Flow Safe F70U Series Instruction manual

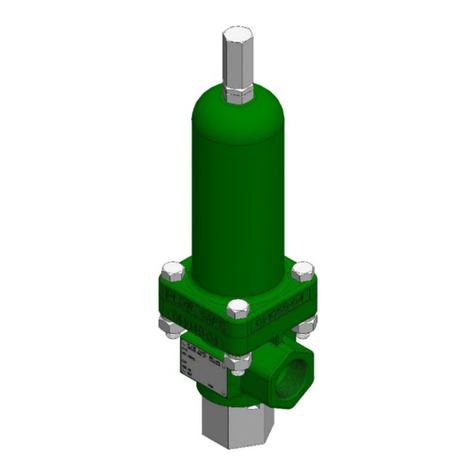

F70U SERIES

UNLOADER VALVE

INSTALLATION,

OPERATION, & MAINTENANCE MANUAL

Revision: E

Date of Issue: Jan. 31, 2022

Approved by: jwo GG

Engineering Projects Dir. Sr. Design Eng.

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F70U Series Rev. E

Unloader Valve Page 2 of 12

TABLE OF CONTENTS

Topic Page

1.0 General................................................................................................3

2.0 Description, Operation, Service Envelope, Installation, & Startup

2.1 Description / Operation........................................................................4

2.2 Service Envelope.................................................................................5

2.3 Installation............................................................................................5

2.4 Startup .................................................................................................6

3.0 Main Valve Maintenance

3.1 Disassembly of the F70U Series Main Valve.......................................6

3.2 Reassembly of the F70U Series Main Valve........................................9

4.0 Testing of the Main Valve Assembly....................................................10

5.0 Final Assembly Testing........................................................................10

6.0 Troubleshooting Guide.........................................................................11

7.0 Accessories

7.1 Softgoods Kits......................................................................................12

7.2 Internals Kits........................................................................................12

Illustrations

F70U Series, Main Valve 1-1/2x3 ……………….............................................7

F70U Series, Main Valve 2x3 and Larger ……………….................................8

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F70U Series Rev. E

Unloader Valve Page 3 of 12

1.0 GENERAL

1) This manual is intended to provide users with direction and guidance for the maintenance of

FLOW SAFE F70U Series valves. This manual indicates the proper method of valve

disassembly, soft goods replacement, and valve reassembly. FLOW SAFE provides this manual

as a guideline and reference only. It is not intended to serve as a training manual or

manufacturing guide. FLOW SAFE assumes no responsibility for personal or property damage

that may occur in conjunction with this manual.

2) FLOW SAFE recommends that all valves be placed on a regular maintenance schedule that

includes the routine replacement of softgoods. FLOW SAFE recommends softgoods

replacement every three years but cautions that each customer make their own determination

and set their own schedule based upon use and environment. FLOW SAFE believes that when

maintenance and reassembly is performed as outlined in this manual there is no safety hazard.

Cycling the valve at least once a year is considered to be good practice to verify operation.

3) When a new valve leaves FLOW SAFE, it has been manufactured and tested by trained and

experienced personnel. When you remove a valve from your system and perform the

maintenance tasks that are outlined herein you will need proper training.

Do not attempt to accomplish these tasks without adequate training and understanding of the

valve operation.

4) Any and all stated or implied warranties that are in effect during the purchase of a new FLOW

SAFE valve are null and void once the valve has been disassembled by someone other than

approved FLOW SAFE personnel.

5) It is highly recommended that all instructions herein be read in full prior to any assembly,

disassembly, or operation of this equipment.

6) The noted manufacturer’s standard lubricants should be used only if compatible with process fluid

and application.

7) Specific design details described in this document are subject to change without notice.

8) Should the need arise for general assistance, contact the FLOW SAFE Sales or Service

department at (716) 662-2585 or (800) 828-1036 in Orchard Park NY. For more detailed

technical assistance, contact the FLOW SAFE Engineering department at (716) 662-2585.

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F70U Series Rev. E

Unloader Valve Page 4 of 12

2.0 DESCRIPTION, OPERATION, SERVICE ENVELOPE, INSTALLATION, and STARTUP

2.1 DESCRIPTION / OPERATION

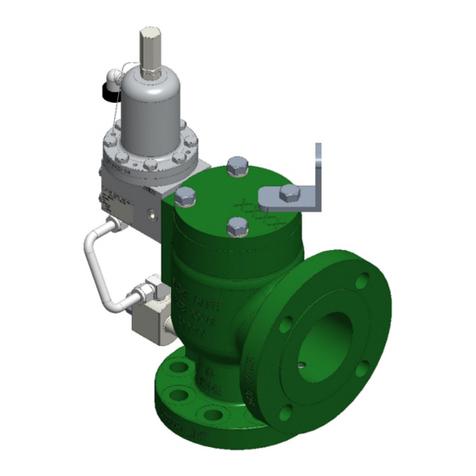

Typical valve assembly (3” x 4” size shown):

CLOSED OPEN

The FLOW SAFE F70U Series unloader valve provides a means to control flow for a variety of process

flow applications, such as compressor and blower unloading. It is designed to be repeatedly cycled at full

pressure throughout its range of rated temperatures.

System pressure is routed from below the valve through the pickup tube to the dome cavity above the

main piston. This dome pressure, acting on a differential area between the top and bottom of the piston,

creates a downward force on the seat to keep it closed.

Control valves in the dome tubing usually include an automatic (electric or pneumatic) valve to exhaust

dome pressure and thus open the main valve, and a manual valve to adjust the rate of dome loading

(pressurization) desired for the closing cycle.

The F70U uses an elastomeric O-ring as the main seat to achieve tight seating. A dynamic piston seal

guards against leakage from the dome cavity to the discharge. Wear rings on the piston help to provide

smooth and consistent operation, particularly for high-cycle conditions. Standard construction of the main

valve assembly includes threaded (in the 1-1/2 x 2 size) or ANSI/ASME Class 150 flanged connections

rated to 285 psig.

DOME

CAVITY

PICKUP

TUBE

INLET

OUTLET

FILTER

(OPTIONAL)

PISTON

ASSEMBLY

BODY

SOLENOID,

2-WAY SHOWN

(OPTIONAL)

SPEED

CONTROLLER

(OPTIONAL)

SEAT

DOME

EXHAUST

DOME

TUBE

INSTALLATION LOCATION

IF 3-WAY SOLENOID

INSTALLED (OPTIONAL)

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F70U Series Rev. E

Unloader Valve Page 5 of 12

2.2 SERVICE ENVELOPE

1Most common elastomers listed; contact Flow Safe for availability of other materials.

2.3 INSTALLATION

Prior to installation, check that the valve size and pressure rating meet system requirements. The F70U

unloader valve should be installed in accordance with accepted piping practices and, if applicable,

governing electrical codes. An upright orientation is preferred for maximum seal life.

F70U unloader valves may be furnished with dome tubing and control valves assembled at the factory,

based on customer specification. Guidelines in the next paragraphs should be followed if an F70U main

valve only has been provided for installation.

The exhaust path from the dome should be free from restrictions (additional valves, filters, etc.) for the

fastest main valve opening times. If a filter is used, it should be installed in the dome tube between the

main valve inlet and solenoid or tee fitting at the cap.

A 3-way solenoid valve should be installed as shown on Page 4, with its pressure port connected to the

dome tube, the cylinder port connected to the main valve dome (cap), and the exhaust port open or

connected to an appropriate discharge system.

If a 2-way solenoid valve is used to control dome pressurization, it must be installed on a separate branch

from the dome tube connection to the main valve cap, such as at the open end of a tee (see below).

For any electric or pneumatic control valve, a “normally closed” or “normally open” configuration should be

selected based on the control system used and the control valve manufacturer’s specifications.

SEAT MATERIAL 1PROCESS TEMP.,

o

F (°C)

UNLOADING PRESSURE,

psig (barg)

Min.

Max.

Min.

Max.

Buna

-

N

-30 (-34) 275 (135) 5 (.34) 285 (19.6)

Viton

®

-30 (-34) 400 (204) 5 (.34) 285 (19.6)

SOLENOID

(2

-

WAY SHOWN)

DOME TUBE

DOME

EXHAUST

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F70U Series Rev. E

Unloader Valve Page 6 of 12

2.4 STARTUP

Foreign particles or dirt can damage the valve and make it inoperative. Prior to installation, clean out the

piping thoroughly. If the valve is not installed immediately, inlet and outlet connections should be

protected and covered.

With the solenoid or pneumatic valve in its proper state to allow the main valve dome to pressurize, the

F70U assembly is ready for service and system pressure can be increased to the operating range.

Inspection and maintenance should be performed on a regular basis, typically once a year, depending on

the service conditions.

3.0 MAIN VALVE MAINTENANCE

3.1 DISASSEMBLY OF THE F70U SERIES MAIN VALVE

(See illustrations on Pages 7 and 8.)

CAUTION: Depressurize the system or safely block incoming line pressure before attempting

to disassemble or remove any valve from the installation.

1) Remove the control valve(s) and dome tube.

2) Remove the bolts and lockwashers that hold the cap in place.

3) With the cap removed, remove the top liner seal or gasket. Newer valves of the 1-1/2” x 2” size

have a press-in liner. In older 1-1/2 x 2’s, which do not have a liner, the piston seal and wear

rings bear directly against a machined bore within the body casting.

4) Carefully remove the piston assembly. Newer pistons may have an interior threaded hole into

which a cap bolt can be inserted to use for lifting. Note that the liner may come out with the

piston assembly. Care must be taken during this removal because any damage might result in an

eventual sealing problem when the valve is reassembled.

5) If the piston seal is in need of replacement, pry from underneath using a flat-blade screwdriver

and work the seal over the edge of its retaining lip at the top of the piston.

6) The liner may then be removed (except in 1-1/2 x 2 size); again, care must be taken not to

damage the liner. Do not attempt to pry or force the liner out as you may score the surface and

cause a sealing problem. Note that on valves 4” x 6” and larger, there is a second liner O-ring

seal in the main valve counterbore where the liner is supported.

7) To remove the seat, first remove the retainer screw. As the screw is held in the piston with the

aid of a locking Heli-Coil thread insert, considerable torque should be required to loosen it.

8) Remove the retainer plate and then the seat. If required, pry the retainer plate using the center

hole. Do not pry where the plate OD contacts the O-ring seat.

9) As required, install new main valve softgoods and reassemble valve per the instructions in

Section 3.2. Replacement parts are referenced in Section 7.0 of this manual.

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F70U Series Rev. E

Unloader Valve Page 7 of 12

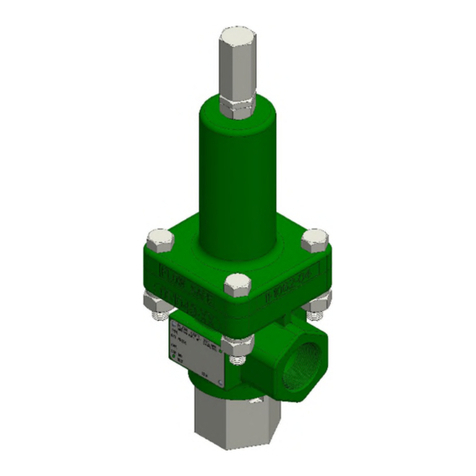

F70U SERIES

MAIN VALVE, 1.5x2

ASSEMBLY ILLUSTRATION

BOLT/

LOCKWASHER

CAP

GASKET

LINER

(NEWER MODELS ONLY,

NOT REMOVABLE)

PISTON

SEAT

WEAR RINGS

(SLYDRINGS)

BODY

PICKUP TUBE

RETAINER

RETAINER SCREW,

LOCKING HELICOIL

PISTON SEAL

(TEFLON V-SEAL

w/ SS SPRING)

DOME FEED

PORT

DRAIN PLUG

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F70U Series Rev. E

Unloader Valve Page 8 of 12

F70U SERIES

MAIN VALVE, 2x3 AND LARGER

ASSEMBLY ILLUSTRATION

BOLT/

LOCKWASHER

CAP

LINER SEAL(S)

(LOWER SEAL

ON 4X6 &

LARGER ONLY)

LINER

PISTON

SEAT

WEAR RINGS

(SLYDRINGS)

BODY

PICKUP TUBE

RETAINER

RETAINER

SCREW / BOLT,

LOCKING HELICOIL

PISTON SEAL

(TEFLON V-SEAL

w/ SS SPRING,

EXCEPT O-RING

ON 12x16

DOME FEED

PORT

LIFT BRACKET

DRAIN PLUG

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F70U Series Rev. E

Unloader Valve Page 9 of 12

3.2 REASSEMBLY OF THE F70U SERIES MAIN VALVE

(See illustrations on Pages 7 and 8.)

1) Prepare new softgoods for installation. Take care in handling of all seats, seals, gaskets, and

metal sealing surfaces. All parts should be clean and free of any debris or contaminants.

2) Reinstall the liner (except 1-1/2 x 2) and liner seal(s) into the body. Do not nick or excessively

stretch the liner seal O-rings. The bottom O-ring (for 4 x 6 and larger) may be carefully set in its

sealing area in the body before the liner is inserted, or it may be fitted onto the liner and, if

necessary, held in place with a suitable lubricant (e.g., Dow Corning 33 or Molykote). For 2 x 3

and larger valves, the top liner seal should be lightly pressed into place in its groove, such that it

is evenly spread around the liner circumference and will not be pinched when reinstalling the

valve cap. For the 1-1/2 x 2 size, position the gasket on top of the body.

3) Insert the seat into the bottom of the piston, using care to position the seat completely within the

groove. Ensure that there are no scratches, gouges, or particles on the seat, and that it is not

twisted. Carefully position the retainer plate over the seat.

4) Apply Vibra-tite or Loctite to the retainer screw threads. Insert the screw(s) into the piston and

tighten firmly, as follows: Retainer

Valve size screw size Torque

1-1/2x2, 2x3, 3x4 1/4-20UNC 80 – 90 in-lbs

4x6, 6x8, 8x10 1/2-20UNF 30 – 35 ft-lbs

12x16 3/8-24UNF 12 – 15 ft-lbs

IMPORTANT: Retainer screw must meet firm resistance against locking Heli-Coil in

piston, and require a wrench to completely install. Replace Heli-Coil if worn or damaged.

5) For all sizes except 12 x 16, install the Teflon piston seal by pressing it evenly over the beveled

retaining lip at the top of the piston. For the 12 x 16, lightly lubricate the O-ring piston seal with

Dow Corning 33 or equivalent and fit into its groove.

6) Fit the wear rings in their grooves around the piston assembly. While holding the wear rings

(especially the free ends) in place, carefully lower the piston assembly into the liner. The piston

should move freely up and down, with some resistance from the seal and wear rings. It is

critically important that this installation result in even seating of the soft seat onto the machined

nozzle surface in the valve body.

7) After checking placement of the top liner seal or gasket [See Step (2)], as applicable, the cap may

then be positioned on top of the body.

8) The cap bolts, with washers, can then be reinserted. Apply anti-seize compound to bolt threads.

The following torque values are recommended:

Valve Size Cap Bolt Size Torque (ft-lbs)

1-1/2x2 1/4-20UNC 8 - 10

2x3, 3x4 1/2-13UNC 55 - 60

4x6 1/2-20UNF 55 - 60

6x8 5/8-18UNF 80 - 90

8x10, 12x16 3/4-16UNF 150 - 160

9) The main valve is now assembled. It should be tested per Section 4.0 before reinstalling control

valve(s) and dome tube, at which time tests described in Section 5.0 should be performed prior to

return to service.

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F70U Series Rev. E

Unloader Valve Page 10 of 12

4.0 TESTING OF THE MAIN VALVE ASSEMBLY

When main valve has been reassembled, it should be tested for leakage and piston lift on a test stand

according to the following. Refer to the figures on Pages 7 and 8.

1) Connect a pressure source to the dome feed port. Plug any openings in the outlet area, such as

the drain.

2) To test the piston seal and liner seal(s) or gasket, pressurize the dome with at least 5 psig (and

not greater than 285 psig) of air.

3) With a bubble tester or wet paper towel over the outlet, verify that there is no leakage. Also verify

no leakage around the cap and cap bolts by spraying the area thoroughly with soapy water and

checking for bubble formation.

4) To test the main valve seat, block off the pickup tube opening in the body by inserting a pipe plug.

CAUTION: Pressurizing the inlet to a higher value than dome pressure may cause the

main piston to open.

Repressurize the dome as in (2), and introduce pressure at the inlet up to the value of dome

pressure. Check for leakage at the main valve outlet.

5) With the dome feed port open, pressurize the inlet up to approximately 5 psig. The piston should

open slightly, allowing air to discharge through the outlet of the valve.

6) To check for full piston lift, install a blind flange on the valve outlet. Again pressurize the inlet up

to 5 psig. The piston should fully lift and hit the bottom of the cap, as indicated by sound or a rod

placed through the dome feed port. If this test is not feasible, attempt to confirm free piston travel

by reaching in the main valve outlet and manually lifting the piston.

7) If leakage is noted past any seal or seat, disassemble the valve and examine the parts for

contamination or damage, or refer to the troubleshooting guide in Section 6.0.

8) Proceed to the next section for testing of the complete valve assembly.

5.0 FINAL ASSEMBLY TESTING

1) Reinstall dome tube and any control valves.

2) With the solenoid or pneumatic valve connected to the normal power or air supply, verify that it

operates according to its “normally closed” or “normally open” configuration. Leave this valve in

its normal position for system operation, to enable the main valve dome to pressurize.

3) Ensure that the manual valve (speed controller) is open.

4) Verify that main piston is down in the seated position.

5) Pressurize the main valve inlet to approx. 10 psig.

6) Verify that the main piston remains closed and is leak-tight.

7) Actuate the solenoid or pneumatic valve and verify that dome exhausts and main piston opens.

8) Restore the solenoid or pneumatic valve to its normal position and verify that dome repressurizes

and the main piston closes.

9) Adjust the manual valve (speed controller), if desired, to change the rate of dome

repressurization. Repeat Steps (5) through (8).

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F70U Series Rev. E

Unloader Valve Page 11 of 12

6.0 TROUBLESHOOTING GUIDE

Symptom

Possible Cause

Remedy

The main valve leaks

around the cap or cap

bolts.

Cap bolt(s) loose, or insufficient /

uneven bolt torque. Retighten the cap bolts per Section

3.2.

Sealing surface on cap is

damaged. Repair defect or replace cap.

Upper liner seal or gasket is

damaged or contaminated. If damaged, replace with new seal(s).

If

contaminated, clean and reinstall.

Air trapped in cap bolt hole(s). Wait until leakage stops (applicable to

very recent cap reinstallation only).

The main valve leaks

through the outlet. Damage to, or contamination on:

piston seat or main valve nozzle,

piston seal / sealing surface, or

lower liner seal / sealing surface.

Disassemble the valve, remove the

piston and liner, and examine the seat,

seals, and sealing surfaces under

magnification. If damaged, replace

with new part(s); if contaminated, clean

and reinstall.

The main valve does

not close. Dome tube, pickup tube, or filter

damaged or plugged. Clean / unplug, or replace if damaged.

Pickup tube is oriented

incorrectly. Ensure intake port in tube is facing

upstream (toward flow to the inlet).

Control valve(s) not functioning

properly. Check valves for proper position,

orientation, and control connections.

Piston seal is leaking. Perform test described in Section 4.0,

Steps (1) – (3).

Contamination between liner and

piston. Disassemble valve. Clean surfaces;

remove any burrs/gouges if possible or

replace damaged parts.

Outlet piping is obstructed or too

small. Check outlet piping for obstructions.

Pipe size should be at least the

nominal size of the valve outlet.

The main valve does

not open. Dome pressure exhaust path

blocked. Check control valve(s) for proper

operation; clear exhaust path of any

blockage.

Piston seized. Check piston and liner surfaces and

wear rings for contamination or

damage. Clean or replace parts as

necessary.

Inlet or outlet blocked. Clear blockage in a safe manner.

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F70U Series Rev. E

Unloader Valve Page 12 of 12

7.0 ACCESSORIES

7.1 SOFTGOODS KITS

Valve Size Softgoods Kit

Part Number

1-1/2 x 2

2 x 3

3 x 4

4 x 6

6 x 8

8 x 10

12 x 16

UN-15X02-7XY

UN-02X03-7XY

UN-03X04-7XY

UN-04X06-7XY

UN-06X08-7XY

UN-08X10-7XY

UN

-

12X16

-

7

XY

Most common elastomers listed;

contact Flow Safe for availability of other materials.

Softgoods Kit contents

(See illustrations on Pages 7 & 8) Qty.

Seat 1

Wear ring 2

Liner seal (2 x 3, 3 x 4) 1

(4 x 6 and up) 2

Gasket (1-1/2 x 2 only) 1

Piston seal 1 Teflon with stainless steel spring except 12x16

7.2 INTERNALS KITS

Applicable to most common F70U sizes; contact factory for other replacement parts.

Kit P/N

1-1/2 x 2 F70U-15X02-KIT (previously 02-3003)

2 x 3 F70U-2X3-KIT (previously 02-3001)

3 x 4 F70U-3X4-KIT (previously 02-3002)

Internals Kit contents

(See illustrations on Pages 7 & 8) Qty.

Piston 1

Retainer 1

Retainer screw 1

Liner (except 1-1/2 x 2) 1

X = Seat Material

Y = Liner Seal / Gasket Material

Code

B

V

E

Z

C

N

Buna-N

Viton ®

EPR / EPDM

Kalrez ®

Chemraz ®

Lo-temp nitrile

Table of contents

Other Flow Safe Control Unit manuals

Flow Safe

Flow Safe F7000 SERIES Instruction manual

Flow Safe

Flow Safe F88 Series Instruction manual

Flow Safe

Flow Safe F70VP Series Instruction manual

Flow Safe

Flow Safe F8000 Series Owner's manual

Flow Safe

Flow Safe F84L Series Instruction manual

Flow Safe

Flow Safe F84L Series Instruction Manual

Flow Safe

Flow Safe F88 Series Instruction manual