick and also by moving travel

speed lever.

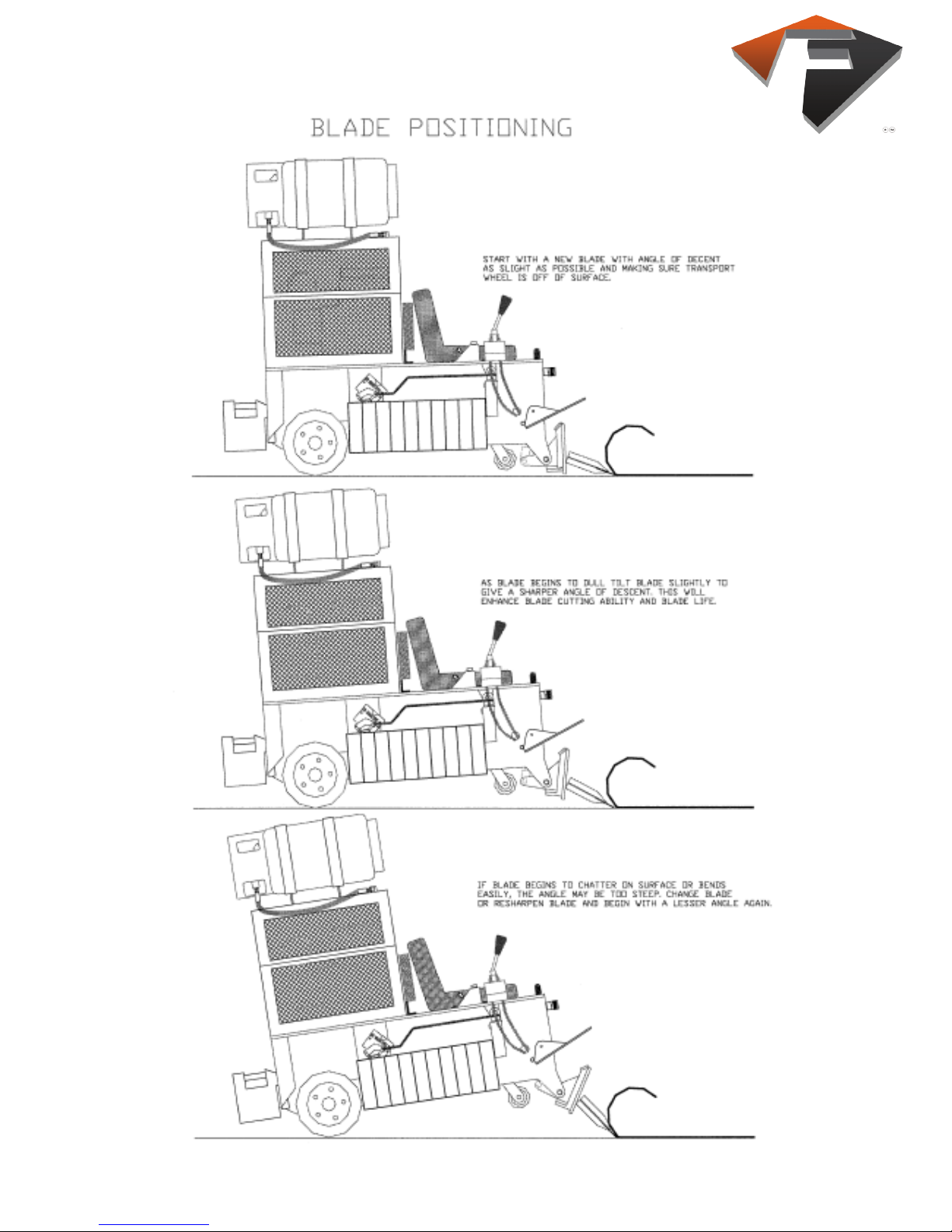

2. The left joystick lever is used to position the blade to the surface. Moving the

lever forward and backward moved the blade up and down. Left and right

movement changes the blade pitch.

3. Throttle control is on the left side of the seat, taking the unit from idle to

3400RPM. The most optimum speed is 2600 to 3200RPM. To change the RPM

of engine turn throttle know clockwise to lower RPM and counterclockwise to

raise RPM.

4. A cooling will rung behind the seat when engine is running to keep hydraulic

oil cool.

5. Hydraulic reservoir is accessed by removing right cowling and removing ll cap.

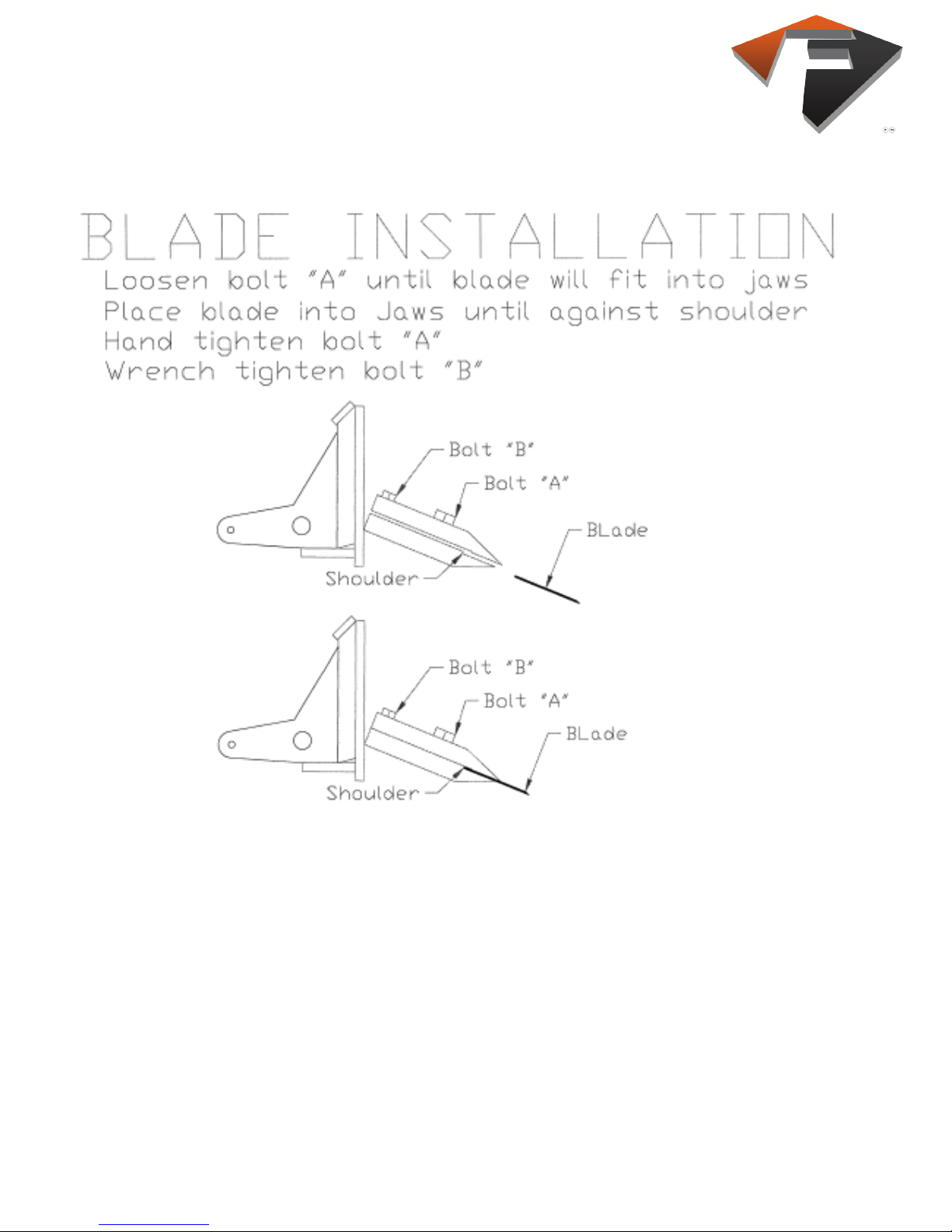

6. To change scrpaing blades; Stop engine. Loosen the set bolt at the rear of the

Blade holder block using a 3/4” open-end wrench. Slide the dull blade our and

Insert a new blade up against the shim stop. Retighten the set bold and raise

the control arms to remove wooden block. Lower control arms and resume

scraping. The large blade holder should not need to be more than hand tight.

With a little practice you should be able to change blades in 15 seconds. Dull

blades can be resharpened and reused many times.

SEE DRAWING OF BLADE CHANGE PROCEDURE

7. Operators should lower the blade by pressing the left hand lever forward each

time they get off the machine. This saftey practice eliminates possible bodily

injury from lowering the blade by unauthorised operators.

8. The transport caster should not be in contact with the oor while scraping. It

will lift off the oor when the blade is lowered. Caster contact with the ooring

while scraping will negatively affect scraper productivity and steering.

9. Do not transport machine with front of machine of the surface high than 1/2”

or irreparable damage to lift cylinder will result.

See Illustration of correct scraping procedures.

Floorex Products © Page 16

Floorex Products © Page 17

Floorex Products © Page 18

Floorex Products © Page 19

SECTION VII

PREVENTATIVE MAINTENANCE

LIGHTNING STRIPPER

FOLLOW KOHLER SUGGESTED SCHEDULE FOR ENGINE

MAINTENANCE

1. DAILY MAINTENANCE

• CHECK HYDRAULIC OIL

• INSPECT FOR HYDRAULIC OIL LEAKS

• SERVICE ENGINE AIR CLEANER

• RETORQUE WHEEL LUG BOLTS

2. 100 HR MAINTENANCE

• GREASE CASTER BEARINGS

• INSPECT ALL BOLTS AND NUTS

AND TIGHTEN IF NEEDED

3. 400 HR MAINTENANCE

• CHANGE HYDRAULIC OIL WITH

MOBIL 1, 15-50 MOTOR OIL

• CHANGE HYDRAULIC OIL FILTERS

Floorex Products © Page 20

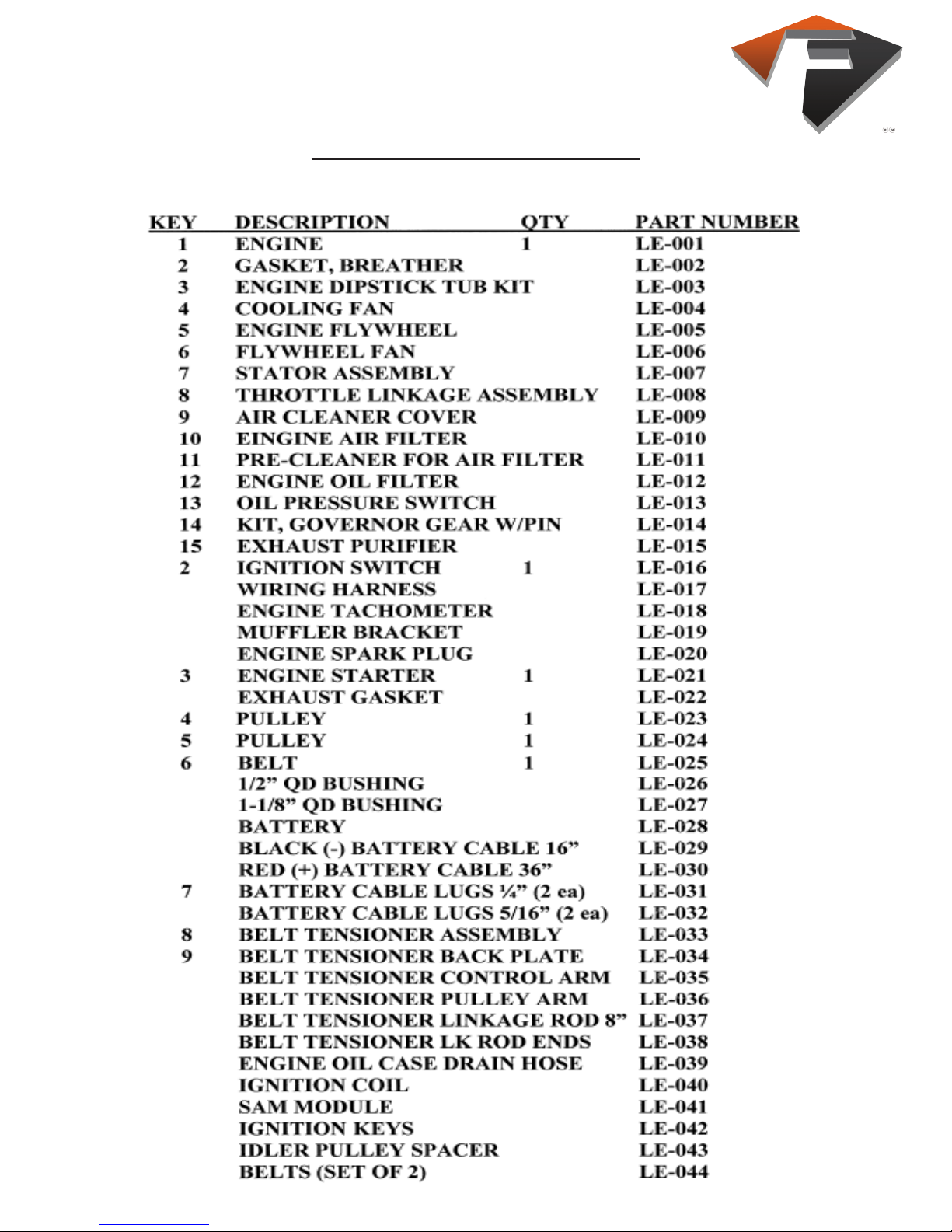

SECTION VIII

ENGINE COMPONENTS LIST

LIGHTNING STRIPPER

Table of contents

Popular Power Tools manuals by other brands

Desoutter

Desoutter PT040-T6000-S10S user manual

MasterCraft

MasterCraft 054-8251-6 instruction manual

Dynapac

Dynapac LH 300 operation & maintenance

KRESS

KRESS 650 SPS operating instructions

Cooper Power Tools

Cooper Power Tools GARDNER-DENVER 105PH Series manual

Powermatic

Powermatic 50-6" Maintenance instructions and parts list