Flow Safe F88 Series Instruction manual

Table of contents

Other Flow Safe Control Unit manuals

Flow Safe

Flow Safe F7000 SERIES Instruction manual

Flow Safe

Flow Safe F8000 Series Owner's manual

Flow Safe

Flow Safe F84L Series Instruction manual

Flow Safe

Flow Safe F70U Series Instruction manual

Flow Safe

Flow Safe F88 Series Instruction manual

Flow Safe

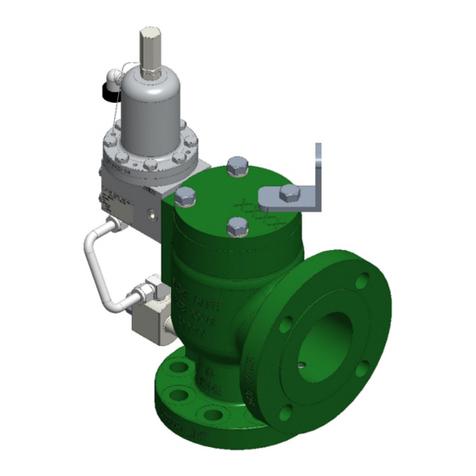

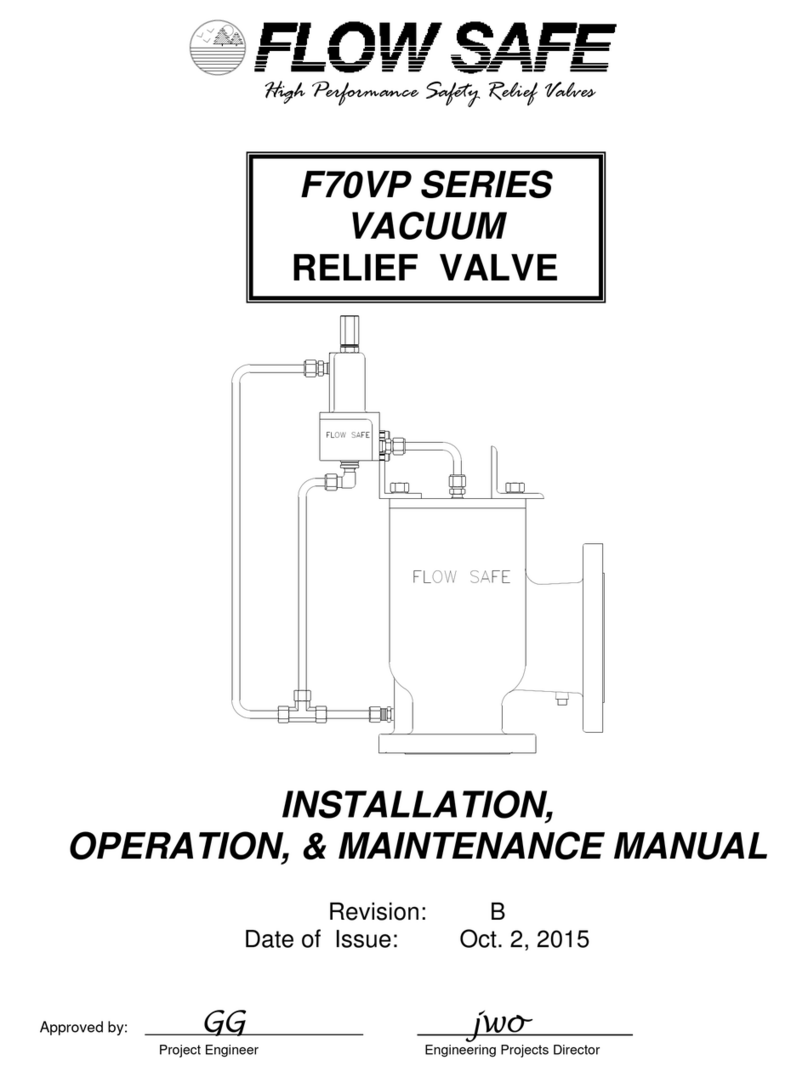

Flow Safe F70VP Series Instruction manual

Flow Safe

Flow Safe F84L Series Instruction Manual

Popular Control Unit manuals by other brands

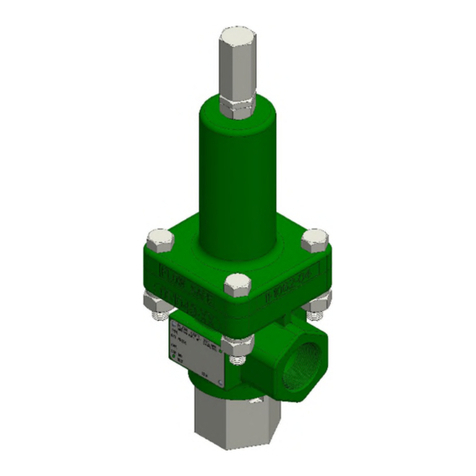

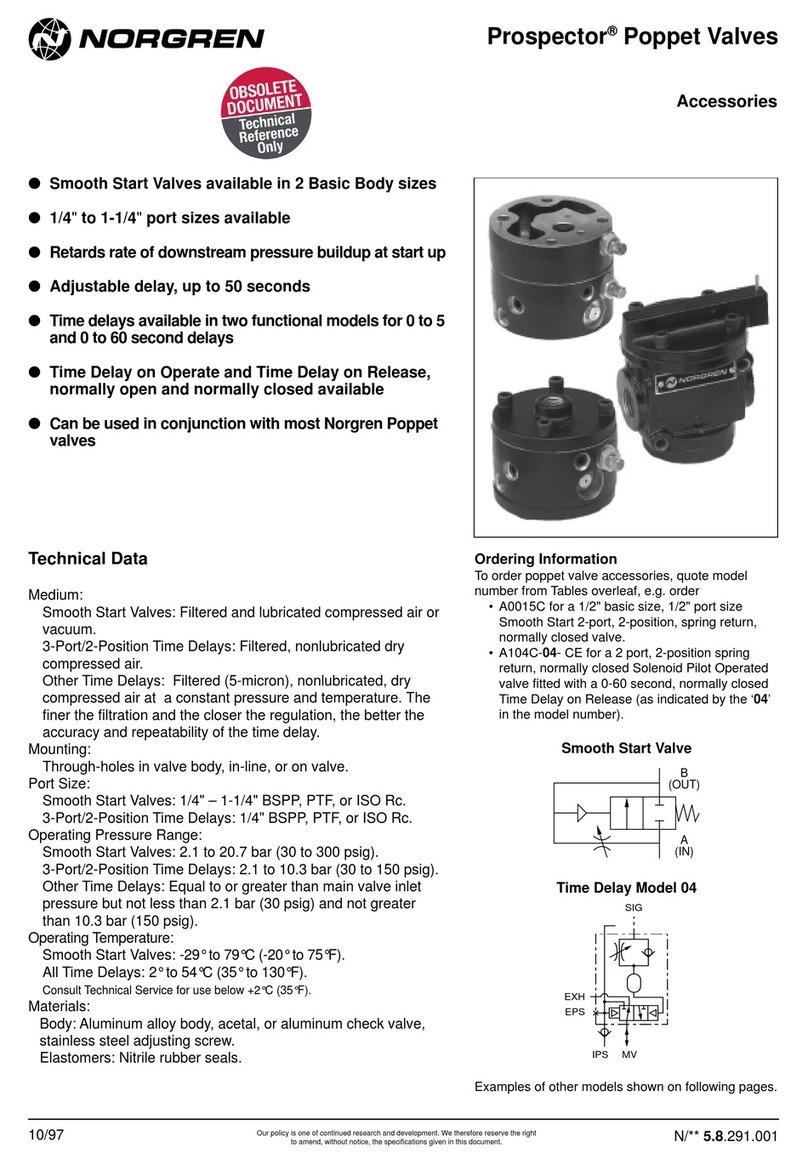

Norgren

Norgren Prospector A00 5A Series manual

Allen-Bradley

Allen-Bradley 1771-OBN installation instructions

Elvox

Elvox ECF4 Installation and operation manual

Mitsubishi Electric

Mitsubishi Electric WD8700U user manual

Wegmatt

Wegmatt dAISy Mini manual

National Instruments

National Instruments NI-SPEEDY-33 installation guide

Lincoln Electric

Lincoln Electric DAMPER BOX DUALFLOW Safety instruction for use and maintenance

MIRI

MIRI AD2006+ Quick start manual

Keysight Technologies

Keysight Technologies J7211A Operating and service manual

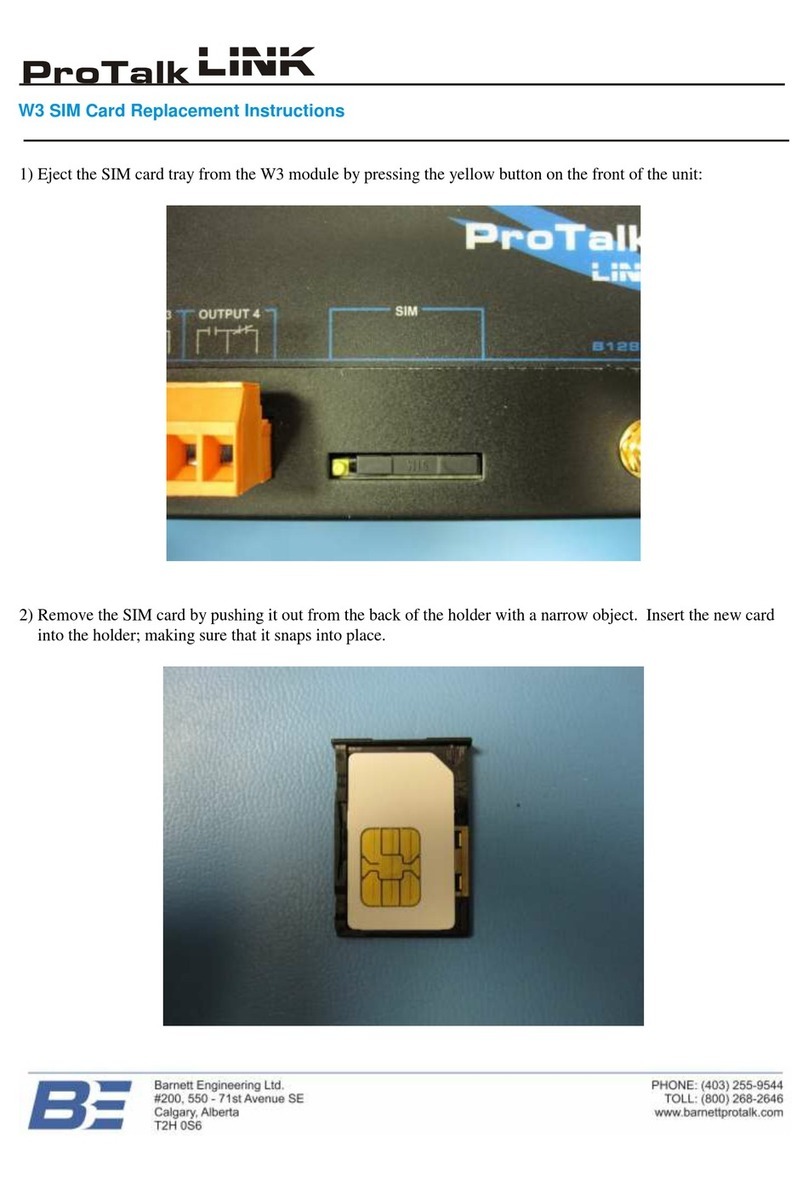

Barnett Engineering

Barnett Engineering ProTalk LINK W3 Replacement instructions

Yoshitake

Yoshitake GD-26GS manual

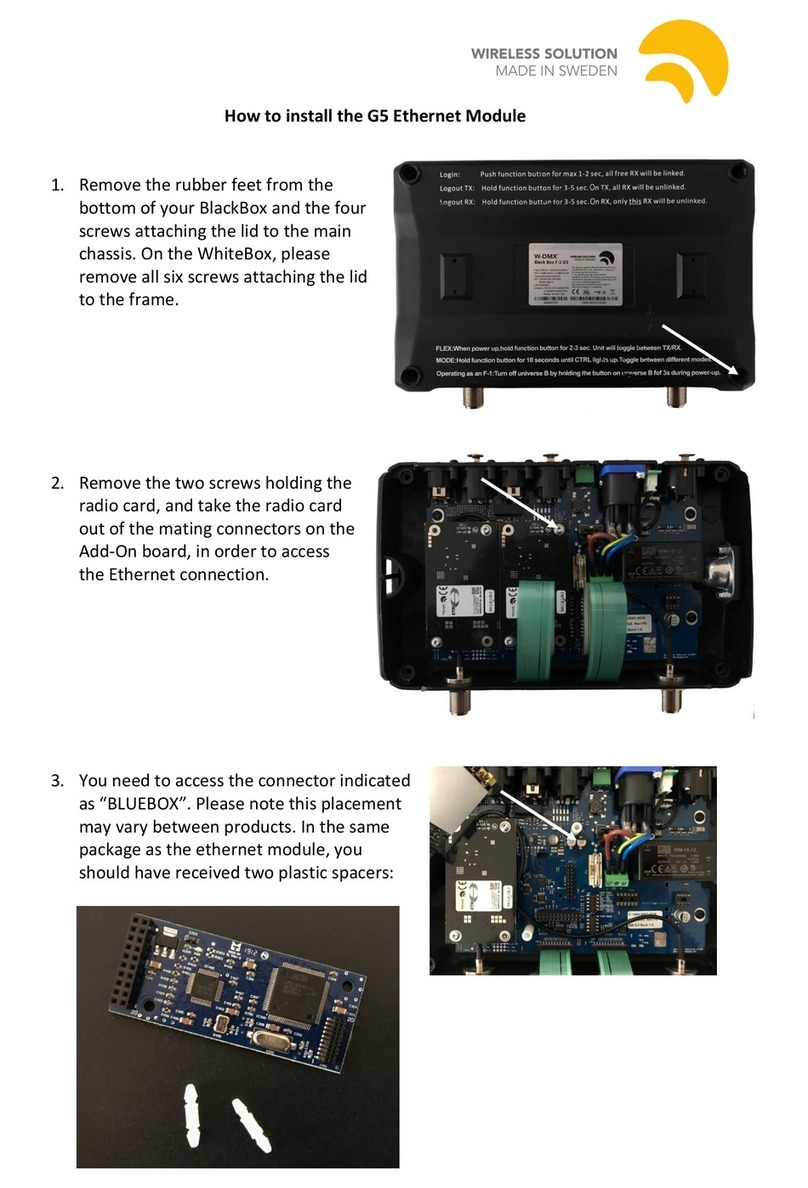

Wireless Solution

Wireless Solution W-DMX G5 How to install

Rockwell Automation

Rockwell Automation Allen-Bradley 800G-XLS Z-EX Series installation instructions

Intermatic

Intermatic K4000 series Instructions for installing

Sentiotec

Sentiotec K1 Next Instructions for installation and use

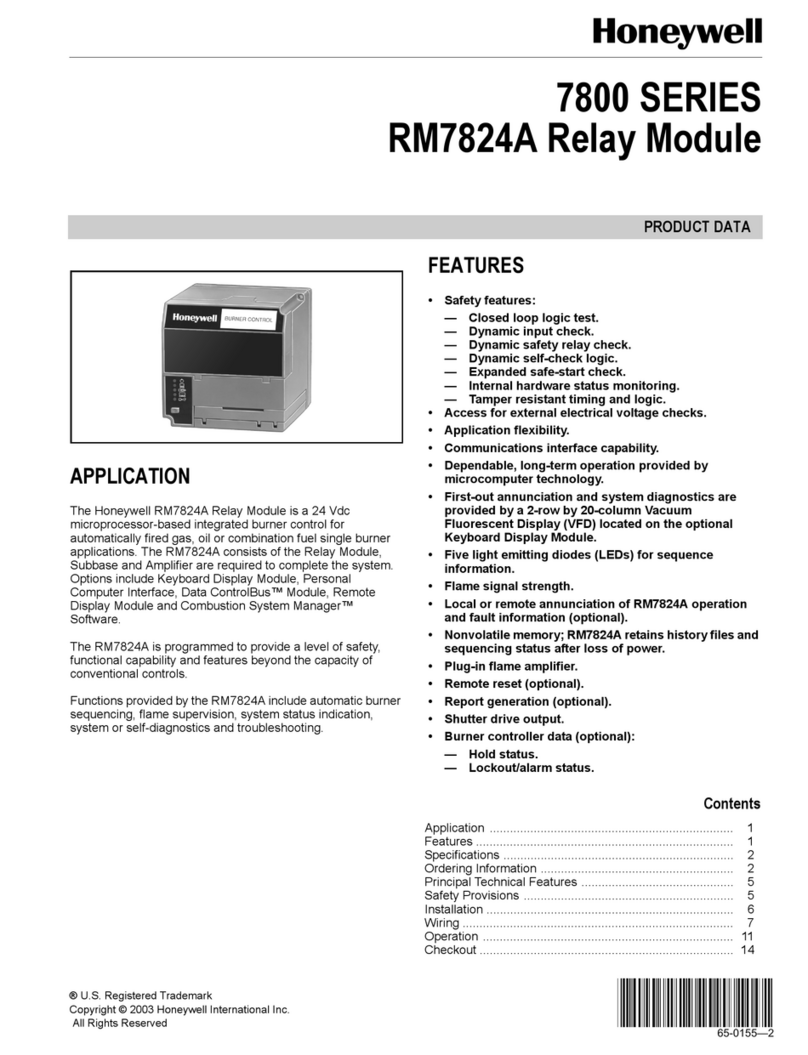

Honeywell

Honeywell RM7824A Product data

Spirax Sarco

Spirax Sarco BSA3HP Installation and maintenance instructions

Texas Instruments

Texas Instruments ADS5231 EVM user guide