Flow Safe F84L Series Instruction Manual

F84L SERIES

SPRING-OPERATED

LIQUID RELIEF VALVE

PLASTIC-SEATED

-2 Orifice (WITH THREADED BONNET)

-3, -4, -8, -G, -J Orifices (WITH BOLTED BONNET)

INSTALLATION,

OPERATION, & MAINTENANCE MANUAL

Revision: J

Date of Issue: Oct. 6, 2021

Approved by: jwo GG

Engineering Projects Dir. Sr. Design Eng.

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F84L Series Liquid Relief Valve Rev. J Page 2 of 18

TABLE OF CONTENTS

Topic Page

1.0 General............................................................................................. 3

2.0 Description, Operation, Service Envelope, Installation, & Startup

2.1 Description / Operation..................................................................... 4

2.2 Service Envelope.............................................................................. 5

2.3 Installation......................................................................................... 5

2.4 Startup .............................................................................................. 6

3.0 Valve Maintenance

3.1 Disassembly...................................................................................... 7

3.2 Reassembly...................................................................................... 7

4.0 Valve Testing and Adjustment

4.1 Test Equipment................................................................................. 8

4.2 Setting / Adjustment Tolerances....................................................... 8

4.3 Set Pressure Adjustment .................................................................. 9

4.4 Seat Tightness.................................................................................. 9

4.5 Lift Lever Operation .......................................................................... 10

5.0 Accessories....................................................................................... 11

6.0 Troubleshooting Guide ..................................................................... 12

Illustrations

F84L-2 Series “Micro” 2-PC Body Assembly (Threaded Bonnet) ................14

F84L-3 / -4 / -8 Series “C” Body Assembly (Bolted Bonnet, Std.) ................15

F84L-3 / -4 / -8 Series “X” Body Assembly (Bolted Bonnet, XL) ................. 16

F84L-3 / -4 Series “Z” Body Assembly (Bolted Bonnet, XXL) …………….. 17

F84L-G / -J Series “D” “E” “X” Body Assembly (Bolted Bonnet) .................. 18

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F84L Series Liquid Relief Valve Rev. J Page 3 of 18

1.0 GENERAL

1) This manual is intended to provide users with direction and guidance for the maintenance of

FLOW SAFE F84L Series liquid relief valves. This manual indicates the proper method of valve

disassembly, soft goods replacement, and valve reassembly. FLOW SAFE provides this manual

as a guideline and reference only. It is not intended to serve as a training manual or

manufacturing guide. FLOW SAFE assumes no responsibility for personal or property damage

that may occur in conjunction with this manual.

2) FLOW SAFE recommends that all valves be placed on a regular maintenance schedule that

includes the routine replacement of softgoods. FLOW SAFE recommends softgoods

replacement every three years but cautions that each customer make their own determination

and set their own schedule based upon use and environment. FLOW SAFE believes that when

maintenance and reassembly is performed as outlined in this manual there is no safety hazard.

During routine maintenance the internal components of the valve should be inspected for damage

or abnormal wear. The valve should also be inspected for excessive corrosion. A corrosion

allowance of 0.06” (1.5 mm) is designed into all carbon steel components subject to corrosion.

Operating the valve with corrosion exceeding this allowance is not recommended.

Cycling the valve at least once a year is considered to be good practice to verify operation and to

confirm that parts are not seized.

3) When a new valve leaves FLOW SAFE, it has been manufactured and tested by trained and

experienced personnel. When you remove a valve from your system and perform the

maintenance tasks that are outlined herein you will need proper training.

Do not attempt to accomplish these tasks without adequate training and understanding of the

valve operation.

4) Any and all stated or implied warranties that are in effect during the purchase of a new FLOW

SAFE valve are null and void once the valve has been disassembled by someone other than

approved FLOW SAFE personnel.

All repair and resetting of "UV"-stamped safety relief valves should be performed either by FLOW

SAFE, Inc., or by a National Board-certified valve repair shop holding a "VR" (Valve Repair) or

“T/O” (Test Only) stamp.

5) It is highly recommended that all instructions herein be read in full prior to any assembly,

disassembly, or operation of this equipment.

6) The noted manufacturer’s standard lubricants should be used only if compatible with process fluid

and application.

7) Specific design details described in this document are subject to change without notice.

8) Should the need arise for general assistance, contact the FLOW SAFE Sales or Service

department at (716) 662-2585 or (800) 828-1036 in Orchard Park NY or (832) 678-2070 in

Houston TX. For more detailed technical assistance, contact the FLOW SAFE Engineering

department at (716) 662-2585.

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F84L Series Liquid Relief Valve Rev. J Page 4 of 18

2.0 DESCRIPTION, OPERATION, SERVICE ENVELOPE,

INSTALLATION, and STARTUP

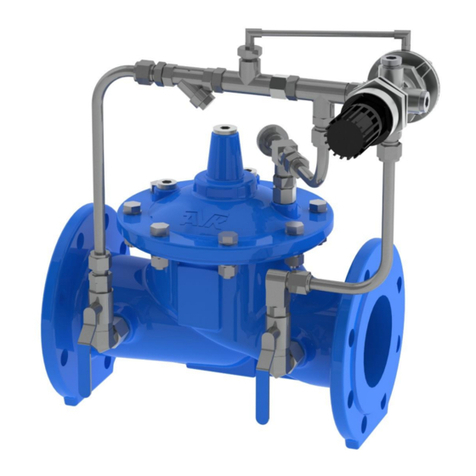

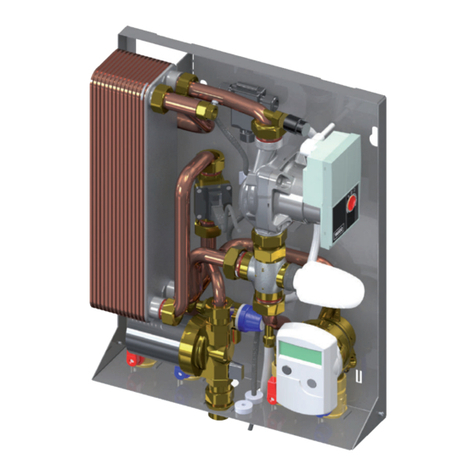

2.1 DESCRIPTION / OPERATION

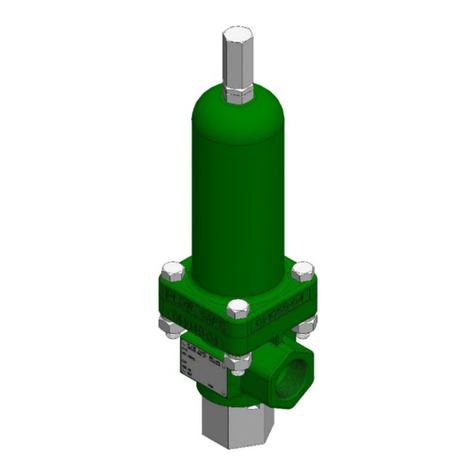

CLOSED OPEN

The FLOW SAFE F84L Series liquid relief valve is a direct-acting spring-loaded relief valve, suitable for

liquid service. The Type F84L is plastic-seated with elastomeric seals.

Orifice sizes are available in -2, -3, -4, -8, -G, and -J with set pressures from 30 to 24,277 psig (depending

on the orifice size).

Blowdown is nonadjustable, designed to be a maximum of 20% for the -3, -4, -8, -G, and –J. For the -2

orifice, blowdown may approach 30-35% whether the valve pops fully open or partially opens at low flow

rates.

OUTLET

SPINDLE

SEAT

(PLASTIC)

(Balanced against

backpressure)

HUDDLING

CHAMBER

Fully open

at 7.5%

over

pressure

BODY

PRESSURE

ADJUSTMENT

(PA) SCREW

INLET

SPRING

PRESSURE ASSIST

DRAG SEAL

(ELASTOMER)

BONNET

LIFT

ATMOSPHERIC

VENT

S

TATIC

BACKFLOW SEAL

(ELASTOMER)

BUSHING

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F84L Series Liquid Relief Valve Rev. J Page 5 of 18

2.2 SERVICE ENVELOPE

BODY

ORIFICE SIZE

SIZE

-

2

-

3

-

4

-

8

-

G

-

J

Minimum

Set

Pressure,

psig (barg)

All 50

(3.45) 50

(3.45) 30

(2.1) 30

(2.1) 30

(2.1) 30

(2.1)

Maximum

Set

Pressure,

psig (barg)

Micro (2-pc.) 24,277

(1674) --- --- --- --- ---

C, D, E

w/ standard bonnet --- 720

(49.6) 720

(49.6) 720

(49.6) 668

(46) 298

(20.5)

C, D, E

w/ XL

b

onnet

--- 4292

(296) 4292

(296) 4292

(296) 3705

(255) 2700

(186)

C Body

w/

XXL

bonnet

--- 8382

(578) 8382

(578) --- --- ---

2Confirm service / application with factory.

3-65 (-54) with low temp nitrile

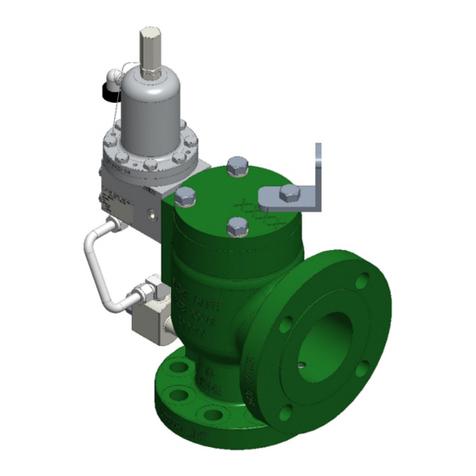

2.3 INSTALLATION

Prior to installation, check that the set pressure on the nameplate is as required, and meets the system

requirements.

The F84L Series liquid relief valve should be installed in the upright position per the figure on the next

page, as close as possible to the pressure source, to minimize pressure losses between the system and

the valve. This should be in accordance with accepted piping practices, as set forth in the API 520 Part II,

which recommends that inlet piping pressure losses should not exceed 3% of the set pressure when the

valve is flowing.

The valve discharge pipe should be sufficiently large so that backpressure does not exceed system

design conditions when relieving. High backpressure may diminish capacity below the value assumed

during the valve’s sizing and selection process.

SOFT GOODS

Temperature, °F (°C)

F84L Seats (Plastic)

MIN.2MAX.

Teflon ® (PTFE) -65 (-54) 400 (204)

Kel-F (PCTFE) -65 (-54) 400 (204)

Polyimide or Polyamide-imide: Vespel ®, Duratron ®, or equal -65 (-54) 500 (260)

Polyetheretherketone (PEEK) 0 (-18) 525 (274)

F84L Spindle Seals (Elastomer)

MIN.2MAX.

Buna-N -30 (-34) 3275 (135)

Fluorocarbon: Viton ® or equal -30 (-34) 400 (204)

Ethylene propylene (EPR/EPDM) -65 (-54) 325 (163)

Perfluoroelastomer: Kalrez ®, Chemraz ®, or equal 0 (-18) 525 (274)

Polyurethane -60 (-54) 225 (107)

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F84L Series Liquid Relief Valve Rev. J Page 6 of 18

The F84L Series valves are balanced against superimposed backpressure, so that the set pressure will

not change with backpressure.

Make sure that the inlet piping/flanges have an opening equal to or greater than the valve's inlet diameter.

Make sure that there are no obstructions like gaskets, fittings, etc., in the flow path to restrict the flow or

cause chatter. Also, misaligned piping connections may result in leaks or induce stresses in the valve

assembly that interfere with good operation. Discharge stacks exposed to the elements should be

configured so as to avoid the accumulation of ice and snow.

If a block valve is used below the relief valve, it should be opened before pressurizing the system. This

block valve should be locked open during normal system operation.

Use only the wrench flats on the valve inlet bushing, taking care not to make any wrench marks, for

tightening and installation. Do not wrench on the cast body or bonnet.

2.4 STARTUP

Foreign particles or dirt can damage the valve and make it inoperative. Prior to installation, clean out the

piping thoroughly. If the valve is not installed immediately, inlet and outlet connections should be

protected and covered.

Pressure can be applied to the valve as system pressure increases, or by opening the block valve (if

there is one) after the system has attained operating pressure. Verify the valve seat is leak-tight, in

accordance with Section 4.4.

The valve is now ready for service. Inspection and maintenance should be performed on a regular basis,

typically once a year, depending on the service conditions.

INLET

OUTLET

F84L SERIES

TYPICAL INSTALLATION

BLOCK VALVE

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F84L Series Liquid Relief Valve Rev. J Page 7 of 18

3.0 VALVE MAINTENANCE

WARNING: It is extremely dangerous to attempt to disassemble any valve while it remains in

service with incoming line pressure. Also, improper assembly of the valve may

result in leakage or failure of the valve when returned to service.

3.1 DISASSEMBLY

(See Illustrations on Pages 14 through 18)

1) Remove the valve from service, or adequately and safely block the incoming pressure before

disassembling the valve and performing maintenance.

NOTE: If bushing remains connected to the system piping, then the valve's internal

components (spring, washer, spindle) will fall out of the body as it is removed.

2) Cut and remove the lockwire.

3) For valves with lift lever, first remove the lock nut and lift lever. Slowly unscrew the bushing,

holding shaft. Unscrew the lift lever housing.

4) Remove the pressure adjusting (PA) screw cap. Measure the height of the PA screw above the

body and record value. For valves with lift lever, measure the distance from the jam nut to top of

threaded lifting rod. Then remove jam nut and lift nut.

5) Loosen the PA screw lock nut. Loosen PA screw until the spring load is removed.

6) a.) Bolted-bonnet valves: Unscrew and remove the four bolts, nuts, and lockwashers between

the body and bonnet. Remove spring washer(s) and spring, and lifting rod subassembly (if

applicable). Remove the bonnet, including attached bonnet base if an older F84L-4 or –8 “large

body,” where these two pieces are joined by a retaining ring.

b.) F84L-2 Two-piece Micro body: Unscrew the bonnet from the body. Remove spring washers

and spring.

7) For the –G and –J orifices, make sure the four small pipe plugs are securely in place in the top of

the body.

8) Unscrew and remove the bushing, using wrench flats.

9) Remove the spindle assembly.

10) a.) For the bolted-bonnet valve sizes and -2 with retained seat, remove retainer screw, retainer,

and seat. Existing O-rings may be removed by carefully prying them out of the spindle grooves.

b.) For the F84L-2 with push-in seat, remove the seat by prying it out with a sharp-edged tool or

small screwdriver. It may first need to be drilled through the center using a 1/16” or 3/32” diameter

drill bit. To remove the two spindle seal O-rings, which are situated in small grooves in the body, a

sharp pointed metal tool must be used to carefully pry them out. Try not to gouge the surrounding

metal surfaces.

11) Replace the softgoods per the instructions in Section 3.2.

Replacement parts may be found in the appropriate FLOW SAFE softgoods kit, as listed

in Section 5.0 of this manual.

3.2 REASSEMBLY

1) Reassembly of these valves is basically the reverse of the disassembly.

NOTE: Care must be taken in the handling of all items, particularly softgoods.

2) Inspect condition of nozzle seating surface and spindle guide surface inside body. Buff out or

polish any scratches that may interfere with a good seal, or replace part if necessary.

3) Apply Neverseez or DuPont Krytox (for oxygen service) to all straight threads.

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F84L Series Liquid Relief Valve Rev. J Page 8 of 18

4) Install the seat dry. For bolted-bonnet valves, insert the plastic seat, seat retainer, and retainer

screw into the spindle. Apply Loctite or Vibra-tite to retainer screw threads. As screw is tightened,

ensure that it meets firm resistance against the locking Heli-Coil in spindle. For the F84L-2 with

push-in seat, the radiused or chamfered edge of the seat must be facing out; push the seat

squarely into the spindle cavity using a clean finger or other soft surface. Do not nick or scratch the

sealing edge.

5) a.) Bolted-bonnet valve sizes and -2 with retained seat: Carefully install new drag seal / spindle

seal(s) in grooves on spindle. Desco 600 grease should be applied to the outside of these O-

rings, except that, for all -2 valves and –3, –4, and –8 valves below 100 psig, Dow Corning

Molykote 33 or equivalent should be used.

b.) F84L-2 with push-in seat: Carefully push new spindle seal O-rings lubricated with Dow

Corning Molykote 33 into the body grooves using a blunt-tipped instrument or small screwdriver.

Even though they may initially twist, they can be gently worked back and forth until they drop into

the groove.

6) Insert the spindle assembly into the body, making sure that it travels freely on the guide surface.

7) Position the bushing seal on the appropriate shoulder of the bushing.

8) Screw the bushing / seal assembly into the body and tighten using the wrench flats.

9) Assemble the spring washer(s), spring, and lifting rod subassembly (if applicable) into the bonnet.

10) a.) For bolted-bonnet valve sizes, assemble the bonnet, adapter plate (for XXL “C” bonnet),

bolts, nuts, and lockwashers to the body. Torque main bonnet bolts to following value:

12-15 ft-lbs -- 3/8-in bolts marked “B8” on ‘C’ body

25-30 ft-lbs -- 1/2-in bolts marked “B8” on ‘D’ or ‘E’ body

65-70 ft-lbs -- 1/2-in bolts marked “B8” on ‘D’ or ‘E’ body

b.) For the F84L-2, ensure that the body and bonnet threads are clean. Then, firmly screw the

bonnet onto the body.

11) Screw the PA screw and lock nut into the top of the body, with top of screw at previously recorded

value.

12) For lift levers, assemble PA screw and lock nut around lifting rod. Then reassemble the lift nut

and jam nut to previously recorded position. Assemble the lift lever housing and then the

bushing, crush rings, shaft, lift lever, and lock nut.

13) Ensure that the rear bolt and seal are secured in the back of the body (except F84L-2).

14) The valve is now completely assembled and ready to be tested. See Section 4.0.

4.0 VALVE TESTING AND ADJUSTMENT

The following tests and adjustments are necessary for F84L liquid service valves: set pressure and seat

tightness. Blowdown is not adjustable, and is fixed at approximately 15 - 20% (20 – 35% for -2 orifice

size) of set pressure.

4.1 TEST EQUIPMENT

Where practical, the F84L should be set using water or other suitable liquid. To obtain full-flow conditions

and observe blowdown, a sufficiently large pressure vessel will be needed. Setting the valve on air may

damage the seat and is not recommended.

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F84L Series Liquid Relief Valve Rev. J Page 9 of 18

4.2 SETTING / ADJUSTMENT TOLERANCES

Set Pressure: Set Pressure Tolerance

> 70 psig + 3% of specified set pressure

< 70 psig + 2 psi

Seat Tightness: There should be ZERO leakage with inlet pressure at or below:

For F84L -3, -4, -8, -G, -J:

0.90 x set pressure, if set pressure > 100 psig

0.80 x set pressure, if set pressure < 100 psig

For F84L-2, LP (retained seat):

0.90 x set pressure, if set pressure > 300 psig

0.80 x set pressure, if set pressure < 300 psig

For F84L-2, HP (push in seat):

0.90 x set pressure, if set pressure > 500 psig

0.80 x set pressure, if set pressure < 500 psig

4.3 SET PRESSURE ADJUSTMENT

NOTES: 1. Set pressure is defined as 93% of the “gush” (pop) pressure. This corresponds to

the first steady stream if valve is being set on a low-capacity test system.

2. If the set pressure is being changed, then the spring, spring washer, PA screw, and

bonnet may need to be changed. Consult the factory or an authorized FLOW

SAFE assembler for the correct parts.

1) Remove the PA screw cap (if installed), loosen the PA screw lock nut, and screw the PA screw in

(clockwise) most of the way.

2) Increase the inlet pressure to 1.075 (1 0.93) of the nameplate set pressure, and then unscrew

(counterclockwise) the PA screw until the valve “gushes” liquid. Full rated flow for the valve will

occur within 110% of set pressure (approx. 102% of “gush” pressure). Tighten down the lock nut

and retest. Readjust as required.

3) Install and tighten down the PA screw cap or lift lever housing. Test valve one more time.

4.4 SEAT TIGHTNESS

1) After any repairs and set pressure adjustments, seat tightness should meet the criteria stated in

Section 4.2.

2) If the valve leaks after repair, refer to the troubleshooting guide in Section 6.0. Check for:

Even seating between the spindle and bushing. With the F84L’s, you should be able to

see a full circular line contact on the bushing surface. Make sure that the seat is installed

all the way in the spindle and that the retainer is tight.

Foreign particles trapped between the seat and bushing. If found, they may have

damaged the seat, requiring that it be replaced.

Scratches in the beveled seating area of the nozzle (bushing).

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F84L Series Liquid Relief Valve Rev. J Page 10 of 18

4.5 LIFT LEVER OPERATION

CAUTION: Do not operate a lift lever unless valve inlet pressure is at least 75% of nameplate set

pressure. Prepare the system as necessary to handle a discharge from the valve.

NOTE: The lift lever enables verification that the valve spindle and seat can open freely, but does

not allow set pressure to be verified.

1) With inlet pressure as stated in the above CAUTION, rotate the lift lever handle clockwise or

counterclockwise until it meets resistance.

2) Continue rotating the handle slowly until there is indication of flow through the valve. NOTE that,

if inlet pressure is greater than reseat pressure (approx. 80% of set pressure), the valve may

develop full flow (gush) and will stay open long enough to blow down to that pressure.

3) Return the lift lever handle to the down position. If flow through valve could not be achieved, or if

the valve does not close, have the valve disassembled and serviced by a qualified organization.

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F84L Series Liquid Relief Valve Rev. J Page 11 of 18

5.0 ACCESSORIES

1) Softgoods Kits (SGK’s)

NOTE: Provide valve serial number(s) whenever possible when ordering softgoods kits

Orifice

Std. Kit P/N

Lift Lever Kit P/N

- 2

- 3 / - 4 / - 8

- G

-

J

F84L-2-XY

F84L-C-XY

F84L-G-XY

F84L

-

J

-

XY

---

F84L-CL-XY

F84L-GL-XY

F84L

-

JL

-

XY

Most common materials listed; contact Flow Safe for availability of other materials.

Bushing seal and rear seal are Teflon.

F84L-2 SGK Contents (See page 14)

Qty. Description

1 Seat

1 Bushing Seal

2 Spindle Seal

F84L-3/-4/-8/-G/-J SGK Contents (See pages 15 through 18)

Qty. Description

1 Seat

1 Bushing Seal

1 Spindle Seal

1 Drag Seal

1 Rear Seal

1* Bushing Crush Ring

2* Shaft Crush Ring * Included with lift lever soft good kits only.

2) Lift Lever Kits (contact factory)

Code X= Seat Material Y = Seal Material

(Spindle)

T

K

W

P

F

B

V

U

E

Z

C

N

Teflon

PCTFE / Kel-F

Vespel / PI / PAI

PEEK

Ekonol-filled Teflon

---

---

---

---

---

---

---

---

---

---

---

---

Buna-N

Viton

Polyurethane

EPR / EPDM

Kalrez

Chemraz

Lo-temp nitrile

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F84L Series Liquid Relief Valve Rev. J Page 12 of 18

6.0 TROUBLESHOOTING GUIDE:

Symptom

Possible Cause

Remedy

The valve leaks around

the bushing. Inadequate bushing torque. Tighten until the bushing bottoms firmly

on the body.

Sealing surface on body or

bushing is damaged. Inspect and polish sealing surfaces.

Bushing seal is damaged or

contaminated. Remove bushing seal. If damaged,

replace with new seal. If contaminated,

clean and replace.

The valve leaks through

the outlet. Seat or nozzle seating surface is

damaged or contaminated. Disassemble the valve, remove the

spindle, and examine the seat and

seating surface under magnification. If

damaged, replace with new seat; if

contaminated, clean and reinstall.

Uneven torque on body-to-bonnet

bolts. Torque bolts evenly (see Section 3.2 for

values)

Operating pressure is too close to

set pressure. Operating pressure should be less than

90% of set pressure for F84L’s at most

pressures, but less than 80-85% of

set pressures ≤ 500 psig for the F84L-2

(HP), 300 psig for the F84L-2 (LP), or

100 psig for bolted-bonnet sizes.

The valve leaks through

the atmospheric vent

hole in bonnet.

Worn / damaged spindle or seals. Disassemble valve, remove spindle

assembly, and inspect spindle and two

seals on upper neck. Look for nicks,

tears, or flat spots. Replace as

necessary.

Pipe plugs are not installed

properly. Tighten or reinstall plug(s).

The valve does not

close. The spindle is stuck. Disassemble and check for binding.

Deburr or replace parts.

The valve opens below

the designated set point. The spring preload is low due to

misadjustment, vibration, or other. Adjust pressure adjusting screw in

(clockwise). Ensure PA screw lock nut

and cap are tight.

The seat leaks due to possible

damage, allowing early simmer

and pop.

Disassemble and inspect seat; replace

if damaged.

Spring washer is not in proper

contact with spindle. Ensure that dimpled area of spring

washer is aligned with top of spindle.

The valve opens above

the designated set point. The spring preload is high. Adjust PA screw out (counterclockwise).

The spindle is stuck or sticking. Disassemble and check for binding.

Deburr or replace parts.

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F84L Series Liquid Relief Valve Rev. J Page 13 of 18

6.0 TROUBLESHOOTING GUIDE (continued):

Symptom

Possible Cause

Remedy

The valve does not

open. Spindle is stuck closed. Disassemble the valve and examine the

sliding surfaces. If damaged, replace.

If contaminated, clean.

Nozzle is stuck to seat. Disassemble and check seat for

permanent impression(s). Harder seat

material may be needed.

The set pressure has not been

reached. Increase inlet pressure. Confirm

pressure gage is calibrated.

Isolation valve is closed. Open isolation (block) valve.

The valve chatters or

rapid-cycles. The valve is oversized for the

application. Install smaller valve.

The inlet is choked. Increase size of inlet piping to be equal

to or greater than the valve orifice.

Check for piping restrictions or partially

closed valves.

Too much built-up backpressure

due to excessive flow, or outlet

piping undersized or too long.

Reduce backpressure by reducing flow

rate or reworking outlet piping (increase

size; shorten; reduce number of turns).

It is recommended that outlet piping

size be equal to or greater than the

valve outlet size.

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F84L Series Liquid Relief Valve Rev. J Page 14 of 18

F84L SERIES VALVE

ASSEMBLY ILLUSTRATION

F84L-2, “Micro” 2-PC (Threaded Bonnet)

SPINDLE

BUSHING

BUSHING SEAL

SPINDLE

SEAL

S

(ELASTOMER)

SPINDLE / SEAT DETAIL

F84L-2, LP

Retainer seat

SPINDLE SEALS

(ELASTOMER)

SEAT

(PLASTIC)

LOCKING

THREAD INSERT

RETAINER

SCREW

PRESSURE

ADJUSTMENT

(PA) SCREW

SPRING

BONNET

SEAT

(PLASTIC)

HP push-in seat shown

(Chamfered end, if present,

must face bushing)

LOCKWIRE /

LEAD SEAL

UPPER SPRING

WASHER

PA SCREW CAP

PA SCREW

LOCK NUT

BODY

LOWER SPRING

WASHER

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F84L Series Liquid Relief Valve Rev. J Page 15 of 18

F84L SERIES VALVE

ASSEMBLY ILLUSTRATION

F84L-3 / -4 / -8, “C” Body (Low Pressure, Bolted Bonnet)

See Page 18 for typical lift lever assembly

SEAT

(PLASTIC)

PRESSURE

ADJUSTMENT

(PA) SCREW

SPRING

BONNET

SPINDLE

BUSHING

LOCKWIRE /

LEAD SEAL

SPRING WASHER

REAR

SEAL

PA SCREW CAP

PA SCREW

LOCK NUT

RETAINER SCREW

(

-

3 /

-

4 SHOWN)

BOLT

DRAG SEAL

(ELASTOMER)

SPINDLE / SEAT DETAIL

F8

4L

-

8

RETAINER

BUSHING SEAL

SEAT

(PLASTIC)

LOCKING

THREAD INSERT

BODY

DRAG SEAL

(ELASTOMER)

LOCKING

THREAD INSERT

SPINDLE SEAL

(ELASTOMER)

BONNET BOLT

NUT /

LOCKWASHER

SPINDLE SEAL

(ELASTOMER)

SPINDLE

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F84L Series Liquid Relief Valve Rev. J Page 16 of 18

F84L SERIES VALVE

ASSEMBLY ILLUSTRATION

F84L-3 / -4 / -8, “X” Body (High Pressure XL, Bolted Bonnet)

See Page 18 for typical lift lever assembly

SPRING

BONNET

SPINDLE

SEAT

(PLASTIC)

LOCKWIRE /

LEAD SEAL

SPRING WASHER

PA SCREW CAP

PRESSURE

ADJUSTMENT

(PA) SCREW

PA SCREW

LOCK NUT

BUSHING

REAR SEAL

BOLT

SPINDLE / SEAT DETAIL

F8

4L

-

8

RETAINER

SEAT

(PLASTIC)

RETAINER SCREW

(

-

3 /

-

4 SHOWN)

LOCKING

THREAD INSERT

SPINDLE

LOCKING

THREAD INSERT

DRAG SEAL

(ELASTOMER)

BUSHING SEAL

DRAG SEAL

(ELASTOMER)

SPINDLE SEAL

(ELASTOMER)

BONNET BOLT

NUT /

LOCKWASHER

BODY

SPINDLE SEAL

(ELASTOMER)

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F84L Series Liquid Relief Valve Rev. J Page 17 of 18

F84L SERIES VALVE

ASSEMBLY ILLUSTRATION

F84L-3 / -4, “Z” Body (Extra High Pressure XXL, Bolted Bonnet)

See Page 18 for typical lift lever assembly

BUSHING

REAR SEAL

BOLT

LOCKING

THREAD INSERT

DRAG SEAL

(ELASTOMER)

BUSHING SEAL

BONNET BOLT/

LOCKWASHER

NUT /

LOCKWASHER

BODY

SPINDLE SEAL

(ELASTOMER)

LOWER SPRING

WASHER

PRESSURE

ADJUSTMENT

(PA) SCREW

ADAPTER

PLATE

CAP

SCREW

SPRING

BONNET

SPINDLE

UPPER SPRING

WASHER

PA SCREW CAP

PA SCREW

LOCK NUT

SEAT

(PLASTIC)

LOCKWIRE /

LEAD SEAL

RETAINER SCREW

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F84L Series Liquid Relief Valve Rev. J Page 18 of 18

F84L SERIES VALVE

ASSEMBLY ILLUSTRATION

F84L-G, “D” or “X” Body (Bolted Bonnet)

F84L-J, “E” or “X” Body (Bolted Bonnet)

PRESSURE

ADJUSTMENT

(PA) SCREW

SPRING

BODY

SPRING

WASHER

BUSHING

RETAINER SCREW

SPINDLE

LOCKWIRE /

LEAD SEAL

REAR

SEAL

BOLT

LOCKING

THREAD

INSERT

BUSHING SEAL

NUT /

LOCKWASHER

BONNET BOLT

BONNET

RETAINER

SEAT

(PLASTIC)

PIPE PLUG

HOUSING

LIFT NUT

LIFTING ROD

PRESSURE

ADJUSTMENT

(PA) SCREW

BUSHING

CRUSH RING

SHAFT

LOCK NUT

BUSHING

LIFT LEVER

LOCK NUT

UPPER

SPRING

WASHER

LOWER

SPRING

WASHER

DRAG SEAL

(ELASTOMER)

SPINDLE SEAL

(ELASTOMER)

LIFT LEVER ASSEMBLY

DETAIL

PA SCREW CAP

PA SCREW

LOCK NUT

JAM NUT

SHAFT

CRUSH RINGS

This manual suits for next models

4

Table of contents

Other Flow Safe Control Unit manuals

Flow Safe

Flow Safe F88 Series Instruction manual

Flow Safe

Flow Safe F8000 Series Owner's manual

Flow Safe

Flow Safe F88 Series Instruction manual

Flow Safe

Flow Safe F70U Series Instruction manual

Flow Safe

Flow Safe F7000 SERIES Instruction manual

Flow Safe

Flow Safe F84L Series Instruction manual

Flow Safe

Flow Safe F70VP Series Instruction manual

Popular Control Unit manuals by other brands

Inficon

Inficon LDS3000 AQ Original operating instructions

Azbil

Azbil NX-CB1 user manual

Progressive Industries

Progressive Industries EMS-HW50C Installation and operation

Wöhner

Wöhner CRITO CrossBoard manual

Lovato

Lovato T-FAST MINI Assembling instructions and maintenance

Aspar

Aspar RS485 MODBUS user manual